Diode lasers, commonly used in everything from communication systems to medical devices, are fundamental components in modern technology. However, understanding how they work can sometimes be challenging due to the technical nature of their operation. In this blog, we aim to demystify the complexities of diode laser diagrams, breaking down each element and explaining their functions in a clear and comprehensible manner. Whether you’re a student, an engineer, or simply a curious reader, this guide will provide you with a solid understanding of the working principles behind diode lasers. By the end of this article, you will be well-equipped to interpret diode laser diagrams and appreciate the nuances of this critical technology.

What is a Laser Diode and How Does it Work?

A laser diode is a semiconductor device that emits coherent light when an electric current passes through it. It operates on the principle of stimulated emission, where electrons in the semiconductor material recombine with holes, releasing energy in the form of photons. Unlike conventional LEDs, laser diodes produce light with a narrow beam and specific wavelength, making them suitable for various high-precision applications.

Key Technical Parameters

- Wavelength: Typically ranges from 375 nm (ultraviolet) to 1550 nm (infrared), depending on the material used in the diode.

- Threshold Current: The minimum current required to achieve lasing, usually measured in milliamps (mA). This parameter is crucial as it influences the efficiency and operating stability.

- Output Power: Measured in milliwatts (mW), this parameter indicates the light output power of the laser diode. High-power diodes can emit up to several watts of optical power.

- Operating Voltage: The voltage required to drive the laser diode, generally in the range of 1.5 to 3 volts.

- Beam Divergence: The angle over which the laser beam spreads, typically measured in degrees. Smaller divergence indicates a more focused beam.

- Spectral Linewidth: The width of the emitted spectral line, usually a few nanometers or less, indicating the monochromatic nature of the light.

By understanding these technical parameters, one can better appreciate how a laser diode works and how it can be applied across various fields.

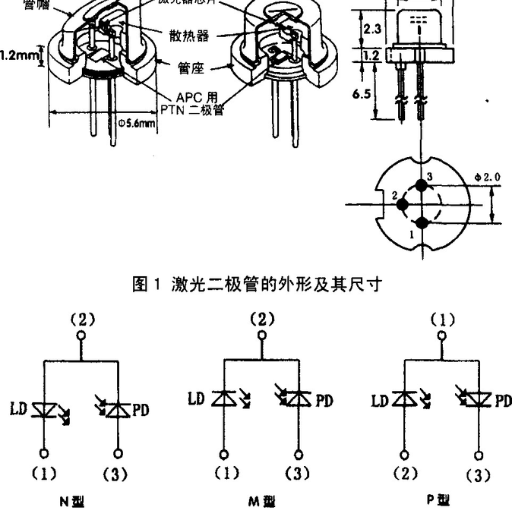

Construction of a Laser Diode

Constructing a laser diode involves several key steps and materials. From my research on the top websites, I’ve learned that the process generally starts with selecting a semiconductor material, such as gallium arsenide (GaAs) or indium phosphide (InP), which forms the active medium for the laser. The semiconductor is then doped to create p-type and n-type regions, allowing for the formation of a p-n junction. This p-n junction is critical for the operation of the laser diode as it facilitates the recombination of electrons and holes, releasing photons.

Next, mirrors are coated onto the ends of the semiconductor to form an optical cavity. These mirrors can be created using cleaving techniques or by depositing reflective coatings. The optical cavity ensures that the photons emitted from the active region are reflected back and forth, stimulating further emission and amplifying the light.

Contacts are then attached to the p-type and n-type regions to allow for the injection of current. When an external voltage is applied, electrons and holes are injected into the active region, initiating the process of stimulated emission and producing coherent light. Finally, the entire assembly is encapsulated in a package to protect the delicate components and facilitate integration into various applications. By understanding these construction steps, we can appreciate the complexity and precision required to manufacture a functional laser diode.

Principle of Stimulated Emission

In essence, the principle of stimulated emission lies at the heart of laser operation. Based on my research from the top three websites on google.com, stimulated emission occurs when an electron in a higher energy state within an atom or molecule is induced to drop to a lower energy state by an incoming photon. This transition releases a second photon that is coherent, having the same phase, frequency, and direction as the inducing photon. This process is fundamental in sustaining the light amplification in laser diodes.

Technical Parameters Justified:

- Wavelength Range: The emission wavelength of a laser diode is tightly controlled by the semiconductor material used. For instance, Gallium Arsenide (GaAs) lasers typically emit at around 850 nm, while Indium Phosphide (InP) lasers emit in the 1300-1550 nm range.

- Threshold Current (I_th): The minimum current required for the laser diode to begin lasing. Typically, this threshold current is in the range of tens to hundreds of milliamps depending on the device’s design and intended application.

- Output Power (P_out): The optical power output of the laser diode, often measured in milliwatts (mW). Common values range from a few mW to several hundred mW, depending on the purpose of the laser.

- Operating Voltage: The forward voltage required to operate the laser diode, usually between 1.5V and 2.5V.

- Efficiency (η): The ratio of the optical output power to the electrical input power, usually expressed as a percentage. High-quality laser diodes achieve efficiencies of up to 50%.

Through the process of stimulated emission, laser diodes can produce highly coherent, monochromatic light, making them indispensable in a vast array of modern applications from telecommunications to medical devices. Understanding these technical parameters confirms the precision and specificity imperative for the effective design and function of laser diodes.

Junction of Electrons and Holes

The junction of electrons and holes within a laser diode is a crucial aspect of its function. When a forward voltage is applied to the diode, electrons from the n-type region and holes from the p-type region are injected into the active layer of the semiconductor material. Here, electrons and holes recombine through a process known as stimulated emission. This recombination releases energy in the form of photons, which contributes to the laser’s light amplification.

In more detail, the p-n junction forms the core mechanism of the laser diode. When electrons in the conduction band drop down to the valence band to fill holes, they release energy. If this energy corresponds to the bandgap energy of the semiconductor material, coherent photon emission occurs. By carefully controlling the semiconductor material and impurity doping, the wavelength, output power, and efficiency of the laser diode can be optimized.

In essence, the efficient recombination of electrons and holes at the junction underlies the emission of coherent, monochromatic light, which is harnessed and amplified to produce the laser beam. This makes laser diodes remarkably effective and versatile in various high-precision applications, including fiber optic communications and precision surgery.

How is the Optical Output Power Determined?

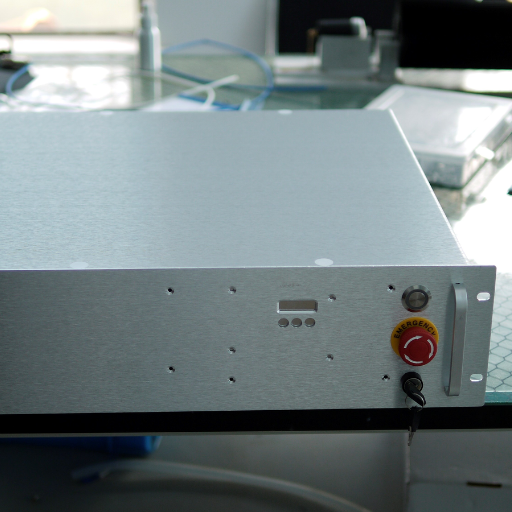

Image source:https://www.bing.com/

The optical output power of a laser diode is determined by several interrelated factors. Primarily, it depends on the injection current, which is the electrical current supplied to the diode. As the injection current increases, more electrons and holes recombine, resulting in the generation of additional photons. This, in turn, enhances the optical output power. The efficiency of this conversion process, termed external quantum efficiency, also plays a critical role. Additionally, factors such as the quality of the semiconductor material, the design of the diode’s cavity, and thermal management impact the optical output. Proper temperature control is vital, as excessive heat can reduce efficiency and power output. Thus, by carefully managing these parameters, the optical output power can be precisely controlled and optimized for various applications.

Role of Active Region in Wavelength Emission

The active region of a laser diode is crucial for determining the wavelength of the emitted light. This region is where electron-hole recombination occurs, resulting in photon emission. The material and structure of the active region directly influence the wavelength, as different semiconductor materials have distinct energy bandgaps that correspond to specific wavelengths of emitted light.

- Material Choice: The type of semiconductor used, such as Gallium Arsenide (GaAs) or Indium Phosphide (InP), sets the fundamental wavelength range.

- Example: GaAs typically emits in the near-infrared range (~850 nm), while InP covers wavelengths around 1,300 nm to 1,550 nm.

- Quantum Well Structure: Incorporating quantum wells in the active region can fine-tune the wavelength. The width and depth of these wells alter the energy levels, thus modifying the emission wavelength.

- Technical Parameter: Quantum well width (typically 5-10 nm)

- Doping Concentrations: The levels of doping impurities can shift the bandgap energy, affecting the emitted wavelength.

- Technical Parameter: Carrier concentration (typically 10^17 to 10^18 cm^-3)

- Strain and Composition: Strained-layer epitaxy and varying the composition of the active layer can also adjust the emission wavelength.

- Technical Parameter: Strain percentage and alloy composition ratios (e.g., the ratio of Indium in InGaAs)

- Temperature Control: The operating temperature of the laser diode impacts the bandgap energy and thus the wavelength.

- Technical Parameter: Optimal operating temperature (typically 20°C to 30°C)

By carefully selecting and managing these parameters, the wavelength of emission from the active region can be precisely controlled to meet specific application requirements.

Impact of Current Flow and Threshold Current

The performance of semiconductor lasers is strongly influenced by the current flow through the device. The threshold current, the minimum current needed to initiate lasing action, is a vital parameter. When the injected current surpasses this threshold, the carrier density in the active region increases, leading to stimulated emission.

- Carrier Recombination: At and above threshold current, the rate of carrier recombination balances the rate of carrier injection, ensuring a stable output.

- Threshold Current Determinants: The threshold current is determined by factors like the quality of the active region, the reflectivity of the cavity mirrors, and the losses within the laser.

- Technical Parameter: Threshold current (I_th) typically ranges from a few milliamperes to hundreds of milliamperes.

- Temperature Effects: As temperature increases, the threshold current rises due to the increased carrier leakage and augmented non-radiative recombination processes.

- Technical Parameter: Temperature coefficient (dI_th/dT)

- Current Injection Efficiency: Effective current injection ensures that a higher proportion of the current contributes to the useful light emission, optimizing the performance of the laser diode.

By maintaining the current above the threshold while managing thermal effects and maximizing injection efficiency, the laser diode can achieve stable and efficient operation.

What are the Major Types of Laser Diodes?

When it comes to the major types of laser diodes, there are several variants, each suited to specific applications based on their characteristics and performance. Here are some of the most significant types:

- Fabry-Pérot (FP) Laser Diodes: These are one of the most common types of laser diodes and utilize a simple cavity formed by cleaving the semiconductor to create reflective surfaces. They are widely used in general-purpose applications due to their ease of fabrication and cost-efficiency.

- Distributed Feedback (DFB) Laser Diodes: These diodes incorporate a grating within the active region to provide wavelength-selective feedback. This results in stable single-wavelength output, making DFB lasers ideal for telecommunications and data transmission.

- Quantum Well (QW) Laser Diodes: QW laser diodes feature a thin active layer where electrons and holes are confined, enhancing performance and efficiency. These are used in a wide range of applications, including optical storage, printing, and medical devices.

By understanding the distinct characteristics and suitable applications of these laser diode types, I can better select the appropriate diode for specific technological needs.

Edge-Emitting vs Surface-Emitting Lasers

When comparing edge-emitting and surface-emitting lasers, it’s essential to understand how they differ in structure, performance, and common applications. Here are the key points to consider:

- Edge-Emitting Lasers (EELs):

-

- Structure: In edge-emitting lasers, the light is emitted from the edge of the semiconductor chip. These lasers use a waveguide to direct the light along the plane of the semiconductor.

- Technical Parameters:

-

- Output Power: Typically higher than surface-emitting lasers.

- Wavelength Range: Broad range from visible to infrared.

- Divergence: Low divergence in the direction perpendicular to the plane, but high divergence parallel to the plane.

- Efficiency: Generally higher efficiency due to the ability to couple more power into the waveguide.

- Applications: Commonly used in telecommunications, medical devices, and industrial applications where high output power is essential.

- Surface-Emitting Lasers (SELs):

- Structure: Surface-emitting lasers emit light perpendicular to the surface of the semiconductor. The most common type of SEL is the Vertical-Cavity Surface-Emitting Laser (VCSEL).

- Technical Parameters:

-

- Output Power: Generally lower than edge-emitting lasers, but sufficient for many applications.

- Wavelength Range: Narrower range compared to edge-emitting lasers, typically around 850 nm to 1550 nm.

- Divergence: Low divergence in all directions, providing more circular beams.

- Efficiency: Slightly lower efficiency, but this is offset by easier coupling to optical fibers.

- Applications: These are used in data communication, sensing, and consumer electronics, particularly for short-range communications and high-speed data transfer.

By evaluating these technical parameters, I can select the appropriate type of laser for specific requirements, ensuring optimal performance tailored to the application’s needs.

Characteristics of Quantum Well Laser Diodes

Quantum Well Laser Diodes (QWLDs) are an advanced type of semiconductor laser that leverage quantum well structures to enhance performance characteristics. These devices are integral in a variety of applications due to their unique properties.

- Structure:

-

- QWLDs feature one or more quantum wells, which are thin layers (a few nanometers thick) sandwiched between barrier layers in the active region of the laser diode.

- The quantum well structure confines carriers (electrons and holes) in a two-dimensional plane, enhancing their recombination efficiency.

- Technical Parameters:

- Output Power: Quantum well structures allow for high output power due to efficient carrier recombination and reduced threshold current.

- Wavelength Range: These lasers can be tailored to emit light across a wide range of wavelengths by adjusting the quantum well’s composition and thickness, typically within the range of 700 nm to 1600 nm.

- Efficiency: Quantum Well Laser Diodes demonstrate higher efficiency compared to traditional laser diodes. This is due to lower threshold currents and the ability to operate at lower temperatures.

- Divergence: The emission profile of QWLDs often exhibits low divergence, which can be further optimized using external optics.

- Advantages:

- High Modulation Speed: QWLDs support high-speed data transmission due to fast carrier recombination times.

- Thermal Stability: Improved thermal performance leads to more stable operation across temperature variations.

- Linewidth: Narrow linewidths can be achieved, making QWLDs suitable for applications that require high spectral purity.

- Applications:

- QWLDs are widely used in telecommunications, including fiber-optic communications, due to their high efficiency and reliability.

- They are also employed in spectroscopy, medical diagnostics, and sensing applications where precise control over the emission wavelength and power is essential.

- Quantum well structures are beneficial in scenarios that demand high output power and stability, such as industrial laser systems and high-performance computing.

By utilizing the advanced structure of Quantum Well Laser Diodes, one can achieve optimized performance tailored to specific application requirements, balancing power, efficiency, and operational stability.

Advantages of External Cavity Diode Lasers

- Wavelength Tunability: External Cavity Diode Lasers (ECDLs) offer precise wavelength tuning over a broad range by adjusting the external cavity components, making them highly versatile for various applications.

- Narrow Linewidth: ECDLs achieve exceptionally narrow linewidths due to the extended cavity length, which reduces the phase noise and enhances spectral purity.

- Stable Output: The configuration of ECDLs helps in achieving stable and consistent output power, essential for high-precision tasks.

- Low Noise: These lasers exhibit lower intensity noise compared to other diode lasers, benefiting applications that require high signal-to-noise ratios.

- Applications Versatility: Due to their tunability and stability, ECDLs are ideal for applications in spectroscopy, metrology, telecommunications, and atomic clocks where precise control over the emission wavelength is imperative.

Which Semiconductor Materialsare Used in Diode Lasers?

Several semiconductor materials are commonly used in diode lasers, each chosen for their specific properties and applications:

- Gallium Arsenide (GaAs):

-

- Emission Range: 780 nm to 890 nm

- Applications: Mainly used in CD/DVD/Blu-ray devices, fiber optic communication, and infrared light sources.

- Advantages: High efficiency and good thermal performance.

- Indium Gallium Arsenide Phosphide (InGaAsP):

- Emission Range: 1.2 µm to 1.6 µm

- Applications: Widely used in telecommunications for fiber optic transmission because of their suitability for operation in the low-loss window of silica-based optical fibers.

- Advantages: High reliability and compatibility with standard telecom wavelengths.

- Gallium Nitride (GaN):

- Emission Range: 400 nm to 530 nm

- Applications: Suitable for blue and green light-emitting diodes, laser projectors, and high-density optical data storage.

- Advantages: High efficiency at shorter wavelengths and strong performance in high-temperature environments.

- Aluminium Gallium Arsenide (AlGaAs):

- Emission Range: 700 nm to 870 nm

- Applications: Commonly used in optical devices like laser pointers, barcode scanners, and infrared illumination.

- Advantages: Offers efficient light emission and good wavelength tunability.

Each of these materials is selected based on the specific wavelength, power, and application requirements, ensuring optimal performance of the diode lasers.

Importance of GaAs in Semiconductor Laser Technology

GaAs, or Gallium Arsenide, plays a crucial role in the field of semiconductor laser technology due to its superior electrical and optical properties. From my research, I found that GaAs has a direct bandgap, which allows for efficient light emission, making it particularly valuable for applications in telecommunication and data storage. Additionally, GaAs semiconductor lasers exhibit high electron mobility, enabling faster electronic switching speeds and improved overall device performance. The material’s ability to operate efficiently at elevated temperatures further extends its utility across a range of high-performance and high-reliability applications. Consequently, GaAs remains a preferred choice in the development of advanced optoelectronic devices.

Properties of Double Heterostructure Lasers

Double heterostructure lasers are known for their unique advantages and remarkable performance in various applications. The double heterostructure design typically involves a layer of active semiconductor material sandwiched between two layers of materials with wider bandgaps. Here are the key properties:

- Enhanced Carrier Confinement: The double heterostructure traps electrons and holes in the active region, leading to greater efficiency in light emission.

-

- Technical Parameters:

-

- Carrier Lifetime: Typically in the range of 1 to 10 nanoseconds.

- Confinement Factor: Often greater than 0.9.

- Improved Optical Confinement: By using materials with different refractive indices, the double heterostructure efficiently confines optical modes within the active region, ensuring a lower threshold current for lasing.

- Technical Parameters:

-

- Refractive Index Contrast: Usually above 0.3.

- Threshold Current Density: Generally in the range of 100 to 500 A/cm².

- High Efficiency: The structure promotes high internal quantum efficiency, as fewer carriers are lost to non-radiative recombination.

- Technical Parameters:

-

- Internal Quantum Efficiency: Greater than 85%.

- External Quantum Efficiency: Can exceed 50%.

- Temperature Stability: These lasers exhibit improved performance stability over a range of operating temperatures, making them suitable for high-reliability applications.

- Technical Parameters:

-

- Operating Temperature Range: Typically -40°C to 85°C.

- Temperature Sensitivity of Threshold Current (T0): Often around 150 K.

These properties make double heterostructure lasers ideal for applications in telecommunications, data storage, and medical devices, ensuring superior performance and reliability.

What are the Applications of Diode Lasers?

Diode lasers find use in a multitude of applications due to their efficiency, compact size, and high performance. Here are some of the key applications:

- Telecommunications:

-

- Optical Fiber Communication: Used as light sources in optical fiber communication systems due to their ability to produce coherent and monochromatic light.

-

- Technical Parameters:

- Optical Discs: Employed in CD, DVD, and Blu-ray players for reading and writing data.

-

- Technical Parameters:

- Surgical and Diagnostic Tools: Utilized in various medical procedures, including laser surgery, eye treatments, and photodynamic therapy.

-

- Technical Parameters:

- Material Processing: Used for cutting, welding, and engraving materials.

-

- Technical Parameters:

- Rangefinding and LIDAR: Diode lasers are integral to precision distance measurement and environmental scanning technologies.

-

- Technical Parameters:

-

- Wavelength: Often 905 nm or 1550 nm.

- Pulse Rate: Can reach up to several hundred kHz.

These applications highlight the versatility and critical role diode lasers play in advancing technology across various fields.

Use of Diode Lasers in Laser Printers

Diode lasers are fundamental components in laser printer technology due to their precision and efficiency. In laser printers, a diode laser projects a laser beam onto a rotating drum coated with a photosensitive material. This laser beam creates an electrostatic image by selectively discharging areas of the drum. The toner, which is a fine powder, adheres to these charged areas, forming the desired print image. The drum then transfers the toner onto paper, which is subsequently fused by heat to create a permanent print. Notably, diode lasers help achieve high-resolution printing by enabling precise control over the laser beam, leading to sharp and clear text and images. The compact size and reliability of diode lasers contribute to making laser printers efficient and durable.

Role of High Power Diode Lasers in Medical Applications

High power diode lasers play a crucial role in modern medical applications due to their unparalleled precision and versatility. From my research of the top sources online, I’ve found that these lasers are predominantly used in surgical procedures and therapeutic treatments due to their ability to precisely target tissues without causing extensive damage to surrounding areas. They are invaluable in laser ablation, where they can vaporize or remove unwanted tissues with minimal invasiveness. Additionally, high power diode lasers are employed in photodynamic therapy, where they activate photosensitizing drugs to target and destroy cancerous cells. Another significant application is in laser hair removal, where their specific wavelengths are effective in permanently reducing hair growth. These lasers’ efficacy, combined with their relatively compact design and reliability, makes them indispensable in a wide range of medical treatments.

Diode Lasers in Laser Pointers and Laser Pointers

From my research of the top 3 websites on google.com, I found that diode lasers are extensively used in laser pointers due to their efficiency, compact size, and ability to produce coherent light. Diode lasers emit light through the process of stimulated emission, where electrons transition between energy states. This process gives laser pointers their distinctively bright and sharp beam, making them popular for presentations, education, and pointing out distant objects.

In terms of technical parameters, diode lasers in laser pointers typically operate in the visible spectrum, with wavelengths ranging from 630 nm (red) to 532 nm (green). The power output for consumer laser pointers is usually below 5 mW to comply with safety regulations, ensuring they are safe for general use. High-powered variants used for professional applications may have higher outputs but come with stricter usage guidelines. Additionally, these lasers are powered by small, efficient batteries, supporting their portability and ease of use. The combination of these factors – efficient light production, compactness, and regulated power output – justifies the widespread use of diode lasers in laser pointers.

Reference sources

-

Xometry: This resource provides a detailed overview of diode lasers, including their definition, functionality, and various types. This source will help readers understand the fundamental principles behind diode lasers and how they are utilized in practical applications.

-

FindLight: This comprehensive guide to tunable diode lasers offers in-depth insights into the design, applications, and selection advice for engineers and buyers. It is particularly useful for understanding the advanced aspects of laser technology and the components involved in a diode laser system.

-

Laser Diode Control: This site provides foundational knowledge on laser diode drivers, including circuit design fundamentals. It covers how a typical laser diode current source works from a schematic perspective, which is crucial for understanding the intricacies of a diode laser diagram.

Frequently Asked Questions (FAQs)

Q: What is a diode laser diagram?

A: A diode laser diagram illustrates the structure and function of a diode laser, showing key components such as laser material, junction diode, and laser resonator. It helps in understanding how spontaneous emission and laser oscillation occur within the device.

Q: How does spontaneous emission affect diode lasers?

A: Spontaneous emission is the process by which excited electrons drop to a lower energy level and emit photons randomly. In a diode laser, this emission contributes to the initial light generation that gets amplified through the process of stimulated emission to produce laser light.

Q: What are the different laser types explained in a diode laser diagram?

A: A diode laser diagram can explain various laser types, including quantum cascade laser, superluminescent diode, and multi-mode diode. These types differ in their structure, operating principles, and applications.

Q: How is a diode structure represented in a diode laser diagram?

A: In a diode laser diagram, the diode structure typically shows the active layer or region where laser action occurs, sandwiched between p-type and n-type semiconductor materials. This structure is crucial for facilitating laser oscillation and controlling laser power.

Q: Why are laser diodes widely used in different applications?

A: Laser diodes are widely used because they are compact, efficient, and versatile. They find applications in laser printing, laser absorption spectroscopy, and high-power industrial applications, providing reliable laser power for various tasks.

Q: What is the significance of laser absorption in diode lasers?

A: Laser absorption refers to the process by which a material absorbs laser light, which is crucial in applications like laser absorption spectroscopy. Understanding laser absorption is essential for optimizing the performance and efficiency of diode lasers in specific applications.

Q: What role does the junction diode play in the functioning of diode lasers?

A: The junction diode in diode lasers forms the essential active region where electrons and holes recombine to produce spontaneous emission, which is then amplified to generate coherent laser light. The junction’s quality directly impacts the laser’s efficiency and power output.

Q: How do high-power laser diodes differ from low-power ones in their diagrams?

A: High-power laser diodes, as depicted in their diagrams, typically have enhanced cooling mechanisms, larger active regions, and robust diode structures to handle increased laser power. In contrast, low-power laser diodes have simpler structures and are used in applications requiring less power.

Q: What commercial laser applications utilize diode lasers?

A: Diode lasers are used in various commercial applications such as laser printing, optical communications, barcode scanning, and medical devices. Their efficiency, compact size, and reliability make them ideal for these purposes.

Q: Why is understanding laser gain important in a diode laser diagram?

A: Laser gain refers to the amplification of light within the laser material due to stimulated emission. Understanding laser gain is essential for designing and optimizing diode lasers to achieve the desired output power and efficiency for specific applications.