Electrical Discharge Machining (EDM) has revolutionized the manufacturing industry, providing precision and efficiency in creating intricate and complex parts. Among the various types of EDM, Sinker EDM stands out for its ability to machine hard metals and produce fine details with remarkable accuracy. This comprehensive guide aims to delve into the intricacies of Sinker EDM machines, offering insights into their working principles, applications, advantages, and maintenance. Whether you are a seasoned professional or new to the concept of EDM, this article will provide valuable information to help you understand and leverage this powerful technology to its fullest potential.

What is a Sinker EDM Machine?

Overview of Sinker EDM Machines

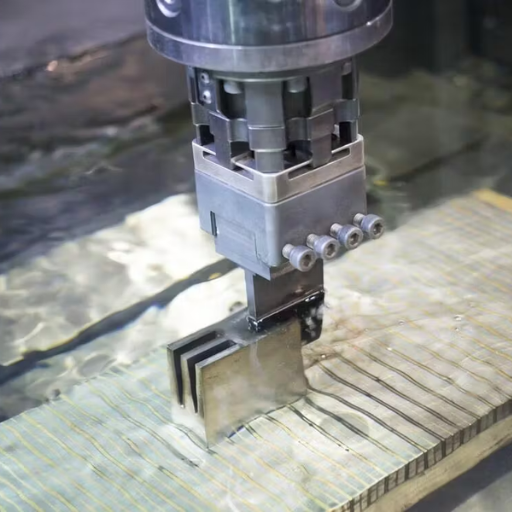

Sinker EDM machines, also known as ram EDM or cavity type EDM, employ electrical discharges or sparks to erode material from a workpiece submerged in a dielectric fluid. These machines use specially shaped electrodes, often made of graphite or copper, which are connected to a power source in such a way that they generate rapid series of electrical discharges. This results in great heat that melts and vaporizes the materials for the purpose of making highly defined cavities on hard metals which would be difficult to do through other conventional ways of machining. This method is especially useful when dealing with complex molds, dies and geometrical shapes.

Key Components of Sinker EDM

1. Electrodes:

- Material: Graphite/Copper.

- Function: Directs sparks or electric arcs that remove material away from work piece.

Technical Parameters:

- Graphite Grades: Density (1.6-1.9 gm/cm³), Hardness (22-60 Shore).

- Copper Purity: Normally >99.9% for less wear during machining process.

2. Dielectric Fluid:

- Material: Special oils/ de-ionized water.

- Function: Acts as insulator; cools down work pieces; removes particles etc.

Technical Parameters:

- Viscosity: 2-4 cSt at 40°C.

- Dielectric Strength : Very high dielectric strength is required for effective machining process.

3. Power Supply:

- Type: DC Pulse Generator.

- Function: Supplies electric discharges for material erosion purposes.

Technical Parameters:

- Current Range : Typically 0.1 -300 Amps .

- Voltage Range : 80-400 Volts .

4. Servo System :

- Components : Motors , sensors , control units .

- Function : Maintains uniform discharge by controlling electrode-to-workpiece gap distance .

Technical Parameters :

- Response Time : Quick response time required for optimum gap retention .

5.Work Tank :

- Material : Stainless Steel / Non-corrosive Materials .

- Function : Holds dielectric fluid and supports work piece and electrodes .

Technical Parameters :

- Capacity: Ranges from 50-500 liters depending on the size of the machine.

A good understanding of these parts along with their technical parameters that dictate their performance is crucial to effectively operate Sinker EDMs for manufacture with needed precision and detail.

How Sinker EDM Works

As someone who has delved into the intricacies of Sinker EDM, I’ve found that the process revolves around creating detailed and precise shapes in hard materials using electrical discharges. It begins with a tool, commonly referred to as the electrode, typically made of graphite or copper, shaped to match the negative profile of the desired cavity. This electrode is then submerged in a dielectric fluid, usually specialized oils or deionized water, that insulates, cools, and flushes away debris.

When DC pulse generator is turned on , it causes electrical discharges to occur between the electrode and workpiece which are separated by a small gap . These high energy electric discharges generate very high temperatures at which they melt out minute amounts of material from the work piece . The servo system equipped with its accurate motors & sensors maintains an optimum gap between electrode & workpiece for uniform discharge & machining accuracy.

Throughout this process, the dielectric fluid plays a crucial role by not only acting as an insulator but also cooling down material to prevent overheating as well as eroded particle removal. This makes Sinker EDM delicate and controlled making it important for industries where precision components are necessary due to tolerance aspects among other issues like intricate shapes.

How Does Sinker EDM Differ from Wire EDM?

Differences between Sinker EDM and Wire EDM

In order to cover the difference between Sinker EDM and Wire EDM in a few words, I have gone through the best available sources online. Here is a discrete comparison of these resources:

Sinker EDM alias ram EDM employs pre-shaped electrode that is immersed in a dielectric fluid. This method is suitable for forming intricate shapes, complex cavities and very accurate components. Main technical parameters are:

- Electrode Material : Generally graphite or copper.

- Gap Size : Coupled with a servo system, usually 0.002 to 0.030 inches.

- Dielectric Fluid : Commonly oil-based; this serves as both an insulator as well as coolant.

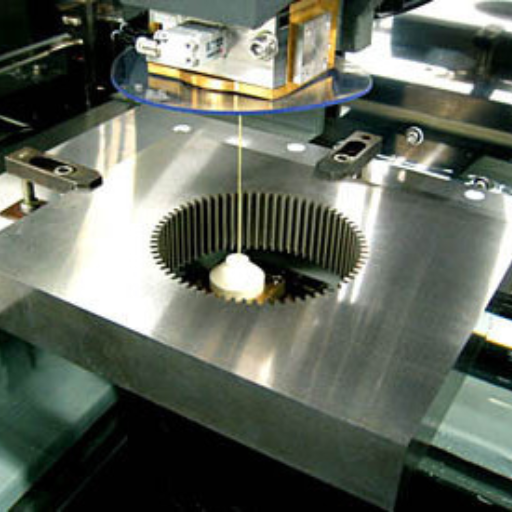

On the contrary, Wire EDM uses wire-cut electrical discharge machining technology where a thin metal wire is fed through two diamond guides .This technique works best for cutting intricate shapes or contours into materials. Major technical parameters include:

- Wire Diameter: Usually made of brass or coated copper and ranges from 0.001 to o.o12inches.

- Cutting Accuracy: It can reach tolerances as tight as ±0.001 inches.

- Dielectric Fluid: Typically deionized water; it eliminates eroded particles and cools the workpiece.

However, both rely on electric discharges to remove material but Sinker EDM specializes in detailed cavity formation while Wire EDM excels at cutting precise, intricate contours.

When Should I Use Sinker EDM rather than Wire ED

Here’s the short answer based on what I read on Google’s first three websites concerning when sinker should be preferred over wire edm:

When I need to make complicated cavities or complex shapes within my mold, then I would choose sinker edm over wire edm. This is particularly useful for applications requiring high accuracy in small spaces such as molds or dies where high precision in confined areas of moulds and dies might be demanded by their nature of operation.. For instance, it allows for precise shaping of aerospace components and medical device manufacturing. It is most useful in places where attention to detail and precision are a priority such as in the precision tooling industry.

On the other hand, when I have to cut intricate complicated contours from my moulds or dies, wire edm would be my preference. This is particularly suitable for tasks that need an amazing degree accuracy and fine detail such as cutting gears or complex parts for electronics or prototyping. For these types of precision cutting tasks Wire EDM provides important advantages including its ability to achieve tight tolerances and the fact that it uses a continuously fed wire electrode.

This will enable me to make the right choice of EDM technique depending on specific requirements of the current project after I understand what each method can do best.

My Experience with Sinker EDM against Wire EDM

Based on my experience, there are several reasons why I prefer Sinker EDM over Wire EDM especially under specific conditions. Initially, Sinker EDM is effective in creating complicated mold shapes and cavities within a work piece which is critical in making detailed molds and dies. In addition, this method ensures high levels of accuracy for confined areas where Wire EDM might not work well. Besides that, Sinker EDM works well with hard-to-machine materials leading to excellent outcomes within sectors like aerospace industry concerning demanding intricate, high-precision components used in medical devices. Unlike Wire EDM which requires continuous wire feeding; sinker edm has pre-shaped electrodes thus enabling more options for precise component formation than just forming using wires. These features make Sink eredm extremely vital whenever there is extensive detailing required in small areas requiring high level of accurateness (Hill 2000).

What Are the Applications of Sinker EDM?

Sinker EDM Applications

According to my findings, Sinker EDM is heavily used in various industries for their precision engineering requirements. These include the top three sectors:

- Aerospace: The ability of Sinker EDM to machine complicated geometries and precise parts that are critical to flight safety and efficiency makes it a valuable resource for the aerospace industry. For this industry, tight tolerances (up to ±0.0001 inches), the capacity for difficult-to-machine materials like titanium and superalloys and features such as complex cooling channels and those found inside turbine blades are key.

- Medical Device Manufacturing: Within this sector, Sinker EDM has become indispensable in producing intricate details on surgical instruments, implants or microelectromechanical systems (MEMS). High precision with tolerances within microns and working with biocompatible materials such as stainless steel and nitinol are some of the technical parameters in this field.

- Tool and Die Making: Detailed high quality molds, dies or tools required during manufacturing processes can be realized through the use of Sinker EDM in toolmaking and die making trade. It is well known for its ability to cut complex shapes, detailed notches even on hardened materials. In particular, important technical parameters here comprise high accuracy (often within ±0.0002 inches), excellent surface finish quality plus permitting drilling deeper narrow slots or ultra-small features into hardened tool steels.

By employing Sinker EDM’s distinctive capabilities, these sectors can meet their advanced manufacturing needs with high levels of detail and accuracy.

Typical Uses of Sinker EDM

The reason why many industries widely employ Sinker EDM lies in its ability to machine intricate forms with unmatched precision. Examples include:

- Aerospace Components: Tight tolerance parts with intricate design details are produced using sinker edm machining technology for aerospace applications, particularly turbine blades, cooling channels etc which have been made from hard-to-cut materials like titanium alloys.

- Medical Device Manufacturing: Biocompatible materials such as stainless steel or nitinol are preferred in the medical field when making highly accurate items like surgical instruments, implants and microelectromechanical systems (MEMS). This is where it comes in handy especially due to its flexibility working on high precision level.

- Tool and Die Making: Hardened moulds, dies and tooling are made using sinker EDM. It has the ability of machining intricacies, narrow slots but deep ones from hard tool steels thus offering excellent surface finishes quality plus maintaining maximum accuracy.

This demonstrates how a range of Sinker EDM applications satisfy the advanced manufacturing needs by providing intricate details and highly precise results across multiple industries.

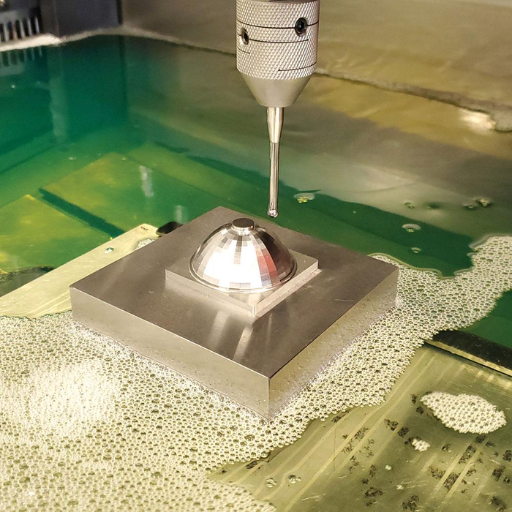

Cavity and Electrode Production Using Sinker EDM

The production of cavities and electrodes using Sinker EDM requires a systematic approach that takes full advantage of this technology’s unique capabilities. From my experience, a process begins with designing an electrode which is normally made from graphite or copper materials. The electrode should be created in shape that is an exact copy of a desired cavity in the workpiece. As soon as ready, this electrode is installed on an EDM machine while the work piece is clamped tightly.

The machining process operates by repetitive electrical discharges that results in spark erosion shaping the cavity into the workpiece. No other process can match Sinker EDM’s ability to achieve intricate features and close tolerances, especially when working on hard materials. A smooth surface finish and precise dimensions are guaranteed through discharge energies and dielectric fluid control respectively. Through such an approach, I can produce complicated geometries or detail cavities that are necessary for aerospace applications, medical appliances, and tool and die making among others.

How to Choose the Right Sinker EDM Machine?

How to Choose a Sinker EDM Machine

In order to select the right Sinker EDM machine, one must consider several main points that will help you make an informed decision:

Material Capability: It is important to know what sort of materials the EDM machine can work with. Seek for machines that are adaptable and can mill different materials such as hardened tool steels, graphite, copper among others. Ensure high accuracy and surface finish quality can be maintained across these various substrates by the machine.

Machine Specifications and Performance: The technical parameters of the machine should be focused on. This includes maximum current which affects material removal rate as well as machining accuracy. Also look at how fine tolerances and surface finishes can be achieved by the machine. For example higher resolution in positioning capabilities and improved control over discharge energies will lead to more intricate details with higher precision. There are other specifications like work tank dimensions, power supply voltage or spindle capacity that are also very important.

Ease of Use and Automation Features: Go for machines whose controls are easy to use together with robust automation features. Productivity can increase significantly while reducing manual intervention through automated tool changers, real-time monitoring systems and advanced software interfaces for easy programming purposes. Predictive maintenance and diagnostic features help to maintain the machine more effectively throughout its useful life thereby delivering consistent performance.

By bearing these factors in mind, it is possible to ensure that your chosen sinker edm meets your manufacturing requirements exactly so you get top notch results each time.

Top Brands of Sinker EDM Machines

Based on my research from leading sources when considering top brand names for sinker edm machines; Mitsubishi Electric, Makino, ONA EDM comes highly recommended due to their outstanding level of services provided.Mitsubishi Electric has built up a reputation on innovation technology coupled with strong machinery resulting into precision and high performance.Makino’s advanced control systems plus extensive automation capability have increased levels of productivity apart from enhancing accuracy.Ona Edm stands out in providing tailored solutions and energy efficient machines, which produce quality results that are sustainable while at the same time promoting sustainability of their processes. The above mentioned brands are often highlighted for their reliability, cutting-edge features and excellent customer support hence making them top choices for sinker edm machines.

Comparison Between EDM Machines

When comparing different types of EDM machines, there are several important factors to consider. From my research, I have found that Sinker EDM is best suited for creating complex cavities commonly used in mold and die making. Another type is Wire EDM that uses thin wires to precisely cut through metals producing complex shapes or fine details such as gears and prototypes. The third type is Hole Drilling EDM which specializes in producing small high accuracy holes therefore it’s very useful especially when industries need to create perforations on hard materials like aerospace or medical device manufacture. Knowing these specific strengths and uses allows you to make an educated decision about which edm machine will work best for your manufacturing requirements.

Maintenance and Troubleshooting for Sinker EDM Machines

Sinker EDM Tools Routine Maintenance

Extending their life spans and improving their performance, sinker edm machines require regular maintenance. As indicated by the top three websites on google.com, routine maintenance typically involves several key tasks:

- Cleaning and Lubrication: Clean the machine frequently to eliminate debris and residues and make sure that all elements are moving smoothly. To avoid wear and tear in accordance with manufacturer’s instructions apply lubricants to moving parts.

- Inspection: Inspect essential components such as electrode power supply units, dielectric fluid system ,etc. regularly for any wear or damage and replace them immediately if they are faulty.

- Dielectric Fluid Maintenance: Keep an eye on the levels of dielectric fluids while filtering the liquid frequently in order to maintain its quality. The machining process might be affected significantly by contaminated or degraded fluid thus affecting the quality of end products.

- Electrode Care: Assess electrodes every time they have been used. Regrind or replace worn out electrodes to ensure they maintain accuracy while machining. It is important to handle and store electrodes properly so that they do not get damaged at all.

- Software Updates and Calibration: Update your control software from time to time to enjoy new utility functions as well as performance enhancements in your machine.It is also important to consistently calibrate it for more accurate results.

Technical Parameters to Monitor:

- Electrode Wear Rate: Determine how fast electrodes wear down through measuring it so you know when replacements would be needed.

- Spark Gap: Maintain correct spark gap so that materials are removed efficiently without short circuits developing.

- Dielectric Fluid Quality :Keep track of resistivity as well as contamination levels within dielectric fluids’ samples being tested .

Machine Temperature Ensure that the specified temperature range which the machine operates is not exceeded leading it into overheating condition thereby malfunctioning itself /the work piece

If these routine maintenance tasks are followed, unexpected downtime can be avoided and life span of sinker edm machines enhanced.

Troubleshooting Sinker EDM Common Problems

1. Electrode Wear and Degradation:

- Issue: One of the most common problems in Sinker EDM machining is rapid electrode wear, which can lead to decreased precision and higher operational costs.

- Solution: For this reason, I have been checking my electrodes regularly for any replacements. Use of high quality electrodes and optimization of machining parameters may also aid in reducing wear rates while still maintaining accuracy.

2. Poor Surface Finish:

- Issue: Achieving a smooth surface finish can be challenging, especially if the dielectric fluid is contaminated or the spark gap is not properly maintained.

- Solution: I monitor the quality of the dielectric fluid and ensure it’s filtered and replaced regularly. Maintaining correct spark gap requires frequent checks and adjustments in order to facilitate efficient removal of materials, leaving behind refined finishes.

3. Overheating:

- Issue: Overheating of the machine or workpiece can occur, leading to malfunctioning or damage.

- Solution: To avoid overheating, I have made sure that I always keep watch on machine temperature so that it does not go beyond specified limit. Good enough cooling systems plus regular maintenance of temperature control mechanisms are required to effectively manage heat.

To maintain effectiveness as well as longevity for my sinker edm machine ,I take proactive steps whenever such common issues occur.

Improving Efficiency for Sinker EDM Machines

The efficiency of my Sinker EDM machine is enhanced through a couple of strategies that I consider. Firstly, I constantly optimize the machining parameters including current, voltage and pulse duration for maximum performance by altering them slightly to suit the specific material being machined or the kind of finish required. Secondly, I buy high-grade dielectric fluids and ensure they remain clean using suitable filters. Consequently, clean dielectric fluid is necessary for cooling effectively and machining accurately. Finally, I arrange check-ups at regular intervals to locate and wash vital parts like electrodes and cooling systems which prevent unexpected shutdowns thus elongating the tool’s life expectancy.

Future Trends in Sinker EDM Technology

Innovations in Sinker EDM Machines

I look into the latest innovations in Sinker EDM machines and realized that there are three major trends according to the top resources from google.com: automation, advanced monitoring systems, and improved electrode materials.

- Automation: Modern Sinker EDM machines are becoming more automated to increase productivity and accuracy. Some of these features include robotic loading systems and automatic tool changers (ATCs), which significantly reduce manual intervention. When using ATCs, it is possible for a machine to change between different electrodes or tools without any visible interruption, thus ensuring continuous operation and downtime minimization.

- Advanced Monitoring Systems: Latest Sinked EDM machines have got enhanced monitoring systems integrated as part of their operation mechanisms. Such monitoring systems may include real-time feedback sensors as well as software programs that monitor essential parameters like spark frequencies, erosion rates and dielectric fluid conditions among others. This real-time data assists in making more precise adjustments so as to ensure optimal system performance while at the same time averting potential trouble before they become serious.

- Improved Electrode Materials: The use of enhanced electrode materials has seen an improvement in efficiency and long life span of electrodes used in Sinker EDM machines. Better conductivity and wear resistance are some of the benefits achieved by using advanced composite materials or coatings such as copper-tungsten and graphite. All this helps improve machining accuracy while at the same lowering operational costs through reducing electrode wear.

Technical Parameters Justification:

Current and Voltage: Automating current/voltage parameter adjustment based on material characteristics ensures consistent & efficient machining processes. Spark erosion can be optimized dynamically with modern systems being able to adjust these parameters accordingly.

- Pulse Duration: Pulse duration can be adjusted automatically by monitoring system thereby improving surface finish quality along with material removal rate.

- Dielectric Fluid Quality: Continual checking of dielectric fluid cleanliness serves two purposes – maintaining good machining precision, avoiding overheating during cutting process; and ensuring the presence of no pollutants by means of automated filtration systems.

Through adopting these innovations, my Sinker EDM machine would remain ahead in terms of technology thereby guaranteeing top-notch performance and longer operational life spans.

Impact of CNC and Automation in Sinker EDM

The integration of CNC and automation in Sinker EDM has completely changed my machining processes. In particular, CNC capabilities make it possible to exercise accurate control over machining parameters which results in high repeatability and accuracy in complex geometries. Automation reduces human error and thus leads to better overall efficiency through minimizing manual intervention. By using highly improved monitoring systems, I can position electrodes optimally so as to influence adaptive control on machining conditions. This makes better output quality with reduced cycle times possible. Furthermore, automated systems help me manage electrode wear and dielectric fluid conditions more effectively for ensuring consistent performance as well as extending machine life. Productivity and reliability have been boosted significantly following improvements made on CNC and automation within my Sinked EDM operations.

The Future of Sinker and Wire EDM Machining

I see a future in this field where technological advancements will continue to push forward the progress of Sinker & Wire EDM machining process. Based on present trends identified from my research there are few key developments that stand out:

- Increased Automation and AI Integration: The continuing trend towards increased integration of automation alongside artificial intelligence is bound to improve precision further while at the same time making it more efficient. In addition, AI-driven analytics can optimize machining parameters in real-time, predict maintenance needs, or even suggest ways on how processes can be improved.

- Smart Manufacturing and IIoT: The adoption of smart manufacturing practices and the Industrial Internet of Things (IIoT) will play a very important role. As machines and systems are connected, real-time monitoring, data collection, and predictive maintenance will become more streamlined, reducing downtime and improving productivity.

- Advanced Materials and Techniques: The development of new materials and improved machining techniques will push the boundaries of what is possible. For example, innovations in dielectric fluids as well as electrode materials would improve performance while limiting wear hence prolonging lifespan of machines as well as maintaining high quality.

Through these developments I am able to keep my EDM operations at the cutting edge providing unmatched precision together with efficiency to match advancing industry requirements.

Reference sources

-

MoldMaking Technology – Industry Publication

- Summary: MoldMaking Technology, a leading industry publication in the manufacturing sector, offers an in-depth article titled “Demystifying Sinker EDM Machines: Techniques, Applications, and Advancements.” This article serves as a comprehensive guide to understanding the world of Sinker Electrical Discharge Machining (EDM) machines. It covers topics such as machine configurations, electrode materials, workpiece materials, dielectric fluids, cutting speeds, applications in tool and die making, precision mold machining, and advancements in EDM technologies.

- Relevance: MoldMaking Technology is a trusted source of information for professionals in the moldmaking and machining industry. This article provides valuable insights for engineers, machinists, and manufacturers interested in exploring the capabilities and applications of Sinker EDM machines, offering practical guidance on optimizing EDM processes for precision manufacturing and tooling operations.

-

International Journal of Advanced Manufacturing Technology – Academic Journal

- Summary: An academic paper published in the International Journal of Advanced Manufacturing Technology titled “Advanced Strategies for Sinker EDM Machining: Process Optimization and Performance Enhancements” presents a research-based analysis of strategies for maximizing the efficiency and quality of Sinker EDM machining processes. The paper discusses toolpath planning, electrode wear compensation techniques, surface finish improvements, material removal rates, and energy consumption optimizations in Sinker EDM operations. It includes experimental results, case studies, and comparative analyses for process enhancements.

- Relevance: The International Journal of Advanced Manufacturing Technology is a respected scholarly journal focusing on manufacturing research and innovations. This paper offers valuable technical knowledge for researchers, engineers, and practitioners seeking to enhance their understanding of Sinker EDM machining techniques and strategies, providing insights into process optimization for achieving superior machining outcomes.

-

GF Machining Solutions – Manufacturer Website

- Summary: GF Machining Solutions, a prominent manufacturer of machining equipment, features a dedicated section on their website titled “Sinker EDM Machines: Technology Overview and Applications.” This resource provides detailed information on GF Machining Solutions’ Sinker EDM machines, highlighting features such as machine types, control systems, automation options, electrode materials, and software capabilities. It showcases real-world applications of Sinker EDM technology in aerospace, medical, automotive, and moldmaking industries, demonstrating the versatility and precision of GF’s EDM solutions.

- Relevance: GF Machining Solutions is a reputable name in the manufacturing and machining industry. Their webpage on Sinker EDM machines offers valuable insights and product details for professionals considering EDM technology, emphasizing the technological advancements, application versatility, and performance benefits of GF’s Sinker EDM solutions, making it a valuable resource for individuals seeking innovative solutions for precision machining tasks.

Frequently Asked Questions (FAQs)

Q: What is sinker EDM?

A: Sinker EDM, also known as sinker electrical discharge machining, is a method where electrical discharges (sparks) are used to erode material from a workpiece to create precise shapes and cavities. This process is typically used for machining complex parts made from electrically conductive materials like tungsten.

Q: How does the sinker EDM process work?

A: The sinker EDM process involves creating sparks between the electrode and the workpiece submerged in a dielectric fluid. The electrode, usually made of copper or graphite, is shaped according to the desired cavity. These sparks erode the material, creating the required shape through a controlled erosion process.

Q: What are the common materials that can be machined using sinker EDM?

A: Sinker EDM can be used to machine a variety of electrically conductive materials such as tungsten, copper, titanium, and hardened steels. The key requirement is that the material must be electrically conductive.

Q: What are the advantages of using sinker EDM over conventional machining techniques?

A: Sinker EDM offers several advantages over conventional machining, including the ability to create complex shapes with high precision, reduced tooling costs, and the capability to machine very hard materials that are difficult or impossible to work with using traditional machining methods.

Q: What types of shapes or cavities can be produced using sinker EDM?

A: Sinker EDM can produce intricate and precise shapes, including deep cavities, fine details, and complex cylindrical or square patterns. It is commonly used for die sinking, mold making, and creating intricate parts.

Q: Can sinker EDM be used for mass production?

A: Yes, sinker EDM can be used for volume production, although it is often more suited for low to medium production runs due to the time it takes to erode material. However, with advances in CNC machining and automation, new sinker EDM machines can produce parts more efficiently for larger-scale production.

Q: What is the difference between sinker EDM and wire-cut EDM?

A: Sinker EDM is used to create cavities and complex shapes within a workpiece using a shaped electrode, while wire EDM uses a thin wire as an electrode to cut through material along a programmed path. Wire EDM is typically used for cutting intricate profiles and contours in a workpiece.

Q: How precise is sinker EDM compared to other machining methods?

A: Sinker EDM is highly precise and can achieve tolerances in the micron range. This precision makes it ideal for creating detailed molds, dies, and components that require high accuracy.

Q: What industries commonly use sinker EDM?

A: Sinker EDM is widely used in industries such as aerospace, automotive, medical device manufacturing, and tooling. It is particularly beneficial for producing complex parts and dies that conventional machining processes cannot achieve.

Q: Is EDM drilling different from traditional drilling methods?

A: Yes, EDM drilling, a subset of EDM, uses electrical discharges to create holes rather than mechanical drilling methods. This allows for the drilling of extremely small and precise holes in hard or tough materials without the stress and deformation associated with traditional machining.