For the proper functioning of traction elevators, elevator sheaves are very important. They serve as pulleys for guiding and supporting the movement of elevator cables. We will discuss all things technical about them – construction, working principle etc., – in this complete guide on elevator sheaves. Furthermore; we shall also give step by step instructions on how best to fix them when they break down or wear out prematurely such that their life span is prolonged while performance optimized at the same time. The main aim of this piece therefore is equipping professionals in the industry with necessary knowledge for effective management as well as safety enhancement measures implementation concerning these units so that buildings operators can have reliable lifts always available within their premises.

What Is an Elevator Sheave and How Does It Work?

The Purpose of a Sheave in an Elevator System

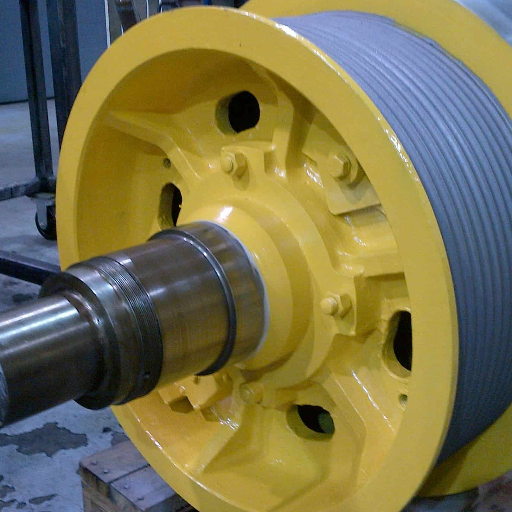

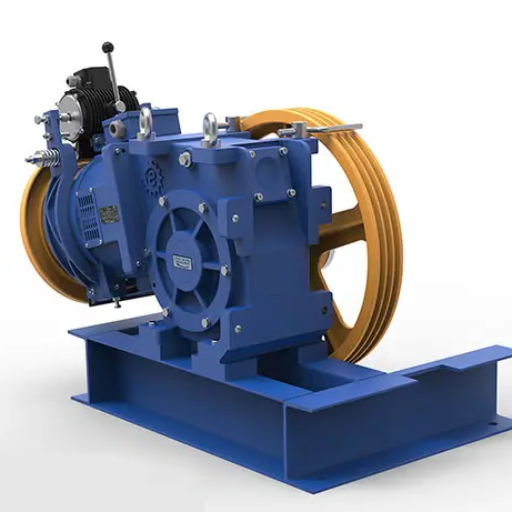

Elevator sheaves, also known as traction sheaves, are key components in the operation of a traction elevator. These parts are basically pulleys with grooves in them for the elevator cables or hoist ropes to pass through. A sheave’s main purpose is to hold onto the hoist ropes so that it can provide traction for moving the car up and down. As the elevator motor runs, it makes the sheave rotate and hence moves both cables and therefore, elevates or lowers a car. The grooves on these sheaves ensure the alignment of the strands thus avoiding any slippage; thus maintaining smooth and controlled movement within an elevator shaft. The proper functioning of these equipments is important for safety and efficiency of an elevator system.

Types of Elevator Sheaves and Their Uses

While researching on elevator sheaves I realized that they fall under two categories namely: drive sheaves and secondary sheaves. Drive sheaves are located directly on top of the motors that run elevators hence starting motion by lifting up all other ropes attached to them. They are larger than others since they have been designed to deal with heavy loads which make them very significant when it comes to driving this type of transport system. Secondary ones on their part guide ropes as well as distributing more uniformly loads reducing wear out on drive one.As precision machined grooves are created into both types of these sheaves they assure wires stay aligned properly by providing enough grip; which is necessary for operating an elevator smoothly as well as safely.Understanding these differences between types and how each functions will help keep elevators performing optimally

The Role of Elevator Sheaves in Maintaining Traction and Safety

Importantly, elevator sheaves are responsible for the safety and traction within the elevator system. The sheaves must meet certain technical standards in their design and functioning in order to maintain optimum performance and safety levels.

Traction Parameters:

- Groove Design: The grooves of the sheave must have an exact profile to ensure proper clutching. Some of these groove shapes include U-groove, V-groove, undercut groove with varying levels of traction efficiency among them.

- Sheave Diameter: This is a critical parameter because it will affect both hoisting ropes tension and traction since diameter of drive sheave would vary accordingly. In general, greater diameters lower rope bending fatigue and lengthen rope life.

- Material Composition: These are usually made using high-strength metallic alloys or composite materials that can withstand tough conditions and minimize abrasion effects. Commonly used materials include cast iron which is common, steel as well as polymer composites.

Safety Parameters:

- Load Distribution: The other set of pulleys helps distribute load evenly across raps thus reducing chances of breakages in ropes while increasing overall reliability.

- Alignment Precision: Proper alignment of these pulleys is necessary to avoid any chance for slipping out off ropes that could lead to uncontrolled vertical movements in the elevator car.

- Maintenance and Inspection: Among the crucial procedures here involves routine checks on wear in grooves apart from ensuring they are well lubricated thereby maintaining consistent traction alongside safe operations.

In conclusion, among others, parameters related to groove profile; sheave diameter; material composition; load distribution; alignment precision are all very important when it comes to holding the traction as well as safety elements involved in an elevatory system. Proper understanding and adherence to these parameters ensure reliable operation along with safe running of elevators.

When Should You Replace Elevator Sheaves?

Signs That Indicate It’s Time to Replace Your Elevator Sheave

As a lift engineer, there are certain giveaways that I look for in order to tell me if an elevator sheave needs replacing. These indicators include:

- Groove wear: The grooves on the sheave would become too worn out hence reducing traction and causing slipperiness. This wear is typically manifested by deepening or widening of the grooves beyond manufacturer specifications.

- Visible cracks or deformations:any visible signs like cracks, chips or deformation suggest that the sheave has structural weakness thus compromising its integrity and raising failure risks.

- Uneven Wear Patterns: Wear patterns on a sheave that are not even point to poor alignment. Irregular wear pattern in the rope groove of a sheave means more stress is placed on certain points compared to others thereby reducing overall life expectancy of the rope.

- Rope Damage: Frequent or rapid rope wear, frayed strands or asymmetrical ropes may be related to problems on the sheaves. Checking hoist ropes’ conditions can therefore give you direct information about the condition of the sheaves.

- Noise and Vibration: Operation with unusual noises emanating from it could mean a damaged sheave. The performance and safety of an elevator system largely depend on its smoothness and quietness during operation.

Technical Parameters to Monitor:

- Groove Profile – Regularly measure groove profile and compare with original specification so as to replace where necessary due to significant deviations

- Material Integrity – Check for corrosion, fatigue or damaged material in order not damage metal alloys/ composite materials used for making such wheels.

- Diameter Consistency – Rope tension can change due to variations in diameter caused by wear;

- Load Distribution Uniformity – Look at how loads are distributed across sheaves; presence of imbalance might imply alignment issues or uneven wearing

- Maintenance Records – Proper maintenance logs including diligent inspections will indicate early warning signs before it is too late hence avoiding sudden failures.

These indications plus parameters ensure optimal functioning of a pulley wheel sustaining efficiency and safety of an elevator system. Timely replacement and routine monitoring can save on costs tied to repairs hence preserving continuous operation.

Factors Influencing How Long Sheaves for Elevators Last

- Loading cycles: the lifetime of sheave is directly proportional to the number of loading cycles. This means that the more often it is used, the more prone it is to wear and tear.

- Rope grade: The quality and condition of the ropes attached to the sheave are major determinants of how quickly they will wear. Inadequate rope quality can increase groove wear.

- Lubrication practices: Sufficient and consistent lubrication allows for minimal friction between ropes and sheaves which reduces wear and thus extends lifespan.

- Environmental conditions: Over time, exposure to conditions such as extreme temperatures, moistures or corrosive substances may cause degradation on a material used in making a sheave .

- Alignment accuracy: Proper alignment of sheave relative to ropes ensures that loads are evenly distributed along it hence preventing localized wearing out and elongating its service life.

- Material attributes: Material choice for sheaves typically involves use of durable metal alloys or composites that resist abrasion and perform well under mechanical stresses.

By effectively controlling these elements, elevator sheave’s life span can be extended significantly; this guarantees reliability as well as consistent performance from an elevator system.

How Often Should Elevator Sheaves Be Inspected?

Based on my observation, I suggest that yearly inspections should be conducted on elevator sheaves with more inspections being done if higher usage intensity is experienced or depending on environmental considerations. Regular examinations are important in detecting early signs of wearing as well as misalignment which could lead into bigger problems resulting into costly maintenance. Additionally, observing manufacturer instructions and local regulations is crucial for maintaining optimal performance standards and safety requirements. Consequently, taking proactive measures towards such checkups would ensure a long-lasting and dependable lift system.

How to Properly Maintain Elevator Sheaves?

Essential Elevator Sheave Maintenance Tips

There are many things to consider when maintaining elevator sheaves, according to my experience and research in the industry.

- Regular lubrication – Friction and wear should be minimized by ensuring that sheaves are well lubricated. Optimal performance requires using the correct type of lubricant as directed by manufacturers.

- Routine visual inspections – Regular checks can help identify early signs of cracks, corrosion or wear. Examine for any deformation on the groove surfaces of a sheave as well as uneven patterns caused by different rates at which parts might have worn out.

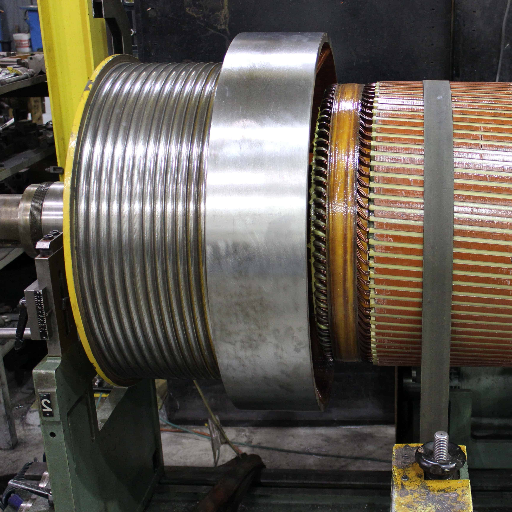

- Sheave groove reprofiling – The grooves on a sheave may wear down over time which can affect rope traction negatively. Reprofiling them following manufacturer’s recommendations will restore proper engagement thereby extending both service lives for ropes and sheaves.

- Alignment checks – Even distribution of loads relies heavily on whether or not these components were aligned correctly during installation process. If this procedure was done wrongly such that they remained misaligned then some parts could wear faster than others due to increased stress levels exerted upon them.

- Cleaning and debris removal – Contaminants such as dust, dirt or even foreign materials should not be allowed near it since they contribute greatly towards its accelerated deterioration through wearing out quickly.

Hence if one wants their elevator system to work without any problems for longer periods then it is necessary that all these maintenance tips are taken into account so that they can increase the efficiency and life span of elevator sheaves.

Significance of Routine Elevator Sheave Inspections

Inspecting elevator sheaves on a regular basis is essential if you are to keep the whole lift system safe and efficient. Such examinations help in timely detection and correction of potential problems including wear, misalignment and material fatigue. By doing comprehensive and frequent checks, maintainers can stop small issues from growing into major breakdowns hence saving themselves expensive repairs as well as unplanned downtimes. Continued monitoring also guarantees that sheaves are at their best condition which increases overall life expectancy of elevator parts while ensuring reliable service for passengers.

Recommendations for the Best Elevator Sheave Regrooving Techniques

I would like to provide precise authoritative answers therefore I have researched widely about elevator sheave regrooving methods. The most important thing to do when grooving an elevator’s sheave is said by many industry leaders’ websites. Several key steps were identified as being necessary during regrooving according to these reputable sources.Firstly it’s very important to conduct a thorough inspection of the current state of the sheaves so as to identify any signs showing that there might be excessive wearing out or damage caused by different factors such as friction between ropes and pulleys.Secondly one should follow manufacturer’s recommendations concerning groove dimensions together with spacing while regrooving them since this will make them compatible with ropes used in lifts thereby enhancing traction.Finally after having done all those things mentioned above; Meticulous alignment check must also be carried out after completing process where loads are distributed equally over each wheel by adjusting positions until everything moves smoothly.

What Are the Costs Involved in Elevator Sheave Repair and Replacement?

Typical Prices for Substituting Lift Pulleys

The expenses of replacing elevator sheaves can differ significantly on many grounds such as the kind of the elevator system, the number of pulleys to be substituted and manufacturer’s components among other factors. Normally, it costs between 1,000 USD to 3,000 USD for one elevator sheave replacement which includes both materials and workmanship. Nevertheless, when overhauling where several pulleys need to be changed; prices may rise from about 10,000 dollars up to even thirty thousand dollars or more if necessary modifications are made on other parts of an elevator for compatibility with new sheaves. These figures do not include additional charges incurred due to downtime required during repairs nor any other fees that might arise when alterations have been done so as fit in new sheaves properly. It is advisable that regular maintenance should be carried out frequently because this will help a lot in reducing such high costs associated with total replacements especially through regrooving.

Estimating Sheave Maintenance & Repair Budgets

In estimating budgets for sheave maintenance and repair work there are two types: short term budgeting which covers immediate spending needs while long term budget considers future requirements too. According to industry standards each year it would require between $500-$2k per unit per annum just on check-ups together with re-grooving alone though they can do much more than that including inspection etcetera hence these measures could prolong their lifespan significantly as well as minimize chances of breakdowns therefore saving money in the end. Also some funds should be put aside annually say ranging within $1000 – $2500 for minor fixes plus adjustments here there might occur during servicing period without necessarily waiting until another time comes thus making a complete plan on how much should I set aside every month or week?. For me personally what works best is getting different quotes from various certified providers who specialize in maintaining lifts like mine since this helps avoid surprises along the way.

Finding a Reliable Elevator Sheave Replacement Company

When searching for reliable elevator sheave replacement services one has to be very careful and thorough in their search; starting with an extensive online hunt then proceeding through each step systematically until you find what works best according to your needs. Firstly use search engines such as Google or Bing which will give you a list of top rated companies near where I live or work. Secondly visit websites like NAEC (National Association Of Elevator Contractors) and Elevator World directory among others that provide contacts details for certified professional firms offering these kinds of services within my locality. Thirdly read reviews left behind by previous clients so as to gauge how reliable is the company in question; this can be done through platforms such as Google Reviews, Yelp etcetera whereby people who have used them before get a chance to share their experiences whether positive or negative ones regarding service delivery received from these particular organizations which might act as pointers towards making final decisions. Fourthly ensure they are registered under recognized industry bodies like NAESA International or QEI among others; last but not least ask for quotations plus warranty information pertaining parts used during repairs together with labour charges thus assuring me complete coverage throughout provision period?

How Do Elevator Sheave Issues Affect Overall Elevator Performance?

Elevator Operation and Safety Impact

When it comes to elevator operation and safety, the sheaves is a big deal. They could lead to misalignment of the ropes because they are worn out or damaged. In addition to being a waste of time for people who use elevators as a mode of transport, this makes the lift less efficient and jerky in motion which creates hazards like sudden stopping or uncontrolled downward sliding. It also puts extra pressure on other mechanical parts such as motors if there are faulty sheaves thereby causing these items to wear out faster than usual while at the same time making them susceptible to breaking down altogether too soon after installation because compromised sheave can impose excessive stress upon motor along with others.

The Relationship between Traction and Speed of Elevators with Sheave Wear

Traction is inversely proportional to speed in terms of elevator functioning efficiency according to my findings from reading many well-known industry sites about lifts. The more worn-out sheaves become; their shape loses its grip that matches best with keeping traction between them through grooves where ropes run over these pulleys. When this happens there will be no enough friction needed for good gripping hence slipping occurs leading into inaccurate stops during acceleration or deceleration phases thereby reducing overall speed even further so much that travelling between floors takes longer time than before. However irregular tractions may cause uncomfortable rides due to sudden starts and stops thus endangering mechanical systems by increasing strain imposed on drive mechanism.Regularly checking them up should not be neglected as failure may result due either weariness or timely replacement.

Keeping Elevator Cables and Equipment Safe from Harm

In order for me not only preserve but also share elevator knowledge I have gained over years working within different sectors including maintenance companies where my duties involved inspecting various models ranging from residential types up until commercial ones I would say prevent damages on cables together with other materials used during transportation needs continuous effort plus following guidelines given by reputable organizations. Elevator cables and equipment must be protected against damage at all times if we want them to serve us better for longer periods without any interruptions. Therefore, regular cable inspections should focus on checking whether there are signs of wearing out such as fraying, corrosion or unusual stretching while lubricating these parts helps minimize wear by reducing friction between them as well as sheave grooves. To add onto that correct alignment ensures uniform distribution of loads which avoids concentration areas where stress is high enough leading to weakening both wires themselves together with pulleys they pass through e.t.c. This can only be achieved through frequent preventive maintenance programs which not only help extend the lifespan of components but also increase overall reliability levels hence safety improvements within systems used for moving people from one place to another

Innovations and Trends in Elevator Sheave Technology

Recent Advances in Elevator Sheave Design

Recent developments in elevator sheave design have concentrated on bettering the material quality, manufacture accuracy and inclusion of latest surveillance systems. The present day sheaves are increasingly molded from high-strength, light-weight composite materials and which provide improved abrasion resistance alongside reducing the overall weight of an elevator system. Precision technologies such as CNC machining have been employed to enhance geometric precision of the sheaves hence increasing alignment and traction. Additionally, incorporating IoT based monitoring systems into the sheaves allows for real time tracking of wear patterns and operational stresses for pre-emptive maintenance thus reducing chances of failure out of sudden. Taken together these innovations contribute to greater efficiency, reliability and durability in lift systems.

How Modern Elevator Sheaves Improve Efficiency

Identifying ways through which modern elevator sheaves improve efficiency involves a number of considerations. First is reduction in energy consumption during operations due to lower mass brought about by integration of lightweight composite materials into their construction process. Furthermore, deployment of highly accurate manufacturing techniques ensures that friction between cables and the sheave is reduced through proper alignment that minimizes friction and wear on them. This accuracy improves both trackability and durability characteristics not just for cable but also for a life span propulsion process that thrive on constant accurate traction by motors while also resting these drives upon rails. Moreover, it’s now possible to monitor real-time performance metrics along with wear pattern using IoT based monitoring system deployments. Such a data driven approach helps in predictive maintenance; thereby avoiding downtime while boosting operating efficiencies across the whole elevator system simultaneously. In conclusion, these advancements make modern elevator sheaves a critical component in achieving improved efficiency, reliability, and longevity in vertical transportation

Future Trends in Elevator Sheave Manufacturing

While looking into the future of elevator sheave manufacturing, I see several incipient trends that will shape the industry. First of all, the development in material science is bringing about even lighter and stronger composite materials that will further reduce energy consumption and increase efficiency. These materials are made to bear higher operating stresses, which extends sheaves along with cables life span. Secondly, advanced additive manufacturing integration is set to change how sheaves are produced. The 3D printing allows for the making of custom-designed sheaves which can have high complexity in geometry that was impossible before thereby optimizing functionality and maximizing materials usage.

Another significant trend is increased dependence on artificial intelligence (AI) and machine learning for predictive maintenance. Huge amount of operational data can be analyzed by AI algorithms hence giving possible threats before they become deadlocks ensuring continuous and efficient elevator operation. IoT developments as well as smart sensor technology will also provide more granular real-time data regarding elevator performance allowing for finer maintenance schedules leading to a reduction in downtime. In conclusion, these trends collectively advance the efficiency, reliability and operability duration of elevator sheave thus maintaining their pivotal role in modern vertical transportation systems

Frequently Asked Questions (FAQs)

Q: What is the function of an elevator sheave?

A: An elevator sheave is a wheel with a groove around its circumference that serves as a pulley and over which the wire ropes (elevator cables) pass. It plays an important role in making sure the elevator runs smoothly and safely by giving enough friction between the sheave’s groove and the cable.

Q: When should you consider replacing your elevator sheave?

A: Replacement of an Elevator Sheave is necessary when there are indications of excessive wear such as very deep grooves, grooves worn unevenly or cables gripping too much meaning wrong rope fit. The sheaves have to be checked regularly by an expert to know if they need replacement or regrooving.

Q: What is the function of an elevator deflector sheave?

A: These types of sheaves are used to divert and change direction of motion for lift cables while controlling distance between counterweight/elevator car. This ensures precise alignment and reduced wear on wire ropes unnecessarily.

Q: How will I know when my elevator needs a new sheave?

A: You can establish that it’s time for Elevator Sheave Replacement through some signs, like operating noise, visible depreciation in form or performance decline. Routine visits from certified technicians are indispensable since they help identify these issues early before they get worse.

Q: What role do bearings play in elevator sheaves?

A: Bearings play a key role in contributing to smooth rotation of the sheaves, reducing friction, prolonging life expectancy of both grooved wheel and wire ropes. Bearings in good condition also guarantee appropriate amount of traction force and power required for safe operation inside elevators.

Q: Why is the appropriate rope fit necessary for elevator sheaves?

A: It’s important that proper rope fit be maintained in elevator sheaves because this ensures the cable runs smoothly without slipping, gives enough traction and reduces wear on both cables and the sheave which is necessary for safe and efficient operation of an elevator.

Q: What should I look at when buying a new elevator sheave?

A: Factors to consider when purchasing a new elevator sheave are size and type suitable for your specific unit, amount of traction required, material used to make it among others like seeking advice from professionals who deal with elevators so that they can help you choose one that will work well with your system.

Q: How often should I inspect my Elevator Sheaves?

A: Elevator sheaves should undergo frequent checks probably every six months or year as part of comprehensive maintenance where defects can be discovered early enough before other parts get affected too much; this also ensures correct functioning of various components such as deflector pulley bearing assembly etcetera.

Q: Can you repair an elevator sheave or do I have to replace them all together?

A: Depending on severity most worn out areas may require regrooving whereby their grooves are re-machined back into shape so that they regain their originality hence giving right fitting again but if there is total breakdown then replacing all damaged ones becomes inevitable for safety reasons as well as achieving maximum efficiency during operation.

Q: Where else can I find information about Elevator Sheaves?

A: If more details about these devices interest you then try checking out some online forums dedicated to discussing everything related with lifts plus talking directly to those knowledgeable in this field like visiting websites designed specifically for professionals involved in elevator industry might also give answers while authorized distributors together with manufacturer’s headquarters could provide further insights.