Laser cutting is an extremely flexible and precise method that uses a beam of light to cut through various materials. More than other laser options, CO2 laser cutters are commonly applied in industry because they proved superior in accuracy on many materials. This blog post will explain the different types of materials that can be used for CO2 laser cutting using a CO2 laser cutter, including their applications, advantages and precautions. Whether you are doing it as a pastime or if you just run a small business or belong to an industrial manufacturing team; understanding what CO2 laser cutting can do and cannot do can greatly influence your decision-making process.

The succeeding parts will outline some of the materials that are effectively laser cut with the use of a CO2 Laser Cutter by focusing on the specific properties and potential applications thereof.

What Types of Materials Can a Laser Cutter Cut?

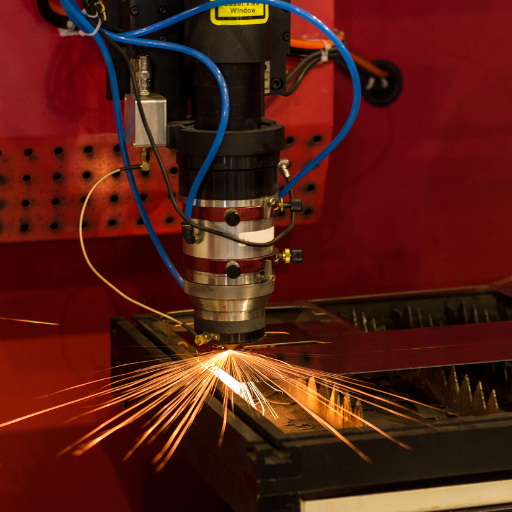

Image source: https://mellowpine.com/

Nearly all kinds of materials can be cut with CO2 laser cutting technology; they have varied exclusive features and applications. Some frequently used materials for laser cutting purposes are:

- Wood: This is a perfect material for cutting out detailed designs, for example signage, furniture and ornamental art.

- Acrylic: It is clear with a polished edge after the cut which makes it good for display stands, signage or lighting.

- Fabric: Fabric can be precisely cut to make textiles useful in fashion design, upholstery making and customized clothing.

- Leather: Used when making custom leather items like belts, wallets among others.

- Paper and Cardboard: Invitations that are personalized, packaging cases as well as prototypes demanding high details can therefore be made from paper and cardboard.

- Plastics: Industrial or consumer products use different types of plastic such as polycarbonate or PETG that can undergo cutting processes.

- Rubber: Stamps are among the common instances where rubber is used alongside other industrial elements like gaskets.

Laser Cutting Machine: Basic Overview

The way it works is that a laser cutting machine guides a highly powered CO2 laser beam to cut or engrave objects with an amazing accuracy. Laser tube, power supply, mirrors and lens are the main elements of a laser cutter which collectively focus the beam on the material’s surface. With its control system, the laser cutter places the beam exactly where it should go following any pre-determined paths for cutting or designs.

Some important things to look for when evaluating a laser cutting machine are:

- Laser Power: Often measured in wattage, higher power levels allow for cutting of thicker materials and improve cutting speed.

- Bed Size: This refers to dimensions of workspace where materials are placed. Bigger bed sizes can handle larger projects as well as multiple parts.

- Cutting Speed: This determines how quickly the head of the laser moves, affecting productivity and precision

- Cooling System: It ensures that temperature stays within safe levels so that performance remains optimized preventing unnecessary wear and tear on lasers tubes.

- Software Compatibility: The machine’s usability depends largely on whether it will work with design software such as AutoCAD, Illustrator or CorelDRAW.

Range of Materials Suitable for Laser Cutting

Laser cutting technology has great flexibility and can work on a variety of materials. Below are some examples of the most commonly laser cuttable materials:

- Metals: In laser cutting, metals such as stainless steel, carbon steel, aluminum or brass are among the frequently used ones. On metal sheets, the laser can produce delicate patterns and exact cuts with clear edges.

- Plastics: There are different kinds of plastics like acrylic, polycarbonate or polypropylene which can be done by this method and they are used for creating parts, signage and decorative items. Every type of plastic has its own properties that affect how it is cut.

- Wood: Laser cutting is perfect for fine details and complex shapes in various wood types including plywood, MDFs (medium density fiberboards) and hard woods. It is widely applied in furniture industry, making models or crafts.

- Textiles: Cottons, polyester fabrics and felt may be accurately severed using lasers. It is particularly important in fashion designing as well as upholstery sectors where one creates custom shapes or designs.

- Paper and Cardboard: With delicate paper or cardboard patterns to be made to it; it is often used for packaging purposes as well as for crafting.

- Foam: There exist many forms of foam material that can be subjected to laser cutting such as those found in packaging products; shock absorbing inserts; custom product cases.

Materials for Laser Cutting and Engraving

Laser cutting and engraving techniques can work with diverse materials. Some common examples of these are:

- Metals: Materials like carbon steel, brass, aluminium and stainless steel can be used for laser cutting because of their ability to create detailed and precise cuts. Metals are often used in making industrial components, art pieces and jewelry.

- Plastics: Acrylics, polycarbonates and polypropylenes amongst others possess the ability to be laser cut as well as engraved thereby being useful in making signage, decorative articles or custom parts. They show different features that influence the nature of cuts such as material density and melting points.

- Wood: Wood types including hardwoods, MDF and plywood are commonly used for laser-cutting applications. It is a popular method employed in furniture making, model construction, craftwork or decorative art due to its inherent beauty.

- Textiles: Examples include cotton fabrics like felt polyester etc which can be cut and engraved with accuracy. This technique is useful in fashion industry as well as upholstery for shaping customized forms with intricate patterns due to capability of laser beam contouring of textile materials.

- Paper and Cardboard: Delicate intricate patterns, designs among other shapes can be made from cutting paper using lasers as it is applicable in packaging (card boxes) crafting (carton), invitations amoung other things.

- Foam: Different foams have distinct characteristics which allow them to serve various needs including packaging materials such as protective inserts, unique product casing shapes when they are cut by lasers or other means. Through accuracy in shaping foams guarantee safety during transportation hence you realize that the products arrive at their destination without damage.

What Are the Best Metals for Laser Cutting?

Using a Fiber Laser for Metal Cutting

Metal Laser Cutting Settings

Metal laser cutting is only achieved at the highest precision through numerous controllable aspects. These include power, speed and focus which must be varied based on the material being cut. Power is a measure of the amount of energy emitted by the laser; for thicker and denser metals, higher power is usually required. Speed controls how fast the laser travels across the material; it’s better to use slow speeds when cutting thick metal because it allows for cleaner cuts to be made. Focus refers to how far apart or close together a material surface and a lens of a laser are, in order to produce precise and sharp edges.

Some other important settings are nozzle distance and assist gas pressure. Assist gas (e.g., Oxygen or Nitrogen) helps in removing molten metal as well as protecting cut edge. The quality of cut depends greatly on both gas pressure level and type used during cutting process. Correct nozzle distance ensures that there is proper focus and also high efficiency in terms of beam thus enabling desired design outcome.

It is very important to follow company guidelines for materials and make test cuts before setting up your machine to ensure good-quality results with precise dimensions in metal-cutting by laser.

Types of Metal Materials Cut with a Laser

Laser cutting machines are versatile and can process a range of metals with high accuracy as well as efficiency. The metal most commonly cut by laser machines include:

1. Steel

Steel, which includes mild steel and stainless steel, is commonly used in laser cutting because of its strength and toughness. While cutting mild steel needs less power and an easier task, higher laser power and assist gas for clean cuts are frequently required on stainless steel.

2. Aluminum

For its lightweight property together with excellent corrosion resistance, aluminum is another option that one may consider going for. It has a very high reflectivity as well as thermal conductivity but lasers cut it effectively especially if using fiber lasers since these types of lasers are much suited for the reflective metal cutting processes.

3. Brass and Copper

Some challenges come about due to brass’s and copper’s thermal conductivity among other things like their reflectivity during the process of laser cutting. But this kind of materials can be cut smoothly by modern lasers taking into account the use of fiber lasers or specialized gas settings optimized for these materials during the cutting.

How Do Different Plastics Respond to Laser Cutting?

Laser Cut Plastics: Performance and Quality

Laser cut plastics’ performance and quality is greatly influenced by the plastic’s type under consideration as well as the exactitude of laser settings. Among all other types, acrylic is singled out for its commendable performance when it comes to laser cutting. Clean cuts with polished edges are achieved using acrylic sheets which makes them ideal for detailed and artistic applications. While polycarbonate may be strong, it tends to discolor and leave behind rough edges thus calling for fine tuning of laser parameters. Being commonly used materials, polyethylene and polypropylene are more likely to melt thus creating burrs that can affect the quality of a cut. Consequently, this means that precise control is often needed alongside post-processing steps in order to achieve desired outcomes.

Polycarbonate and Other Plastics for Laser Cutting

Polycarbonate is commonly used in many industries because of its strength and clearness. However, there are difficulties with laser cutting polycarbonate. When laser is used to cut this material, it tends to change color and leave rough edges. These problems can be solved by changing the laser power, speed and frequency. It is important to have good ventilation and take safety precautions when dealing with the smoke produced during cutting.

In addition to polycarbonate, other plastics that are often cut with lasers include acrylic, polyethylene and polypropylene. Acrylic is easy to cut and gives a polished finish which makes it suitable for projects requiring high precision. On the other hand, when polyethylene or polypropylene is melted by the laser it creates burrs which may need further processing in order to obtain smooth edges.

To get the best outcome while cutting plastic materials using laser machines requires one to adjust their settings according to different types of plastics. Therefore by adjusting speed, power and frequency balance you can significantly improve on quality of cuts thus reducing defects hence making them more functional and appealing aesthetically as well as functionally too.

Handling Potential Toxic Fumes When Cutting Plastics

One must consider that cutting plastics with a laser can let out poisonous fumes. Proper ventilation is necessary to reduce health risks in this regard. Ventilation should be adequately done by applying an exhaust system for the removal of harmful particles and gases or using a fume extractor.

Apart from ventilating the area, it is important that we also use high-quality air filter systems. These types of equipment are meant to draw off any impurities which may be suspended in air thus making the work environment cleaner and safer. Furthermore regularly maintaining these filters ensures their continued working ability.

When operating laser cutting machines, masks or respirators should be worn as personal protective equipments (PPE). These measures combined with good practices on ventilation and air filtration are some ways through which people can protect themselves against dangerous fumes produced during different types of plastic materials being cut using lasers.

Can Wood Be Cut Using a Laser Cutter?

Types of Wood Suitable for Laser Cutting

Laser cutting is best done with certain woods because of what they are made up of and how tightly packed together the particles are.

- Plywood: Plywood is a material that people frequently use when laser cutting because it can be very strong and also extremely even. It works by having many thin layers of wood veneer glued together, which allows for a variety of different applications. Birch plywood happens to work particularly well due to its smoothness as well as lack of voids.

- MDF (Medium Density Fiberboard): This type of wood fiber board mixed with resin makes great surfaces for lasers cut through consistently without any bumps or unevenness along the way. MDF produces clean cuts but does create lots smoke and dust so it’s not suitable if you’re working in an area without proper ventilation, however this feature also means that this material is perfect for highly detailed work.

- Hardwood: Laser cutters can be used on various hardwoods including cherry, maple, and walnut. Hardwoods provide strength plus an attractive appearance after being sanded down which makes them ideal for intricate designs or premium products. On the other hand these types of woods may require higher power settings due to their density therefore more time might need to be spent waiting during cuts made from such materials.

Optimizing Laser Power for Different Woods

Achieving Clean Cut Edges in Laser Cut Wood

What Materials Should Not Be Cut with a Laser Cutter?

Recognizing Unsafe Materials for Laser Cutting

Why Certain Materials Are Unsuitable for Laser Cutting

What Are the Applications of Laser Cutting Across Various Materials?

Laser Cutting and Engraving Projects

It also finds wide usage within industry where branding needs to happen fast along side promotions while at the same moment producing unique signs too; branded merchandise should always come out looking professional so promotional materials must be eye-catching enough but still ensure uniqueness never seen before while custom signage has to stand out without looking odd against its surroundings either (anything from plexiglass light boxes mounted on walls). The reason why such precision, versatility and efficiency are possible with laser technology lies in it being able to do things down at such detailed levels – this is what hobbyists love about it with their need for perfectionism plus professionals who want nothing less than absolute perfection when working on intricate designs requiring complete customization every single time.

Types of Laser and Their Capabilities

There are many types of lasers used in laser cutting and engraving, all with different capabilities.

- CO2 Lasers: CO2 lasers are used for cutting, engraving and boring. They have high efficiency and good beam quality, which makes them perfect for materials like wood, acrylics, glass, textiles and leather. The wavelength of CO2 lasers is 10.6 micrometers which suits these materials best.

- Fiber Lasers: Fiber lasers are known for their power and precision so they can cut metals as well as non-metals. They operate at a wavelength of 1.064 micrometers that allows them to cut thinner metals like gold or silver or brass but also aluminum much faster than any other type of laser could do it without sacrificing accuracy too much. These lasers are also used for marking and engraving on harder materials such as steel or titanium.

- Nd:YAG Lasers: Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) lasers can be utilized in various processes including metal cutting, marking or engraving applications among others because this type has versatile features available to use depending on the requirements needed by the user during the operation itself. Nd:YAG lasers have a similar wavelength to fiber laser that is 1.064 micrometers but what makes them unique is their ability to perform deep engravings and cuts through thicker metals where most other types would fail at doing so adequately enough Still they also work great when you need high peak powers with low repetition rates such as welding or drilling applications.

Wide Range of Materials Used for Different Applications

Reference sources

- Baison Laser

- Source Link: https://baisonlaser.com/uncategorized/what-materials-can-a-co2-laser-cut/

- Summary: This article details the capabilities of CO2 lasers in cutting materials like wood and plywood, making them ideal for intricate designs and signage.

- xTool

- Source Link: https://www.xtool.com/blogs/xtool-academy/laser-cutting-materials-list

- Summary: This blog post outlines the best materials for CO2 laser cutting, including wood, paper, leather, and some types of plastics, highlighting the versatility of CO2 laser cutters for non-metal applications.

- FabCreator

- Source Link: https://www.fabcreator.com/materials

- Summary: The article discusses common materials used in laser cutting like birch plywood, which is harder than poplar and can be used to produce more durable products.

Frequently Asked Questions (FAQs)

Q: What types of different materials can be laser cut using a CO2 laser cutter?

A: A CO2 laser cutter is versatile and capable of cutting many materials, including wood, acrylic, paper, fabric, leather, and certain types of glass. It’s also used for laser cutting various plastics and some types of rubber. However, it’s less effective for metals, where a fiber laser cutting system might be more suitable.

Q: Can a CO2 laser machine cut metals?

A: Generally, a CO2 laser machine is not suitable for cutting metals. Metals are better cut using a fiber laser cutter, which is designed to handle the specific demands of metal cutting. CO2 lasers are more suited to materials like wood, acrylic, and paper.

Q: What laser cutting materials are best suited for CO2 laser engraving?

A: Suitable materials for CO2 laser engraving include wood, acrylic, glass, and certain plastics. These materials can be engraved with intricate designs and text, making them ideal for customized laser engraving projects.

Q: Is it possible to cut glass with a CO2 laser cutter?

A: While CO2 laser cutters can engrave glass, cutting glass is challenging due to the material’s properties. Typically, materials that can be cut using a CO2 laser are plastics, wood, and similar substances. For cutting glass, other methods like waterjet cutting might be more appropriate.

Q: How effective is a CO2 laser cutter for cutting leather?

A: CO2 laser cutters are quite effective at cutting leather. This type of laser cutting material is often used in crafting and fashion industries to create detailed and precise cuts, making it one of the many materials suitable for laser cutting projects.

Q: Are all plastics suitable materials for laser cutting with a CO2 laser?

A: Not all plastics are suitable for cutting with a CO2 laser cutter. Materials such as acrylic are excellent for both cutting and engraving. However, some plastics like PVC release hazardous fumes when laser-cut and should be avoided. Always check the material’s specifications before using a CO2 laser machine.

Q: What are the limitations of using a CO2 laser cutter on different materials?

A: While versatile, CO2 laser cutters have limitations. They struggle with cutting metals and materials like glass and epoxy resin. Additionally, thick or dense materials may be difficult to cut cleanly. Different materials respond differently to laser energy, so testing and adjustments may be necessary to achieve optimal results.

Q: How does a diode laser differ from a CO2 laser in cutting materials?

A: Diode lasers are less powerful and typically used for engraving or cutting thinner, softer materials like paper, cardboard, and thin wood. In contrast, CO2 lasers are more powerful and can cut through thicker materials like acrylic and hardwood. Thus, the specific laser type chosen depends on the material and project requirements.

Q: Can a CO2 laser engraver be used for both cutting and engraving?

A: Yes, a CO2 laser engraver can be used for both cutting and engraving. The versatility of CO2 lasers makes them ideal for creating detailed engravings and also for making precise cuts in various suitable materials like wood and acrylic.

Q: What is the role of laser light in the laser cutting process?

A: In laser cutting, the laser light is concentrated into a high-energy beam that melts, burns, or vaporizes the material it is directed at. This concentrated laser energy allows for precise cuts and engravings, making it a powerful tool in various cutting methods used across different industries.