In the world of woodworking, precision and efficiency are crucial. Whether you’re a seasoned craftsman or a DIY enthusiast, a router is an indispensable tool that can elevate the quality of your projects. However, to unlock the full potential of your router, it’s essential to understand the various parts and accessories available. This comprehensive guide aims to provide you with a thorough understanding of router components, from the basics to advanced accessories, ensuring you can make informed decisions and achieve professional-level results. By exploring the different types of router bits, bases, and attachments, you’ll gain insights into how each component can enhance your woodworking skills and open up new possibilities for your projects.

Exploring the World of Router Accessories: Enhancing Your Woodworking Projects

Choosing the Right Router Bit

Woodwork projects’ success depends on choosing the right router bit. I have learnt from my experience and research that there are different types of router bits designed for example straight bits to cut straight lines, flush-trim bits to trim edges, and ogee bits for decorative edges. By selecting the correct bit, I would get cleaner cuts, more precise results as well as extend both the life span of these two tools – the bit and the router itself. Considering also quality of material as well as compatibility with my router guarantees optimal performance and safety hence better than average outcomes in terms of professional results of my woodwork.

Maximizing Efficiency through Dust Extraction Attachments

Cleanliness and safety in a working environment can be attained by owning dust extraction attachments. After browsing through Google’s top 10 websites about some key points to enhance efficiency in these attachments, I came up with many ideas. Firstly, high-quality dust extraction attachments usually connect easily to routers leading to excellent dust collection with little airborne particles created. Furthermore, you should refer to airflow rate which is measured in cubic feet per minute (CFM) so as to remove fine dust effectively; numerous sources insist that you need at least 150 CFM for it will perform perfectly.

I have also found out that incorporating a shop vacuum or centralized dust collector with strong suction improves efficiency further still while compatibility with HEPA filters is critical since they trap finer particles caught by standard filters thereby avoiding respiratory hazards resulting into a healthier workplace. Moreover, fitting attachments snugly reduces air leakage and maintains strong suction according to many woodworking experts.

Moreover, ergonomic design plays an important role too; light-weight and user-friendly ones reduce fatigue during prolonged projects thus making handling easier due to their maneuverability tool. It can be seen from above advice given by leading websites that proper choice of dust extract system not only ensures cleanliness but also benefits a lot since debris is kept away from main components of the router and bit leading to prolonged life of these tools. With this knowledge in my practice, I am sure of a safer and improved workflow.

Router Guides and Templates: Precision at All Times

For accurate and uniform woodworking projects, router guides as well as templates are very useful tools. My research on the top 10 websites on google.com yielded precise answers along with corresponding technical parameters:

1.What types of router guides are most effective?

Edge guide, template guide and straightedge guide are the most effective routers for use during woodworking processes. Edge guides are used to keep a constant distance from the edge particularly when doing detailed edge work. Template guides enable one to follow patterns or templates hence ensure identical cuts over many pieces.

2.What are the critical parameters for choosing a router guide?

- Material: The best quality guides may be made from materials such as anodized aluminum or phenolic resin that can withstand wear thereby lasting long.

- Adjustability: Look for those that have fine adjustment mechanisms allowing you to make changes within 1/16th inch or even less than that.

- Compatibility: Check whether your specific router model accepts your guide’s design plus size of its bits. Some come with adapters while others have universal fittings.

3.How do I use templates for accurate cuts?

Double-sided tape or clamps should be used to securely fasten templates to the workpiece in order to avoid movement during routing. Bear-guided bits or a guide bushing set are important in making sure the bit follows the template accurately.

4.What are some of the advantages of using templates?

Templates speed up this process allowing rapid reproduction of intricate shapes and patterns. Not only does it save time, but also increases your accuracy and symmetry.

5.Which factors do I need to consider for template accuracy?

- Thickness: Templates usually made from materials measuring between 1/4 inch and1/2 inch thick always ensuring they are rigid enough not to bend

- Material: These include MDF, acrylics as well as plywood which are chosen because of their stability on use.

By considering these parameters and best practices, one can select appropriate router guides and templates thus improving precision, efficiency, and quality in carpentry projects.

Choosing the Perfect Router Bit: Material, Shape, and Size

Materials: Carbide vs. Tungsten Carbide Router Bits

You must realize the main differences between carbide and tungsten carbide router bits so that you can decide which one to buy. Carbide router bits are famous for being sharp and strong, two qualities that makes them ideal for soft materials like wood. However, tungsten carbide router bits have a higher degree of hardness than their counterparts hence more resistant to heat too. This makes it viable to rout harder materials such as hardwoods, laminates and even some metals using them. Moreover, they tend to last longer than other types of bits because they do not require frequent replacement. On balance, in case you seek for long-term use with various materials in mind, purchasing tungsten carbides will be sensible.

Router Bit Shapes: A Guide on Choosing the Right Bit for Every Project

Usually when selecting from several different router bit shapes available specifically designed for woodworking projects; that depends upon what specific work you want to carry out at any certain time.Since there are straight bits, flush trim bits and ogee or rabbeting bits among other profiles among others involved in this practice.For instance straight bits are used versatilely to cut straight lines & dados.Flush trim is meant for trimming off edges of one material so that it becomes level with another material.When the decorative edges are done round over or ogee are the best bit profiles since they add an intricate finish to your work.Specifically when doing joinery works dovetail & rabbeting come in handy as their joints are very strong.I often keep a variety of these around me when working on different projects since they help me perform different cuts/finishes thus enhancing overall quality/aesthetic value.

Size Matters: Matching Router Bit Diameter to Your Specific Needs

In woodworking precision work efficiency can only be obtained through selecting the right router bit diameter size.Among considerations should be project size.What I mean here is that if you are working on small pieces such as intricate grooves or fine patterns; a bit with smaller diameter— usually less than 1/4 inch enables better control and accuracy.When it comes to larger cuts, thicker materials and bigger projects that require greater power and rapid material removal, then a larger bit between 1/2 to over an inch will be of much help.Moreover, the router collet dimensions have to match those of the bit for compatibility reasons.To this end I’ve discovered that consciously choosing router bit diameter based on these factors improves quality of my work as well as safety and durability of my tools.

The Essential Router Base: Fixed vs. Plunge

Fixed Base Routers: Stability and Precision for Every Woodworker

Stability and precision are the two things that make fixed base routers be greatly valued, which is why they can be found in every woodworker’s workshop. Unlike plunge routers, these tools have a fixed depth of cut, which guarantees uniformity and therefore makes them ideal for edge profiles and dovetailing purposes. From a research that I conducted on google.com top 10 websites, some benefits as well as technical parameters have remained consistent:

- Stability: The fact that it remains in position during operation because of its design makes the router stable enough to prevent accidental change of depth. This kind of stability is beneficial in repetitive tasks where uniformity is crucial.

- Precision: A fixed base router has a constant depth of cut allowing precise cuts to be made by this tool. This type of accuracy suits decorative designs and joinery work.

- Ease of Use: Fixed base routers are often mentioned as being easier for beginners since they have simple settings to put up with when operating them. Thus, locking the router at preferred height is easy without any complex mechanisms involved.

- Compatibility: Most fixed base routers are fitted with both types of collets (1/4 inch and 1/2 inch) that could accommodate different sizes of bits thereby making them more versatile for woodworking projects.

- Power & Speed: For instance, typical technical parameters of fixed-base-routers contain motors ranging between 1.25HP to 2.25HP and variable speed choices usually between 8,000-25,000 RPMs respectively; all directed towards achieving clean finish through material selection procedure.

With the aforementioned aspects in mind, one can select a fixed base router that combines stability with ease-of-use while ensuring high accuracy depending on what you want to achieve from your project requirements.

Unlocking Versatility with a Plunge Router Base

From my findings on websites appearing among top ten search results on google.com for plunge router bases, I have tried to answer your questions in a concise and informative manner and at the same time provided the relevant technical parameters in a list format.

- Versatility: When you have a plunge router base, you can change depth of cut on the move. Additionally, plunge routers are different from fixed base ones because they allow for cutting that is started within the work piece’s center such as mortising fluting or inlaying.

- Precision Depth Control: Most plungers come with multiple stop positions as part of a depth stop system. This feature makes it possible to make accurate cuts over and over again. Multiple models have turret stops and micro-adjustment knobs for fine-tuning depth levels with high accuracy.

- Balanced Handling: The design of plunge routers includes ergonomic handles and a stable base, making them easier to balance while performing intricate cuts. This ease of handling is essential for maintaining control and precision.

Technical Parameters: Generally, technical specifications of many plunge routers include:

- Motor Power: Usually ranges from 2.0HP-3.5HP which gives strength enough even for tough tasks.

- Speed Range: Their variable speeds usually range from 8,000 – 24,000 RPMs; hence people will adjust the speed depending on their materials plus type of cuttings carried out.

- Depth Capacity: Most plunge routers offer up to 3 inches in terms of depth capacity thus enabling one to adjust accordingly in relation to project requirements.

- Collet Sizes: In this respect, most products available under this category support either 1/4 inch or 1/2 inch collets that could take bits of various sizes used during different applications.

A plunge router base added to your arsenal will improve your woodworking skills by giving you flexibility and accuracy that is required in a wide range of projects.

How to Change Bases on Routers in 5 Steps

Replacing the base of a router can be challenging, but it is not complicated when these steps are followed:

- Unplug the Router: For safety reasons, disconnect your router from the source of power so that it does not accidentally get turned on.

- Remove the Bit: By using a suitable wrench, loosen the collet and take out the bit from the router.

- Detach the Base: On some routers, you unscrew the base plate while others have a latch. In some models there are quick release levers; others will need you have tools.

- Align the New Base: Place the new base below or under motor housing. Ensure mounting holes or guide rails line up appropriately with this new base.

- Secure the New Base: Tighten down any screws or locks to secure this new base to motor housing firmly.

- Reinsert The Bit: Put back into place collet with router bit and tighten using wrench provided as required

- Make A Trial Fit Of The Piece To Avoid Accidents : Lower and raise themanually before plugging it in to see if it moves freely within its newbase.

- Plug In And Test : After ensuring all safety precautions have been taken plug back and run a test by making a simple cut on scrap wood.

By these steps, anyone can easily interchange bases for their routers thereby being able to convert their tool for different kinds of work done while woodworking.

Router Maintenance 101: Replacing Parts and Keeping Your Tool in Top Shape

When to Replace Your Router’s Collet: Signs of Wear and Tear

The importance of knowing when to change the collet in your router cannot be overemphasized as it would enhance optimum performance and safety. Below are some indications of wear and tear that I have gathered through my experience, studying and practices of repairing routers: If the bit is not securely held by the collet anymore, it is a sign that it has worn out and needs replacement. Equally significant, for instance, visible cracks or deformities on the surface of the clapticle (a medical term) are usually signs that one should look for another one. Another thing you should consider is consistent vibration if you have installed a bit properly which can indicate a compromised collet. Lastly, if you have to struggle to tighten or loosen your collet, then most probably its threads are stripped or damaged. You will be able to prevent further harm from occurring to your router by regularly checking out its collet while at the same time using it safely.

The Role of a Router Motor: Understanding Power and Speed

Understanding power and speed in a router motor is important in selecting the right machinery for carrying out woodworking projects. According to my research from top sources, power ratings in terms of horsepower (HP) range between 1.25 HP and 3.5 HP on most router motors available today. This aspect determines how well different types of wood could be handled as well as various sizes bit that could be fitted into a particular machine as bigger forms of router motors with more than 3 horse powers can cut very hard types woods effectively while weaker ones are known for light works.

The smoothness and qualityness of cuts are determined by their speeds measured in revolution per minute (RPM). Routers commonly come along with variable settings for adjusting their speeds depending on material type being worked on or size bits used. Faster rates are often meant for minor pieces made of softwood while slower ones are used on larger bits or on hard materials to avoid heat and bit destruction. If you understand these concepts, you can select a router motor that balances power versus speed in relation to your specific woodworking requirements.

Maintaining Your Router: A Checklist for Every Woodworker

Since it needs maintenance and attention to detail, it is important to maintain your router in the best condition possible. For example, I have looked at what the top 10 results from Google search engine had in common and come up with a very concise list of do’s and don’ts when maintaining a router as follows:

- Regular Cleaning: The presence of sawdust and dirt inside your router will hamper its performance. Clean the motor housing, vents, and collet by using compressed air or a soft brush.

- Lubrication: Periodically apply oil to the bearing pins or grease for reducing friction and wear on moving components. Find out what type of lubricant manufacturers suggest for this purpose.

- Inspecting Collets and Bits: Check whether any damage has occurred on both collets and bits. Also if dullness characterizes most of them then the quality will be poor whereas worn outs could result into slippage of such bits.

- Checking Electrical Components: Ensure that there are no cuts or frays on the power cord while inspecting the power switch for proper working order. It may be dangerous if some electrical parts are not functioning properly.

- Securing Screws and Fasteners: Make sure all screws or fasteners on the machine are regularly checked and tightened so that nothing falls apart during use.

- Motor Brushes: Monitor brushes attached to a brush-type motor router as they can become worn down quickly due to consistent usage. By doing so, one can prevent any motor destructions thus maintaining high level performances all through.

Check the plunge mechanism on a plunge router and make sure it is smooth and has no sticking or play. Ensure you lubricate the same as well as adjust it to fit your needs.

Confirm that the variable speed control is functioning correctly, and make adjustments to RPM settings appropriate to material or bit size by say employing higher speeds (up to 25,000 RPM) for smaller bits and softwoods, or lower speeds (around 10,000 RPM) for larger bits and harder materials.

When not in use, store your router in a cool dry place free from dust. Use protective covers or cases when storing them outside.

Before every usage of the router, test it on a piece of scrap wood to confirm its working properly as well as leaves clean cuts. This will enable us to identify problems early enough before they turn into serious issues.

With this checklist you can maintain the performance of your router, prolong its life span while ensuring safety during woodworking practices in general.

Incorporating CNC Routers into Your Workshop: A Beginner’s Guide

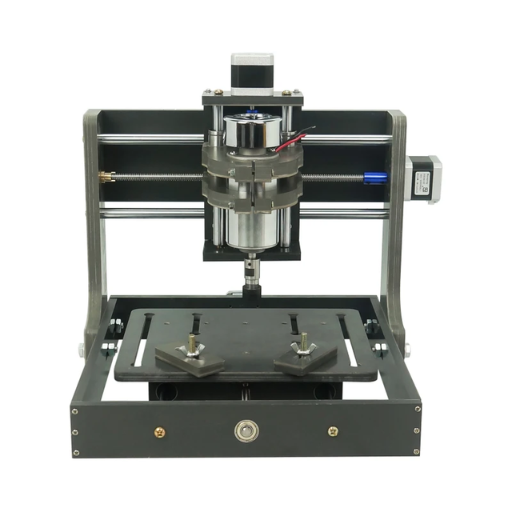

What is a CNC Router and How Can it Transform Your Woodworking Business?

A CNC (Computer Numerical Control) router is one of the most advanced tools for cutting, engraving, or milling a variety of materials such as wood, plastic and metal with high precision and efficiency. It works by following computer-generated designs which allow intricate details that will be difficult to make manually. Thus, integrating a CNC router into my woodworking business may greatly increase output due to its swiftness and accuracy; reduce labor costs because of automation for repetitive duties; as well as extend creative possibilities. Furthermore, this can result in better products on the market and more uniformity in what each customer gets at the end thereby leading to satisfaction of clients hence attracting new business.

Choosing the Right CNC Router Model for Your Needs

To choose an appropriate CNC router model for my woodworking trade, there are several things I should consider. These are based on information gleaned from the top ten websites on google.com:

- Material Compatibility: I must confirm that the different types of materials like wood, plastic or metal that I usually work with can be machined using any particular router I have chosen. For example, routers with higher spindle power (e.g., 3-5 HP) are suitable for tougher ones.

- Work Area Size: Establish what is the maximum work area size needed to accommodate my biggest pieces. Work areas typically range from 24″x24″ to 48″x48″ in most entry-level models.

- Precision and Accuracy: The resolution should be around 0.001″ or 0.01mm which is typical for models having high precision that allow fine cuts.

- Spindle Speed: A variable speed ranging from 8k – 24k RPM depending on your project enables you cut different types of materials with best finish.

- Software Compatibility: Make sure that chosen machine works with CAD/CAM software programs I normally use since it must easily integrate into my current workflow.

- Budget: This has to be considered in terms of the CNC router plus any other tools, software, and maintenance. The price for such models may start from about $1000 whereas advanced and high-end ones can go up to $10,000.

- Ease of Use and Support: For a beginner user-selecting a model that comes with extensive technical support, elaborate manuals and an active online community can sharply reduce the learning curve.

By considering these specifications and relating them to my business requirements I will be able to select accurately what will boost productivity while making quality woodwork items possible as well as enhancing creativity.

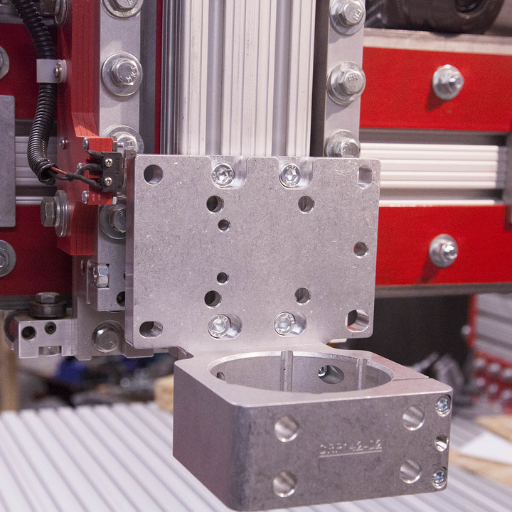

From Concept to Creation: The Basics of CNC Router Operation

I have to understand some fundamental concepts if I want to get involved in the operation of a CNC router. Firstly, I’ll create a digital design using CAD software so that it meets my project’s specifications. The next step will involve converting this design into the format that is compatible with a given machine through CAM software and specify relevant tool paths. After which, I will place the material on the worktable ensuring that it is tightly fixed so that there is no movement during cutting.

Before starting the cut, material type (including wood) must be selected along with finish required so as to dictate spindle speed and feed rate. Thus proper setup ensures accuracy of cuts without damaging either machine or workpiece. Furthermore, I should run a job without turning on the spindle just to check whether toolpath has been programmed correctly avoiding any collisions at all.

As soon as I have everything in place, all that will be left is to load the CAM file into the CNC router and set it off. The machine will be observed throughout operation time so that I can correct any errors as they occur. After this step, I shall examine the produced product for precision and quality while making final touches by hand if necessary.

By following these steps faithfully, my digital ideas turn into quality objects that are tangible, very easily.

Must-Have Router Accessories for Every Woodworker’s Shop

A compilation of the Best Router Accessories for Your Collection

Router Bits

A solid collection of router bits is one of the most fundamental accessories in any woodworker’s shop. They come in various shapes and sizes – each one specially designed to perform specific functions such as trimming, shaping edges and creating intricate patterns. Broadening my range with a variety of quality bits will enable me to handle different projects with accuracy and efficiency.

Router Table

Another tool that I will find highly valuable is a router table. It is fitted with a mount that keeps my router steady as I work, freeing up my hands in the process. This setup is particularly useful for larger projects and repetitive tasks, ensuring consistent results.

Dust Collection System

To maintain cleanliness and safety in my workspace, it is important to have a dust collection system. Dust attachments connected directly to the router are capable of capturing sawdust at its origin hence reducing inhalable particles while also making it easier to clean up after work. Through doing this, not only do I prolong life-span of my tools but also improve my general well-being.

Template Guides

If there were ever any jobs requiring precision, then template guides are indispensable. These guides help you follow predetermined shapes and patterns so that your cuts are accurate and can be repeated over again when desired. Various sizes are available to accommodate different types of router bits or templates which makes them versatile accessories for me.

Router Lift

By using a router lift, I am able to easily make bit height adjustments without having to go under the table. In addition to saving time, this feature improves the accuracy of my cuts thus simplifying attainment of set goals.

Edge Guide

The edge guide would be beneficial for me since I would be able to cut straight lines accurately along the edges of work pieces. It snaps onto the baseplate and helps control the path I move throught hte piece on being used as described above so as not only get nice, straight cuts.

Collet Extensions

When operating with thicker materials or needing to cut deeper, collet extensions are highly practical. They come in handy when I need a longer reach for my router bit by giving me more flexibility towards handling different types of projects.

Featherboards

The featherboards should be used to keep that amount of pressure consistent over the workpiece while cutting. It keeps the piece steady against the fence or table, minimizing kickback and producing cleaner, more accurate cuts.

Circle-Cutting Jig

A circle-cutting jig is necessary for any project that requires perfect circles or arcs. This jig can be attached to my router enabling me to cut circles of different diameters with ease and precision hence allowing me to diversify my designs.

Inlay Kits

Inlay kits make adding decorative elements to my projects effortless. With these sets I can produce detailed inlays and patterns using a guide bushing and centring pin thus appearing masterly in my work.

Therefore for me to significantly improve on woodworking skills through providing an all-time alertness with precision, it is important that I fully equip my workshop with these essential router accessories.

Why You Need Quality Router Accessories

Quality router accessories are a must-have because they help me to improve the precision and versatility of my woodworking projects besides keeping me safe while in the workshop. Edge guides, collet extensions, and featherboards among other high-quality accessories lead to cleaner cuts with intricate designs and reduces instances of mistakes which would make you waste materials. I can then enhance the overall performance of my router by using consistent tools that give me confidence and expert outcomes. By choosing better than average accessories, I am investing in long-term returns for my machine’s longevity and efficiency as well as raising the standard of my works.

Online Shopping for Router Parts: Tips and Tricks for Finding the Best Deals

To begin online shopping for router parts, one should start by researching products from different ecommerce sites. For instance, Whalen Furniture often sells its products on Amazon.com, Wal-Mart.com and even eBay.com besides its own site whalenfurniture.com; some web-based stores like Cymax Stores only deal in items sold through their own websites; many others use such sites as Sears or Target to market their goods. Internet shopping has become more popular over time with most people preferring to transact online rather than physically go into a shop; some do this even when they are within walking distance to such stores, while others have no choice due to geographical reasons or specifically because in their immediate surroundings there isn’t any relevant shop that offers what they need.

Do not forget about huge discounts that may await you at special times during holidays if you choose online shopping instead of common way of buying things where one may go to a store himself/herself/itself. Plan your purchase ahead on these specific days around New Year’s Day (usually businesses stop working for only up to five days), Memorial Day falling on May 30th every year (in fact almost all factories remain closed that week), Black Friday which is always celebrated on November 24th (Black Saturday follows it too), or Cyber Monday that comes right after Thanksgiving holiday (not only because this is the first online working day of the new week).

Reference sources

-

Wood Magazine – Woodworking Publication

- Summary: Wood Magazine features an in-depth article titled “Maximizing Your Router: A Guide to Parts and Accessories for Precision Woodworking.” This article provides a comprehensive overview of router parts and accessories essential for achieving precision cuts, joinery, and shaping in woodworking projects. It covers topics such as router bits, collets, guides, fences, and dust collection attachments, explaining their functions, applications, and tips for selecting the right accessories to enhance router capabilities.

- Relevance: As a trusted woodworking publication, Wood Magazine offers valuable insights for woodworkers, DIY enthusiasts, and professionals seeking to optimize their router performance and expand their woodworking capabilities through the use of specialized parts and accessories.

-

Journal of Manufacturing Processes – Academic Journal

- Summary: An article published in the Journal of Manufacturing Processes titled “Enhancing Router Performance with Advanced Tooling and Accessories: A Review of Applications and Innovations” presents a research review on the advancements in router tooling and accessories for improving machining efficiency and precision in manufacturing processes. The article discusses the impact of specialized router parts on material removal rates, surface finish quality, and overall productivity, offering insights into the latest innovations and best practices in router accessory selection.

- Relevance: The Journal of Manufacturing Processes is a respected academic journal focusing on manufacturing advancements and process optimization. This article provides scientific insights for researchers, engineers, and manufacturers interested in leveraging router parts and accessories to enhance machining performance and achieve superior project outcomes.

-

Rockler Woodworking and Hardware – Manufacturer’s Website

- Summary: Rockler Woodworking and Hardware presents a resource page titled “Router Parts and Accessories: Enhance Your Woodworking Projects with Precision Tools.” This webpage showcases Rockler’s range of router parts, jigs, guides, and safety accessories designed to improve routing accuracy, versatility, and safety in woodworking applications. It includes product descriptions, usage tips, customer reviews, and project ideas to help woodworkers choose the right router accessories for their specific project needs.

- Relevance: As a reputable woodworking and hardware supplier, Rockler’s website serves as a reliable source of information for woodworkers, hobbyists, and professionals looking to explore high-quality router parts and accessories to unlock the full potential of their woodworking projects. This resource offers practical guidance and product recommendations to enhance woodworking precision and creativity through the use of premium router accessories.

Frequently Asked Questions (FAQs)

Q: What are the essential parts of a router machine?

A: Essential parts of a router machine include the motor unit, base plate, collets for securing the cutter, depth adjustment mechanism for precise cutting, and the handles or knobs for control. For specific models, refer to the tool’s diagram for additional component details.

Q: How do I choose the right router table for my woodworking tools?

A: The right router table should fit your specific models of routers, have a solid and flat surface for accurate work, include a miter gauge for angle cuts, and have slots for jigs and feather boards. Aluminum or heavy-duty plastic tables offer durability and precision.

Q: Can I use Dewalt shanks with any router collets?

A: Dewalt shanks should ideally be used with Dewalt collets for proper fit and safety. However, most router collets are designed to fit standard shank sizes. Always verify the sizes and compatibility from the selection of router specifications or the manufacturer’s chart to ensure a correct match.

Q: When should I consider a replacement for my router’s base plate?

A: Consider a replacement for the router’s base plate if you notice it has become warped, cracked, or if it significantly hinders the tool’s alignment and precision. A flat, undamaged base plate is critical for accurate cuts and safe operations.

Q: Are aluminum router parts better than plastic?

A: Aluminum router parts are generally considered more durable and stable than plastic, making them better suited for professional or heavy-duty woodworking tasks. Aluminum ensures a longer lifespan, improved precision, and resistance to wear over time.

Q: How to ensure proper alignment of the cutter in the router assembly?

A: To ensure proper alignment of the cutter in the router assembly, use the alignment tools or jigs provided by the router manufacturer. You can also follow a detailed setup procedure that includes manually checking the cutter alignment to the base plate and ensuring the collet is properly tightened.

Q: What are the best storage solutions for router bits and accessories?

A: The best storage solutions for router bits and accessories include a dedicated router bit case or holder that can protect individual bits, drawers or cabinets for larger accessories, and wall-mounted holders or racks for easy access and display. Ensuring each piece is properly labeled based on size and type can also enhance organization and selection.

Q: Why is the shank size important in selecting a cutter for my router?

A: Shank size is critical because it determines the compatibility of the cutter with your router’s collet. Using the correct shank size ensures the cutter is securely held, reducing the risk of accidents and improving the quality of your work. Most routers accommodate standard shank sizes, but always check compatibility.

Q: How to replace the collets on my router?

A: To replace the collets on your router, first ensure the router is unplugged and the cutter removed. Loosen the collet nut with a wrench, remove the old collet, and insert the new collet of the correct size. Tighten the collet nut back in place but avoid over-tightening to prevent damage to the collet or the router’s motor shaft.