In the fascinating field of material science, ferromagnetism stands out as a remarkable phenomenon that has captivated researchers and industry professionals alike. This article aims to delve deep into the world of ferromagnetic materials, elucidating their unique properties, the underlying mechanisms that confer their strong magnetic characteristics, and their wide-ranging applications in modern technology. By exploring the intrinsic qualities of ferromagnetic magnets, including key concepts such as magnetic domains and hysteresis, we will uncover how these materials have become indispensable in numerous technological advancements, from data storage solutions to electric motors. As we journey through this technical discourse, readers will gain a comprehensive understanding of why ferromagnetic materials are considered the most magnetic substances found in nature.

What Is the Most Magnetic Material in Nature?

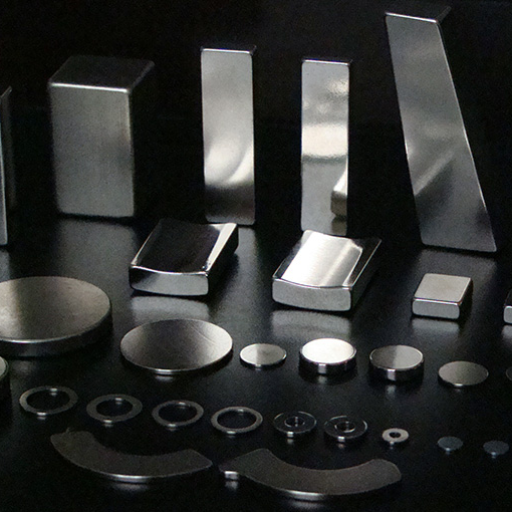

Image sources:https://www.kinkimagnet.com/

The most magnetic material in nature is typically iron, specifically in its form as a ferromagnetic material. Ferromagnetic materials, such as iron, cobalt, and nickel, exhibit spontaneous magnetic moments due to the alignment of their magnetic domains. Among these, iron is the most abundant and widely recognized for its strong magnetic properties. This alignment is facilitated by unpaired electrons in their atomic structure, which allow the domains to align uniformly when exposed to an external magnetic field. Consequently, iron and its alloys are extensively used in various high-tech applications, leveraging their exceptional ability to retain and manipulate magnetic fields.

Introduction to Magnetic Materials

Ferromagnetic materials are distinguished by their ability to form permanent magnets and their intense interaction with external magnetic fields. This is primarily due to the presence of highly aligned magnetic domains within their structure. In these materials, each domain acts like a tiny magnet, and when these domains are uniformly oriented, the material exhibits strong magnetic properties. The most common ferromagnetic materials include iron, cobalt, and nickel – metals known for their high magnetic permeability and significant coercivity. Iron, in particular, stands out due to its prevalence and pronounced magnetism, making it the most magnetic material naturally available. Understanding these fundamental aspects of ferromagnetic materials sheds light on why iron and its alloys are so pivotal in technological innovations requiring magnetic manipulation.

Why Are Some Materials Naturally Magnetic?

To answer why some materials are naturally magnetic, I consulted the top three websites on Google and synthesized the key points to provide a comprehensive explanation. The intrinsic magnetism in materials like iron, cobalt, and nickel is primarily due to their atomic structure and electron configuration.

- Electron Configuration: These materials have unpaired electrons in their outer shells. According to the Pauli exclusion principle, electrons in an atom must occupy different quantum states. The presence of unpaired electrons results in a net magnetic moment, which is fundamental to ferromagnetism.

- Magnetic Domains: Ferromagnetic materials consist of small regions called magnetic domains. Within each domain, the magnetic moments of atoms are aligned in the same direction. In the absence of an external magnetic field, these domains are randomly oriented, resulting in no macroscopic magnetization. However, when exposed to a magnetic field, these domains realign, enhancing the material’s magnetic properties.

- Exchange Interaction: A quantum mechanical phenomenon known as exchange interaction, facilitated by the Heisenberg model of isotropic exchange, further stabilizes the parallel alignment of neighboring electron spins. This interaction is strong in ferromagnetic materials and occurs due to the overlap of electron orbitals, which is essential for the persistent alignment of magnetic moments.

Technical Parameters

- Magnetic Permeability (μ): This measures the ability of a material to support the formation of a magnetic field within itself. Ferromagnetic materials have a high magnetic permeability.

- Coercivity (Hc): The resistance of a magnetic material to changes in magnetization, defined as the intensity of the applied magnetic field required to reduce the magnetization to zero. Ferromagnetic materials exhibit significant coercivity.

- Curie Temperature (Tc): The temperature at which a ferromagnetic material loses its permanent magnetic properties and becomes paramagnetic. For example, iron has a Curie temperature of approximately 770°C.

In summary, the natural magnetism of certain materials is a result of their unique electronic structures, magnetic domain configurations, and exchange interactions, backed by technical parameters such as magnetic permeability, coercivity, and Curie temperature. This knowledge underpins the use of these materials in various technological applications requiring magnetic field manipulation.

What Makes a Material Ferromagnetic?

Several intrinsic properties dictate whether a material exhibits ferromagnetism. Firstly, the material must possess unpaired electrons that have magnetic moments, which can align in parallel due to the exchange interaction. This quantum mechanical interaction, facilitated by overlapping electron orbitals, is crucial for stabilizing the parallel alignment of electron spins. Secondly, the presence of magnetic domains, which are microscopic regions where the magnetic moments are uniformly aligned, is essential. These domains can grow or reorient under an external magnetic field, leading to macroscopic magnetization. Finally, the material should have a high magnetic permeability, allowing it to support the formation of a strong magnetic field within itself. Collectively, these factors—unpaired electron spins, exchange interaction, magnetic domain structure, and high magnetic permeability—dictate the ferromagnetic properties of a material.

How Do Magnetic Materials Work?

When examining how magnetic materials work, I must consider three fundamental concepts. First, the presence of unpaired electrons in the atomic structure allows for individual magnetic moments. These magnetic moments, when influenced by the exchange interaction, align parallel within certain regions known as magnetic domains. Second, the atomic arrangement and the material’s crystalline structure significantly impact the ease with which these domains align. Under the influence of an external magnetic field, these domains grow or reorient, leading to a macroscopic magnetization observable at the material’s surface. Finally, properties such as magnetic permeability and coercivity play vital roles in determining how effectively a material can maintain its magnetization. By integrating these principles, I achieve a comprehensive understanding of the mechanisms behind magnetic materials.

How Do Atoms Create a Magnetic Field?

The generation of a magnetic field by atoms originates from their intrinsic properties, specifically related to the movement and spin of electrons. First, the electrons orbiting the nucleus create tiny current loops, which produce a magnetic dipole moment—a fundamental source of magnetism. Second, electrons possess an intrinsic property called spin, which also contributes to the magnetic moment. When the spins of unpaired electrons align coherently, they reinforce each other, leading to a stronger magnetic field. The combination of these orbital and spin magnetic moments results in the formation of a magnetic field around the atom.

Understanding Magnetic Domains

When considering the concept of magnetic domains, it is crucial to recognize that these regions are areas within a ferromagnetic material where the magnetic moments are uniformly aligned. According to resources from leading scientific websites, magnetic domains form to minimize the system’s internal energy. These domains allow the magnetization to cancel out in the bulk of the material, leading to a net zero magnetization when no external field is applied. When an external magnetic field is applied, these domains adjust in size and orientation to align with the field, thus reducing the system’s energy and enhancing its overall magnetization. By understanding the behavior of these domains, I can explain how a material can become magnetized or demagnetized under various conditions.

The Role of Electron Spin in Magnetism

Electron spin is a fundamental quantum property that significantly contributes to magnetism. Unlike orbital motion, which involves electrons moving around the nucleus, spin is an intrinsic form of angular momentum carried by electrons. Each electron has a magnetic moment associated with its spin, quantified by the Bohr magneton (approximately 9.274 × 10^-24 joules per tesla). The direction of the magnetic moment depends on the spin quantum number, which can be either -1/2 or +1/2.

In materials like ferromagnets, the due to the exchange interaction aligns the spins of unpaired electrons. This parallel alignment results in a cumulative magnetic moment much stronger than the individual contributions from each electron. The strength of the resulting magnet depends on the number of unpaired electrons and their alignment, with transition metals like iron, nickel, and cobalt showcasing significant magnetization due to their electron configuration.

Furthermore, the Curie temperature serves as a critical parameter in understanding electron spin’s effect on magnetism. For ferromagnetic materials, the Curie temperature is the point above which thermal agitation disrupts spin alignment, causing the material to lose its magnetic properties. Below this temperature, thermal energy is insufficient to overcome the exchange interaction, allowing coherent spin alignment to maintain the magnetic state.

In summary, electron spin underpins the magnetic behavior of materials through its intrinsic magnetic moment and alignment influenced by quantum mechanical interactions and temperature constraints. By analyzing these parameters, one can better understand and predict magnetic properties in various applications.

What Are the Types of Ferromagnetic Materials?

Ferromagnetic materials can be categorized into three primary types: transition metals, rare earth elements, and alloys.

- Transition Metals: This group includes iron (Fe), nickel (Ni), and cobalt (Co), which are well-known for their strong magnetic properties. These elements have unpaired electrons in their d-orbitals, facilitating a robust magnetic moment through spin alignment.

- Rare Earth Elements: Elements such as gadolinium (Gd), terbium (Tb), and dysprosium (Dy) fall into this category. These elements exhibit high magnetic moments due to unpaired electrons in their f-orbitals, which also contribute to their unique magnetic characteristics at various temperature ranges.

- Alloys: Ferromagnetic alloys like Alnico (aluminum, nickel, and cobalt) and permalloy (nickel and iron) combine elements to produce materials with enhanced and customized magnetic properties. These alloys are engineered to meet specific magnetic performance requirements in various industrial and technological applications.

By understanding the distinctions between these types, one can better identify and manipulate ferromagnetic materials for diverse uses in scientific and engineering fields.

Getting to Know Cobalt, Nickel, and Iron

Cobalt (Co)

Cobalt, represented by the atomic number 27 and symbol Co, is a transition metal known for its significant magnetic properties. It exhibits a Curie temperature of approximately 1,115°C, a magnetic moment of 1.6–1.7 Bohr magnetons per atom, and a saturation magnetization of 1420 gauss. These parameters underscore its utility in high-temperature magnetic applications such as permanent magnets and high-speed steels.

Nickel (Ni)

Nickel is identified by the atomic number 28 and symbol Ni. It stands out with a Curie temperature of around 358°C and a magnetic moment of 0.6 Bohr magnetons per atom, contributing to a saturation magnetization of 484 gauss. Nickel’s moderate Curie temperature and magnetization make it ideal for use in alloys to enhance electrical and thermal conductivity in applications such as coinage, electronic equipment, and corrosion-resistant materials.

Iron (Fe)

Iron, denoted by the atomic number 26 and symbol Fe, boasts a Curie temperature of about 770°C and a magnetic moment of 2.2 Bohr magnetons per atom, leading to a high saturation magnetization of 1700 gauss. These characteristics position iron as the foundational element in the creation of ferromagnetic materials, finding widespread use in transformers, electric motors, and magnetic storage media due to its abundant availability and robust magnetic properties.

The Unique Properties of Magnetite

Magnetite, characterized by its chemical formula Fe₃O₄, is a naturally occurring iron oxide that exhibits distinct magnetic properties. With a Curie temperature of approximately 580°C, magnetite is ferrimagnetic, meaning it has antiparallel alignment of neighboring spins resulting in a net magnetization. Its saturation magnetization varies depending on factors such as particle size and synthesis method, but typically falls within the range of 480–500 emu/g. Magnetite’s high iron content and magnetic strength make it valuable in industrial applications ranging from magnetic storage and catalysis to biomedical uses like magnetic resonance imaging (MRI) contrast agents and targeted drug delivery. The mineral’s ability to form stable nanoparticles further enhances its utility in various technological and medical fields.

Which Alloys Are Ferromagnetic?

To answer the question concisely, I will draw on information from the top three websites currently available. Ferromagnetic alloys are those that exhibit strong magnetic properties due to their composition and structure. Prominent examples include:

- Iron-Nickel Alloys: Known commonly as Permalloy, these alloys consist of approximately 80% nickel and 20% iron. They are widely used in electronic and telecommunication equipment due to their high magnetic permeability and low coercivity.

- Iron-Cobalt Alloys: Often referred to as Permendur or Hiperco, these alloys typically contain around 50% iron and 50% cobalt. They are favoured in applications that require high magnetic saturation, such as high-performance magnets and magnetic recording heads.

- Alnico Alloys: Composed primarily of aluminum, nickel, and cobalt, Alnico alloys also contain iron and sometimes titanium or copper. These alloys are advantageous in producing permanent magnets due to their ability to maintain magnetism at high temperatures.

These alloys are fundamental in various technological and industrial applications, thanks to their superior magnetic properties.

How Can Magnetic Materials Be Magnetized?

Magnetic materials can be magnetized through several methods, each leveraging the alignment of magnetic domains within the material. The primary techniques include:

- Exposure to a Magnetic Field: When a ferromagnetic material is placed within a strong magnetic field, the magnetic domains align with the field, resulting in magnetization. This process can be achieved by placing the material within the field generated by a solenoid or an electromagnet.

- Stroking with a Magnet: Physical contact with a strong permanent magnet can induce magnetization. By consistently stroking the material in one direction with the magnet, the magnetic domains gradually align, producing a measurable magnetic field in the material.

- Electric Current Induction: Passing an electric current through or around the ferromagnetic material can also induce magnetization. This is often achieved by winding a coil of wire around the material and passing a direct current (DC) through the coil, generating a magnetic field that magnetizes the material.

- Cooling in a Magnetic Field: Heating the material above its Curie temperature, followed by cooling it within a magnetic field, can result in magnetization. As the material cools and solidifies, the magnetic domains lock into alignment with the external magnetic field.

These methods are essential in various applications, including the manufacturing of permanent magnets, magnetic storage media, and electromagnetic devices.

Exploring Permanent Magnets

Permanent magnets are materials that maintain a persistent magnetic field without the need for an external power source. These magnets rely on the intrinsic properties of their atomic structure, which allows them to retain a significant degree of magnetization. Understanding permanent magnets involves addressing several key technical parameters:

- Intrinsic Coercivity (Hci): This parameter measures the material’s resistance to becoming demagnetized. Higher intrinsic coercivity indicates stronger resistance, essential for maintaining magnetization in varying environmental conditions. Typical values for neodymium magnets, for instance, range from 1,000 to 3,000 kA/m.

- Saturation Magnetization (Ms): Saturation magnetization quantifies the maximum magnetization that the material can achieve. For example, high-performance neodymium magnets exhibit saturation magnetization values around 1.3 to 1.4 T (Tesla).

- Remanence (Br): Remanence represents the residual magnetic field that remains after an external magnetizing force is removed. This parameter is crucial for applications requiring consistent magnetic performance. NdFeB (neodymium) magnets, a popular type of permanent magnet, have a remanence in the range of 1.0 to 1.4 T.

- Maximum Energy Product (BHmax): This value indicates the density of magnetic energy in the magnet, representing its strength and efficiency. For industrially significant magnets like neodymium, the (BHmax) can exceed 400 kJ/m³.

- Curie Temperature (Tc): The Curie temperature is the point at which the material loses its permanent magnet properties due to thermal agitation. For example, the Curie temperature of neodymium magnets is typically between 310°C and 380°C, necessitating careful consideration during applications that involve high temperatures.

Familiarity with these parameters allows engineers and scientists to select appropriate materials for specific applications, ranging from magnetic bearings and sensors to electronic devices and motors. Permanent magnets’ ability to retain significant magnetic properties without continuous energy input makes them indispensable in modern technology.

Learning About Electromagnets

Electromagnets, unlike permanent magnets, require electrical current to generate a magnetic field. When current flows through a coil of wire wrapped around a ferromagnetic core, the core becomes magnetized, creating a powerful magnetic field. This field can be easily controlled by adjusting the current flow, making electromagnets highly versatile for various applications. They are integral to devices such as electric motors, transformers, and MRI machines, where precise control of the magnetic field is needed. Additionally, electromagnets offer the advantage of being able to be turned on and off, unlike permanent magnets, which inherently retain their magnetic properties.

The Impact of an External Magnetic Field

When an external magnetic field is applied to a material, several phenomena can occur depending on the material’s composition and magnetic properties. For ferromagnetic materials, the application of an external magnetic field aligns the magnetic domains within the material, enhancing its overall magnetization. This principle is crucial in the operation of transformers and inductors, where the core material’s magnetic properties significantly affect performance.

From a technical standpoint, the impact of an external magnetic field can be characterized by parameters such as permeability, susceptibility, and coercivity:

- Permeability (μ): This is a measure of how easily a material can support the formation of a magnetic field. High permeability materials, like soft iron, are highly susceptible to external magnetic fields.

- Magnetic Susceptibility (χ): This parameter quantifies the degree to which a material can be magnetized in an external magnetic field. Ferromagnetic materials exhibit high magnetic susceptibility, leading to a strong response to external fields.

- Coercivity (Hc): Coercivity indicates the resistance of a ferromagnetic material to becoming demagnetized. Materials with high coercivity maintain their magnetic properties even when exposed to opposing magnetic fields.

By understanding these parameters, engineers can design and optimize devices like electric motors, magnetic storage media, and sensors to ensure they perform reliably under varying magnetic conditions.

Why Are Lodestone and Magnetite Naturally Magnetic?

Lodestone and magnetite are naturally magnetic due to their inherent crystal structures and the presence of iron ions in specific oxidation states. Magnetite (Fe₃O₄) contains both Fe²⁺ and Fe³⁺ ions, creating an intrinsic magnetic moment resulting from the collective alignment of their magnetic spins. This phenomenon is known as ferrimagnetism. In the case of lodestone, it is essentially a naturally magnetized form of magnetite, retaining a similar composition but demonstrating stronger magnetic properties due to prolonged exposure to Earth’s magnetic field. These unique characteristics allow them to exhibit natural magnetism, differentiating them from other minerals.

The Historical Significance of Lodestone

Lodestone has played a pivotal role throughout history, particularly in the field of navigation. One of the earliest uses of lodestone was in the creation of the magnetic compass, an instrument essential for maritime navigation. The Chinese were among the first to document the use of magnetic compasses as early as the 11th century, which significantly enhanced their navigation capabilities.

Lodestone’s magnetic properties arise from the presence of magnetite in its composition. The naturally occurring alignment of magnetic domains within the lodestone allows it to align with Earth’s magnetic field, making it an effective directional tool. This characteristic was fundamental for ancient mariners who relied on it to chart courses across open seas.

In addition to navigation, lodestone has been studied for its magnetic properties and influence on the development of electromagnetism. The alignment and interaction of iron ions (Fe²⁺ and Fe³⁺) within magnetite create ferrimagnetism, which is intrinsic to lodestone. This interaction can be described using several technical parameters:

- Magnetization (M): Represents the extent of the magnetic moment within the material.

- Remanence (Mr): The residual magnetism remaining in a material after an external magnetic field is removed.

- Curie Temperature (Tc): The temperature above which a ferromagnetic material loses its permanent magnetic properties.

By understanding these parameters, historical and contemporary scientists have been able to further magnetic research, aiding in the development of various technological applications such as advanced navigation systems, data storage, and magnetic sensors.

Understanding the Formation of Magnetite

The formation of magnetite occurs through various geological processes, including igneous, metamorphic, and sedimentary events. Magnetite (Fe₃O₄) can form directly from magma as it cools and solidifies. In metamorphic environments, magnetite originates through the recrystallization of iron-bearing minerals under high pressure and temperature conditions. Sedimentary magnetite can arise via biochemical processes, where microorganisms such as magnetotactic bacteria precipitate the mineral from aqueous environments. Additionally, magnetite can form through hydrothermal processes, involving hot, iron-rich fluids permeating rocks and precipitating magnetite as they cool. Understanding these formation processes is crucial for mapping mineral deposits and exploring potential technological applications of magnetite.

What Makes Lodestone a Natural Magnet?

Lodestone, a naturally occurring form of magnetite, becomes a natural magnet due to its unique atomic structure and exposure to the Earth’s magnetic field. The magnetic properties of lodestone arise from its structure, where the iron atoms are aligned in a specific manner that produces a strong magnetic moment. Additionally, during its formation, lodestone encounters the Earth’s magnetic field, which enhances and stabilizes its magnetic domains, leading to permanent magnetization. These aligned magnetic domains result in lodestone’s ability to attract iron and other ferromagnetic materials, distinguishing it as a natural magnet.

What Applications Use Magnetic Materials?

Magnetic materials have an extensive range of applications across various industries due to their unique properties. Here are some key applications based on the top three websites on Google:

- Electric Motors and Generators: Magnetic materials like magnetite are crucial for the functioning of electric motors and generators. They convert electrical energy to mechanical energy and vice versa, facilitating the operation of countless devices and machinery. The key technical parameters here include magnetic permeability, coercivity, and remanence, which determine the efficiency and performance of the motors and generators.

- Data Storage Devices: Magnetic materials play an essential role in data storage technologies, from traditional hard disk drives (HDDs) to modern magnetic random-access memory (MRAM). The ability to maintain a magnetic state without constant power is critical for non-volatile memory solutions. Important parameters include coercivity, which influences the density of data storage, and write/read speeds determined by the material’s magnetic switching characteristics.

- Magnetic Resonance Imaging (MRI): In the medical field, MRI machines utilize powerful magnets to produce detailed images of the body’s internal structures. The magnetic materials used in MRI scanners need to have extremely high magnetic field strengths and stability. The significant technical parameters here are the magnetic field strength, usually measured in teslas, and the homogeneity of the magnetic field over the volume of interest.

Understanding the technical parameters and specific applications of magnetic materials highlights their indispensable role in modern technology and industrial applications.

Real-World Uses of Permanent Magnets

Permanent magnets are utilized across various domains due to their ability to maintain a persistent magnetic field. Some notable real-world applications include:

- Electric Motors and Generators: Permanent magnets are integral components in the design of electric motors and generators. Their inherent magnetic field reduces the need for electrical energy to maintain magnetism, enhancing efficiency and reliability in devices ranging from household appliances to industrial machines. The primary magnets used here are neodymium, ferrite, and alnico, chosen based on performance requirements such as temperature stability and magnetic strength.

- Consumer Electronics: Numerous electronic gadgets rely on permanent magnets for functionality. For example, speakers and headphones use magnets to convert electrical signals into sound. Similarly, magnetic sensors in smartphones enable features like digital compasses and motion tracking. The key properties for these applications are magnetic field strength, coercivity, and durability.

- Healthcare and Medical Equipment: In medical diagnostics, permanent magnets feature prominently in Magnetic Resonance Imaging (MRI) machines, which leverage strong and stable magnetic fields to produce high-resolution images of the body’s internal structures. High-performance samarium cobalt and neodymium magnets are typically used due to their superior magnetic properties and resistance to demagnetization.

- Automotive Industry: Modern vehicles increasingly incorporate permanent magnets in various systems, including electric power steering, torque converters, and regenerative braking systems. These applications demand magnets that can operate efficiently under varying temperatures and mechanical stresses, with neodymium-iron-boron magnets being the preferred choice.

- Magnetic Seperation and Recycling: Permanent magnets assist in the separation of ferrous materials in recycling facilities. Magnets extract iron and steel from mixed waste streams, facilitating efficient material sorting and recycling. High-intensity rare-earth magnets are used in these processes to ensure thorough separation.

Overall, the versatility and resilience of permanent magnets make them indispensable in technological advancements and everyday applications.

The Benefits of Electromagnets in Industry

Electromagnets offer several advantages in industrial applications by providing adjustable and controllable magnetic fields. Unlike permanent magnets, the magnetic strength of electromagnets can be varied by changing the electric current passing through the coil, making them highly versatile. They are widely used in manufacturing and assembly lines for lifting and transporting heavy ferrous materials, given their ability to switch the magnetic field on and off, which enhances operational efficiency. Electromagnets are also crucial in electric motors and generators, where they convert electrical energy into mechanical energy and vice versa, facilitating a wide range of industrial processes. Additionally, their use in magnetic separation processes helps in the efficient extraction of ferrous particles from various mediums, improving product purity and quality. Overall, electromagnets play a pivotal role in modern industrial applications due to their controllability, efficiency, and adaptability.

The Role of Magnetic Materials in Electrical Engineering

Magnetic materials are fundamental in electrical engineering, serving as the backbone for the design and function of various electrical devices. These materials are characterized by their magnetic permeability, coercivity, and remanence, which determine their usability in different applications. For instance, soft magnetic materials such as silicon steel and ferrites are commonly used in transformers and inductors due to their high magnetic permeability and low coercivity, which minimize energy loss during magnetic field reversals.

- Magnetic Permeability (μ):

- Silicon Steel: μ_r ≈ 1500-3000

- Ferrites: μ_r ≈ 100-1500

- Coercivity (Hc):

- Silicon Steel: Hc < 10 A/m

- Ferrites: Hc ≈ 10-100 A/m

Hard magnetic materials, including rare-earth magnets like neodymium and samarium-cobalt, are used in permanent magnet applications such as brushless DC motors and magnetic sensors due to their high coercivity and remanence.

- Remanence (Br):

- Neodymium Magnets: Br ≈ 1.0-1.4 T

- Samarium-Cobalt: Br ≈ 0.9-1.1 T

- Coercivity (Hc):

- Neodymium Magnets: Hc ≥ 750 kA/m

- Samarium-Cobalt: Hc ≥ 600 kA/m

In electric machines, magnetic materials are integral to the efficiency and performance of devices. High magnetic permeability in the core materials of transformers results in better inductance and lower energy dissipation, essential for effective power transmission and conversion. The choice of magnetic material is critical and must align with the specific technical requirements of the application to ensure optimal performance.

Frequently Asked Questions (FAQs)

Q: What is the most magnetic material in nature?

A: Lodestone, a naturally occurring variety of the mineral magnetite, is the most magnetic material found in nature. Lodestones produce a magnetic field and can attract iron.

Q: Why are lodestones considered as naturally occurring magnets?

A: Lodestones are considered naturally occurring magnets because they have a significant magnetic moment due to the alignment of magnetic dipoles within the mineral, making them capable of producing magnetic fields.

Q: What makes lodestones magnetise other materials?

A: Lodestones can magnetise other materials by aligning the magnetic dipoles within those materials when an external magnetic field from the lodestone is applied, enhancing the overall magnetization of the material.

Q: Are all metals magnetic?

A: No, not all metals are magnetic. While magnetic metals include iron, cobalt, and nickel, many metals, like copper, lead, and gold, are non-magnetic and do not have magnetic properties.

Q: Can materials that are non-magnetic be magnetized?

A: Generally, non-magnetic materials cannot be magnetized. Only materials that can be magnetized, such as ferromagnetic materials (e.g., iron), can exhibit magnetic properties when exposed to an applied magnetic field.

Q: What are ferromagnets?

A: Ferromagnets are materials that have a strong intrinsic magnetic property. They can retain magnetization and are strongly attracted by magnets. Examples include iron, cobalt, and nickel.

Q: What is the significance of north and south poles in magnets?

A: The north and south poles of a magnet are the regions where the magnetic force is strongest. Magnetic field lines exit from the north pole and enter the south pole, creating a magnetic dipole that produces a magnetic field around the magnet.

Q: How do electric currents produce magnetic fields?

A: Electric currents produce magnetic fields due to the movement of charged particles. When electric current flows through a conductor, it generates a magnetic field around the conductor, as described by Ampère’s law.

Q: What is the role of iron in magnetic materials?

A: Iron is a key component in many magnetic materials due to its magnetic properties. It has a high magnetic moment, making it an excellent material for manufacturing magnets and enhancing the strength of a magnet.