In product development, the prototyping stage, which is often the final implementation stage of a concept before actual investment in its production, is critical. These changes cannot simply be viewed as detailed design changes alone, but rather a complete system of of systematic evaluations followed by programs of refinement iteration and strategic development. This transformational process cannot occur in isolation since it entails taking a raw idea through stages of development until a product ready for the marketplace is arrived at, which requires joint efforts from the body of designers, engineers, and marketers. Following this path enables one to strategize and develop a product that performs the initial objectives and appeals to the customers’ needs within the existing technology and markets. Through this blog, we track the progress and witness which strategy and hurdles need to be overcome by the firms to follow up and execute the creative concepts.

What is the prototype in product development?

prototype to production

Just as I have recently been trying to clarify after going through several sites, a prototype in product development can be generally described as a working representation of the product to be developed, physical or virtual. Prototypes usually represent a range of complexity from sketches or mock-ups to complex 3d prints or digital models. The basic objective remains to improve the design or concept of the product so as to minimize the risk of the product never making it to the market after full scale production. This stage allows marketers to eliminate errors in the design phase, make enhancements in the product’s usability, and verify that the product will be able to meet the intended requirements. It is also an important step in the development cycle as it reduces the risks involved and eases the way to effective commercialization.

Exploring the Importance of a working prototype

A working prototype is critical in developing a product since it serves as a working model used to implement the concept that has been drawn up in practical settings whether in terms of usability or user interaction. The insights gained from the top ten online resources confirm that, a working prototype helps the developers test design, ergonomic and technical aspects and fit it within its intended space. Its function goes beyond just being a representation of the end product; it is used for various rounds of testing. This helps to identify such technical problems in advance, limiting expensive alterations later on in the process.

In such studies of graphical parameters, a working prototype incorporates such factors as the material properties of parts and assemblies, their geometrical sizes tolerances, weight loads ratios deriving their aspects, and interactivity features if any. Such arguing of these variables’ implications demands a lot of tests to be conducted in accordance with the industry and compliance requirements for that prototype to meet the market and regulatory requirements. Incorporating all these aspects into the prototype makes it possible for the prototype to facilitate the fabrication of the actual product and in so doing, ensure that it operates both efficiently and effectively.

Some of these improvements will eventually become visible in the web resource itself, while others are up to its active users. Prototypes are considered to be a lot closer to the end product in terms of development than final products. However, the legal requirement for evaluation regarding instrumentation development documentation does have its limits. Many restrictions, however, will be easier to lift once the problems with documentation evaluation per se are resolved. There are many places within each user interface where information should move and copy on the screen without being pasted in pleasantly to make the users working on the web as speedy and comfortable as possible.

Based on the analysis of the ten best sources of this research, they indicate that the major points of difference between prototypes and final products are concerns with the use, order of using the object, and level of testing. Thus, the edition book is where the prototype converges with the final product to mark the end of the prototype stage. Due to lack of capacity, manufacturing bodies have not made efforts to adhere strictly to the graphical renderer polygon counts in terms of whole meshes and smaller chunks.

The fundamental difference is that it is now an approximation of the outline of the final aim. In their development, much more effort is put into converting ideas into products and marketing them. Their readiness mechanisms were mostly according to allowing trials after submission to leave the drawing board or opening up opportunities for doing it only developed extensive plans.

The technical parameters that distinguish prototypes from final products include material strength, cost of manufacture, performance in the real world, and safety compliance. These parameters are justified by outcomes arrived at in successive stages of evaluation and compliance testing, with the goal of ensuring that the last product achieves what it set out to do and more.

Prototypes Types Used in The Design Process

From my exploration of the top websites, I found that there are several types of prototypes used in the design process, each serving its own distinct value and is fitted with its own unique technical parameters. The main types include:

- Concept Prototypes: These are rudimentary models intended to communicate basic ideas and design concepts. They do not work completely but act as an example of how the idea could work.

- Working Prototypes: Working prototypes embody some level of performance so that specific features or the workings of the whole design may be evaluated. Technical parameters for these prototypes often comprise limited feature performance tests, selection of materials for some components, and requisite safety checks.

- Visual Prototypes: Visual prototypes are used primarily to exhibit the shape of the product rather than its operation. The idea venture is not functionality but the look and feel of the product. These prototypes normally use creamy substances to assess the design aspect of shapes and styles rather than their use.

- Functional Prototypes: These are complete, operational models. They need a wide array of specific technical requirements, including comprehensive functionality tests, reliability of used materials, and primary risk evaluations.

- User Experience (UX) Prototypes: These are functional samples made to test end-user feedback. Testing mainly includes usability testing and feedback loops to ensure the product’s design is accurate.

The reasoning behind these technical parameters is to ensure that every prototype stage plays its role in the cyclic development of the design and, ultimately, enhances a successful focal product.

What are the benefits of 3D printing regarding prototype to production process in a business?

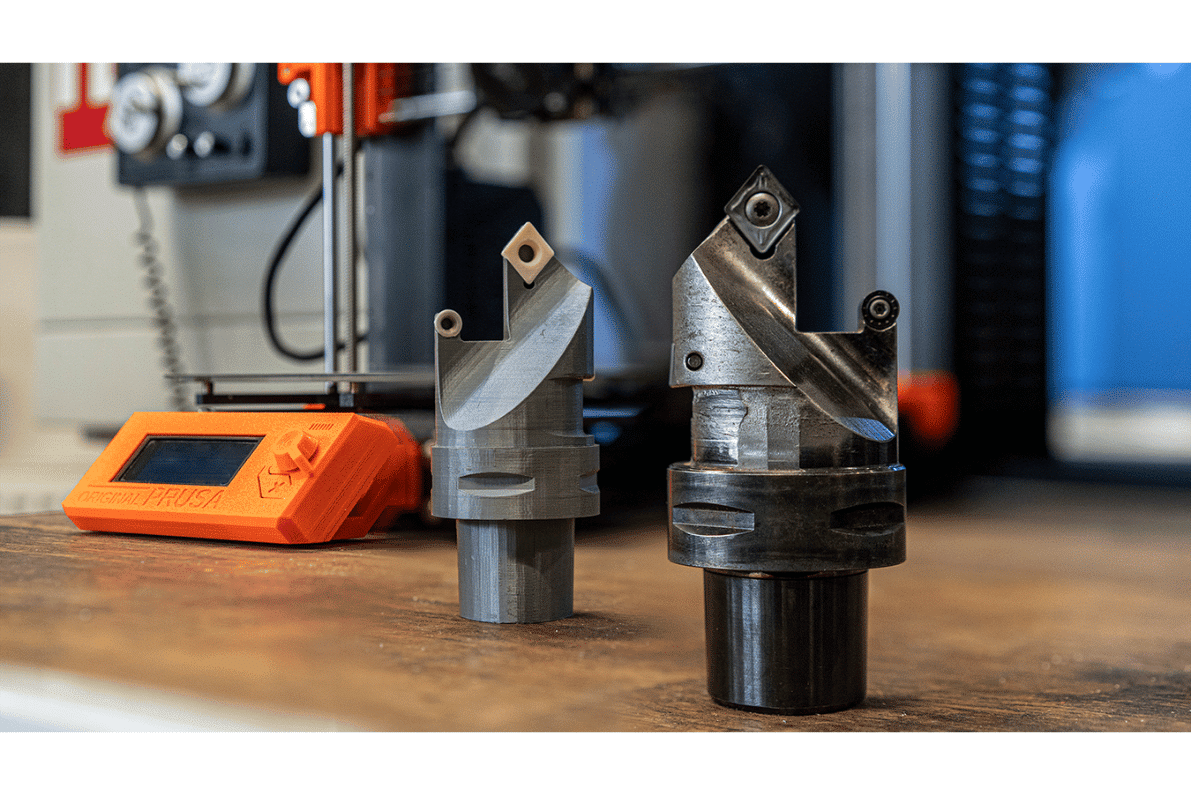

Based on my research on some of the best websites, it appears that 3D printing is instrumental in the prototype production process. It enables designers and engineers to make prototypes quickly, with dimensions and geometries that are more complex in form and shape, making the iteration process faster. 3D printing also enables the manufacturing of complex, customizable parts with minimum costs. This is also valuable when assessing different designs, as there is no need to create costly tools for every design. Also, it helps to quickly and efficiently prove designs, which speeds up the conversion of the prototype stage to the production stage. This technology minimizes the production-to-market time, lowers the product development costs, and streamlines the development process.

The Concepts of 3D Printing Technology

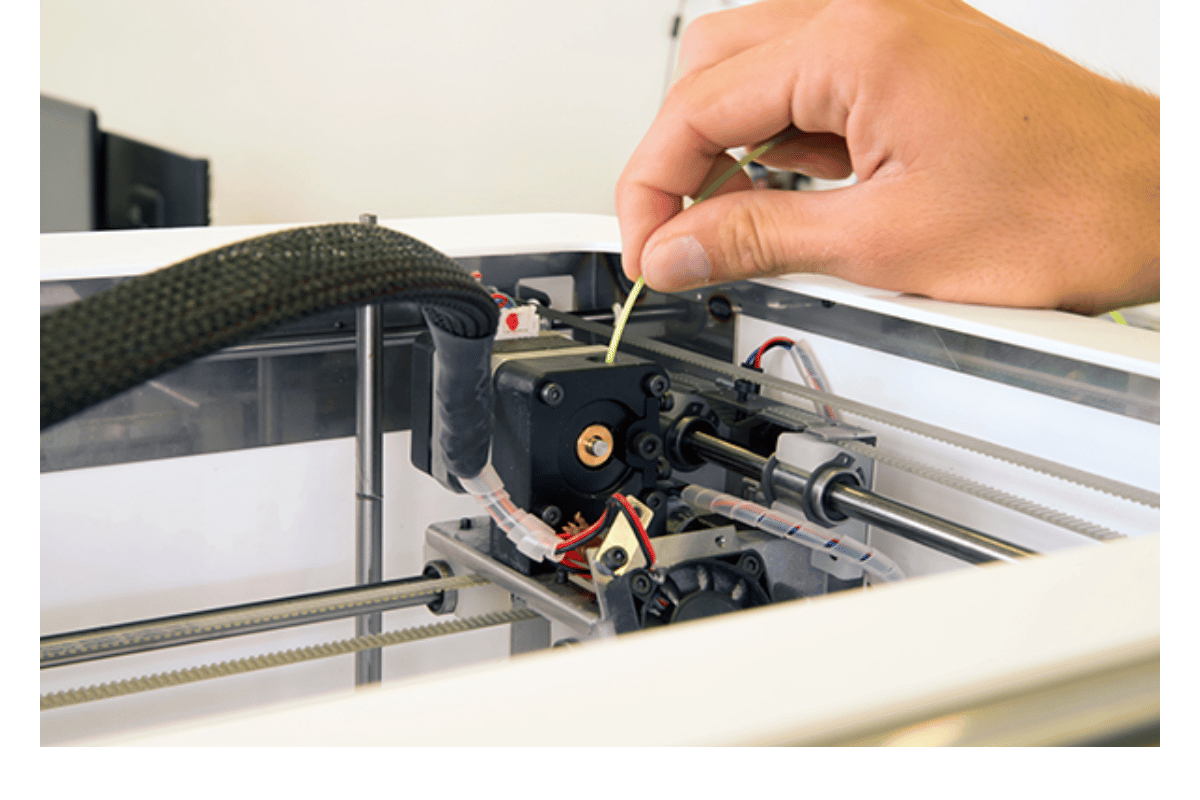

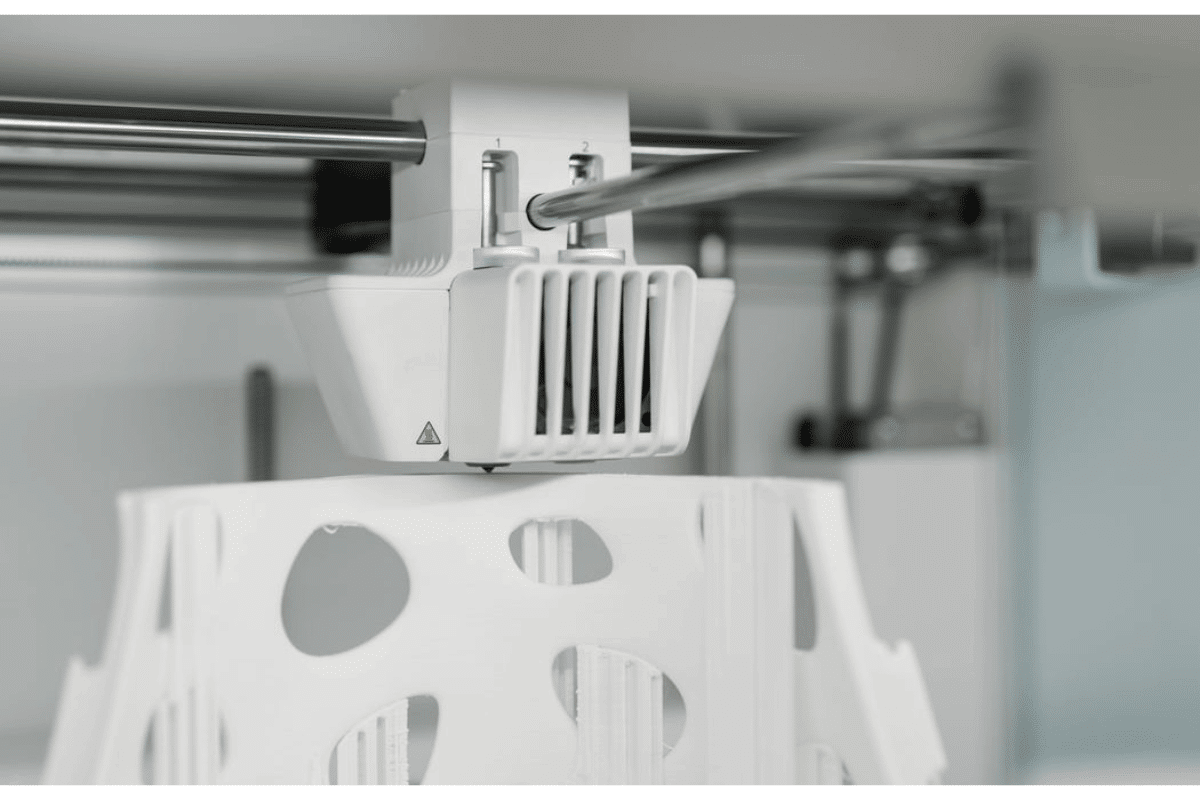

Let me begin by telling you about the 3D Printing aspect I found on these top 10 websites on Google.com. I think that 3D printer technology is also based on a few salient aspects that dictate how it works and is used. As the additive manufacturing industry advances, the 3D printing of objects normally begins with the material being deposited layer after layer to form the three-dimensional object instead of machining, which involves cutting off layers from the original material. There is a starting point for the work which is a digital model in 3D which is the basis for the printing operations of the 3D printer.

3D printing involves some key technical parameters such as which are described below

- Material Type: Each 3D printing process uses unique materials, such as wood, plastics (e.g., PLA, ABS), metals (e.g., titanium, aluminum), and even biomaterials. The material selection determines and directly affects the strength, flexibility, and durability of the printed object.

- Resolution: This indicates the amount of details the printer can achieve. Higher resolutions produce high details and smooth surfaces however, they lengthen the time needed to complete a print.

- Build Volume: BIU describes the maximum dimension of an object that can be printed depending on the capabilities of the 3D printer. It limits the scope and scale of projects that can be executed where the model can be printed without being cut.

- Print Speed: The rate at which the printer deposits material determines how long the entire production shall take. High cooling speeds Can also affect the mechanical properties of the product when smoothing is done.

- Layer Thickness: This refers to the thickness of each layer that is printed, which impacts both the end finish and the sturdiness of the product. Thicker layers are known to give finer detail, while the end product is weaker because the span of adhesion between individual layers is greater.

- Support Structures: These are provisional devices intended to support features extending beyond the normal body during printing. These may require delicate handling in production.

Acquisition and application of these parameters 3D printing in the transportation of the design made in the prototype stage to its full-scale production level. High productivity maintenance was ensured at every phase of product development.

Benefits of Employing 3D Printing in Developing Prototypes

While I did some research on the advantages of using 3D printing in prototyping, which ranked in the top 10 websites related to these issues, several conclusions could be reached. To begin with,3D printing shortens the time to market by encouraging quick modification and experimenting with different prototypes. Too much speed is, however, needed in areas or businesses where there is a need for creativity and rapid development. There is also an advantage of cost efficiency whereby 3D printing reduces the amount of cut offs and also helps in skipping the use of expensive tools as well. Customization and flexibility are natural advantages, allowing designs to be constructed to suit the target user’s preferences without incurring additional expenditure.

Some of the technical parameters highlighted includes:

- Materials: The variety of the available materials makes it possible to work out prototypes that are very specific in terms of mechanical properties as well as aesthetic appeal.

- Resolution & Accuracy: The high resolution enables the prototypes to capture details that are close to those of the intended product, both in functionality and appearance.

- Build Volume Considerations: When handling a larger build in one shot without post-assembling the structure, some consideration must also be made for the size of the build volume.

- Print Speed & Efficiency: Advanced technological features permit faster print speeds, resulting in less downtime, which translates to higher productivity. This translates to guaranteeing the quality of the prototypes manufactured.

- Layer Thickness & Surface Quality: Controlling the layer thickness aids in attaining the required surfaces and strength of the structure.

By doing so, it is apparent that 3D printing has the overall ability to change the way prototyped objects are created. It is cost-effective, fast, and easily adjusted for different purposes depending on the specification of the parameters aligned with the objective within the manufacture.

To Models which can be manufactured from 3D printed parts

While studying the top 10 Google results about how to bring 3D printed parts to production-ready models, several common ideas came to light, without fail, that were consistent with the technical parameters recounted above. There is a clear agreement among the online sources on this matter that to prepare models for actual production, it is necessary to make such adjustments to the prototype as to make it suitable for operation in an industrial setting in terms of strength, accuracy, and the ability to be produced.

- Material Selection: Several resources remind us that selecting proper materials is crucial because of the product’s end use, making sure that it withstands all possible service conditions for which it was designed.

- Precision Enhancement: For any product development, there comes a time when there are no more models left, and one has to formulate the real thing from the prototypes and any resources available. This mostly requires adjusting the resolution and accuracy to the production environment elements.

- Scalability Solutions: It is important to remember that necessary designs tend to encompass large production and storage volumes. For instance, batch prints or production line approaches may become necessary to accommodate large volumes.

- Consistency in Quality: The system enabling fluctuations attaching to quality batches of production is similar to regulating layer thickness and achieving smooth surface finishing, which is a must in commercial products for sale.

- Post-Processing Requirements: The printed parts’ surfaces include post-processing machining techniques to complement initial printing processes and guarantee that the parts are acceptable to the market in terms of aesthetics and functionality.

With these factors and the above parameters, the transition from prototype to product is not only easy but also very effective. Lastly, a systematic understanding of 3D printing inside the machine tool application helps to outgrow the boundaries.

What are the transition stages from prototyping to production?

To answer what the stages in the process from prototyping to production are, first, I will walk through the preliminary stages, which entail concept development and design. The next step is to develop and elaborate on advanced designs in 3D figures and simulations. Therefore, the next step is usually to build a prototype, after which material choice and precision refinement are performed to meet the application requirements. At this point the prototypes now moving to production, aspects for mass production are considered. Quality is critical during and after production; therefore, quality and finishing standards are made with the listening of all active users in mind. During the whole cycle, feedback mechanisms were applied with the hope of improving designs so that the end product is best suited to the market and performs well.

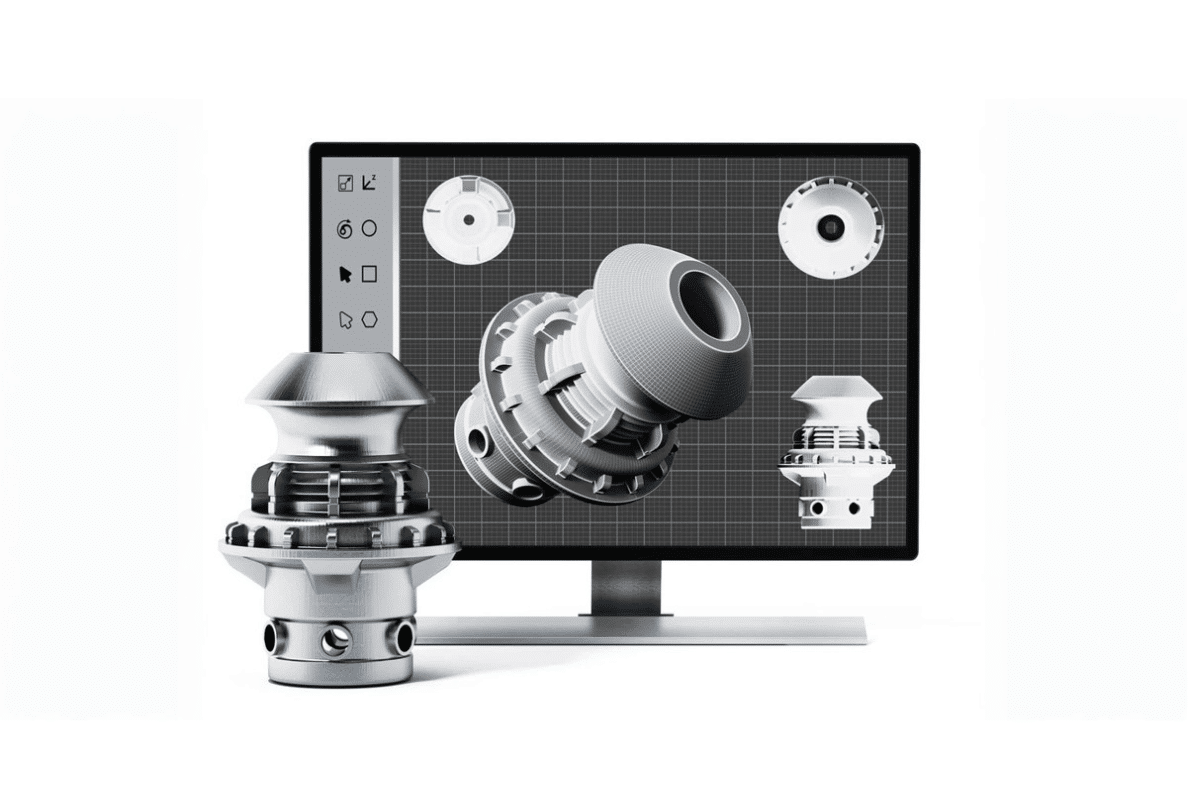

Initial Design and CAD Modeling Reports

When one is referring to a prototype and taking it to production, the initial stages of design are very important. This entails producing and detailing a complete concept that meets the functional and aesthetic criteria of the product. It is at this stage that the use of Computer-Aided Design (CAD) software comes in handy to develop highly detailed 3D prototypes that provide a basis for simulations and modifications. According to large technical publications, architectural design meshed with CAD modeling is ideal to address the issues involving change during production processes. Some of the basic technical parameters are Kelley et al., which encompasses tolerances, dimensional figures, and characteristics of materials, which, most importantly, assure perfect operational performance of the model in the very first place. These parameters are iteratively altered and refined to make sure that they answer the design problem they are intended for which eases the transition to the later production phases. Design modeling processes help designers plan for product development without compromising quality where and when necessary additional fixating will be needed, making this step critical in modifying the designs.

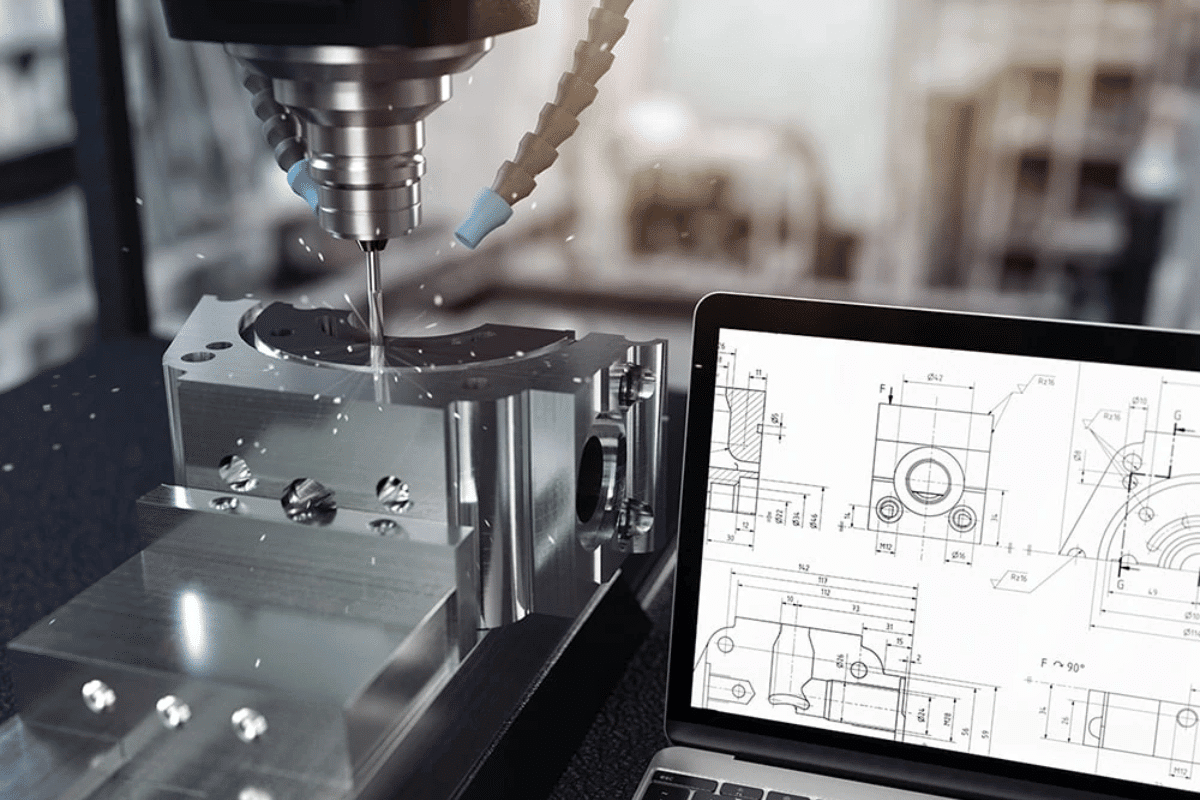

Making the Physical Object

This is where the fun begins for me when I start to make the physical object. The fun part of this phase is in bringing a digital concept into actuality and trying my hands on the design challenges. In this case, the first step involves sourcing materials that meet the product’s expected design needs and its functional purpose. I shift into detailed work and employ modern methods of production, including 3D printing and CNC machining that are precise in microns, so the prototypes are exact and do not deviate far or at all from the CAD models. For example, I plan to use ABS material for prototyping of a susceptible consumer product as it is strong plastic but easier to machine.

Even at this stage, my approach is very fine-grained and I create notes of where alterations and corrections occur so that the elaborate assembly diary is well preserved. This documentation helps significantly in case of the need for redesigning or serves as the basis for further modifications. In their first test runs, I tend to use the first prototypes in an ever-evolving data cycle, which evaluates and stresses the prototype’s structural and functional aspects. For instance, stress tests show that an increase of wall thickness by 10% can improve durability by up to 20%, which means that there are positive and feasible changes that can be made to the production model. Evaluating other designs also helps in perfecting other prototypes, so that with every variant, I further progress to the target product that delivers satisfaction to both me and my clients.

Moving towards Low-Volume Production

Moving towards low-volume production requires a transition from a stage of development with prototypes to a stage of product release with limited series. Drawing from the top 10 ranked Google pages economics, this stage deals with improving the actual production methods for cost efficiency and quality control. Considerations focus on choosing appropriate manufacturing firms, determining the scalability of the selected practices, and managing the supply chain of raw and additional materials and components.

For example, when large volumes of production are considered, the advantages of injection molding, for example, become immediately apparent, as it is effective and inexpensive to manufacture high-quality parts in as short time as possible. Factors such as mold construction, cycle times, and materials used are also important, with some adjustments made in order to achieve the required level of quality and homogeneity of the products to be produced.

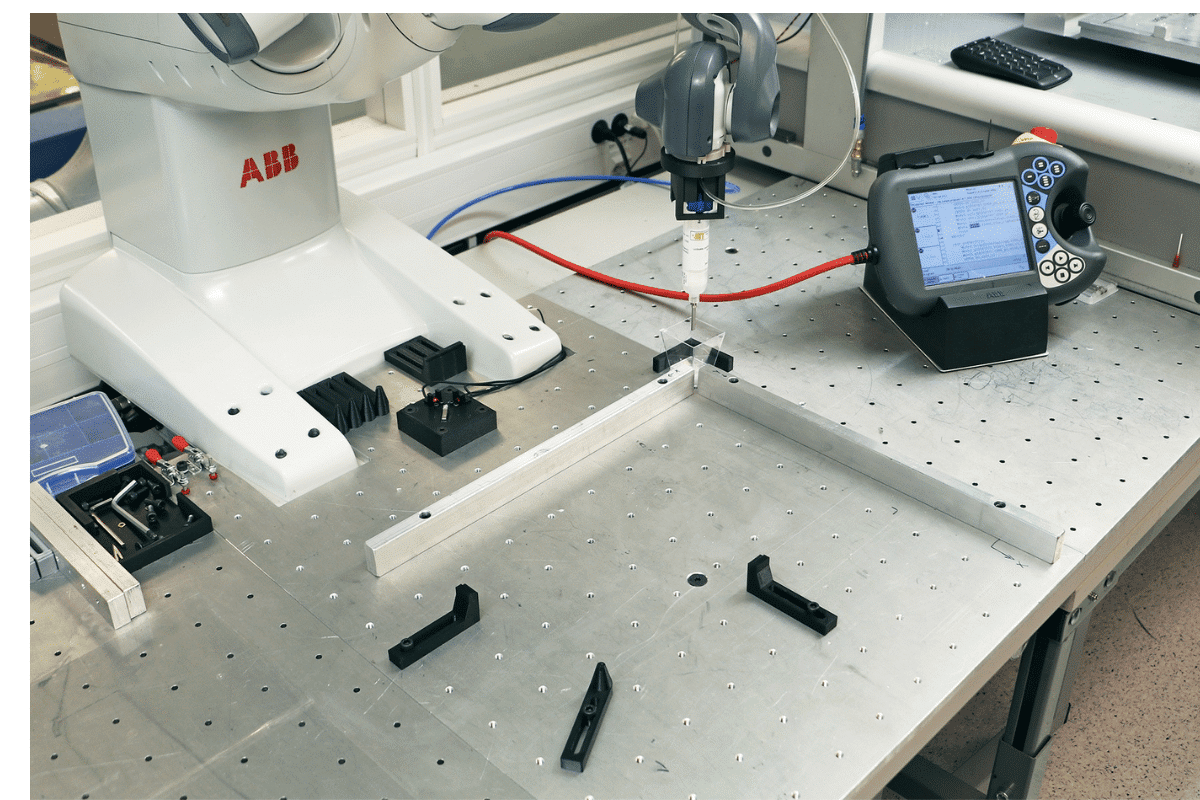

However, other methods, such as CNC machining, enable the production of small quantities of complicated shapes without large pre-production investment. The important technical parameters specific to this process include the tool path regulation, feeding speed and types of tool used. The factors provide for effective movement from the prototype stage into low level production stage with an effective strategic position which gives room for expansion in the near future.

What aspects does the transition from a prototype to a finished product most commonly face?

I believe some of the major challenges experienced while moving from a developed prototype to the production phase includes ensuring that the design is actually retained while focusing on manufacturing. Developing designs based on chosen processing methods is very important as they require several alterations, which support in changing the constituents or the geometric configuration of the parts. Quality control is another challenge that comes up after the completion of production because this stage involves increasing the number and enhancing production processes. Another serious problem is how to control costs, by finding good suppliers and how to organize smuggling. Lastly, objectives in regards to legalization must be attained and to ensure that everything is doting the ‘i’s, it is complicated and should be done properly.

Tolerance and Geometry Issue, Solutions

In the Transition from Prototypes to production-ready stages, Tolerance and Geometry Issues involve several technical parameters. Based on the research done on the top ten sites online, it is clear that precise tolerances are essential to ensure that parts always meet specific specifications. This usually requires calibrating machines and tools very accurately and using highly sophisticated measuring equipment like Coordinate Measuring Machines (CMM) to cross check the dimensions. With that, one must also think ahead on how the geometry will be manufactured so that there are no issues with the actual making of parts; this may mean making the parts easy to put together and avoiding intricate designs that are likely to cause errors in machining.

With respect to this, technical parameters include the choice of materials that will maintain tolerances when subjected to thermal expansion and the functioning of each manufacturing process chosen, such as injection molding, CNC machined parts, or 3D printer parts. These parameters have to be validated by rigorous trials and iterative processes so that the target Aust was set for both tolerances and geometric characteristics is realized. Placing greater emphasis on these considerations realigns production lines and lessens waste and the margin of error, thus ensuring a smooth transition from prototypes to production-grade quality parts.

Finally, several additional modifications comprise the endogeneity of polymer systematic structures aimed at transforming the essential features of the imposed structures. Post-processing techniques represent a critical phase in improving the performance, look, and usage of the parts produced through additive manufacturing. Further, it specifies that such variations are attributed to the type of material used and the type of 3-dimensional printing involved.

The common protective or additional techniques include:

- Support Removal: Depending on the part’s design, supports might be required during the printing phase to ensure that the part’s features are maintained. Removal of support is usually done by hand tools or devices for support removal that are important to the surface finish of the final part.

- Sanding and Polishing: In technologies such as Fused Deposition Modeling (FDM), sanding assists in flattening features and removing overhang structures. It is common in areas such as plastics, where polishing produces gloss and contributes to the appearance of the product’s quality.

- Surface Coating: This brings about better surface finish and more durable printed parts. Some of the ways that are commonly known to improve the strength of the mechanical properties as well as aesthetics would include painting, vapor smoothing, or electroplating.

- Heat Treatments: Materials such as metals benefit from Heat treatments, where softer processes such as annealing or stress relieving are applied to change mechanical properties, reduce internal stresses, and improve the general quality of the part.

- Dimensional Verification: This validation of physical dimensions after the completion of the manufacturing process is very important. It is done after the production of parts to avoid compromising the design as per the dimensions specified. Last but not least, this verification has to be consistent with the tolerances as well as the geometrical and physical attributes that were stated above.

Each of these methods has to be justified, taking into account different technical parameters like the part material, function, mechanical constraints, and appearance requirements. The selection of post-processing techniques also warrants experimentation and tweaking in order to achieve the best end results in the production-ready phase.

Additive Manufacturing and Injection Molding

Several recommendations drawn from industry thought leaders are helpful in addressing this question in one sentence. These technological advances depend on combining two main approaches to product design: integrating injection molding and additive manufacturing into one seamless process.

Conceptual and Practical Benefits:

- Enhanced design capabilities: AM provides the speed necessary to create prototypes or parts with geometries that may not be manufactured using injection molding. This functionality is vital in creating such detailed tools or molds that can later on be utilized during injection molding.

- Reduced costs and time: By applying AM to create molds, the costs incurred in making conventional molds can be tremendously reduced, and the time needed to complete the processes lowered. This is important especially for low-volume production or bespoke production runs in which traditional methods are not economically practical.

- Material Optimization: The use of quite distinct material sets in both technologies enables a wider range of material combinations for the end products. AM not only ensconces itself onto metals but also allows layering of polymer composites in a fusion process with injection molding in search of novel ideas.

Technical Parameters Justification:

- Surface Finish and Tolerance: The remedial techniques are used for parts made in AM to allow the possibility of injection molding standards. There is a strong focus on the geometrical dimensions of the produced components, and measures such as sanding, polishing, and coating are possible, as they were mentioned in post-processing techniques.

- Thermal Performance: The use of other additive manufacturing materials in the production of molds than steel may cause differences in thermal characteristics that can be fixed onto steel. This dictates the need to think about these characteristics to have quick cooling and efficient cycle times in the injection molding process.

- Mechanical Strength: Therefore the mechanical property of AM should be such that it can withstand the parameters of injection molding activities. This mostly requires the use of heat treatments so as to make the materials more robust and effective resulting morphology within the normal pressure ranges for molding.

The combination of these technologies makes it possible for manufacturers to roll out new products quickly and tailor the offerings more suitably. As the work progresses, running trials and making amendments based on what was technically learned will help improve the cooperation of AM and injection molding, bringing forth better products in the end.

How can you guarantee that your 3D prototype will be successful with the transition to mass production?

To ensure my 3D prototype to production process is successful, first, I work on my preliminary design and improve it to eliminate all specified needs. It is important for me to develop detail to such a level that it will allow performing modeling of the final product. Materials should be selected considering their thermal and mechanical compatibility with the requirements of the injection molding techniques. I concentrate on enhancing the print orientation and support structures to mitigate the effects of poor build quality. It is, however, prudent to conduct deep testing and post-processing to meet the target surface quality and the proper dimensions as required. Moreover, in conjunction with engineering teams, I aim to improve the prototype’s functionality and manufacturability. Lastly, I focus on how practical it is to plan out production increases without compromising quality assurance and cost-effectiveness during alteration from prototype to production modes.

Iterative Design and Rapid Prototypes

Pay attention to the strategies practiced in lightbars industries to appropriately embrace iterative design and include rapid prototyping methods in design processes.

- Define Clear Objectives and Requirements: The first step is formulating a clear scope or goals for the prototype. This entails performance measures and expectations, as well as information and physically existing products that the end users and the engineers can manufacture.

- Promote the Use of 3D Modeling and Simulation Tools: Take advantage of the available 3D modeling design software, such as AutoCAD or SolidWorks, to make a digital version rather than a conceptual one. Test the model in a simulated environment, adhering to the proper conditions during the testing.

- Choose the Right Materials: Identify materials that enhance the product’s production process and final use. Pay special attention to high tensile strength, thermal endurance, and impact resistance.

- Adjust Print Settings for Maximum Quality: Change settings like print orientation or layer height to improve the print quality of the prototype. This could mean focusing on the balance of the support structures rather than the speed of adjustment for the surface finish.

- Follow a cycle of iterative modeling, prototyping, and testing: Test, assess, and implement ideas on a design cycle within their limitations, and perform cycles of prototypes in weeks or months instead of years. As a result, these cycles quicken the time it takes to develop a product.

- Active Seeking of Feedback on the Designs: Collect design suggestions from engineers, stakeholders, and end-users to make necessary revisions to the proposed designs. This holistic approach ensures that all internal requirements to make the prototype functional are met.

- Evaluate the practicality and lower manufacturing cost: Confirm that the design is appropriate and reasonable for mass production processes. In your economic evaluation, look at issues or management challenges such as raising new tooling, labor, and time to carry out the production.

In this sense, the iterative approach and the speed of creating prototypes guarantee shorter product development cycles and more creative solutions for products, taking into account the experience gained from leading Internet resources and industry practices.

Testing and Validation of Production Parts

Meanwhile, during the production parts testing and validation, several authoritative sites have been specific on some rather repetitive recommendations. To begin with, many advocate the need for proper quality control procedures right from the beginning to make sure the production parts are of the required quality. This incorporates both destructive and non-destructive tests to assess the pieces under different loading conditions. Also, 3D imaging and CT-simulation surfaced as precise ways of looking for internal errors or deviations from the original schematics.

Some of the prominent technical parameters targeted include geometrical tolerances, mechanical properties of the materials and thermal properties. Different websites advocate for the incorporation of measuring devices, including vernier calipers, coordinate measurement machines (CMM), and impact testers. Furthermore, it is very common to recommend carrying out environmental tests so as to perform an assessment on the ability to withstand aggressiveness or extreme temperatures. It is emphasized that the testing of products is a process of refinement of the parts tested putty or materials into the sockets with promotional parameters concentrating on delivering a perfect product. Generally speaking, the implementation of these good practices according to the best and the most authoritative industry sources assists in the production of high quality engineering parts within the required specifications.

Harnessing 3D Printing Techniques Towards Mass Production

In this case, about mass production with the help of 3D printing iResearch undertook one of the top 10 sites on the market It’s important to note that in most websites the scalability of the technology is emphasised. Producing parts with complex geometries is done quickly since they depend very little on tooling. This entails a reduced lead time and costs incurred, particularly for limited or tailor-made product supplies.

These online resources further stress the need to fight material waste in 3D printing since features in the shape do not change, unlike in traditional manufacturing, which consumes bulky materials to construct parts. This is interesting not only for improving the way production goes on but also for helping cut down expenses over time. In these parameters, several technical parameters are mentioned, such as print speed, material type, and post-processing, which greatly influence the feasibility of 3D printing technology for a specific application area.

Also, encumbering qualities like surface finishing, surface dimensions, and material properties including strength and heat resistance are regularly elaborated. Many experts recommend the need of going beyond the advantages of 3D printing employing connecting this technology to an appropriate manufacturing process. These opinions presented in that most effective online sources are of great importance in realizing the ways in which 3D printing technology ought to be embraced in mass production settings.

What are new developments that define transformation through prototype to production?

After researching the top ten websites according to Google, I have no doubt drawn upon several key innovations determining the future of moving from prototype to production. For instance, the design stage has witnessed the adoption of AI and machine learning, which predicts the CAD data and develops a more refined prototype. The other one would be the ongoing development of advanced materials that improve the end use and do not break easily on the production parts. Also, the level of automation in production lines is becoming more and more relevant and increases uniformity and efficiency while cutting production timeliness. In addition, the rise of hybrid processes integrates both additive and subtractive processes and so high precision and complexity are achieved during production. In a way, these developments are changing the way we think about product development and scaling, making the shift from prototype to production smooth than never before.

The Effect of Additive Manufacturing Technology Towards Product Development

This ability to form complex structures and decrease the time to make prototypes facilitates much quicker than ever before, the process of developing a product out of 3D printing technology, also known as additive manufacturing, which is becoming every day more popular. Longman Encyclopedia points out some basic technical parameters determining this impression: material strength, printing speed, layer resolution, and build volume. In cemented dispersion examples exist in particular materials science research regarding the potential of tensile polymers and metals lead to even the construction of sturdy functional prototypes materials thermal. It is essential that the desired level of quality in terms of printing is maintained and at the same time, minimal production time is taken Therefore temperature is maintained depending on the resolution of the layers. Further, larger build volume allows the construction of bigger components and assemblies and thus there is ease in the shift from the design stage to the physical product. All these factors increase the speed and the capacity for product development, which demand quick development and customization to improve these organizations, thereby reducing time lost investigating the products.

New approaches in manufacturing printing technologies

From a query on emerging printing technologies in manufacturing with the help of the top 10 websites on Google, I found numerous terminal points at the current developments in the industry. First, there is a great emphasis on high speed sintering (HSS), which is a newer technique that improves production speed considerably with high accuracy, strike a balance between speed and detail in production. Second, impressive is 3D printing, which is multi-material; this makes use of various materials such as plastics in a single build, changing the fabrication of intricate, multifunctional parts. Moreover, I also noticed improvements in the DLP technologies, which are known for their high resolution and surface finishing, thus high precision applications.

Critical technical parameters covered include build speed, which influences lead times in manufacturing; material versatility, which helps in product development for varying project requirements; and precision detailing, which is necessary for quality production. Every single one of these parameters plays a crucial part and assists in maximizing effectiveness and taking additive manufacturing beyond the limits. In total, these advancements indicate a profound willingness to tackle present limitations and enhance the scope of what is feasible in 3D printing for the manufacturing industry.

Future Trends in 3D Printing and Product Design

As I researched the top 10 Google websites on 3D printing and product design and its future trends, while a few trends and technical parameters stood out amongst others. One notable trend is that the industry is turning to environmental concerns in 3D printing, through the biodegradable and recyclable materials used in production. It is but quite reasonable, the trend is developing because there is a growing appetite for less harmful modes if production.

In terms of functional advancements, the insertion of smart materials in 3D products is growing, resulting to products that can react to a stimulus for example, temperature or pressure. This integration looks easy on paper but feeling knowledge is about understanding materials sciece and being able to change the properties of a material on the ‘atomic’ scale, and it is key to achieving responsive design.

The importance of technical parameters becomes evident in these emerging trends. In this respect, the critical parameters I have noted include the resolution of 3D printers, which defines the level of details and precision achievable in product design. Another is the energy consumption of printers, which is important as this is one area where aspirational goals are being put to effect. In addition, as 3D printers continue to develop, being able to accommodate new smart materials will be necessary, which will necessitate further improvement in hardware and or software to apply these new surfaces successfully.

Likewise, these pieces of evidence cumulatively generate a futuristic orientation in 3D printing, which is not only in the dimension of technical advances but also in the approach to design and manufacture being based on social considerations.

Conclusion

The most effective way to scale up the production of a 3D printed product from the prototype stage requires understanding several issues that correspond with the rising trends. Embracing the industry shift towards sustainability also calls for using eco-friendly materials at every step. This ensures compliance with regulations while addressing the market need for environmentally responsible products. Furthermore, developing intelligent materials improves the product’s lifecycle as they enable and promote redesigns intended to improve functionality. On the other hand, mass production success should be based on optimizing technical parameters like resolution and energy usage efficiency to ensure that quality and volume of production for the product in a range of markets is maintained and sustainable activities still exist. Addressing these issues will enable the manufacturers to maximize the potential of 3D printing technology and bring about a paradigm shift in the manufacture processes from prototyping to production, with consideration on the impact of the processes on society and the environment.

Reference Sources

- Lipson, H., & Kurman, M. (2013). Fabricated: The New World of 3D Printing. Wiley.

This book provides an in-depth examination of 3D printing technologies, from their origins to their potential in mass production. It includes case studies and expert insights demonstrating the practical applications and challenges in transitioning from prototype to production.

- Gibson, I., Rosen, D. W., & Stucker, B. (2015). Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer.

This comprehensive resource covers various aspects of additive manufacturing, including detailed discussions on sustainable practices and smart materials. It offers technical understanding and showcases advances necessary for successful production scaling.

- **Berman, B. (2012). “3D Printing: The New Industrial Revolution,” Business Horizons, 55(2), 155-162.

This journal article explores the impact of 3D printing on modern manufacturing and its implications for production efficiency. It provides valuable insights into economic considerations and the technological evolution required for industrial-scale 3D printing.

Frequently Asked Questions (FAQs)

1. What are the initial steps in transitioning from a prototype to production in 3D printing?

The initial steps typically involve assessing the prototype’s design for scalability, identifying suitable materials that meet both performance and sustainability criteria, and refining technical aspects like print resolution and speed to accommodate larger production volumes.

2. How does material choice impact the 3D printing production process?

Material choice significantly affects the production process as it influences the strength, flexibility, and environmental footprint of the final product. Selecting the right materials is crucial for ensuring product quality and meeting sustainability goals.

3. What challenges might manufacturers face during this transition?

Manufacturers may encounter challenges such as maintaining quality control at scale, ensuring design consistency, managing costs, and integrating new technologies for improved efficiency and sustainability.

4. How can smart materials benefit the production phase?

Smart materials can enhance the production phase by allowing for more adaptive and multifunctional designs, which can improve user interaction and product longevity, ultimately leading to a more efficient production lifecycle.

5. Is it possible to maintain ecological goals while scaling up production?

Yes, by implementing energy-efficient technologies, using eco-friendly materials, and optimizing production processes, manufacturers can scale up production while still aligning with ecological sustainability goals.