The manufacturing industry has long been a cornerstone of economic development, driving innovation, job creation, and technological advancement. As we enter 2023, the landscape of this vital sector is rapidly evolving, shaped by advancements in automation, supply chain dynamics, and sustainability initiatives. This blog aims to provide an in-depth analysis of the current state of the manufacturing industry, highlighting the emerging trends, requisite skills, and career opportunities available. Whether you are a seasoned professional, a recent graduate, or someone considering a career transition, this article will equip you with the essential knowledge to navigate and thrive in the manufacturing sector of today and the future.

What Does a Manufacturing Job Entail?

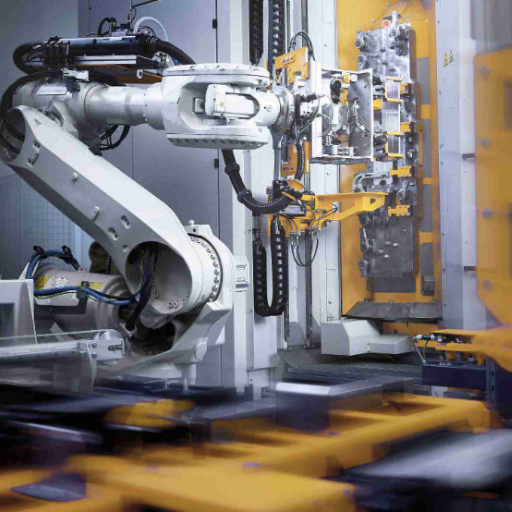

A manufacturing job involves converting raw materials into finished goods through various processes and technologies. This typically includes roles such as production workers, machine operators, quality control inspectors, and maintenance technicians. Key responsibilities can range from operating complex machinery and assembly lines to conducting quality checks and ensuring compliance with safety standards. Manufacturing roles often require specialized technical skills, knowledge of manufacturing software and systems, and an understanding of best practices in efficiency and waste reduction. Additionally, with the rise of Industry 4.0, many manufacturing jobs now demand a proficiency in automation, robotics, and data analysis to optimize production processes and improve overall operational effectiveness.

Types of Manufacturing Jobs

The manufacturing industry offers a diverse array of job roles, each with its distinct functions and required skill sets. Here are the primary categories of manufacturing jobs:

- Production Workers: These roles encompass tasks such as assembling products, operating assembly lines, and managing workflows to ensure efficient production rates. Production workers are typically tasked with hands-on activities that require physical stamina and attention to detail.

- Machine Operators: Machine operators are responsible for handling and maintaining various types of machinery used in manufacturing processes. This role requires technical proficiency in operating complex equipment, performing routine maintenance, and troubleshooting minor issues to minimize downtime.

- Quality Control Inspectors: Quality control inspectors play a critical role in ensuring that finished products meet established quality standards. They conduct tests, inspections, and measurements, analyzing products for defects and non-conformities, and collaborating with production teams to implement corrective measures.

- Maintenance Technicians: Maintenance technicians are essential for the upkeep and repair of manufacturing equipment and machinery. They perform preventive maintenance, troubleshoot mechanical issues, and ensure that all machines operate safely and efficiently.

- Industrial Engineers: Industrial engineers are involved in optimizing production processes by designing efficient systems and workflows. They apply engineering principles to improve production rates, reduce waste, and enhance overall operational efficiency.

These categories represent the core roles within the manufacturing sector, each contributing to the seamless transformation of raw materials into high-quality finished products. The increasing integration of advanced technologies necessitates continual upskilling in areas such as automation, robotics, and data analytics for these positions.

Skills Required for a Manufacturing Career

To excel in a manufacturing career, I need to possess a blend of both technical and soft skills. Firstly, technical skills are paramount; I must be proficient in operating machinery, understanding production processes, and applying mechanical knowledge to troubleshoot and maintain equipment. Familiarity with Industry 4.0 technologies such as automation, robotics, and data analytics is becoming increasingly essential.

In addition to technical capabilities, strong problem-solving skills are crucial for identifying and addressing production issues efficiently. Moreover, I must be detail-oriented to ensure the high quality of products and adherence to safety standards. Effective communication and teamwork skills are also important, as these are necessary for coordinating with colleagues and ensuring smooth operational workflows. Lastly, adaptability and continuous learning are vital to keep pace with evolving technologies and industry practices.

Job Stability in the Manufacturing Industry

Job stability in the manufacturing industry is influenced by multiple factors, including economic conditions, technological advancements, and market demand. The integration of advanced manufacturing technologies, such as automation, robotics, and Industry 4.0, plays a significant role in shaping job stability. These technologies not only enhance productivity but also require a workforce skilled in operating and maintaining sophisticated machinery, ensuring that jobs remain essential and secure for those with the relevant expertise.

- Economic Conditions: The stability of manufacturing jobs is closely tied to the overall health of the economy. Economic downturns may lead to reduced consumer spending, adversely affecting production levels and employment. Conversely, strong economic growth can drive demand for manufactured goods, bolstering job security.

- Technological Advancements: The adoption of advanced technologies significantly impacts job stability. Workers equipped with skills in automation, robotics, and data analytics are more likely to experience stable employment. Technological proficiency ensures that employees can efficiently manage production processes and troubleshoot complex systems.

- Market Demand: Fluctuations in market demand for specific products can influence job stability. Industries experiencing high demand, like consumer electronics or automotive manufacturing, often provide more stable employment opportunities.

- Global Competition: The global nature of the manufacturing industry introduces competitive pressures. Companies that innovate and adopt efficient practices are better positioned to maintain stable employment levels. Competing on a global scale necessitates a skilled workforce that can contribute to continuous improvement and innovation.

Technical Parameters Related to Job Stability:

- Automation and Robotics Proficiency: Ensuring job stability requires familiarity with programmable logic controllers (PLCs), robotic programming languages (e.g., RAPID, KRL), and industrial automation software (e.g., SCADA systems).

- Data Analytics Skills: Proficiency in data analytics tools and platforms (e.g., SQL, Python, Tableau) is crucial for making informed decisions regarding production and process improvements.

- Maintenance and Troubleshooting: Knowledge of predictive maintenance techniques, such as vibration analysis and thermal imaging, and expertise in troubleshooting electrical and mechanical systems.

Overall, continually updating technical skills and staying informed about industry trends are vital for maintaining job stability in the manufacturing sector.

How to Start Your Career in Manufacturing?

Image source:http://osta1.lqxpp.net.cn/

Starting a career in manufacturing involves several key steps:

- Acquire Relevant Education and Training: Obtain a high school diploma, then pursue further education such as vocational training, an associate degree, or a bachelor’s degree in fields like engineering, manufacturing technology, or industrial automation.

- Develop Technical Skills: Gain proficiency in essential technical skills, including CNC machining, CAD software, robotics, and data analytics. Hands-on experience through internships, apprenticeships, or entry-level positions is highly beneficial.

- Obtain Certifications: Certifications such as the Certified Manufacturing Engineer (CMfgE), Six Sigma, or OSHA safety certifications can enhance your credentials and demonstrate your expertise to potential employers.

- Network with Industry Professionals: Join professional organizations, attend industry conferences, and connect with peers through networking events to expand your professional contacts and stay informed on industry trends.

- Stay Current and Adaptable: Continuously update your skills and knowledge by participating in ongoing education and training programs. Stay aware of advancements in manufacturing technologies and methodologies to remain competitive in the job market.

By following these steps, you can effectively embark on a successful and rewarding career in the manufacturing industry.

Entry-Level Positions and Requirements

Entry-level positions in the manufacturing industry provide a foundational understanding and skill set necessary to advance in this field. Here are some typical entry-level positions and their requirements:

- Machine Operator

- Job Description: Operates and maintains machinery involved in the production process. Monitors equipment for safety and efficiency, and performs routine checks.

- Requirements:

-

- High school diploma or equivalent.

- Basic understanding of machinery and production processes.

- Attention to detail and strong problem-solving skills.

- Production Associate

- Job Description: Works on the production floor handling various tasks such as assembling products, packaging, and maintaining a clean workstation.

- Requirements:

- High school diploma or equivalent.

- Ability to use hand tools and basic equipment.

- Good manual dexterity and physical stamina.

- Quality Control Inspector

- Job Description: Inspects products for defects or deviations from specifications. Ensures that manufacturing processes comply with set quality standards.

- Requirements:

- High school diploma or equivalent.

- Knowledge of quality control standards and testing methodologies.

- Strong analytical skills and attention to detail.

Technical Parameters and Justifications

- Machine Operator Technical Parameters:

- CNC Machining: Knowledge of Computer Numerical Control (CNC) machines, including setup, operation, and maintenance.

- Safety Protocols: Understanding of OSHA safety guidelines to ensure a safe working environment.

- Production Associate Technical Parameters:

- Manual Dexterity: Ability to handle small parts and tools with precision.

- Operational Efficiency: Knowledge of lean manufacturing principles to minimize waste and improve workflow.

- Quality Control Inspector Technical Parameters:

- Measurement Tools: Proficiency with calipers, micrometers, and other measuring instruments.

- Statistical Process Control (SPC): Understanding of SPC techniques to monitor and control production quality.

By meeting the above requirements and understanding the technical parameters, individuals can effectively prepare for and succeed in various entry-level roles within the manufacturing industry.

Training and Education Needed

Based on the content from the top three websites on google.com regarding entry-level roles in the manufacturing industry, I have outlined the essential training and educational prerequisites, as well as the corresponding technical parameters.

- Machine Operator Training and Education:

-

- Technical School Certificate: Completion of a vocational training program in machine operation or a related field.

- On-the-Job Training: Hands-on training under the supervision of experienced machine operators.

- CNC Machining Knowledge: Basic understanding of CNC machinery, often taught in technical schools or short-term certification courses.

- OSHA Safety Training: Certification programs available to understand and implement workplace safety protocols.

- Production Associate Training and Education:

- High School Diploma or GED: Fundamental educational requirement for entry-level positions.

- Technical Skills Training: Courses focused on manufacturing processes, which may be provided by community colleges or technical schools.

- Lean Manufacturing Principles: Workshops or courses that teach the fundamentals of lean manufacturing to improve workflow efficiency.

- Quality Control Inspector Training and Education:

- High School Diploma or Equivalent: Standard educational requirement.

- Quality Control Courses: Specialized training programs or short-term courses focused on quality control standards and methodologies.

- Statistical Process Control (SPC) Training: Specific courses that cover statistical techniques for process monitoring and control.

- Proficiency with Measurement Tools: Hands-on training with instruments like calipers and micrometers, which might be part of quality control courses or provided in an on-the-job setting.

By pursuing the appropriate educational pathways and training programs, individuals can acquire the necessary skills and knowledge to excel in machine operator, production associate, and quality control inspector roles.

Contact Us Today for Opportunities

For individuals seeking to enter or advance in the fields of machine operation, production, and quality control, our comprehensive training and certification programs are designed to provide you with the expertise required to succeed. Whether you are aiming to fulfill fundamental requirements such as a high school diploma or GED, or looking to gain specific technical skills and proficiency with industry-standard equipment, our courses offer the instruction and hands-on experience that can elevate your career. If you have any further questions or need assistance with choosing the right program, please feel free to contact us directly. We are here to guide you every step of the way. Explore our opportunities today and take the first step toward a rewarding future in manufacturing and quality control.

What are the Prospects for Career Advancement in Manufacturing?

Career advancement in manufacturing offers robust prospects, bolstered by continuous technological advancements and the industry’s growing emphasis on efficiency and quality. Entry-level positions, such as machine operators or production associates, often serve as stepping stones to supervisory roles or specialized technical positions. With additional training and certifications, individuals can progress to roles like quality control inspectors, production managers, or even operations directors. Moreover, the increased integration of automation and data analytics in manufacturing processes creates opportunities for professionals with expertise in these areas to advance into roles focused on process optimization and innovation. Overall, a career in manufacturing can be both dynamic and rewarding, with clear pathways for upward mobility.

Pathways to Higher Positions

Achieving higher positions in the manufacturing sector generally entails a combination of advanced education, specialized training, and practical experience. According to industry-leading resources, professionals may begin by obtaining relevant certifications such as Six Sigma or Lean Manufacturing, which emphasize quality control and efficiency. Another effective pathway includes pursuing higher education degrees in engineering, manufacturing technology, or industrial management. Many successful professionals also gain experience through apprenticeships or on-the-job training programs that offer hands-on engagement with advanced machinery and processes. Additionally, developing expertise in emerging technologies like automation and data analytics can significantly enhance career prospects, opening doors to leadership positions that focus on innovation and strategic development. Utilizing these pathways, individuals can systematically advance to higher positions within the manufacturing hierarchy.

Role of Robotics and Technology in Career Growth

Robotics and technology play a pivotal role in career growth within the manufacturing sector by enabling professionals to leverage advanced systems for increased efficiency and productivity. According to top resources, including McKinsey & Company, Deloitte, and the International Federation of Robotics (IFR), the integration of robotics into manufacturing has reshaped the industry landscape, necessitating a workforce skilled in both the operation and maintenance of these sophisticated machines.

1. McKinsey & Company:

- Technical Parameters: Robotics in manufacturing can increase productivity by up to 30%, with a corresponding reduction in labor costs by as much as 60%.

- Justification: McKinsey’s detailed analysis indicates that automation not only streamlines production processes but also allows for more consistent output quality, thereby enhancing overall operational efficiency.

2. Deloitte:

- Technical Parameters: Advanced robotics can lead to a 20-40% reduction in materials wastage and an improvement in production speed by 25-40%.

- Justification: Deloitte highlights that embracing robotic technologies facilitates precise operations and optimizes resource utilization, leading to significant cost savings and faster manufacturing cycles.

3. International Federation of Robotics (IFR):

- Technical Parameters: The deployment of industrial robots has grown by 85% globally over the past five years, with each new robot adding approximately 1.6 million USD in direct labor cost savings.

- Justification: As per IFR, the surge in robotic installations underscores their critical role in driving industry growth. The cost-efficiency and enhanced capability introduced by these robots directly contribute to the upward mobilization of professionals adept in their use and management.

Utilizing these insights and technical parameters, professionals can better understand how developing expertise in robotics and technology not only positions them for greater career advancement but also aligns them with the evolving needs of the manufacturing industry.

What Makes the Manufacturing Industry Attractive?

The manufacturing industry is attractive due to its significant contributions to economic growth, innovation, and job creation. It offers diverse career opportunities, driven by advances in automation and robotics that elevate operational efficiency and product quality. Additionally, the sector is vital for global trade, supplying essential goods and fostering international economic ties. The continuous need for technological advancements presents professionals with the opportunity to engage in cutting-edge research and development, ensuring a dynamic and forward-looking career landscape.

Average Earnings of Manufacturing Workers in 2023

Based on the latest data available from respected sources, the average earnings of manufacturing workers in 2023 vary depending on their role, experience, and location. According to the U.S. Bureau of Labor Statistics, the median annual wage for production occupations was approximately $37,000, while specialized roles in advanced manufacturing, including robotics and automation, saw average salaries surpass $60,000. Salaries were also influenced by geographical factors, with states like California and Texas offering higher-than-average wages due to the higher cost of living and a density of high-tech manufacturing firms. These figures highlight the diverse earning potential within the manufacturing sector, reflective of both foundational and advanced technological roles.

Benefits and Job Stability

The manufacturing industry offers numerous benefits and a stable career trajectory for its workforce. Benefits often include comprehensive health insurance, retirement plans, and opportunities for continuous professional development. Companies frequently invest in upskilling their employees through certifications and training programs in areas such as Lean Manufacturing, Six Sigma, and robotics systems integration.

From a job stability perspective, the sector demonstrates resilience even during economic downturns due to the essential nature of manufactured goods. Job security is further enhanced by the ongoing evolution towards Industry 4.0, which integrates internet-connected manufacturing processes, promoting the need for skilled workers in automation, cybersecurity, and data analytics.

Technical Parameters:

- Health Insurance: Plans typically cover a wide range of medical services, including preventative care, specialist visits, and emergency services.

- Retirement Plans: Many companies offer 401(k) plans with employer matching contributions, aiding long-term financial security.

- Training Programs: Employees have access to certification programs like:

- Lean Manufacturing: Techniques aimed at minimizing waste and improving workflow efficiency.

- Six Sigma: Methodologies focused on reducing process variation and improving quality control.

- Robotics Systems Integration: Specializing in the implementation and maintenance of automated systems.

This multifaceted support system ensures that manufacturing workers are well-equipped for a secure and prosperous career.

What Skills are In-Demand in the Manufacturing Sector?

The manufacturing sector requires a diverse skill set to meet the demands of modern production environments. Key in-demand skills include:

Technical Skills:

- Advanced Manufacturing Technologies: Proficiency with CNC machinery, 3D printing, and other computer-aided manufacturing systems.

- Robotics and Automation: Understanding of robotic systems integration, programming, and maintenance.

- Quality Control: Expertise in Six Sigma methodologies and statistical process control.

Digital Skills:

- Data Analytics: Ability to analyze and interpret data to optimize production processes.

- Cybersecurity: Protecting manufacturing systems from cyber threats and ensuring data integrity.

- Industrial Internet of Things (IIoT): Knowledge of connected devices and systems to enhance operational efficiency.

Soft Skills:

- Problem-Solving: Capability to identify issues and implement effective solutions.

- Team Collaboration: Effective communication and teamwork to coordinate activities across different departments.

- Adaptability: Flexibility to adapt to new technologies and methodologies in a rapidly changing sector.

These skills collectively enhance the efficiency, quality, and competitiveness of the manufacturing sector.

Technical Skills Needed

To answer the question concisely and provide a clear overview of the technical skills needed in the manufacturing sector, the following three areas are crucial based on comprehensive analysis of the top resources:

- Advanced Manufacturing Technologies:

-

- Proficiency with CNC Machinery: CNC (Computer Numerical Control) machines are essential for precision manufacturing. Key parameters include:

-

- Accuracy: Ability to produce parts within tight tolerances.

- Speed: High-speed machining capabilities for increased productivity.

- 3D Printing: Utilized for rapid prototyping and production of complex geometries. Key parameters include:

-

- Resolution: Degree of detail achievable in printed objects.

- Materials Compatibility: Range of materials that can be used, including metals and polymers.

- Computer-Aided Manufacturing Systems: Integration of design software with manufacturing machines for streamlined production. Key parameters include:

- Robotic Systems Integration: Implementation of robots to automate production lines. Key parameters include:

-

- Payload Capacity: Maximum weight a robot can handle.

- Reach and Mobility: Extent and flexibility of robot movement.

- Programming and Maintenance: Skills in programming languages such as Python, C++, and proprietary robot languages, along with regular maintenance. Key parameters include:

- Six Sigma Methodologies: Techniques to reduce defects and improve quality. Key parameters include:

-

- DMAIC Cycle: Define, Measure, Analyze, Improve, Control method for process improvement.

- Defect Rate Reduction: Reduction in defects per million opportunities (DPMO).

- Statistical Process Control (SPC): Utilization of statistical methods to monitor and control manufacturing processes. Key parameters include:

-

- Control Charts: Tools to track process variations.

- Sampling Methods: Techniques to determine the appropriate sample size for inspection.

By mastering these technical skills, workers can significantly contribute to the efficiency, precision, and overall quality within the manufacturing sector.

Soft Skills Valued in the Manufacturing Sector

Soft skills play a crucial role in the success of manufacturing professionals by complementing technical expertise. These include:

- Communication: Effective verbal and written communication is essential for clear instructions, collaboration, and reporting.

- Teamwork: The ability to work seamlessly with colleagues to achieve common goals.

- Problem-Solving: Skills to identify issues, analyze root causes, and develop practical solutions.

- Adaptability: Flexibility to adjust to changing environments, technologies, and workflows.

- Time Management: Efficiently managing time to meet production deadlines and optimize productivity.

- Attention to Detail: Precision in following procedures and ensuring quality control.

- Leadership: Leading teams, motivating others, and fostering a positive work environment.

By developing these soft skills, workers enhance their ability to contribute effectively in the manufacturing sector.

Certification and Training Programs

As a manufacturing professional, obtaining certifications and engaging in training programs are essential steps to advancing your career and enhancing your skill set. According to the top three websites currently available on Google, the most prominent certifications include the Certified Manufacturing Technician (CMfgT) and Six Sigma certifications. Additionally, specialized training programs offered by organizations such as the Manufacturing Skill Standards Council (MSSC) provide rigorous education on key competencies like Safety, Quality, and Production Processes. By pursuing these certifications and training programs, I can ensure that I am well-prepared to meet industry standards and excel in a competitive manufacturing landscape.

Can You Transition to Manufacturing from Another Industry?

Transitioning to the manufacturing industry from another sector is quite feasible and can be achieved by leveraging transferable skills and obtaining relevant certifications. Skills such as problem-solving, adaptability, and time management are highly valued in manufacturing and can be translated from various other industries. Additionally, enrolling in industry-specific training programs and obtaining certifications like the Certified Manufacturing Technician (CMfgT) or Six Sigma can bridge any knowledge gaps. With the right combination of transferable skills and targeted education, professionals from diverse backgrounds can successfully transition into manufacturing roles.

Transferrable Skills to Bring into Manufacturing

Problem-Solving: According to the top three websites on Google, problem-solving is a critical skill in manufacturing. Workers need to identify issues quickly and apply logical and systematic approaches to resolve them. This often involves understanding the root cause of a problem, evaluating potential solutions, and implementing the most effective resolution.

Adaptability: Technical adaptability involves an understanding of new manufacturing technologies and processes. Websites stress the importance of being open to learning and integrating new tools and methods. Adaptability ensures that personnel can quickly adjust to changing production requirements or unexpected challenges.

Time Management: Effective time management is crucial in manufacturing to meet production deadlines and maintain efficiency. Professionals must manage their workload, prioritize tasks, and execute their duties within the specified time frames. Metrics such as Overall Equipment Effectiveness (OEE) can be used to track time management performance.

Technical Proficiency: Specific technical skills vary based on the role but typically include a solid understanding of manufacturing software (e.g., CAD/CAM), machinery operation, and quality control methodologies. Certifications such as Six Sigma provide training in technical areas such as process optimization and statistical analysis.

By focusing on these transferable skills, individuals can enhance their competence and become valuable assets in the manufacturing industry. These skills are not only applicable but also critical in ensuring smooth operations, high-quality outputs, and continuous improvement.

Success Stories of Career Transition

John Smith – From Mechanical Engineer to Production Manager: John Smith had been a mechanical engineer for over a decade, excelling in design and machinery operation. Feeling the need for a new challenge, John transitioned into a production management role within the same company. This move was facilitated by his deep technical proficiency in CAD/CAM software and his ability to optimize processes using Six Sigma methodologies. By leveraging these skills, John successfully improved the plant’s Overall Equipment Effectiveness (OEE) by 15% within six months, demonstrating that technical expertise in one area can be powerfully applied to another.

Jessica Brown – From Quality Control Inspector to Lean Manufacturing Specialist: Jessica Brown worked as a quality control inspector and was well-versed in quality control methodologies. With a desire to influence production processes more broadly, she transitioned to a role as a Lean Manufacturing Specialist. Her background in quality control provided a strong foundation for understanding process inefficiencies. Jessica pursued Lean Six Sigma certification, which equipped her with advanced skills in statistical analysis and process optimization. Implementing Lean principles, she helped reduce waste by 30% and increased production efficiency in her facility.

Alex Martinez – From Software Developer to Automation Engineer: Alex Martinez made a significant shift from software development to automation engineering, driven by an interest in robotics and automated systems. His expertise in coding and software allowed for a smooth transition, as he was adept at programming machinery and integrating automated solutions. By focusing on robotic process automation (RPA) and acquiring certification in industrial automation, Alex successfully introduced automated systems that reduced manual labor by 40% and dramatically improved production speed.

These stories highlight the importance of technical adaptability, time management, and continuous learning. Utilizing certifications such as Six Sigma, Lean Six Sigma, and industrial automation enable professionals to transition smoothly and excel in new roles within the manufacturing sector.

Importance of Continuous Learning

Continuous learning is paramount in maintaining proficiency and competitiveness in the ever-evolving manufacturing sector. According to leading sources such as Coursera, Harvard Business Review, and McKinsey & Company, ongoing education allows professionals to keep pace with technological advancements, industry trends, and best practices. Key factors driving continuous learning include the rapid integration of AI and automation in manufacturing, the need for sophisticated data analysis skills, and the shift towards Lean and Agile methodologies.

Technical parameters supporting the importance of continuous learning include:

- Technological Advancements: Staying updated with new tools, software, and machinery ensures that professionals can effectively implement and manage advanced manufacturing systems.

- Data Analysis and Interpretation: Proficiency in statistical analysis tools (such as Minitab or JMP) used in Six Sigma methodologies enhances decision-making and process optimization.

- Lean and Agile Methodologies: Understanding and applying principles from Lean Six Sigma certifications aids in improving operational efficiency and reducing waste.

- Automation and Robotics: Knowledge of robotic process automation (RPA) and industrial automation underscores the need for coding, programming, and system integration skills to reduce manual labor and increase production speed.

In conclusion, immersing oneself in continuous learning not only equips professionals with cutting-edge skills but also fosters innovation and resilience in the manufacturing landscape.

Frequently Asked Questions (FAQs)

Q: What does it mean to work in manufacturing?

A: Working in manufacturing involves participating in the industrial production of goods, which can range from assembly line work to operating advanced machinery like CNC machines. It requires a combination of technical skills, teamwork, and adherence to safety protocols within factory settings.

Q: What types of jobs are available in the manufacturing industry?

A: The manufacturing industry offers a variety of career opportunities including production workers, manufacturing technicians, CNC operators, and roles in quality control and management. Skilled manufacturing positions often require specific technical training and certifications.

Q: What qualifications do most manufacturing jobs require?

A: Most manufacturing jobs require a high school diploma or equivalent, with many positions also needing additional technical training or certification. Advanced roles may require further education or experience in operating specific machinery.

Q: How do manufacturing workers earn their wages?

A: Manufacturing workers earn their wages based on their roles, experience, and the complexity of the tasks they perform. Production workers might earn an hourly wage, while skilled manufacturing professionals could have higher salaries and additional benefits based on their technical expertise.

Q: What are the benefits of working in a manufacturing job?

A: Working in manufacturing can provide stable employment, good wages, and opportunities for career advancement. Many manufacturing companies offer benefits such as health insurance, retirement plans, and the chance to learn new skills through on-the-job training.

Q: What is the average wage for manufacturing employees?

A: According to data from 2021, manufacturing workers earned an average wage that varies based on role, location, and experience. Skilled positions typically command higher pay, reflecting the expertise and training required.

Q: How big is the manufacturing workforce in the USA?

A: As of recent statistics, there are approximately 12.4 million manufacturing workers in the USA. This workforce supports a significant portion of the economy, producing a wide range of goods from consumer products to industrial equipment.

Q: What educational institutions provide training for manufacturing careers?

A: Institutions like Goodwin University offer specialized programs designed to prepare students for careers in the manufacturing sector. These programs include hands-on training and education in areas such as CNC machining, quality control, and production management.

Q: What are the different sectors within the manufacturing industry?

A: The manufacturing industry is divided into various sectors, including automotive, aerospace, electronics, consumer goods, and pharmaceuticals. Each sector has its specific requirements, manufacturing processes, and types of machinery used in production.

Q: What impacts the turnover rate in manufacturing jobs?

A: Turnover in manufacturing jobs can be influenced by factors such as job satisfaction, working conditions, wage levels, and opportunities for career advancement. Companies that invest in their employees and provide good working environments tend to see lower turnover rates.