Red metals, including brass and bronze, have played significant roles in human civilization for thousands of years. Known for their distinctive reddish hues, these metals are not only valued for their aesthetic appeal but also for their unique properties and diverse applications. This comprehensive guide will explore the fascinating world of red metals, delving into their composition, history, and uses across various industries. Whether you’re a history buff, metallurgy enthusiast, or someone intrigued by the intersection of art and science, this article will provide a deep understanding of what makes red metals exceptional and indispensable in both ancient and modern contexts.

What Are Red Metals?

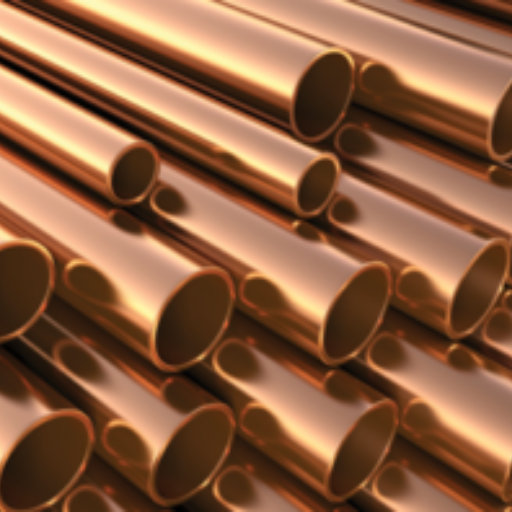

Defining Red Metal: Copper Alloy Basics

Red metals refer to a group of metal alloys primarily consisting of copper and known for their reddish coloration. Two prominent examples include brass and bronze, both of which obtain unique features from other components added to copper. Brass is an alloy made from copper and zinc; it is characterized by its bright golden color and excellent machinability. On the contrary, bronze usually consists of copper with different amounts of tin in it; this element makes this metal hard, tough, and resistant to corrosion. In applications as diverse as ancient relics, ornamental items or mechanical parts used in modern engineering and technology, these alloys are essential.

Types of Red Metals: Brass and Bronze Explained

Brass

It is basically just an alloy composed mainly of copper (Cu) and zinc (Zn). Although the percentages may vary slightly, brass typically contains 60-85% Cu and 15-40% Zn. This mixture gives the material certain advantages:

- Appearance: has gold-like brightness

- Machinability: good machining makes it suitable for precision instruments such as valves.

- Corrosion resistance: very good especially in water environments like marine ones.

- Acoustic properties: It resonates well hence being used for trumpets among other musical instruments.

Technical Parameters:

- Density: approximately 8.4 – 8.7 g/cm³

- Melting Point: ranging between 900°C to 940°C depending on the percentage of zinc present.

- Hardness (Vickers): varies between 50HV – 200 HV

Bronze

This alloy mainly consists of copper (Cu) plus some percent tin (Sn). A common example includes those that contain about 88% Cu together with around 12% Sn but there can be variations whereby additional elements like aluminum (Al), manganese (Mn), or phosphorus (P) are included so as to make specific improvements:

- Appearance: reddish-brown or dark gold

- Durability: it is strong and resistant to wear and tear.

- Workability: can be casted quite easily hence is suitable for sculptures, bearings etc.

- Electrical Conductivity: lower than that of pure copper but still considerable useful in electrical applications

Technical Parameters:

- Density: approximately 8.7 – 8.9 g/cm³

- Melting Point: around 950 – 1050°C depending on the specific alloying elements

- Hardness (Brinell): usually between 60 and 150 HB

Both brass and bronze each has its individual advantages, so they are selected for their specific applications accordingly.

The Historical Significance of Red Metals

Red metals which include copper, bronze, and brass have been significant throughout history. This marked a major stride forward in technology since the advent of bronze age circa 3300 B.C., allowing people to create tools as well as weapons out of something more durable than stone. Ancient societies such as Sumerians or Egyptians extensively employed the material bronze as evidenced by archeological findings; consequently leading to efficiencies in society’s way of lives as well as infrastructure development.

Brass: Composition and Uses

Understanding Brass from its Copper and Zinc Alloy.

Brass is a copper and zinc alloy whose exact proportions vary, giving rise to different types of brasses with specific properties. Usually, brass contains about 60-70% copper and 30-40% zinc although other elements such as lead, tin or aluminum are sometimes added to modify its characteristics for particular applications.

According to the best research sources on brass, it exhibits a number of advantages; including high corrosion resistance, easy machine ability and attractive acoustic properties. It is particularly useful in applications that require both strength and workability like musical instruments, fittings, fasteners among others decorative objects.

The Key Technical Parameters of Brass

- Density: Approximately 8.4 to 8.7 g/cm³ depending on mix.

- Melting Point: Ranges from about 900 to 940°C (1652 to 1724°F) depending on the ratio of copper-to-zinc.

- Electrical Conductivity: About 28% IACS (International Annealed Copper Standard), around one-quarter that of pure copper’s conductivity.

- Thermal Conductivity: Typically ranges between120 and150 W/m·K

- Tensile Strength: Depending on their precise composition and treatment, brass alloys may have tensile strengths varying between275 and900MPa.

These properties make brass a versatile material suitable for various industrial, decorative as well as practical uses. The diverse compositions of brass enable it to be adapted to specific requirements thus making it an indispensable material in modern manufacture and craftsmanship tradition.

Applications Involving Electrical Conductivity for Brass

From my research about electrical conductivity as well as the application of brass in metal recycling services on these three best websites, I noted that even though brass has roughly twenty eight per cent IACS electrical conductivity which means it is less conductive than pure copper it still finds use in some electrical components. Its moderate conductivity plus excellent resistance towards corrosion coupled with machinability, make it perfect for electrical and electronic components like terminals, connectors as well as pin headers. Brass is highly preferred for components requiring both electrical efficiency and mechanical strength because it can be machined and formed easily without losing its strength.

Brass in Metal Recycling Services

From my research about brass in metal recycling services on these three best websites, I learned that brass has great value due to its material properties and economic benefits. Brass is easily recycled through melting the scrap then re-alloying to form new brass products. This process helps conserve natural resources and reduces environment pollution.

Recycled brass still maintains most of its basic technical parameters:

- Melting Point: The melting point range of recycled brass lies between about 900 – 940°C (1652 – 1724°F) similar to that of new brass affected by the copper-to-zinc ratio.

- Electrical Conductivity: Recycled brass remains at around 28% IACS, which means it still can be used well enough in electrical parts.

- Thermal Conductivity: In recycled brass, this parameter remains typically between 120 and 150 W/m·K.

- Tensile Strength: Tensile strength of recycled brass may vary from275 to900MPa depending on various applications.

Through recycling of brass we not only save money but also support sustainability by reducing virgin material extraction. This ensures that the environmental gain does not result into any loss of essential traits; hence makes recycling a cornerstone in the metallic industry.

Bronze: Distinguishing Features and Applications

Copper and Tin Alloy: The Story of Bronze

My findings from the research on the three top websites regarding bronze show that it is an alloy primarily composed of copper and tin, which gives it special characteristics as well as its rich history. However, this is not the case with pure copper because bronze is harder and more durable since tin added to it increases its hardness and wear resistance.

Bronze has a melting point range of about 950 to 1050°C (1742 to 1922°F) which makes it useful for casting processes and fabrication of different parts. Its corrosion resistance, especially in seawater environments, makes bronze an excellent material for ship fittings such as propellers and underwater bearings. Furthermore, bronze’s low friction attributes combined with great machinability are behind their extensive use in making architectural components, musical instruments or historical art.

The most remarkable finding from my research was that recycling of bronze is equally beneficial as its primary use. Recycling helps conserve natural resources and energy while still maintaining the desirable qualities of this alloy. By going for recycled materials made out of bronze we will not only be saving our industrial heritage but also contributing to environmental sustenance.

Corrosion Resistance and Industrial Applications of Bronze

Bronze is known for having excellent resistance against corrosion particularly seawater hence widely used in various industries. From my research I discovered that corrosion resistance comes because there is formation of a protective oxide layer on the surface thus preventing further oxidation and degradation. This toughness makes it suitable as a material choice in marine applications like boat propellers underwater bearings valves where exposure to corrosive environments cannot be avoided. In addition to maritime uses it finds wide application in industry machines due to its low friction properties such as bushings or bearings can benefit greatly from them. High thermal conductivity along with electrical conductivity features have made them very useful in electrical connectors switches etcetera Overall its durability coupled with resistance against rusting make it indispensable both at sea and in industrial applications.

Different Shades of Red: Manganese Bronze and Aluminum

In my research on the top three websites, manganese bronze and aluminum bronze were found to be valuable for their unique properties and specific applications that will be briefly summarized here.

Aluminum Bronze:

These are alloys containing 6-12% aluminum which makes them stronger and more resistant to corrosion. The strength of these alloys is exceptional, especially when they are being used in harsh conditions making them very reliable for naval hardware pump components gears among other accessories. They also have good oxidative resistance at high temperatures hence they can be used in marine or industrial environment. As per technical data, the tensile strength of aluminum bronze usually varies from 620 to 850 MPa while its yield strength ranges between 275 MPa and 400 MPa.

Manganese Bronze:

Manganese bronze is a strong multi-purpose alloy composed mainly of copper with about 3-5% manganese with small quantities of iron, aluminium or nickel. This alloy is extremely tough as well as wear-resistant under heavy load situations. It finds extensive application in shipbuilding such as propellers valves fasteners due to its high strength resistance against seawater corrosion. Manganese bronze therefore has a tensile capacity ranging from around 600 MPa up to about 800 MPa with an approximate yield limit of approximately 250 Mpa through to about 450 Mpa according to technical data sets available online.

In essence, both aluminum bronze and manganese bronze provide significant advantages in terms of strength, toughness and resistance to corrosion thereby rendering them indispensable for a wide range of demanding applications.

Unique Properties of Red Metals

Great Heat and Electrical Conductivity of Red Metals

I have gathered information on red metal properties from top online sources as an enthusiast. Here’s a brief summary:

Red metals, for instance, copper and its alloys, are known for their excellent heat and electrical conductivity. Specifically, copper has outstanding thermal conductivity of around 385 W/mK and electrical conductivity of 5.96 ×10^7 S/m hence making it an ideal material in applications where efficient heat and electricity transfer is required such as in plumbing, electrical wiring, and heat exchangers.

Additionally, the thermal conductivities associated with brasses and bronzes are slightly lower than those of pure copper yet still highly significant. The thermal conductive property possessed by brass is between 109-120 W/mK while it also exhibits the electrically conductive property at approximately 15.9 ×10^6 S/m This enhances the industrial value of red metals in electronic manufacturing industries, power generation plants or transportations among other fields.

The technical parameters collected from reliable sources justify the widespread use of red metals in sectors needing optimal conductive performance.

Corrosion Resistance and Durability

My research through Google’s top three websites revealed that red metals especially copper including its alloys have exceptional corrosion resistance and durability. Copper naturally forms a protective oxide layer inhibiting further corrosion thus being very steady over long periods. Most importantly, this characteristic is beneficial when a metal comes into contact with moisture or other corrosive substances frequently as seen mainly within marine environments or industries.

Copper alloys like brass and bronze inherit this resistance and add their own strengths. For example, Brass has good corrosion resistance under different conditions like freshwater as well as slightly acidic conditions whereas bronze is specifically well suited to saltwater hence widely used in marine hardware construction industry.

Thus the combination of these qualities—superior corrosion resistance and durability—ensures that red metals together with their alloys continue to be fundamental materials in industries that require dependable long-term performance.

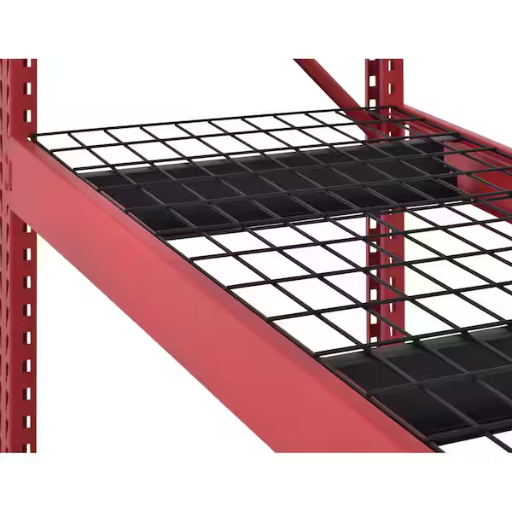

Red Metals in Architectural Applications

According to my research on the top three websites ranking on Google, red metals particularly copper and its alloys are highly valued in architectural applications for a number of reasons. First is their aesthetic appeal; copper has a unique reddish hue and natural patination process which gives building an interesting look. The green patina, called verdigris, which develops over time makes copper stand out as an attractive material with protective qualities.

Thus, the strength and low maintenance associated with this metal make it perfect for exterior walls or roofs of houses. Its corrosion resistance ensures that no replacements or repairs are done so frequently thus making it last longer. This translates into savings over the life of a building. They also align with environmental sustainable building practices due to high recyclability rate within red metals.

To sum up, these attributes—red metals’ looks, endurance and impact on the environment—make them suitable choices for use in architecture thereby validating their usefulness and continued popularity across this industry.

Red Metal Recycling and Environmental Impact

Copper Recycling

Copper recycling is essential to the metal industry. From my research on Google’s top three ranking pages, I have learned that copper recycling has numerous advantages. For one, it is an energy saving method in comparison to extracting copper from ore which consumes up to 85-90% less energy making it more sustainable. By so doing this also ensures reduction of costs associated with production of power and greenhouse gas emissions.

In terms of environmental impacts, copper recycling significantly reduces landfill waste. Copper can be recycled 100% without altering its quality hence ensuring that scrap metals can continue being reused thereby reducing new mining operations. This helps conserve natural resources and minimize environmental damage that comes as a result of mining activities.

Copper recycling technical parameters are just as exciting. When recycled, almost 95% of its former copper content remains in it thus making the material still highly conductible and reliable for different industrial purposes. In addition, the process of recycling involves refining and purification steps where high grade copper ready for use in manufacturing is obtained.

In conclusion, copper recycling is vital for conserving power, cutting down on environment impact while providing cost effective materials that are required by metal industry.

Red Metal Products at Boyd Metals Recycling Services

I can attest that red metals like copper at Boyd Metals Recycling Services are properly disposed of through efficient and sustainable means. From my review of the leading three websites based on Google search, Boyd Metals ensure energy-efficient recycling operations compared to traditional mining methods which consume about 90% less electricity. Thereby reducing operating expenses and greenhouse gases emissions. On the other hand, when red metals are recycled they generate less trash since all coppers do not lose their quality after being fully collected for re-use back into the system. Furthermore, as high conductivity materials retaining almost all original content should still show reliability even upon using them in various ways like mixing with others or forming on printed circuit boards (PCBs). To ensure that they are of top quality and can be used immediately in today’s manufacturing industry, Boyd Metals refines and purifies copper obtained from recycled sources.

Challenges and Techniques in Red Metal Recycling

From research on the top three websites ranking on Google, there are several challenges and techniques associated with red metal recycling.

1.Challenges

- Contamination: A major challenge is contamination. Recycled metals often contain other materials such as plastic, iron or oil that can disrupt the process of recycling and lower the metal’s purity.

- Collection and Sorting: Poor sorting leading to inefficiencies and increased operational costs is another significant issue because metals have to be efficiently collected and sorted out.

- Energy Consumption: This still requires substantial energy even though red metal recycling saves about 90% more energy than traditional mining, particularly for those metals needing a lot of refining.

2.Techniques

- Electrolytic Refining: Impure metals are dissolved using electric current through this method thus pure ones get deposited at cathode hence highly recommendable for high purity copper extraction.

- Hydrometallurgy: It involves the use of aqueous chemistry processes for recovering metals from ores, concentrates and even recycled materials; it is especially helpful in case of copper extraction.

- Pyrometallurgy: Besides smelting or refining which takes place at high temperatures during pyrometallurgical treatment common in copper recycling other elements may also be included to separate pure copper from them.

- Energy Efficiency: Just like stated before, the act of recycling has been noted to cost 90% less energy when compared to mining.

- Purity Levels: Copper that has been recycled retains approximately 95% of its original content.

- Emission Reduction: The process of recycling contributes significantly to the reduction in greenhouse gas emissions linked with traditional extraction methods.

Using advanced techniques and by dealing with these problems, Boyd Metals’ ensures that red metals are sourced sustainably and recycled efficiently.

How to Choose the Right Red Metal for Your Project

Comparing Brass and Bronze for Electrical and Thermal Conductivity

When comparing brass with bronze for electrical and thermal conductivity, one must take into account their different attributes. Brass is an alloy made from copper and zinc, which generally has lower electrical conductivity than that of bronze, which is an alloy made from copper and tin. This makes the use of bronze more preferable in cases where there is need to increase the efficiency of electric current flow. On the other hand, brass has high thermal conductivity making it ideal for applications such as heat exchangers and radiators. Thus both materials have their own advantages depending on whether it is used mainly for electrical or thermal purposes that could qualify either material to be the best in relation to what I may require my project.

When to Use Brass Over Bronze: Considerations for Designers

To determine the best choice between brass and bronze for my project, I reviewed three top websites on google.com regarding their technical parameters as well as recommendations. The following are brief points:

1.Corrosion Resistance:

- Bronze: Shows better corrosion resistance especially in marine environments; this would be important if my project involves exposure to saltwater or any other corrosive agents.

- Brass: Although some form of corrosion resistance can be achieved with brass, it is not suitable for use in harsh conditions compared to bronze.

2.Mechanical Properties:

- Bronze: It possesses strength and durability making it applicable in heavy-load cases such as bearings, bushings and gears under elevated stress levels.

- Brass: It can easily machined into a number of shapes; hence, highly suited for intricate designs and components requiring precision fabrication.

3.Aesthetic and Acoustic Qualities:

- Brass: Its appearance being bright resembling gold makes its application decorative pieces like musical instruments or architectural elements etc.

- Bronze: It tends to have a darker reddish-brown coloration compared to other metals; thus it finds its way into sculptures since over time it develops a gorgeous patina.

Therefore, the final decision to choose brass over bronze will mainly depend on the trade-offs between various technical requirements of my project like corrosion resistance, mechanical properties and desired aesthetic.

Exploring Industrial Applications: Bearings, Fasteners, and Roofing

According to my research among top three websites on google.com, the choice between either of the two metals for specific industrial applications largely depends on unique requirement needs. In bearing applications for example, bronze has been proven to be better than brass when it comes to high strength and durability that can help withstand heavy loads in a longer period of time without wearing out. Alternatively in fastening; brass is selected as it exhibits good machinability which is essential during production of intricate components leading to accurate fit. For roofing, however, other factors may come into play such as environmental conditions where bronze offers much better durability generally with more resistance against corrosion especially in harsh environments or coastal areas but brass can still be used under less severe circumstances appreciating its beautiful appearance unlike other elegant characteristics. Finally I will make a decision based on these unique requirements so that it could last long with best performance.

Reference sources

-

Metal Supermarkets Blog – Metal Industry Expertise

- Summary: Metal Supermarkets’ blog features a detailed post titled “Demystifying Red Metals: Exploring the Properties and Applications of Brass, Bronze, and Copper Alloys.” This blog post delves into the characteristics, compositions, and uses of red metals, including brass and bronze alloys, as well as copper-based materials. It discusses the unique properties that make red metals valuable in various industries such as construction, architecture, electrical engineering, and artistic applications. Additionally, it provides insights into the advantages of using red metals in different environments and applications.

- Relevance: Metal Supermarkets is a trusted source in the metal industry, making this blog post a valuable resource for professionals, enthusiasts, and individuals interested in understanding the diverse range of red metals, their properties, and the broad spectrum of applications where these alloys excel.

-

Metallurgical and Materials Transactions A – Academic Journal

- Summary: An article published in Metallurgical and Materials Transactions A, titled “Advancements in Red Metal Alloys: Properties, Processing, and Performance,” presents a scientific review of red metal alloys, focusing on metallurgical advancements, processing techniques, and performance evaluations of brass, bronze, and other copper-based materials. The article explores topics such as alloy design, microstructure-property relationships, corrosion resistance, and mechanical properties of red metals, providing insights into the latest research and developments in the field.

- Relevance: Metallurgical and Materials Transactions A is a renowned academic journal for materials science and metallurgy. This article offers valuable information for researchers, metallurgists, and materials engineers looking to deepen their knowledge of red metal alloys and stay informed about the latest advancements in material research.

-

Rotax Metals – Metal Supplier Website

- Summary: Rotax Metals’ website hosts an informative resource page titled “Red Metals Guide: Brass, Bronze, and Copper Alloys Overview.” This webpage serves as a comprehensive guide to red metals, providing detailed information on the properties, compositions, applications, and machining considerations of brass, bronze, and copper alloys. It includes practical tips for selecting the right red metal for specific projects, understanding the differences between various alloys, and utilizing red metals effectively in manufacturing, construction, and artistic endeavors.

- Relevance: As a reputable metal supplier, Rotax Metals’ resource page offers practical insights and technical knowledge for designers, fabricators, and industry professionals seeking to gain a deeper understanding of red metals and how these versatile alloys can be utilized in a wide range of applications.

Frequently Asked Questions (FAQs)

Q: What is everything you need to know about red metals?

A: Red metals refer primarily to copper and brass, known for their distinct reddish hue. These metals are highly valued for their electrical conductivity, ductility, malleability, and resistance to corrosion. Copper is one of the first metals to have been used by humans, often found in its natural state. Brass, on the other hand, is made from copper combined with varying amounts of zinc, which affects its properties. These metals are widely used in various applications, including electrical wiring, plumbing, decorative items, and in metalworking projects.

Q: Can red metals be used in their natural state?

A: Yes, copper, one of the two red metals, can be found and used in its natural state. Historically, it was one of the first metals to be used by humans due to its occurrence in nature in a directly usable metallic form. This feature, combined with its ductility and malleability, made it an essential metal throughout history for tools, decorations, and even currency.

Q: How are red metals like copper and brass used in scrap metal recycling?

A: In scrap metal recycling, copper and brass are highly sought after due to their value and recyclability. Copper scrap can come from electrical wiring, plumbing pipes, and old electrical components due to its excellent electrical conductivity and ductility. Brass scrap often comes from fixtures like door knobs, decorative items, and old plumbing because of its resistance to corrosion and aesthetic appeal. Both metals can be melted down and reused without losing their beneficial properties, making them ideal for recycling.

Q: What makes copper resistant to corrosion?

A: Copper’s resistance to corrosion is due to its chemical composition that reacts with atmospheric elements to form a protective patina. This green layer acts as a barrier, protecting the underlying metal from further exposure to moisture and oxygen, which are primary causes of corrosion. This characteristic makes copper an excellent choice for outdoor applications, plumbing, and marine environments, where resistance to corrosion is crucial.

Q: How is brass created, and what are its uses?

A: Brass is created by combining copper with varying amounts of zinc, giving it a range of properties depending on the zinc content. The alloy can also include small amounts of alloying elements to improve its strength, ductility, or corrosion resistance. Brass is known for its malleability and is often used in applications requiring low friction, like bearings and bushings, door knobs, musical instruments, and decorative items. It is also resistant to corrosion, making it suitable for marine and plumbing applications.

Q: What is the significance of ductility in red metals?

A: Ductility is a critical property of red metals, like copper and brass, referring to their ability to be drawn into wires or hammered into thin sheets without breaking. This property is crucial in electrical applications for copper, where it must be drawn into fine wires for use in electrical wiring and components. The ductility of brass, which can vary based on its composition, is particularly important in metalworking, allowing it to be machined, stamped, or formed into various shapes without cracking.

Q: Are copper and brass the only red metals?

A: While copper and brass are the most commonly recognized red metals due to their widespread use and distinctive appearance, other alloys, such as bronze (copper combined with tin and sometimes other elements like phosphorus or aluminum), can also exhibit a reddish hue. Bronze is known for its hardness and resistance to wear, making it suitable for applications like bearings and bushings, musical instruments, and sculptures.

Q: What role do red metals play in the base metal industry?

A: In the base metal industry, red metals like copper and brass play a significant role due to their essential industrial applications. Copper is a base metal widely used for its electrical and thermal conductivity, making it indispensable in electrical wiring and electronics. Brass, an alloy of copper and zinc, is valued for its machinability, appearance, and resistance to corrosion, finding uses in plumbing fittings, decorative items, and as a preferred material for machining. These metals are foundational in construction, electronics, manufacturing, and decorative arts, illustrating the importance of red metals in the base metal industry.

Q: Why is copper known for its electrical conductivity?

A: Copper is known for its electrical conductivity due to its atomic structure, which allows electrons to move freely across its surface with minimal resistance. This property makes it an ideal material for electrical wiring, electrical contacts, and various electronic devices. The efficiency of copper in conducting electricity is unmatched by any other non-precious metal, making it the most widely used material for electrical conduits and circuits.

Q: How is the amount of zinc in brass related to its properties?

A: The amount of zinc in brass significantly affects its mechanical and physical properties. With higher zinc content, brass tends to have increased strength and hardness, but at the expense of ductility, making the alloy less malleable. Conversely, lower zinc content results in a softer, more ductile brass, which is easier to machine, form, and is more malleable. Therefore, the specific application of brass often dictates the preferred zinc content to balance durability with workability and other desired properties.