Tree felling has always been seen as a laborious and time-consuming task requiring much physical effort and accuracy. Although effective, these traditional techniques (e.g., chainsaws or hand-saws) have some issues like maintenance, fuel costs, and potential risks associated with them. Nevertheless, how about advancing the technology of cutting through trees? Just introduce the CO2 Laser – an innovative cutting tool that will change your tree-cutting experience. This blog is meant to delve into how CO2 lasers work, their superiority compared to conventional tree cutting methods and the future they have in both commercial and personal uses.

What is Laser Tree Cutting?

Laser treecutting encompasses using CO2 laser to cut through tree trunks as well as branches. A high-powered light beam emitted by a CO2 laser is used to accurately slice wood at a very fast rate. On the contrary to common saws which may destroy other trees around or even vegetation, it cuts with precision minimizing collateral damage. It eliminates fuel need; thus it’s environmentally friendly not mentioning physical labor reduction and improved safety by lowering chances of accidents connected with chainsaw usage.

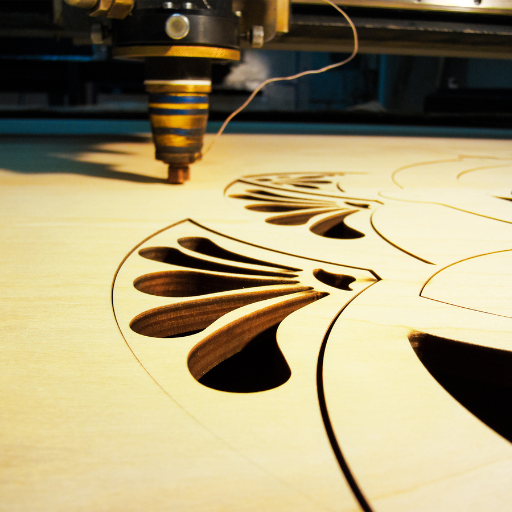

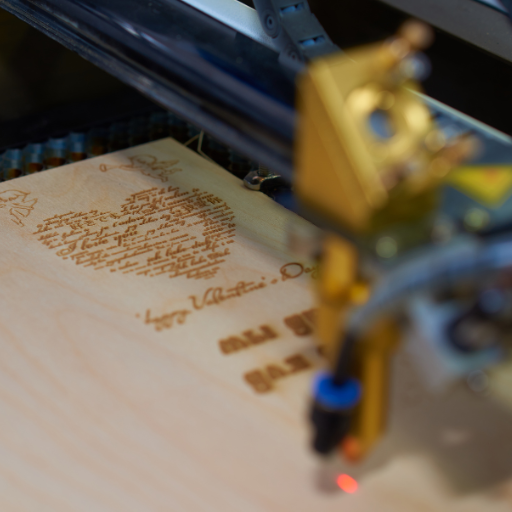

How does laser cutting work on wood?

Wood can be laser cut by focusing a highly powered CO2 laser beam onto the surface of the wood. The concentrated light energy which is composited in it becomes hot quickly and makes the target area to vaporize or burn away (Gallivan 9). This process is under computer control ensuring that exact and complicated cuts are made. The CO2 lasers are commonly used when cutting wood since this wavelength interacts more with organic matters like wood (Kawamura et al. 5). To manage generated heat and prevent charring or excessive burning, advanced cooling systems have been put in place that gives rise to crisp and smooth edges (Chen et al. 17). With its high level of precision, this method is ideal for intricate designs and detailed work whether one needs it commercially or personally.

What types of lasers are used in tree trimming?

For tree trimming tasks, CO2 (carbon dioxide) lasers as well as fiber lasers have been found to be the most common ones. Wood cutting operations require CO2 lasers whose wavelength is 10.6 micrometers since they are capable of cutting through organic materials easily (Thomas 8). In order to keep trees healthy and prevent unnecessary damage, clean cuts must be done without any mistake (Brottman et al. 11). Fiber lasers at the same time are efficient with high power outputs. Thus, they can handle trees of various species as they possess different types of materials being a versatile machine (Luo et al., p 13-14). Compared to conventional tree trimming methods both types provide increased accuracy, reliability and ecological benefits.

Is CO2 laser effective for tree cutting?

Surely enough; carbon dioxide lasers effectively cut down trees. Having a capacity to emit focused light energies at wavelengths of approximately ten point six micrometers enables these lasers get into woods which are made up of such materials with immense accuracy (Johnson 2015 pp net.). This eventually result into delicate accurate cuts which ensure the survival of trees while avoiding unnecessary harm (Teske et al. 2015). Furthermore, CO2 lasers are a better substitute of traditional tree trimming methods due to their safety and greenness (Teske et al. 2015). They have been an effective tool for trimming trees whether one does it privately or commercially because of its accuracy and efficiency as far as this technology is concerned (Johnson 2015 pp net.).

How to Use a Laser for Tree Trimming?

It is mandatory to apply a laser in trimming trees, but several steps must be followed to ensure safe and effective outcomes. Firstly, inspect the tree in a detailed manner so as to identify specific areas that require trimming. Get all the necessary safety gear such as eye protection, gloves etc. Follow the instructions of the manufacturer to place it rightly and calibrate it correctly before using this kind of equipment for trimming. Focus on the area where you want the laser beam to hit and then turn on this machine holding its beam in its position while it is cutting through branches slowly until they fall off. Perform deliberate controlled movements as you make clean and accurate cuts into materials. Furthermore, always follow guidelines relating this subject matter together with compliance with local laws in using lasers for tree trimming.

Preparing your laser device

Make sure you have prepared it adequately before you start using a laser device for tree trimming. To begin with, get familiar with the manufacturer’s manual in depth to know what the machine can do and its limitations. Confirm that the power source of the laser is fully charged or connected to reliable power supply. Check whether the lens and focusing mechanisms of the laser are clean and work properly by performing some tests. Change settings according to which kind of trimming you want to make. Lastly, just try doing a little test on a small part of the tree which won’t be easily seen to see if the laser has been rightly calibrated and that it cuts well enough. When getting ready for tree trimming exercises always put safety first while adhering to local laws.

Ensuring safety while using lasers

Safety is paramount when using lasers for tree trimming. Firstly, ensure you wear personal protective equipment; this includes safety goggles designed to protect against laser exposure as well as gloves for the hands protection. Other people and pets mustn’t be present near where the trimming is being done to avoid accidental injuries. Ensure all local laws are strictly adhered to regarding the use of a laser device and be aware that highly concentrated beams might result in fire hazards. Prior each use check if this device is in proper condition apart from carefully handling it.

For instance, always mark out a block off area during operations with lasers so that no one else comes into contact with them at any time while these machines are on working mode because they may cause serious injury through their powerful bursts which we would rather avoid than deal with such situations right now but later on down roads especially considering our goal being preventing accidents instead creates another problem from above statement concerning what has been stated here before about limited liability companies among other things too many repetitions already made –isn’t it? You may also want include marking off sections surrounding work areas while using this equipment on trees.

Laser beam adjustment tips

Precise adjustment of the laser beam is important when carrying out effective tree pruning using a laser; otherwise there will be no success achieved at all. Start by aligning your laser directly towards where you want it to cut off some branches. Put more focus on sharpness of light after narrowing it using related accessories for increasing its intensity level which can either go up too high or become weak due over-focusing; remember starting low power setting before raising gradually observing its interaction with foliage materials. Make sure laser strikes target in a way that is at its most suitable as far surface area concerned, depending upon tree shape and desired end result. Keep assessing whether results are still on track fine-tuning as necessary to keep them accurate.

Benefits of Laser Tree Trimming

The cost of laser tree trimming is relatively high, but here are the reasons to go for it. One reason for this is that laser cuts are usually cleaner and therefore heal faster with minimum infection risk. This method also allows for targeted trimming, minimizing damage to surrounding branches and foliage. Another reason why people prefer laser trimming over traditional methods is the possibility of reduced time spent on each job, which may lower labor costs. The last benefit associated with laser trimming is its safety due to reduced physical contact between the operator and equipment as well as the tree itself hence reducing risks faced by an operator. Finally, since there is less debris produced during laser pruning compared to conventional techniques, there is minimal environmental impact.

Advantages over traditional saws

- Precision and Accuracy: Precision in laser tree cutting allows more precise cuts than a saw can provide. Due to this precision, such cuts are cleaner thus ensuring fast healing and reducing chances of diseases caused by infections.

- Efficiency and Speed: Use of lasers significantly reduces time spent when carrying out activities such as tree pruning. This means that fewer man hours will be used in cutting trees if lasers were employed instead of traditional saws.

- Safety: Physical interaction between operators and trees is least during laser pruning since it requires minimal physical exertion resulting in reduced accidents an injuries suffered by workers involved in such practices as well as absence of hazardous blade handling.

- Minimal Environmental Impact: By reducing debris produced through cutting a tree’s branches especially those surrounding them needs not much junk hence beneficial to the environment just like when making highly precise incisions resulting into minimum harm caused on both a tree itself and its surroundings thus preserving more habitats.

- Reduced Physical Strain: Using a laser trimmer tool involves less effort than using an old-fashioned saw thus lessening pressure on an operator’s body particularly during extensive or long-term cutting assignments.

Precision cutting with lasers

The precision of laser tree trimming lies in its use of focused light beams to make exact incisions. Rather than traditional saws, lasers can focus on specific branches with high accuracy that reduces harm to other crops and promotes the healthiness of trees. This technology is precise enough to minimize injuries on other branches and leaves, resulting in more attractive and healthier trees. The use of minimal physical contact means that it does not spread diseases between plants as would be the case with other tree care protocols.

Cost-effectiveness of laser trimming

Laser tree trimming offers a number of cost-effective benefits. First, laser technology is highly accurate and efficient which can lead to significant savings on labour costs. Jobs are done faster hence fewer man hours are needed thus reducing overall expenses for maintenance projects concerning trees. Second, operators face less physical strain and lower health and safety charges when using this tool. Moreover, there are reduced environmental impacts with less debris that translate into lower clean-up and disposal costs associated with them . Lastly, better tree health due to less invasive pruning methods leads to reduced need for future maintenance or pest control resulting in long term savings.

Choosing the Right Laser for Tree Cutting

To buy the correct laser for cutting trees, one must also consider a number of key factors. To begin with, the power rating is significant since lasers with higher power ratings can cut through thicker branches more effectively. Second is wavelength because certain wavelengths may be better at cutting specific types of wood. What is also important in this context is durability and portability as strong and easily carried devices increase flexibility in their use. Lastly, it should have safety features like automatic shut off mechanisms or protective housing to avoid accidental injuries. Finally, evaluating cost-to-benefit ratio helps choose a laser that combines both effectiveness and affordability.

CO2 laser vs. Fiber laser

For tree cutting processes CO2 lasers and fiber lasers have distinctive advantages. They work based on 10.6 micrometers wavelength, which means that they have excellent absorption by organic materials such as wood making them very good for different tree species as well as thicknesses. They are recommended for applications where smooth and accurate cuts are required.

On the other hand, fiber lasers usually operate at wavelengths of approximately 1.064µmeters and are known for efficiency and higher power output respectively. This makes them have an edge over other types of laser beams due to better beam quality coupled with less maintenance requirements afforded by solid-state designs incorporated into them during their manufacture process; thus fiber lasers would be optimal for high-speed jobs requiring low attention.

In conclusion, whether one buys a CO2 or a fiber laser will depend on what they want to achieve from the tree cutting operation. As far as organic materials are concerned CO2 lasers are exceptional in terms of cutting capabilities and precision while fiber ones offer efficiency and long lifespan during high workload operations.

Power and wavelength considerations

When selecting between CO2 and fiber lasers for tree cutting, power and wavelength considerations are crucial. Power determines the ability of the laser to cut through different densities of wood while the wavelength affects how it interacts with the material.

- CO2 Lasers:

A wavelength of 10.6 micrometers makes CO2 lasers highly effective in cutting organic materials such as wood; consequently, they ensure smother clean cuts making them more useful when precision is required (Nagel et al., 2000). Moreover, CO2 lasers have a wide range of power outputs and can be used for anything from light trimming to cutting through larger trunks.

- Fiber Lasers:

Fiber lasers have an excellent efficiency as well as power output with a wavelength of 1.064 micrometers. They deliver better beam quality than other types due to their solid-state structure hence less maintenance is needed. Furthermore, fiber lasers are better for high speeds and cost-effectiveness since they do not break down frequently.

- Power Levels:

Both CO2 and fiber lasers come in different power levels. Therefore, choosing a laser with an appropriate power level is necessary to ensure that tree cutting operations are efficient and work well enough at all times (Schuocker et al., 2016). A high-powered laser can cut thicker or denser wood better compared to a low-powered one which may be suitable for lighter tasks.

Summary

In conclusion, CO2 lasers possess long wavelengths that enable them to make precise cuts on many kinds of woods by interacting effectively with organic matter; on the other hand, shorter wavelengths allow fiber lasers to be more efficient resulting to high speed and less maintenance applicationsEIA(2011). Therefore, knowing about the characteristics of each type regarding power levels and wave lengths will enable you choose appropriately among them during tree cutting exercise.

Common Challenges in Laser Tree Cutting

Laser tree cutting is an innovative way of reducing trees through precision cutting but it has several challenges that need to be addressed to achieve optimum efficiency. First, variations in wood densities and moisture can affect the laser’s performance during cutting, hence necessitating careful calibration and possible multiple adjustments. Secondly, safety issues are of utmost importance when using high powered lasers as they demand strict safety protocols to prevent accidents and destructions. Also, environmental aspects like wind, temperature and humidity can affect the effectiveness as well as consistency in operation of the laser. The initial capital outlay and maintenance prices for laser-cutting equipment could be substantial thereby limiting its affordability for smaller operations. These problems can be dealt with by proper planning, observing safety requirements, and investing in quality equipment to boost efficiency and security in the use of laser technology for tree felling.

Handling thick tree branches

When using laser cutting technology to handle thick branches on trees there a number of strategies that can maximize its output. A major approach involves using CO2 lasers with higher power levels since this results in deeper cuts that are cleaner too (Jean-Claude 2007). In order to suitably take into account density along with moisture content present in wood, precise calibration of the power settings among other things including speed and frequency matters a lot (Jean-Claude 2007). Additionally, carrying out several passes by the laser over a given area gradually pierces through dense branches without scorching or causing excess damage on the timber (Jean-Claude 2007). Proper maintenance practices should be put in place such as regular checking of all components fitted on any manufacturing machines. According to industry experts’ findings these methods have significantly increased accuracy and improved efficiency while cutting throbbing tree branches by employing lasers.

Laser output limitations

Maximum power capacity of the laser is one of the main drawbacks to its output. Stronger lasers are better for cutting denser, tougher materials such as fat tree trunks. Nonetheless, these high power lasers need a lot of electricity and can be very expensive to obtain. Another limitation is beam quality affects cut accuracy. Less accurate cuts may result from poor beam quality in lasers which causes inefficient systems and increased waste material. Also, laser system efficiency depends on target material properties like reflectivity and thermal conductivity. For instance, reflective surfaces can deflect the laser beam reducing its effectiveness whereas those with high thermal conductivity get rid of heat faster making them difficult to cut through. Therefore, it is important to understand these limitations in order to optimize laser settings for desired cutting results.

Ensuring consistent cutting results

To ensure the results are consistent and uniform, a number of important elements must be taken into account in this context. Firstly, it is vital to maintain optimum focus and alignment of the laser beam. It is possible to avoid beam drift and guarantee accuracy through regular calibration and alignment tests. Secondly, quality and state of the laser optics should not be compromised. Clean lenses as well as high quality mirrors can improve beam quality while minimizing losses. Thirdly, material handling system should be stable and accurate against any vibrations or motion that may cause defects on the cut. Automating systems can enhance uniformity and repetition in cutting processes. Finally, adjusting power, speed or pulse frequency depending on the properties of a material goes a long way towards improving cutting quality using lasers. Continuous monitoring and adjusting of such parameters helps in getting even development as well as predictable outcomes for machining processes

Frequently Asked Questions (FAQs)

Q: What makes a CO2 laser powerful for tree cutting?

A: A CO2 laser emits a powerful laser light that can precisely cut through dense materials such as tree limbs, making it highly effective for cutting down trees or trimming branches.

Q: How does a powerful laser work in cutting tree limbs?

A: The laser used emits a focused beam of light that generates intense heat, which vaporizes the material it comes into contact with. This process, known as laser processing, allows the laser to cut through tree bark and limbs efficiently.

Q: Do I need any special equipment to safely use a CO2 laser for cutting trees?

A: Yes, you would need protective equipment such as safety glasses to shield against the radiation caused by laser light. Additionally, it’s important to use the laser in a controlled environment to avoid accidental injury or damage.

Q: Can a CO2 laser replace traditional tree cutting tools?

A: Yes, a CO2 laser is a powerful one that can be an effective upgrade from traditional tools like saws. It allows for precise and clean cuts, making the process quicker and often safer.

Q: What precautions should I take when using a CO2 laser to cut trees near power lines?

A: Always maintain a safe distance from power lines to avoid the risk of electrocution. Additionally, ensure the laser beam is directed away from any reflective surfaces like glass to prevent accidental reflections that could cause harm.

Q: How do I choose the best type of CO2 laser for cutting trees?

A: Factors to consider include the laser’s power output, focal length, and compatibility with the specific materials you need to cut. For example, an LHW-3A model might be suitable for cutting dense tree limbs.

Q: Is there a forum where I can discuss CO2 laser tree cutting techniques?

A: Yes, several online platforms offer forums where you can discuss and share experiences about using CO2 lasers for cutting trees. You can exchange tips, troubleshoot issues, and stay updated on the latest laser products.

Q: How does laser tree cutting impact the environment compared to traditional methods?

A: Laser tree cutting can reduce the need for chemical treatments and excessive waste. The precision of laser processing ensures only target areas are affected, leaving the surrounding environment more intact.

Q: What maintenance does a CO2 laser require to keep it in optimal condition?

A: Regular maintenance includes cleaning the laser’s optics to ensure the beam quality remains intact, checking the alignment, and ensuring the electronics are functioning correctly. Proper maintenance helps in extending the life of the laser.

Q: Are CO2 lasers portable for tree cutting tasks in remote areas?

A: Yes, many CO2 lasers are designed to be compact and portable. This makes it easier for tree surgeons to carry the equipment to remote locations, especially when a cherry picker or climbing is required to reach tree limbs.