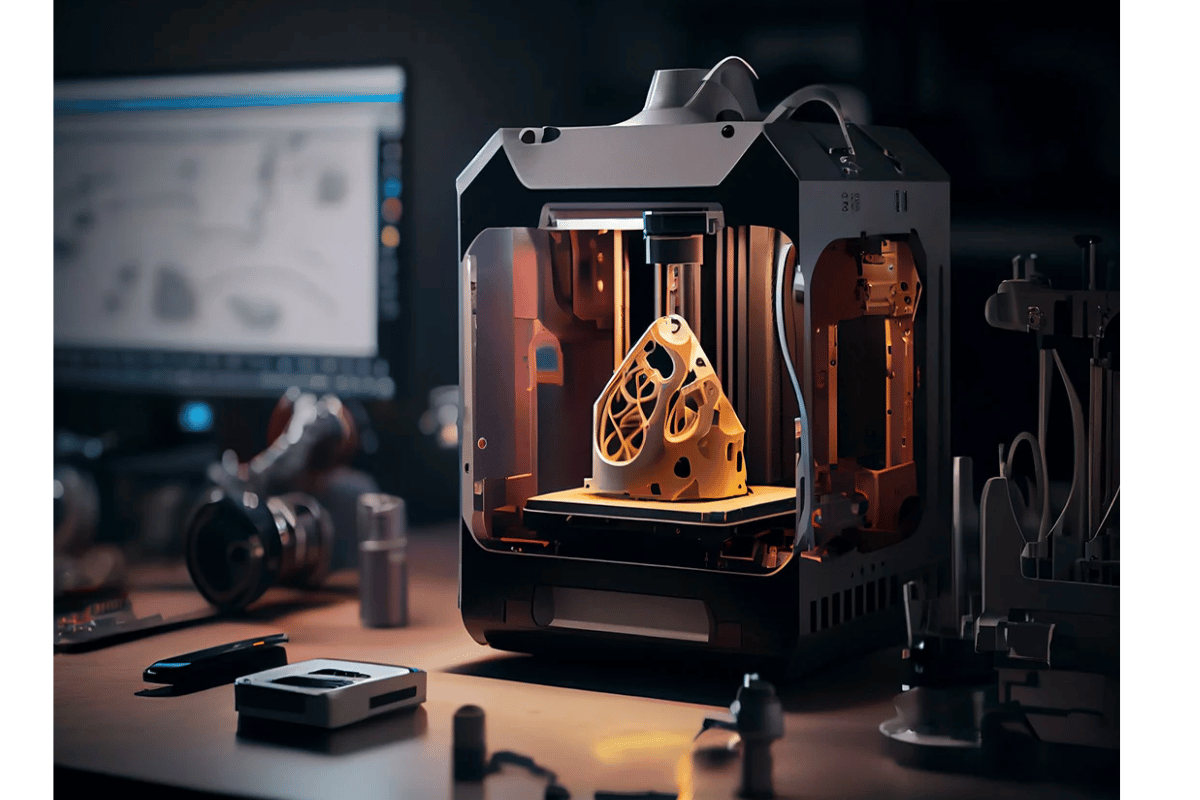

Polylactic Acid (PLA) thread has become an essential constituent of the 3D printing industry because it is easy to use and has a sustainable source. PLA is made from natural sources like cornstarch or sugarcane, thus providing an environmentally friendly alternative to most conventional plastics. The blog will outline various aspects of PLA, ranging from temperature resistance to tensile strength, that would be vital for 3D printing enthusiasts, whether experienced in this area or beginners. Therefore, if you have specific designs or robust prototypes to create, being aware of the properties of PLA is crucial to ensure that your project works well and you have satisfactory print results.

What are the Mechanical Properties of PLA in 3D Printing?

Image source: https://www.innovationnewsnetwork.com/

Mechanical properties of Polylactic Acid (PLA) are essential in understanding its performance in 3D printed applications. This means it can withstand a lot of tension before breaking, making it suitable for many structural components. Compared with other materials, the elongation at break is relatively low, 2-10%. This suggests that it tends to be rigid during printing, maintaining its shape better than some substances. Furthermore, PLA has shore hardness approximated at about 85D, thus forming a solid and durable surface. In addition, it has a low glass transition temperature (about 60°C), which means high heat could deform it, thereby limiting its employment in high-temperature applications. Given these mechanical properties, PLA is best suited for prototyping and intricate printing, where stability and ease of use are essential factors to consider.

How does tensile strength affect 3D-printed parts?

When it comes to evaluating the performance of 3D-printed objects, tensile strength is crucial, as it is responsible for a material’s ability to resist breaking when pulled or stretched. Objects with higher tensile strength can carry more loads and withstand more significant stress while being used. For example, materials with higher tensile strength, which help prevent breakage during operation, are essential in parts that require durability, such as functional prototypes and mechanical elements. Yet other materials like PLA may be limited in their applications due to low elongation at the break despite having reasonable tensile strength, especially where impact is concerned or high-stress situations. Therefore, understanding the tensile strength of materials in 3D printing will determine the filament choice and final part performance.

What are the thermal properties of PLA?

Polylactic acid (PLA) has several distinct thermal characteristics that make it useful for 3D printing. One of the most prominent features includes its glass transition temperature, which is around 60°C. That means that above this point, PLA loses its rigidness and starts to deform under load. Additionally, PLA has melting point range of between 150°C to160°C making it easy to print using standard 3D printers. Nevertheless, the material cannot be exposed to higher temperatures due to its low heat resistance capabilities. When one needs more excellent thermal stability than PLA can offer, one should consider changing to other types of plastic that can retain structural integrity upon exposure to elevated temperatures.

How does layer adhesion influence mechanical behavior?

The mechanical behavior of 3D printed parts is a function of layer adhesion, which impacts their overall strength and durability. The bonds between layers must be strong enough for the printed object to withstand loads without delaminating or falling apart. Hence, weak areas will result in lower tensile and impact strengths due to poor bonds between layers. Some factors that affect layer adhesion include print temperature, speed, and environmental conditions during printing, among others. A higher print temperature can improve inter-layer bonding, while low temperatures may result in poor fusion between layers. Additionally, the filament type and printer settings affect how well layers stick together, thereby determining how good the part will be.

How Does PLA Compare to Other 3D Printing Materials like ABS?

Two common materials used in 3D printing are PLA and ABS, each with unique characteristics. PLA is more environmentally friendly since it is biodegradable and more accessible to print because it sticks on the bed well without requiring a heated bed, making it ideal for small intricate designs where high precision is required. However, due to PLA’s low heat resistance, it should not be used in applications exposed to high temperatures. On the other hand, ABS has excellent toughness, better impact resistance, and thermal stability and is best suited for functional parts and prototypes. Nevertheless, some challenges are associated with ABS, such as warping problems; thus, proper ventilation ought to be maintained so that fumes can be managed accordingly during printing. Ultimately, whether one chooses PLA or ABS will depend on project-related requirements like strength needed, thermal tolerance required, or appearance desired upon completion.

What are the critical differences between PLA and ABS?

- Material Properties: PLA (Polylactic Acid) is a thermoplastic that can be decomposed by microorganisms. It’s made of corn starch and similar agro-based materials, making it more environmentally friendly. On the other hand, ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based plastic that is well known for its toughness and impact resistance.

- Printing Ease: PLA, on the other hand, is usually easier to print with since it sticks well to the print bed and does not require a heated bed; it is suitable for beginners. ABS can be problematic in printing due to warping and the high requirement for a controlled environment that can prevent cracking.

- Temperature Resistance: PLA’s heat resistance is lower, about 60°C, which makes it unsuitable for high-temperature applications. ABS, on the other hand, has a better capability to withstand higher temperatures, reaching up to 100°C, thus being used in functional parts subjected to heat.

These differences show why choosing the suitable material is essential based on what you need, such as ease of use, environmental factors, or strength under heat.

When should you choose PLA over ABS for your projects?

Often, when I want my projects done without much hassle and thinking about green environment implications, I go with PLA. Because PLA is user-friendly, it suits beginners or those who work under less regulated conditions and don’t experience warping. Also, I like using my prototyping decorative purposes because this material gives a smooth surface finish and bright colors. Finally, when making something printed at low temperatures, I prefer using biodegradable PLA since, apart from aligning with my values, its eco-friendly characteristics are evident.

What are the limitations of using PLA compared to ABS?

PLA has some limitations when compared to ABS. To begin with, PLA has lower heat resistance, making it susceptible to deformation in high-temperature environments. This means it is unsuitable for functional parts that may be exposed to heat, unlike ABS, which can handle higher temperatures. Secondly, PLA is not as good at absorbing shock as ABS, making it brittle and more likely to break under strain or impact. Thirdly, while PLA is biodegradable, exposure to moisture and UV light outdoors limits its longevity, leading to degradation over time, rendering its use less viable for outdoor purposes. Lastly, PLA has an overall strength and flexibility that are much lower than what is needed by some mechanical applications where toughness matters.

What are the Best Printing Parameters for PLA Filament?

The ideal extrusion temperature of PLA filament is usually between 190 °C and 220 220°C. Most sources recommend starting at about 200°C, as it seems to perform well with different types of PLA filaments. However, variations in temperature may still be needed, given the type of filament you are using, the machine, and the environment that you work in, to achieve the right prints and their adhesion.

What printing temperature is optimal for PLA?

In a PLA print, the nozzle size can make a huge difference in its quality and speed, among others. Based on my experience, I use larger nozzles, typically measuring around 0.4mm or more, for bigger models where detail does not matter as much because this permits faster printing speeds. In contrast, I employ tiny nozzles such as 0.2mm when making complex designs with more minor details because they help improve accuracy and bring out each layer distinctly. Consequently, any changes done on the nozzle can significantly affect other parameters like temperature; hence, optimal results might be hard to attain unless these are matched accordingly during the printing process. Generally speaking, though, it will depend on if you want something that high in detail over one that takes less time.

How does the nozzle size affect PLA printing?

For optimum performance when printing with PLA materials; layer height should be between 0.1 mm and 0.3 mm For balancing print quality versus speed a number of printers prefer using a layer-height (z-axis) between 0 .1-2 mm although this will vary by printer and material being used. A low z-axis resolution (< 100 microns) may be used for highly detailed surfaces, while larger parts overhangs can use higher resolutions (>300 microns). In addition, users need to consider lowering the resolution if they want finer parts and increasing it for coarser ones, although other factors also come into play.

What layer height should be used for optimal results with PLA?

To get the best results when printing with PLA, use a layer height between 0.1 mm and 0.3 mm. 0.2 mm is the right balance between quality and print speed for most prints, giving a good surface finish while keeping the printing time reasonably low. A smaller layer height of about 0.1mm for highly detailed models increases precision and surface quality. In contrast, more significant parts or faster prints may use a higher layer height of 0.3mm to hasten the process. Accordingly, it is necessary to precisely adjust the layer height according to print requirements and printer capabilities in general.

What are the Advantages of Using PLA in 3D Printing?

Polylactic Acid (PLA) filament is one of the favorite materials used in additive manufacturing mainly because of its merits. To begin with, it is biodegradable and derived from renewable sources, thus making it an eco-friendly alternative to petroleum-based filaments. Moreover, PLA requires lower extrusion temperatures, resulting in less warping and excellent bed adhesion, making it easier to print correctly. Furthermore, this material also has minimal shrinkage during cooling, ensuring dimensional stability during prints . Additionally, it comes in many hues and surface textures, thus offering more design freedom. Finally, PLA is often characterized by its smooth surfaces and fine details, rendering it suitable for prototyping, among other applications.

Why is PLA considered easy to print?

There are several reasons why PLA can be deemed one of the easiest-to-use filaments in three-dimensional (3D) printing technology, and they are pretty simple, though necessary. Firstly, this means that a wide variety of printers can accommodate this material within their extruder temperature range since it melts at lower temperatures than many others, which makes warping much less likely to happen than if printed by nylon or ABS, for instance, making it possible to work on printers without heat beds. Secondly, PLA sticks very well on different print surfaces, ensuring good bed adhesion, which is critical in ensuring the first layer looks nice. Additionally, it has a minimal shrinkage rate that significantly reduces the chances of dimensional inaccuracies, enhancing user-friendliness. Lastly, this material comes in a wide range of vibrant colors and textures accompanied by solid print quality, thus promoting individuality and innovation for both novices and professionals alike.

What are the environmental benefits of using PLA?

While thinking about the advantages of using PLA for the environment, I discovered that it is made from renewable materials such as cornstarch or sugarcane, thus reducing our dependence on fossil fuels. PLA, however, undergoes biodegradation in industrial composts, unlike its conventional plastic counterparts, meaning this type of polymer can be broken down quickly and does not pose much danger to natural habitats if disposed of properly. Besides, compared to petroleum-based plastics, the production method of PLA usually leads to lower levels of GHG emissions. This set of sustainable sourcing, biodegradability, and reduced carbon footprint makes 3D printing possible in a more environmentally friendly way.

How does PLA perform in terms of durability and usability?

PLA is popularly recognized for its simplicity when applied, thus making it an ideal filament, even for starters or those who have gained enough experience. Regarding strength and stiffness, PLA is rigid yet less flexible than other materials like ABS or PETG, which may restrict its application in high-stress conditions. Nevertheless, due to its rigidity, this kind of plastic offers an advantage in accurate modeling. When usability comes into play, there are few defects, mainly because there is good printing with excellent layer adhesion in case the same type is used for manufacturing. Moreover, little odor emanates during printing, plus no warping occurs; hence, similar results can be obtained without a heated bed every time one prints, thereby creating a low odor process. Generally speaking, PLA offers the best usability required by intricate designs and sufficient durability in diverse structures.

What Are the Common Applications of PLA in 3D Printing?

Polylactic acid (PLA) has found its way into many 3D printing applications due to its ease of use and eco-friendliness. For example, it is widely employed in rapid prototyping, where detailed print quality is essential for design verification. Similarly, the filament allows for intricate designs and comes in various vibrant colors for producing custom figurines, toys, and educational models. Additionally, PLA can make low-stress items like household decoratives, art projects, or packaging prototypes. Lastly, its biodegradable nature makes it preferable for one-off products, such as prototypes for biodegradable packaging solutions and marketing materials.

What types of printed parts are best suited for PLA?

PLA is most suitable when printed parts do not need strength or high heat resistance. Where detail and finish are significant, some ideal examples include sculptures and models, which should be decorated with more information at places like home. It works excellently on prototypes and low-stress components requiring precision, such as fixtures, but usually non-functional prototypes. Educational tools that use this filament benefit from PLA’s inherent vibrancy and detailed attributes. Furthermore, pencil holders and lightweight containers are commonly produced using PLA because of their easy printing ability and minimal warping features. In cases where aesthetic quality is more important than mechanical performance, like display pieces and art installations, PLA can also be used in functional applications.

Where is PLA commonly used in the additive manufacturing industry?

Various sectors within the additive manufacturing industry, such as education, hobbyist projects, and rapid prototyping, use PLA. This filament is often used by students in educational settings to design engaging projects that encourage an understanding of 3D printing technology. The ease of use and extensive range of color options are why many hobbyists prefer the material for making personalized items, among other artistic outputs. Furthermore, I often turn to PLA in rapid prototyping to create highly detailed yet aesthetically pleasing models essential in validating designs and presentations, especially in consumer goods or packaging design. Additionally, it is a biodegradable element that complies with the modern demand for eco-friendly materials in contemporary manufacturing.

How can PLA be utilized in prototyping and production?

PLA has several methods that can be utilized during prototyping and production by exploiting its unique characteristics. First is its printability aspect, which permits designers to swiftly generate prototypes suitable for consumer products, thereby allowing them to iterate their designs quickly on some aspects. In addition, industries like automotive and aerospace also use PLA because it portrays high-quality models with great visual appeal, hence serving as a means for showing concepts through client presentations, among other techniques. Also, due to its lower melting temperature, ABS does not put so much stress on 3D printer components, making it possible to achieve consistent results with such machines both at small scale or larger production runs. For eco-conscious businesses looking to minimize their carbon footprint, its biodegradability offers an option where even the disposal phase of products should comply with sustainability principles.

How do you properly store and handle PLA filament?

It must be well stored and handled to guarantee that PLA filament stays in operation for a substantial period. Store PLA in a cool, dry place away from sunlight to avoid degradation by high temperatures and exposure to UV light, which may affect its structural integrity. Keep the filament in airtight containers or bags with desiccants since higher humidity can cause bubbling or oozing during printing. Handling filament without touching it with bare hands reduces the risk of oil transfer and contamination. Also, ensure no dirt or residue on the spool and use spool holders during printing to prevent tangling.

What are the best practices for storing PLA to maintain quality?

- Optimal Environment: Keep PLA in a low-temperature location free from moisture, with temperatures between 15°C and 25°C (59°F and 77°F), away from direct sunlight and heating elements so that it does not degrade.

- Sealed Storage: Put your filaments in airtight boxes, plastic bags sealed tightly, or vacuum-sealed bags containing desiccants, molecular sieves, or salt, which will absorb all water/moisture dampness absorbed from the air. Otherwise, even slight humidity, which can enter any box or bag used, may negatively impact print quality.

- Handling Precautions: When handling your filament, avoid touching it with your bare hand to minimize the transfer of oil. Ensure no dust particles or residues are on the spool before using spool holders while printing to eliminate tangling issues.

Following these practices will help you preserve PLA plastic for longer periods, achieving consistent outcomes every time you engage in 3D printing activities.

How does humidity affect PLA filament?

PLA filament performance in 3D printing can be significantly affected by humidity. PLA has moisture absorption properties that make it sensitive to high ambient humidity, which ultimately causes a range of printing problems. I have discovered that the absorbed water gets converted into steam during printing, thereby making the PLA bubble, ooze, or adhere poorly. Besides, increased humidity causes filament weakness, resulting in unexpected fractures during printing. Therefore, PLA should be stored in an environment whose levels of humidity are low, hence guaranteeing good results.

What are the signs of degraded PLA filament?

Degraded PLA filament has specific tell-tale signs that can affect 3D print quality before deterioration. First and foremost, any changes in color, such as dullness or discoloration, may indicate that the filaments are no longer as they were initially manufactured. Physical brittleness is another indicator that it loses its elasticity if bent or pulled out of shape easily. Also, variations in diameter can cause feeding issues, leading to under-extrusion or clogging within the printer’s nozzle tip. Lastly, irregular surface textures on the material arise due to either contamination or absorption of moisture. Regularly inspect and test your PLA filament after every few prints for your PLA to produce excellent prints.

Frequently Asked Questions (FAQs)

Q: What is PLA in 3D printing?

A: PLA, or Polylactic Acid, is a biodegradable thermoplastic commonly used in 3D printing. It is derived from renewable resources like corn starch or sugarcane, making it a popular choice for environmentally conscious printing.

Q: What are the material properties of PLA?

A: PLA’s material properties include its rigidity, low shrinkage during the cooling process, and lower melting point compared to other plastics. These characteristics make PLA easy to print and suitable for detailed models.

Q: How does FDM 3D printing work with PLA?

A: FDM 3D printing, or Fused Deposition Modeling, works with PLA by extruding the filament through a heated nozzle, layer by layer, to build a 3D object. This process is efficient for creating complex shapes using PLA material.

Q: What are the limitations of 3D printing with PLA?

A: The limitations of 3D printing with PLA include its lower heat resistance than other plastics, making it unsuitable for high-temperature applications. Additionally, PLA can be brittle, affecting the mechanical strength of 3D-printed PLA objects.

Q: Can PLA be used in SLA 3D printing?

A: No, PLA is not typically used in SLA 3D printing, which relies on liquid resins cured layer by layer with a UV light source. PLA is primarily associated with FDM 3D printing technologies.

Q: What are some typical applications of 3D-printed PLA?

A: Common applications of 3D printed PLA include prototyping, educational models, hobbyist projects, and decorative items. Its ease of use and environmentally friendly properties make it ideal for creative projects.

Q: How does PLA compare to other 3D printing materials?

A: PLA vs other materials like ABS or PETG reveals that PLA is more accessible to print and offers better detail resolution. However, it lacks the durability and heat resistance found in materials like ABS, making it less suitable for functional parts.

Q: What is the best way to store PLA filament?

A: To ensure the quality of PLA filament, it should be stored in a cool, dry place away from direct sunlight. Using airtight containers can help prevent moisture absorption, which can affect the printing process.

Q: What should I consider when choosing a 3D printer for PLA?

A: When choosing a 3D printer for PLA, consider the printer’s nozzle temperature, bed temperature, and compatibility with 3D printing filament. Most FDM 3D printers are well-suited for printing PLA, but ensure they can reach the required temperatures for optimal results.