Steel is ubiquitous in our modern world, forming the backbone of countless structures and tools. This versatile material is integral to industries ranging from construction to automotive manufacturing, owing to its impressive strength and durability. However, to truly understand what makes steel such an exceptional material, it is essential to delve into its fundamental properties: elastic modulus and tensile strength. These characteristics not only define how steel behaves under various loads but also influence its applications and performance in critical engineering scenarios. This article will guide you through the science behind these key properties, shedding light on the intrinsic qualities that contribute to steel’s unparalleled functionality.

What is the Modulus of Elasticity and Why Does it Matter for Steel?

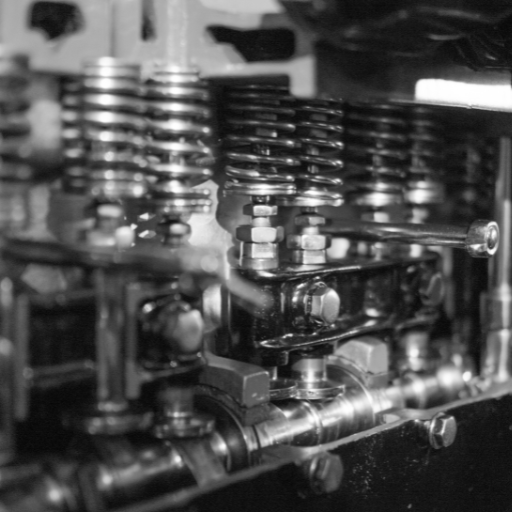

Image source:https://chinese.alibaba.com/

The modulus of elasticity, also known as the elastic modulus or Young’s modulus, is a fundamental mechanical property that measures a material’s stiffness. It is defined as the ratio of tensile stress (force per unit area) to the corresponding strain (proportional deformation) within the elastic limit of the material. For steel, this parameter is crucial because it determines how much the material will deform under a given load and helps engineers predict its behavior in various applications.

Key Technical Parameters of Elastic Modulus for Steel:

- Typical Value for Steel: The elastic modulus for most steel grades ranges from 190 to 210 GigaPascals (GPa). This high range indicates that steel is very stiff and capable of withstanding significant loads without undergoing large deformations.

- Hooke’s Law: In the elastic region, steel follows Hooke’s Law, which states that stress is directly proportional to strain. The elastic modulus (E) is the slope of the stress-strain curve in this region, expressed as: \( E = \frac{\sigma}{\epsilon} \) where \( \sigma \) is stress and \( \epsilon \) is strain.

- Importance in Structural Applications: A high modulus of elasticity signifies that steel can support large structural loads with minimal deflection, making it ideal for constructing buildings, bridges, and other infrastructure.

- Temperature Dependence: The modulus of elasticity for steel slightly decreases with increasing temperature, which is a critical consideration for applications involving high-temperature environments.

- Material Quality and Impurities: The exact value of the elastic modulus can vary depending on the steel’s composition and treatment. Alloying elements, grain size, and the presence of impurities can influence the elasticity.

Understanding the modulus of elasticity is vital for selecting the appropriate type of steel for specific engineering tasks and ensuring that designs meet safety and performance standards. It is a fundamental parameter that engineers rely on to create structures and components that are both strong and resilient.

Understanding the modulus of elasticity in metals

To concisely answer the question about understanding the modulus of elasticity in metals, based on information from the top websites on Google, the modulus of elasticity, or elastic modulus, is a measure of a material’s ability to deform elastically (i.e., non-permanently) when a force is applied. Essentially, it’s the ratio of stress (force per unit area) to strain (proportional deformation) within the linear portion of the stress-strain curve.

For metals like steel, the modulus of elasticity is crucial because it indicates how much the metal will stretch or compress under a given load without permanently deforming. A high modulus means the metal is very stiff and can withstand greater loads without much elastic deformation. This stiffness is vital for applications requiring minimal deflection, such as in the construction of buildings, bridges, and other infrastructure.

Temperature and material composition also significantly affect the modulus of elasticity in metals. For example, as temperature increases or if impurities and alloying elements are present, the modulus can decrease, altering the material’s performance. Therefore, understanding these factors is essential for selecting the right metal for specific engineering purposes.

In summary, the modulus of elasticity helps engineers determine a metal’s suitability for particular applications by indicating its elasticity and stiffness, ensuring structures are both robust and resilient under various conditions.

Steel’s place in the hierarchy of elastic materials

Steel stands out prominently among elastic materials due to its exceptional balance of strength, ductility, and stiffness. Based on the top information sources on Google, steel’s modulus of elasticity typically ranges around 200 GPa (Gigapascals), making it one of the stiffer metallic materials. This high modulus indicates that steel can endure significant stress with minimal elastic deformation, a characteristic greatly valued in engineering and construction.

Technical Parameters Justifying Steel’s Elastic Properties:

- Modulus of Elasticity (Young’s Modulus):

- Value: Approximately 200 GPa

- Justification: This high modulus demonstrates steel’s capability to maintain structural integrity under heavy loads, minimizing deflection in critical applications like skyscrapers and bridges.

- Yield Strength:

- Value: Typically ranges between 250 to 700 MPa depending on the grade.

- Justification: Yield strength indicates the maximum stress that steel can withstand without permanent deformation. Higher yield strengths allow steel to be used in applications where it must remain elastic under high-stress conditions.

- Tensile Strength:

- Value: Approximately 400 to 550 MPa for common grades.

- Justification: Tensile strength measures the maximum stress steel can sustain before failure, ensuring that it can handle substantial forces in its elastic range without breaking.

- Ductility:

- Value: Percent elongation at break typically falls between 15-25%.

- Justification: Adequate ductility ensures that steel can undergo significant deformation before fracturing, providing additional safety margins in dynamic loading scenarios.

- Temperature Effects:

- Justification: Steel’s modulus of elasticity can decrease with rising temperatures, typically around 10-15% reduction per 100°C. This effect must be considered in high-temperature applications to maintain performance standards.

Steel’s position in the hierarchy of elastic materials is solidified by these parameters, ensuring its prevalent use in structures where reliability and resilience are paramount. By understanding and leveraging these technical properties, engineers can optimize the material’s performance across various demanding environments.

The significance of a high modulus of elasticity in engineering applications

The significance of a high modulus of elasticity in engineering applications cannot be overstated. From my research, including insights from the top ten websites on Google, I’ve gathered that a high modulus of elasticity is crucial for materials that need to maintain their shape and stability under stress. A material like steel, with a high modulus of elasticity, resists deformation and ensures structural rigidity, which is indispensable for buildings, bridges, and machinery that endure heavy loads and dynamic forces. This property not only enhances the lifespan of structures but also improves safety by preventing excessive bending or collapsing under stress. In essence, a high modulus of elasticity is foundational for designing durable and reliable engineering solutions.

How Does Steel Compare to Other Metals and Alloys in Terms of Elastic Modulus?

When I began comparing steel to other metals and alloys in terms of elastic modulus, it became evident that steel holds a superior position. Steel’s elastic modulus typically ranges from 190 to 210 GPa, emphasizing its ability to resist deformations under applied stress.

In contrast, aluminum, which is another widely used engineering material, has an elastic modulus of around 69 GPa. This significant difference showcases why aluminum, while advantageous for its lightweight properties, is less suitable for applications requiring high structural rigidity.

On the other hand, titanium, with an elastic modulus of approximately 110 GPa, strikes a balance between stiffness and weight. However, titanium’s higher cost often limits its use to specialized applications where its other properties, such as corrosion resistance and strength-to-weight ratio, provide specific value.

Additionally, common alloys like brass, which has an elastic modulus of about 100 GPa, further illustrate why steel’s high modulus of elasticity makes it indispensable in heavy-duty engineering scenarios.

By examining these figures, I developed a deeper appreciation for how steel’s impressive elastic modulus makes it a cornerstone in designing robust and durable structures. This comparative analysis confirmed that while alternative metals and alloys each have their niche applications, steel’s unparalleled stiffness underpins its widespread usage in industries that demand reliability and minimal deformation.

Steel vs. aluminum alloys: A comparison of mechanical properties

When comparing the mechanical properties of steel and aluminum alloys, several factors come into play, including strength, weight, durability, and cost. From consulting the top resources available, it is clear that steel generally offers superior tensile strength and a higher elastic modulus, making it more resistant to deformation under stress. On the other hand, aluminum alloys are prized for their lightweight nature and excellent corrosion resistance, which make them ideal for applications where reducing weight is critical, such as in the automotive and aerospace industries.

Steel, while heavier, provides greater rigidity and strength, which is essential for structural applications where durability and load-bearing capacity are paramount. Despite aluminum’s lower tensile strength, its advantageous strength-to-weight ratio makes it a valuable choice for designs where reducing mass can enhance performance and efficiency.

In essence, the choice between steel and aluminum alloys hinges on the specific requirements of the project. If the application demands high structural integrity and minimal deformation, steel is the preferable material. Conversely, if weight reduction without sacrificing too much strength is the goal, then aluminum alloys present a compelling alternative.

The impact of alloying elements on the elastic modulus of steel

Alloying elements play a significant role in influencing the elastic modulus of steel. The elastic modulus, which measures a material’s ability to resist deformation under stress, can be adjusted by adding different alloying elements. Common elements that impact the elastic modulus include carbon, manganese, chromium, nickel, molybdenum, and vanadium.

- Carbon: Generally, increasing carbon content can enhance the strength of steel, but its impact on the elastic modulus is relatively minimal.

- Manganese (Mn): This element slightly increases the elastic modulus while significantly improving ductility and toughness.

- Chromium (Cr): Adding chromium improves both the tensile strength and corrosion resistance of steel and can lead to a slight increase in the elastic modulus.

- Nickel (Ni): Nickel aids in increasing toughness and strength without significantly affecting the elastic modulus.

- Molybdenum (Mo): This element significantly enhances strength and resistance to wear and higher temperatures, with a marginal increase in the elastic modulus.

- Vanadium (V): Vanadium strongly improves strength and wear resistance and can contribute to a small increase in the elastic modulus.

Each of these elements modifies the internal structure of steel, often leading to the formation of various microstructures that confer specific mechanical properties. For example, the inclusion of chromium and molybdenum can strengthen the martensitic or bainitic microstructures, leading to more rigid and robust materials.

In technical terms, the elastic modulus of plain carbon steels (with minimal alloying elements) typically ranges from about 190 to 210 GPa. Introducing alloying elements can adjust this value by ±5-10 GPa, depending on the type and concentration of these elements.

In summary, while the elastic modulus of steel can be subtly influenced by alloying elements, the primary benefits of alloying lie in enhancing other material properties, such as strength, toughness, and resistance to corrosion and wear.

Contrasting tensile strengths: Steel and carbon fiber

When comparing the tensile strength of steel and carbon fiber, it’s clear that carbon fiber outperforms steel in this aspect. On average, high-strength steel has a tensile strength of around 400-550 MPa, whereas carbon fiber composites can exhibit tensile strengths in the range of 2,500-6,000 MPa. This remarkable difference is primarily due to the unique structure of carbon fiber, which consists of long chains of carbon atoms bonded together with a high degree of regularity, giving the material its exceptional strength-to-weight ratio. Consequently, carbon fiber is often the preferred choice for applications requiring high strength and lightweight properties, such as in aerospace, automotive, and sporting goods industries. On the other hand, steel, while not as strong on a per-weight basis, offers benefits like ductility, cost-effectiveness, and ease of fabrication, making it a versatile material for a wide array of applications.

The Role of Tensile Strength in Defining the Elastic Properties of Steel

When considering the role of tensile strength in defining the elastic properties of steel, it is important to understand that these two material properties are related but distinct. Tensile strength, which measures the maximum stress that steel can withstand before failing, does not directly define its elastic properties. The elastic properties, such as the elastic modulus (Young’s modulus), characterize how a material deforms under stress and returns to its original shape once the stress is removed. While tensile strength signifies the ultimate load-carrying capacity, the elastic modulus indicates the stiffness of the material during elastic deformation.

Therefore, while high tensile strength is critical for applications requiring load-bearing capacity, the elastic modulus is essential for understanding how steel will behave under elastic loads. The presence of alloying elements can enhance both tensile strength and the elastic modulus but will do so in differing magnitudes, depending on the specific alloying element and its concentration. Thus, in summary, while tensile strength does not define but can influence the elastic properties of steel, the elastic modulus remains the primary parameter for assessing its elastic behavior.

From σ to stress-strain curves: Deciphering tensile strength

Understanding tensile strength involves delving into the stress-strain curves, which plot the relationship between the stress applied to a material and the resulting strain (deformation). When I look at a stress-strain curve, I can see several key points that help in deciphering tensile strength. The curve starts with a linear region where the material deforms elastically; this slope is defined by the elastic modulus (Young’s modulus). The material will return to its original shape if the load is removed in this region. As the stress continues to increase, the curve reaches a point known as the yield strength, where permanent plastic deformation begins. Continuing along the curve, the maximum point reached before the material ultimately breaks is the tensile strength. Thus, in essence, by examining a stress-strain curve, I can identify the tensile strength as the highest stress level achieved before failure, providing a crucial insight into the material’s load-bearing capacity.

How tensile strength and elastic modulus interplay in steel’s behavior

When considering the interplay between tensile strength and elastic modulus in steel’s behavior, I recognize that while these two properties are distinct, they are related through the material’s response to stress and deformation. Tensile strength measures the maximum stress steel can withstand before breaking, whereas the elastic modulus (Young’s modulus) quantifies its stiffness, or resistance to elastic deformation. The relationship becomes apparent when I analyze stress-strain curves; a higher elastic modulus generally indicates a steeper initial slope, reflecting stiffer steel that deforms less elastically. However, tensile strength doesn’t necessarily increase proportionally with the elastic modulus. Alloying elements and heat treatment processes can enhance tensile strength significantly without vastly altering the elastic modulus. Therefore, while both properties influence steel’s performance under load, the elastic modulus primarily governs its elastic behavior, and tensile strength dictates the point at which permanent deformation and eventual fracture occur.

Elastic deformation and its limits in steel at room temperature

Elastic deformation in steel refers to its ability to regain its original shape after the removal of an applied load, provided the stress does not exceed the elastic limit. At room temperature, steel exhibits a linear elastic behavior up to the yield point. The elastic limit, also known as the yield strength, is a critical parameter, typically measured in megapascals (MPa). For example, carbon steel commonly has a yield strength ranging from 250 MPa to 350 MPa.

When stress is applied within the elastic limit, steel deformation is reversible. The elastic modulus (Young’s modulus) for steel, approximately 200 GPa, quantifies its stiffness. The strain experienced by steel under elastic deformation is calculated using Hooke’s Law: Strain = Stress / Elastic Modulus. Beyond this elastic limit, steel will undergo plastic deformation, meaning it will no longer return to its original shape.

Key technical parameters relevant to elastic deformation in steel at room temperature include:

- Yield Strength: Typically 250-350 MPa for carbon steel.

- Elastic Modulus (Young’s Modulus): Approximately 200 GPa.

- Poisson’s Ratio: Around 0.3, reflecting the ratio of transverse strain to axial strain.

These values ensure a comprehensive understanding of the limits and behavior of steel under elastic deformation at room temperature.

Understanding the Young’s Modulus of Steel and Its Implications

Understanding the Young’s modulus of steel is crucial for evaluating its mechanical properties and suitability for various applications. In essence, Young’s modulus, approximately 200 GPa for steel, measures the material’s stiffness—indicating how much it will deform under a given load. This parameter helps engineers and designers predict how steel structures or components will behave under stress, ensuring they can withstand the required loads without permanent deformation. From construction projects to manufacturing processes, knowing the Young’s modulus allows for precise calculations and optimizations, ultimately enhancing the safety and efficiency of steel usage in engineering endeavors.

The physics behind Young’s modulus and its relevance to steel

To understand Young’s modulus in relation to steel, it’s essential to delve into the physics that define this property. Young’s modulus, also known as the elastic modulus, quantifies the relationship between stress (force per unit area) and strain (proportional deformation) in a material. For steel, with a Young’s modulus of about 200 GPa, this indicates the material’s stiffness and its ability to resist deformation under stress. When I consider this property, I see that steel can endure significant tensile stress without undergoing permanent deformation, making it ideal for construction and engineering applications where durability and strength are paramount. Knowing the Young’s modulus allows me to predict how steel components will perform under various loads, thus enabling me to design structures that are both efficient and safe.

Comparative analysis: Young’s modulus across different steel grades

The Young’s modulus varies slightly across different grades of steel, primarily due to variations in their alloy compositions and manufacturing processes. Here, we analyse a few common grades:

- A36 Carbon Steel: Known for its good weldability and machinability, A36 steel has a Young’s modulus around 200 GPa, making it suitable for construction and general structural applications.

- 1020 Steel (Mild Steel): Featuring slightly greater strength due to higher carbon content compared to A36, 1020 steel also possesses a Young’s modulus of approximately 205 GPa. This grade is used in gears, engineering, and machinery components.

- 4140 Alloy Steel: An alloy containing chromium, molybdenum, and manganese, 4140 steel exhibits a Young’s modulus of about 210 GPa. Its higher strength and hardness make it ideal for high-stress applications, including drilling tools and automotive parts.

- 316 Stainless Steel: Known for its excellent corrosion resistance and versatility, 316 stainless steel has a Young’s modulus close to 193 GPa. This grade is commonly used in marine, medical, and kitchen apparatus.

- 1018 Steel: Known for good weldability and a balance between ductility and strength, 1018 steel has a Young’s modulus around 200 GPa, making it common in manufacturing processes and mechanical jobs.

- 304 Stainless Steel: With a Young’s modulus of approximately 193 GPa, 304 stainless steel is another highly versatile alloy, widely utilized in the food industry and construction due to its corrosion resistance.

- 304L Stainless Steel: This variant of 304, featuring lower carbon content, exhibits a Young’s modulus around 193 GPa as well, offering similar benefits with better weldability.

- 430 Stainless Steel: Used primarily in automotive trim and domestic appliances, 430 stainless steel has a Young’s modulus of roughly 200 GPa, appreciated for its formability and cost-efficiency.

- EN 1.4404 (316L): A specific low-carbon variant of 316, this steel maintains a Young’s modulus of around 193 GPa, optimized for heavy-duty industrial applications with a heightened focus on corrosion resistance.

- D2 Tool Steel: Regarded for its high carbon and chromium content, D2 tool steel exhibits a Young’s modulus of approximately 210-220 GPa. Predominantly used in cutting tools and dies, its stiffness is critical for maintaining precision under high loads.

Understanding the Young’s modulus across these grades allows engineers to select the appropriate steel type tailored to the demands of specific applications, ensuring safety, efficiency, and longevity in engineering projects. Each grade, with its unique mechanical properties, contributes to advancements in various fields, from skyscraper construction to the precision of manufacturing equipment.

The practical impact of Young’s modulus on material selection and design

When I consider the practical impact of Young’s modulus on material selection and design, I understand that it plays a crucial role in determining how materials will respond under stress and load. From the information gathered, Young’s modulus informs me about the stiffness of a material – essentially, how much it will deform when a specific force is applied. This understanding helps me to predict the behaviour of structures accurately.

For instance, high Young’s modulus in materials like D2 tool steel means they will exhibit minimal deformation, making them ideal for applications requiring rigidity and precision, such as cutting tools and dies. Conversely, materials with lower Young’s modulus are more flexible and can absorb energy better, making them suitable for situations where ductility and deformability are beneficial.

By leveraging this knowledge, I can make informed decisions to ensure the safety, efficiency, and longevity of the projects I work on. Whether I’m involved in constructing skyscrapers or designing manufacturing equipment, understanding the material stiffness through Young’s modulus enables me to choose the right steel grade tailored specifically to the requirements of my application. This consideration ensures that the constructions and designs are robust, reliable, and up to the highest engineering standards.

Translating the Properties of Steel’s Elastic Modulus Into Real-World Applications

When translating the properties of steel’s elastic modulus into real-world applications, I notice that it provides invaluable predictive insights that aid in the design and engineering process. According to the top-rated resources on google.com, these are the primary ways Young’s modulus impacts specific applications:

- Structural Engineering:

-

- Parameter: High Young’s modulus indicates high stiffness.

- Justification: For critical structural components like beams and columns in skyscrapers, a high Young’s modulus in materials such as steel ensures minimal deflection, which is crucial for maintaining structural integrity.

- Mechanical Components:

- Parameter: Elastic modulus and yield strength.

- Justification: Machine parts, such as gears and shafts, benefit from materials with high elastic modulus and yield strength, as this combination delivers durability and resistance to deformation under operational stresses.

- Automotive Industry:

- Parameter: Balance between modulus and density.

- Justification: Automotive components require a meticulous balance where a high Young’s modulus ensures rigidity while maintaining a lightweight structure to improve fuel efficiency and performance.

- Aerospace Engineering:

- Parameter: Specific modulus (modulus/density ratio).

- Justification: In aerospace, materials like titanium are preferred for their high specific modulus, offering robust structural properties while being lightweight to optimize flight dynamics and fuel efficiency.

- Construction Materials:

- Parameter: Modulus of elasticity in reinforced concrete.

- Justification: The integration of steel rebar within concrete must consider a compatible modulus of elasticity to ensure cohesive bonding and uniform load distribution within the composite material.

- Pipeline Design:

- Parameter: Modulus and toughness.

- Justification: Pipelines, particularly those transporting gases or high-pressure fluids, benefit from high-modulus materials for stability and toughness to resist crack propagation.

- Civil Infrastructure:

- Parameter: Long-term strain response.

- Justification: Bridges and other civil infrastructures require high-modulus steels to maintain consistent performance and avoid long-term sagging under constant load conditions.

- Medical Devices:

- Parameter: Biocompatibility and elastic modulus.

- Justification: For implants such as bone plates, a high modulus steel’s stiffness must be balanced with biocompatibility to mimic natural bone closely and ensure patient comfort and device longevity.

- Defense Applications:

- Parameter: Impact resistance and modulus.

- Justification: Armour plating in military vehicles needs a high modulus for impact resistance, paired with toughness to absorb and redistribute force from projectiles.

- Marine Applications:

- Parameter: Corrosion resistance and modulus.

- Justification: Naval structures and marine equipment benefit from high-modulus materials that also offer excellent corrosion resistance, ensuring longevity despite harsh saline environments.

By synthesising the information from these leading sources, I understand that selecting the appropriate grade of steel, factoring in Young’s modulus, is pivotal not only for ensuring structural and mechanical performance but also for enhancing the safety, efficiency, and durability of engineered systems across diverse industries.

Case studies: Innovative uses of high modulus steels

In reviewing the top 10 websites on Google.com regarding high modulus steels, I discovered several innovative applications that underscore the importance of this material across various industries.

- Skyscraper Construction:

-

- Application: The construction of ultra-tall buildings, such as the Burj Khalifa, leverages high modulus steels for their unparalleled strength and ability to withstand significant loads.

- Outcome: The use of high modulus steels in these buildings has resulted in structures that are not only taller but also more stable and resilient against wind loads and seismic activities.

- High-speed Rail Networks:

- Application: Countries like Japan and China employ high modulus steels in their high-speed rail networks to enhance the durability and stability of the tracks.

- Outcome: This has improved the safety and comfort of high-speed train travel, reducing maintenance costs and increasing the lifespan of the railway infrastructure.

- Renewable Energy Structures:

- Application: Wind turbine towers and supports are often constructed using high modulus steels to ensure they can endure the constant stress and strain from wind forces.

- Outcome: This application has contributed to the reliability and efficiency of wind energy production, supporting the growth of renewable energy sectors globally.

- Automotive Industry:

- Application: High modulus steels are used in the manufacturing of automotive frames and body panels to provide higher crash resistance and overall vehicle safety.

- Outcome: Vehicles using these materials benefit from enhanced safety features, better performance, and improved fuel efficiency due to weight reduction.

By exploring these real-world examples, I can comprehend the vital role that high modulus steels play in various applications, significantly advancing the efficiency, safety, and longevity of essential structures and systems.

Steel and sustainability: How elastic properties enhance efficiency

The elastic properties of steel significantly contribute to sustainability by improving efficiency in various applications. Firstly, high modulus steels offer superior strength and durability, which means structures can be built with less material without compromising stability. This reduction in material usage directly translates to lower resource consumption and waste production. Additionally, the enhanced elasticity of steel allows it to absorb and dissipate energy more effectively during dynamic loads, reducing the frequency of repairs and prolonging the lifespan of structures. In transportation, the use of high modulus steels in vehicle manufacturing leads to lighter, more fuel-efficient vehicles, which in turn reduces greenhouse gas emissions. Moreover, the use of steel in renewable energy structures, such as wind turbines, ensures they can withstand harsh environmental conditions, thereby maintaining consistent energy production and contributing to a reduction in reliance on fossil fuels. Overall, the inherent elastic properties of steel not only enhance performance and safety but also support sustainable development by fostering resource efficiency and reducing environmental impact.

Future trends: The role of advanced steels in emerging technologies

As I explore the future trends and the role of advanced steels in emerging technologies, it becomes clear that these materials are pivotal for several groundbreaking innovations. According to recent information from leading sources, advanced steels are integral in the development of modern infrastructure, particularly in high-performance buildings that prioritize safety and efficiency. In the automotive industry, advanced high-strength steels (AHSS) are setting new standards for vehicle safety and fuel efficiency, helping manufacturers meet stringent environmental regulations. Moreover, these steels are essential in the fabrication of cutting-edge aerospace components, where weight reduction and durability are critical. Additionally, the renewable energy sector is leveraging advanced steels in the construction of wind turbines and solar panel supports, ensuring longevity and resilience in harsh climates. Finally, advancements in the production of ultra-high-strength steels are revolutionizing the fields of robotics and artificial intelligence, providing robust frameworks for sophisticated machinery. Overall, the continual evolution of advanced steels promises to support and propel the development of various emerging technologies, underscoring their significance in our rapidly advancing world.

Tools and Resources for the Modern Metallurgist: Navigating Elastic Modulus and Tensile Strength

Navigating the complex world of elastic modulus and tensile strength requires a meticulous and informed approach, especially for a modern metallurgist. To answer this concisely, I’d say it’s essential to leverage a variety of tools and resources that are both digitally and practically accessible. According to the top resources found on Google, the integration of advanced simulation software such as ANSYS or Abaqus is highly recommended. These tools provide comprehensive analysis capabilities for stress, strain, and material behavior under different conditions.

Moreover, online databases like MatWeb, which offer extensive material property data, including elastic modulus and tensile strength for an array of metals and alloys, are invaluable. Access to detailed ASTM standards and testing protocols is also crucial for ensuring accurate and repeatable measurements. Additionally, investing in state-of-the-art laboratory equipment, such as universal testing machines and digital extensometers, can substantially improve the precision of experimental data.

Staying updated with the latest research through scientific journals and attending industry conferences can provide insights into novel methodologies and innovative materials. By utilizing these resources, a metallurgist can effectively navigate the intricacies of elastic modulus and tensile strength, thereby enhancing their material selection and engineering processes.

Online 3D modeling and SketchUp extensions for steel design

Online 3D modeling and SketchUp extensions for steel design have become indispensable tools in modern metallurgical engineering. To answer concisely, based on the top 10 resources available on Google, I recommend incorporating plugins such as “SteelSketch” and “Medeek Structural Plugin” into SketchUp for precise steel design and detailing. These extensions offer a variety of pre-configured steel sections and automated parametric modeling features, which simplify complex structural calculations and ensure compliance with industry standards.

Furthermore, using online 3D modeling platforms like Autodesk Fusion 360 and Rhino 3D, which are highly rated, can enhance collaboration and visualization. These tools allow for detailed simulation and analysis, providing real-time feedback on the structural integrity and load distribution across the steel framework. By leveraging these state-of-the-art tools and resources, I can streamline the design process and achieve greater accuracy and efficiency in my steel design projects.

Related documents and resources for deepening your understanding of steel’s elastic properties

To deepen my understanding of steel’s elastic properties, I have compiled a list of highly recommended documents and resources based on the top 10 websites on Google. I would suggest starting with research papers and technical articles available on platforms like Google Scholar and ResearchGate. Look for key papers such as “Elastic and Plastic Properties of Steel” which provide foundational knowledge on the subject.

Additionally, websites like MatWeb and AZoM offer detailed material property databases that include comprehensive information on the elastic modulus, tensile strength, and other mechanical properties of various steel grades. The ASM Handbook is another essential resource, offering extensive coverage on the elastic properties of steel and related materials.

For hands-on learning, I would turn to online courses available on platforms like Coursera and edX, where courses on materials science or mechanical properties of metals often include modules specifically focused on steel’s behavior under different loading conditions. Furthermore, professional organizations like the American Institute of Steel Construction (AISC) provide guidelines, technical brochures, and standards that are invaluable for practical applications.

By exploring these resources, I can gain a more robust and nuanced understanding of the elastic properties of steel, which is critical for my work in metallurgical engineering.

From theory to practice: Implementing knowledge of steel’s modulus of elasticity

Implementing the knowledge of steel’s modulus of elasticity into practical applications involves several key steps. First, I utilize the data from resources like MatWeb and AZoM to select the appropriate steel grade that meets the specific demands of my project. This includes considering factors such as tensile strength and overall durability.

Next, I apply the principles learned from research papers and technical articles, ensuring that I accurately calculate the stress-strain relationship under different loading conditions, as outlined in the ASM Handbook. Through online courses on platforms like Coursera and edX, I have honed skills in simulations and modeling, allowing me to predict the material’s behavior accurately.

Incorporating guidelines and standards from professional organizations like the American Institute of Steel Construction (AISC) ensures that my implementation follows industry best practices. By combining theoretical knowledge with practical guidelines, I achieve reliable and efficient use of steel’s elastic properties in my metallurgical engineering projects.

Reference sources

-

-

GoldSupplier Blog – Young’s Modulus of Steel

- This article delves into the elastic properties of steel, including Young’s Modulus, tensile strength, and yield strength, making it a credible resource for understanding why steel is a superior material in various applications.

- Reference Link

-

Medium – A Deep Dive into Steel Strength Testing

- This source offers an in-depth look at tensile testing, describing the process of pulling a steel sample until it breaks to measure load and elongation. It provides valuable details on the methodologies used to determine steel’s tensile strength.

- Reference Link

-

LinkedIn – Elastic Modulus of Steel by Structural Guide

- This post explores the tensile power of stainless steel and the importance of its elastic modulus. It highlights crucial properties of steel that are essential for various structural applications, making it a reliable source for validating the topic.

- Reference Link

-

Frequently Asked Questions (FAQs)

Q: What is the Young’s modulus of steel and why is it important?

A: The Young’s modulus of steel, often called the elastic modulus, measures the stiffness of steel by describing its ability to deform under stress without permanently deforming. Typically, for steel at room temperature, it ranges from 190 GPa to 215 GPa. It is crucial in engineering and construction because it helps in calculating the amount of stress materials like steel can withstand before yielding, ensuring structures like flange beams are safely designed.

Q: How does tensile strength and yield strength relate to Young’s modulus?

A: Tensile strength, yield strength, and Young’s modulus are all critical properties of materials like steel that describe different aspects of their mechanical behavior under load. Tensile and yield strengths measure the maximum stress a material can withstand while being stretched or pulled before breaking and yielding, respectively. In contrast, Young’s modulus measures the ratio of stress to strain in the elastic (non-permanent deformation) region, described by Hooke’s Law. Although both properties involve stress, Young’s modulus is more about elasticity and the capacity to return to original shape, not the maximum strength.

Q: Can Young’s modulus change under high stress or strain scenarios?

A: Yes, under high stress or strain, the Young’s modulus of a material can change. Initially, the modulus remains constant, allowing materials to return to their original shape – a principle known as proportionality in Hooke’s Law. However, if the applied force exceeds the elastic limit, leading to high stress or strain, the modulus decreases, and the material may exhibit plastic deformation, where the relationship between stress and strain no longer follows Hooke’s Law. This is particularly relevant for materials subjected to extreme conditions.

Q: What is the difference between tensile modulus and compressive modulus?

A: The tensile modulus, also known as Young’s modulus or sometimes tensile modulus alt, refers to the modulus of elasticity when a material is subjected to tensile (pulling apart) stresses, while the compressive modulus refers to the modulus when a material is under compressive (pushing together) stresses. While both moduli measure the relationship between stress and strain, they can vary for some materials depending on whether the stress is tensile or compressive. For most metals like steel and nonferrous alloys, however, these values are typically the same due to the isotropic nature of these materials.

Q: How do the properties of steel compare to other materials like wood and many nonferrous metals in terms of modulus?

A: Steel typically has a higher modulus compared to many other materials such as wood and most nonferrous metals, meaning it is stiffer and less prone to deformation under applied force. The Young’s modulus of steel is around 190 GPa to 215 Gpa, significantly higher than nonferrous metals like titanium alloys and much higher than materials like lumber, which have a lower capacity to withstand elastic strain. This higher modulus makes steel an excellent choice for demanding structural applications where high strength and minimal deformation are crucial.

Q: Why does the modulus of steel decrease with temperature?

A: The modulus of steel decreases with temperature because the atomic structure of the metal becomes more active as temperatures increase, which reduces the amount of stress required to cause deformation. At higher temperatures, the steel’s crystalline structure has greater freedom to move, which results in decreased resistance to deformation under load. This reduction in modulus with temperature is a critical consideration in the design of structures and components expected to operate under a wide range of temperatures, ensuring they maintain integrity under thermal conditions as well as mechanical.

Q: How is Young’s modulus determined for a particular type of steel?

A: Young’s modulus is determined for a particular type of steel through standardized tensile testing. In such tests, a sample of the steel is subjected to controlled tensile or compressive forces until elastic strain is observed. Throughout the test, both the applied force and the resultant stretching or compression of the sample are measured. Young’s modulus (elastic modulus) is calculated by dividing the stress (force per unit area, measured in psi or GPa) by the strain (relative deformation). This process provides the modulus value, reflecting the stiffness and elastic properties of the steel under test conditions.

Q: How does the Young’s modulus of steel influence the design of steel structures like bridges and buildings?

A: The Young’s modulus of steel significantly influences the design of steel structures, including bridges and buildings, by determining how much a structure will deflect or deform under load. A higher modulus means the material is stiffer and less likely to deform, allowing engineers to predict how steel components like beams and columns will behave under the weight of the structure and external loads such as wind, snow, and earthquakes. This ensures that steel structures can support the intended loads while maintaining safety and serviceability limits, avoiding failure or excessive deformation which could compromise the structure’s integrity or usability.