When it comes to selecting the right metal for a project, knowing the distinct characteristics and advantages of each option is crucial. This blog aims to provide an insightful comparison between cast aluminum and other commonly used metals. By understanding their unique properties, practical applications, and cost implications, you will be better equipped to make informed decisions for your engineering, manufacturing, or DIY endeavors. Whether you’re concerned with weight, strength, corrosion resistance, or thermal conductivity, this article will cover all key aspects to help you grasp how cast aluminum stands out against other metals.

What is Cast Aluminum?

Image source:https://www.bing.com/

Cast aluminum is a type of aluminum that has been melted and poured into a mold to achieve a specific shape. This process of casting results in a solid, durable material that is widely valued for its lightweight properties and excellent corrosion resistance. Cast aluminum is known for its versatility and is commonly used in various industries, including automotive, aerospace, and construction, due to its ability to be easily molded into intricate designs and its superior strength-to-weight ratio.

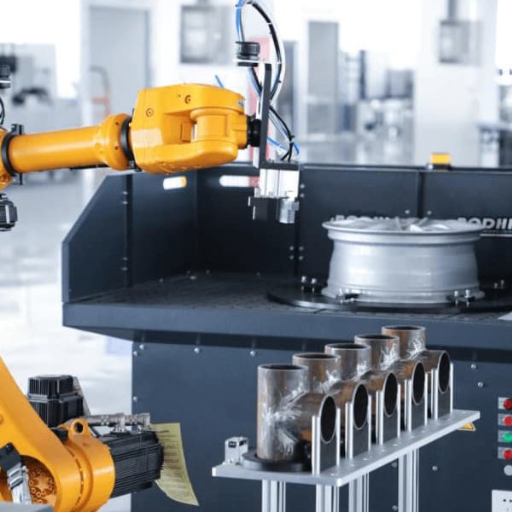

How is Cast Aluminum Made?

The production of cast aluminum starts with melting pure aluminum or an aluminum alloy in a furnace. Once in a molten state, the aluminum is poured into a mold, which can be made of sand, metal, or even ceramic, to form the desired shape. The mold is designed to allow the molten aluminum to flow into every detail of the pattern, ensuring accuracy in the final product. After the casting has solidified and cooled, the mold is removed to reveal the cast aluminum part. This part may then undergo secondary processes such as heat treatment, machining, or finishing to enhance its properties and meet specific application requirements. This method of production is prized for its ability to produce complex geometries with a high degree of precision and consistency.

What are the Properties of Cast Aluminum?

Cast aluminum exhibits a combination of properties that make it highly valuable in various industries. Some of the key properties include:

- Lightweight: One of the most notable characteristics of cast aluminum is its low density, approximately 2.7 g/cm³, which makes it much lighter than many other metals like steel, which has a density of around 7.85 g/cm³.

- High Strength-to-Weight Ratio: Cast aluminum offers excellent strength while remaining lightweight, making it ideal for applications where structural integrity is crucial without adding significant weight.

- Excellent Corrosion Resistance: Due to the formation of a protective oxide layer on its surface, cast aluminum resists corrosion effectively, making it suitable for use in harsh environments.

- Good Thermal Conductivity: With a thermal conductivity of about 140-180 W/m·K, cast aluminum is an excellent material for heat dissipation applications, such as in heat sinks and engine components.

- High Electrical Conductivity: Cast aluminum also exhibits good electrical conductivity, typically around 37.7 million siemens per meter, which is beneficial for electrical applications.

- Malleability and Ductility: These properties allow cast aluminum to be easily shaped and formed into complex designs without cracking or breaking, contributing to its versatility in manufacturing processes.

- Recyclability: Aluminum is highly recyclable, and cast aluminum parts can often be re-melted and reused without significant loss of their properties.

These technical parameters and attributes justify the widespread use and popularity of cast aluminum in automotive, aerospace, construction, and many other sectors.

Applications of Cast Aluminum

From my research on the top websites, it’s clear that cast aluminum is utilized extensively due to its favorable properties. Primarily, it’s a staple in the automotive industry where its lightweight and high strength-to-weight ratio contribute to enhanced fuel efficiency and better handling. Components such as engine parts, wheels, and transmission housings are commonly made from cast aluminum. In the aerospace sector, its excellent corrosion resistance and high thermal conductivity make it indispensable for manufacturing aircraft parts, especially where reducing weight without compromising strength is critical. Additionally, cast aluminum is widely used in construction for window frames, roofing, and structural components thanks to its malleability, recyclability, and durability. These diverse applications underscore the material’s versatility and indispensability across various industries.

What are the Different Types of Aluminum Casting Processes?

Aluminum casting processes can be broadly categorized into several types, each with its unique advantages:

- Die Casting: This method involves forcing molten aluminum into a steel mold under high pressure. It is highly efficient and is ideal for producing high-volume, high-precision parts with excellent surface finishes.

- Sand Casting: In this traditional method, a sand mold is used to shape the molten aluminum. It is particularly suitable for creating large parts and allows for more complex geometries. However, it typically yields a rougher surface finish than die casting.

- Investment Casting: Also known as lost-wax casting, this process involves creating a wax model of the part, coating it with a ceramic shell, and then firing it to create a mold. The molten aluminum is then poured into the mold, allowing for the production of intricate and detailed components.

- Permanent Mold Casting: This technique uses reusable metal molds instead of sand or ceramic ones. The molds are preheated, and molten aluminum is poured into them, resulting in components that are more uniform and have better mechanical properties than those produced by sand casting.

- Gravity Die Casting: Often used interchangeably with permanent mold casting, this process relies on gravity to fill the mold rather than high pressure. It produces parts with good dimensional accuracy and a finer grain structure.

These processes are selected based on the specific requirements of the part being produced, such as size, complexity, and desired properties.

Sand Casting

Sand casting is a versatile and widely employed method for producing aluminum components, particularly for large parts and complex geometries. Here are some key technical parameters and justifications for the process:

- Mold Material: Typically, silica sand mixed with a binder (such as clay or resin) is used to create the mold. The sand can be reused multiple times after reconditioning.

- Pattern Creation: A pattern, usually made of wood, metal, or plastic, is created in the shape of the final part. The pattern is pressed into the sand to form the mold cavity.

- Mold Assembly: Consists of two main parts—the cope (top half) and drag (bottom half)—which are aligned using alignment pins. Vents, risers, and gates are incorporated into the mold to ensure proper metal flow and venting of gases.

- Molten Metal Pouring: Aluminum is melted in a furnace and poured into the mold cavity. The temperature must be carefully controlled, typically between 650°C and 700°C, to ensure proper flow and solidification.

- Cooling and Solidification: The molten aluminum cools and solidifies within the sand mold. Cooling rates can be managed to affect the internal grain structure and mechanical properties of the final part.

- Surface Finish: The resulting surface finish is relatively rough (typically Ra 250-900 μin), compared to other casting methods. Post-processing, such as machining or polishing, is often required for applications where a smoother surface is necessary.

- Dimensional Accuracy: Dimensional tolerances for sand casting typically range from ±0.020 to ±0.125 inches, depending on the size and complexity of the part.

Selection of sand casting is justified for applications requiring large or uniquely detailed parts without the need for high precision or fine surface finishes. Its ability to accommodate complex geometries makes it especially useful in industries such as automotive, aerospace, and heavy machinery.

Permanent Mold Casting

Permanent mold casting involves the use of reusable molds, typically made from metal, to produce high-quality metal parts with excellent dimensional accuracy and surface finish. Here are the key aspects and technical parameters:

- Mold Material: Permanent molds are usually made from steel or cast iron. These materials are chosen for their high thermal conductivity and durability, enabling multiple uses.

- Mold Life: Molds can be used for thousands of casting cycles, making this method cost-effective for high-volume production runs.

- Molten Metal Pouring: The metal, often aluminum or magnesium, is melted and carefully poured into the preheated mold (usually between 300°C and 500°C for aluminum). The temperature is controlled to ensure proper filling and minimal defects.

- Cooling and Solidification: Cooling is more rapid in permanent molds compared to sand molds, resulting in finer grain structures and improved mechanical properties. Cooling rates and solidification times vary, typically influenced by the wall thickness of the casting.

- Surface Finish: Permanent mold casting produces parts with a smoother surface finish (typically Ra 100-300 μin) than sand casting, reducing the need for post-processing.

- Dimensional Accuracy: Permanent mold casting offers better dimensional tolerances, ranging from ±0.010 to ±0.060 inches, depending on part complexity and size.

Overall, permanent mold casting is favored for parts that require consistent quality, tighter tolerances, and superior surface finishes. It is widely used in the automotive, aerospace, and consumer products industries, where such characteristics are paramount.

Die Casting

Die casting is a manufacturing process where molten metal is forced into a mold cavity under high pressure. Similar to permanent mold casting, die casting is used to produce metal parts with high precision and excellent surface finishes. Here, we’ll answer the questions based on key aspects and technical parameters associated with die casting:

- Mold Material: Die casting molds, also known as dies, are constructed from tool steel grades such as H13 or SKD61, which can withstand repeated thermal cycling and high-pressure casting conditions.

- Mold Life: Dies used in die casting typically have a shorter lifespan compared to permanent molds, enduring around 100,000 to 300,000 cycles depending on the metal being cast and maintenance practices.

- Molten Metal Injection: Molten metal, often alloys of aluminum, zinc, or magnesium, is injected into the die at pressures ranging from 1,500 to 25,000 psi. The high pressure ensures that the metal fills the mold cavity completely and rapidly.

- Cooling and Solidification: Rapid cooling in die casting is achieved through the mold material and cooling channels within the die, leading to fine microstructures and enhanced mechanical properties. Solidification times are extremely short, typically a few milliseconds to seconds, depending on the part’s size and thickness.

- Surface Finish: Die casting produces parts with superior surface finishes, usually in the range of Ra 50-150 μin, which often eliminates the need for additional finishing processes.

- Dimensional Accuracy: This process achieves very tight dimensional tolerances, often within ±0.002 to ±0.005 inches, making it ideal for complex and precision components.

Overall, die casting is highly suitable for producing high-volume, intricate parts with consistent quality and fine detail. Its applications are widespread in industries such as automotive, aerospace, and consumer electronics, where these characteristics are essential.

Cast Aluminum vs. Cast Iron: Which is Better?

The choice between cast aluminum and cast iron ultimately depends on the specific application and requirements. Cast aluminum is favored for its lightweight, excellent corrosion resistance, and good thermal and electrical conductivity, making it ideal for automotive and aerospace components, as well as electronics enclosures. On the other hand, cast iron is known for its superior strength, durability, and excellent machinability, often used in heavy-duty applications such as engine blocks, pipes, and machinery components. While aluminum offers significant weight savings and ease of handling, iron delivers robustness and better wear resistance. Therefore, the decision should be based on the prioritization of weight versus strength, as well as the specific demands of the intended use.

Weight and Strength Comparison

When comparing the weight and strength of cast aluminum and cast iron, several technical parameters can help clarify their differences:

- Density: Cast aluminum has a density of approximately 2.7 g/cm³, whereas cast iron is much denser, with a density of around 7.2 g/cm³. This means aluminum is significantly lighter, which is advantageous in applications where weight reduction is crucial.

- Tensile Strength: The tensile strength of cast aluminum ranges from 130 to 310 MPa, while cast iron typically boasts a tensile strength of 200 to 800 MPa. Hence, cast iron provides greater strength and durability, which is essential for high-stress applications.

- Yield Strength: Cast aluminum generally exhibits a yield strength between 65 to 280 MPa. Cast iron’s yield strength, on the other hand, can range from 170 to 540 MPa, making it more suitable for components exposed to high loads.

- Thermal Conductivity: Cast aluminum has a thermal conductivity of about 180-210 W/m·K, significantly higher than cast iron, which ranges around 50-60 W/m·K. This makes aluminum ideal for applications requiring efficient heat dissipation, such as heat exchangers or electronic enclosures.

- Corrosion Resistance: Aluminum offers excellent corrosion resistance, particularly when exposed to atmospheric conditions, thanks to the formation of a protective oxide layer. Cast iron, while more prone to rust, can be treated with coatings or used in environments where its corrosion resistance is sufficient.

In summary, if lightweight components with good thermal conductivity and corrosion resistance are needed, cast aluminum is the suitable choice. Conversely, cast iron should be selected for applications demanding high strength, durability, and superior wear resistance.

Heat Conductivity Differences

When comparing cast aluminum and cast iron in terms of heat conductivity, several technical parameters justify their differing applications.

- Thermal Conductivity Values: Cast aluminum boasts a thermal conductivity range of 180-210 W/m·K. This high thermal conductivity makes it ideal for applications such as heat exchangers and electronic enclosures, where efficient heat dissipation is crucial.

- Cast Iron’s Lower Conductivity: In contrast, cast iron has a significantly lower thermal conductivity, typically around 50-60 W/m·K. This lower conductivity makes cast iron less suitable for applications requiring rapid heat transfer.

- Application Suitability: Due to its superior thermal conductivity, cast aluminum is preferred in applications needing effective heat management. Conversely, despite its lower heat conductivity, cast iron’s strength and durability make it suitable for other high-stress applications where thermal conductivity is less critical.

Durability and Corrosion Resistance

When evaluating the durability and corrosion resistance of cast aluminum and cast iron, it’s essential to consider their inherent material properties and how they perform under varying environmental conditions.

- Durability:

- Cast Aluminum: Known for its light weight, cast aluminum offers sufficient strength for various applications while being less durable than cast iron. It has a tensile strength of around 90-270 MPa, depending largely on the specific alloy and treatment used. This makes it suitable for components where weight-saving is a priority but not suitable for high-wear environments.

- Cast Iron: Cast iron exhibits high durability and is significantly stronger, with a tensile strength ranging from 200-1100 MPa. This makes it ideal for applications where resistance to wear and deformation under high stress is crucial, such as in construction, heavy machinery, and automotive parts.

- Corrosion Resistance:

- Cast Aluminum: Aluminum naturally forms a protective oxide layer when exposed to air, which enhances its resistance to corrosion. This property makes it highly desirable for applications exposed to moisture and atmospheric conditions, like outdoor structures and marine components. However, in highly acidic or alkaline environments, additional coatings may be necessary to ensure long-term durability.

- Cast Iron: More susceptible to rust and corrosion, cast iron requires protective coatings or treatments to enhance its longevity in harsh environments. It is more prone to oxidation, particularly in moist conditions, which can undermine its structural integrity over time. Methods such as galvanizing, painting, or applying other protective barriers are often employed to mitigate this vulnerability.

In conclusion, while cast aluminum offers excellent corrosion resistance with adequate durability for many applications, cast iron provides superior strength and wear resistance, making it the preferred choice for high-stress scenarios, albeit with the need for additional corrosion protection measures.

How Does Cast Aluminum Compare to Extruded Aluminum?

When comparing cast aluminum to extruded aluminum, it’s essential to understand their distinct manufacturing processes and resultant properties.

- Manufacturing Process:

- Cast Aluminum: Produced by pouring molten aluminum into a mold, allowing it to cool and solidify. This allows for the creation of complex shapes with high dimensional accuracy.

- Extruded Aluminum: Formed by forcing aluminum through a die under high pressure, resulting in long, continuous shapes with uniform cross-sections. This process is suitable for producing profiles with consistent and precise dimensions.

- Strength and Durability:

- Cast Aluminum: Generally offers lower tensile strength compared to extruded aluminum, with typical tensile strength values ranging from 120-240 MPa. It is more brittle, which may limit its use in high-stress applications.

- Extruded Aluminum: Boasting higher tensile strength, typically around 200-300 MPa, extruded aluminum is also more ductile, making it ideal for structural applications requiring both strength and flexibility.

- Corrosion Resistance:

- Both cast and extruded aluminum form a protective oxide layer, offering good resistance to corrosion. However, additional surface treatments, such as anodizing or powder coating, can enhance durability, especially in harsh environments.

- Weight:

- Both cast and extruded aluminum share similar low density characteristics, making them lightweight compared to other metals. This is advantageous for applications where reducing weight is a critical factor, such as in aerospace and automotive industries.

- Versatility in Design:

- Cast Aluminum: Excellent for creating intricate shapes and is ideal for parts with complex geometries.

- Extruded Aluminum: More suited for creating long, continuous shapes with uniform cross-sections, such as beams, rails, and frames.

In summary, cast aluminum is preferred for applications requiring complex shapes and moderate strength, whereas extruded aluminum is better suited for components demanding higher strength and uniformity. Both types of aluminum offer good corrosion resistance and are lightweight, making them versatile materials in various industries.

Manufacturing Differences

The manufacturing processes for cast and extruded aluminum differ significantly, impacting their respective properties and ideal applications.

- Cast Aluminum: This process involves pouring molten aluminum into a mold, where it cools and solidifies into the desired shape. Casting allows for the creation of complex geometries and intricate designs, often without the need for extensive machining. The most common casting methods are sand casting, die casting, and permanent mold casting, each offering unique advantages in terms of production speed, cost, and detail.

- Extruded Aluminum: In this process, aluminum billets are heated and forced through a die to create long shapes with uniform cross-sections. This method is highly efficient for producing standard items such as rods, tubes, and channels. Extrusion provides excellent control over dimensional tolerances and surface finishes, making it suitable for high-precision applications.

Overall, cast aluminum is ideal for intricate parts that require complexity in design, while extruded aluminum is preferred for continuous, high-strength profiles. Both processes contribute to the versatility and widespread use of aluminum in various industries.

Material Properties

Understanding the material properties of cast and extruded aluminum is crucial for selecting the right type for specific applications. Here are the key properties for each:

- Cast Aluminum:

- Density: Approximately 2.7 g/cm³

- Tensile Strength: Typically between 130-230 MPa

- Yield Strength: Around 90-150 MPa

- Elongation at Break: Generally between 3-10%

- Corrosion Resistance: Good, but can be improved with surface treatments

- Extruded Aluminum:

- Density: Approximately 2.7 g/cm³

- Tensile Strength: Typically between 200-310 MPa

- Yield Strength: Around 140-300 MPa

- Elongation at Break: Generally between 10-18%

- Corrosion Resistance: Excellent, especially with anodizing or other protective coatings

These properties indicate that extruded aluminum usually exhibits higher tensile and yield strength compared to cast aluminum, making it better suited for high-load applications. In contrast, cast aluminum’s strength can vary more due to the casting process but allows for more complex shapes and designs. Both types retain good corrosion resistance, though extruded aluminum often offers better performance in high-stress environments.

Applications and Uses

Cast and extruded aluminum find applications across various industries due to their unique properties and advantages.

- Cast Aluminum Applications:

- Automotive Industry: Engine blocks, cylinder heads, and various other components due to its ability to form complex shapes.

- Aerospace: Airplane components that require intricate designs and moderate strength.

- Consumer Goods: Cookware, furniture, and decorative items where detailed designs are needed.

- Extruded Aluminum Applications:

- Construction: Window frames, doors, and structural components thanks to its high strength and lightweight nature.

- Transportation: Railings, automotive parts, and bicycle frames requiring high strength-to-weight ratios.

- Electronics: Heat sinks and casings for electronic devices due to excellent thermal conductivity and durability.

By leveraging the strengths of each type, industries can optimize performance, functionality, and cost-efficiency in their various applications.

Why Choose Cast Aluminum Patio Furniture?

I choose cast aluminum patio furniture for several compelling reasons. Firstly, cast aluminum is renowned for its durability and resistance to rust and corrosion, a crucial factor for outdoor furniture exposed to varying weather conditions. This ensures longevity and minimal maintenance, making it a practical choice for outdoor settings.

Secondly, cast aluminum offers excellent strength without being overly heavy. This balance allows for robust patio furniture that can withstand daily use and outdoor elements while remaining easy to move and rearrange. The casting process also enables the creation of intricate designs, enhancing the aesthetic appeal of the furniture and adding an elegant touch to any patio.

Moreover, cast aluminum furniture typically features a powder-coated finish, which further enhances its durability and protects it from scratches, chips, and fading. This finish also provides a smooth surface that is easy to clean and maintain, contributing to its overall convenience and appearance.

In summary, the key technical parameters that justify choosing cast aluminum patio furniture include:

- Durability and Corrosion Resistance: Long-lasting and able to withstand diverse weather conditions.

- Strength-to-Weight Ratio: High strength without excessive weight.

- Design Versatility: Capable of intricate and detailed designs for aesthetic appeal.

- Powder-Coated Finish: Additional protection against scratches, chips, and fading, making it easy to clean and maintain.

These advantages make cast aluminum patio furniture a smart and stylish choice for any outdoor space.

Advantages of Cast Aluminum Patio Furniture

When I opted for cast aluminum patio furniture, I knew I was investing in both durability and style. One of the major benefits I’ve found is its outstanding durability and corrosion resistance, which ensures the furniture can handle various weather conditions without rusting or deteriorating. Another key advantage is the lightweight nature of cast aluminum, making it easy to move and reposition, yet strong enough to endure daily use. Additionally, the versatility in design allows for intricate patterns that add a touch of elegance to my outdoor space. The powder-coated finish further protects the furniture from scratches and fading, maintaining its pristine appearance with minimal maintenance. In summary, choosing cast aluminum patio furniture has provided me with a long-lasting, attractive, and practical solution for my outdoor seating needs.

Maintenance Tips for Cast Aluminum Patio Furniture

Maintaining cast aluminum patio furniture is relatively straightforward and ensures its longevity and pristine appearance. First, regularly clean your furniture with mild soap and water to remove dirt and debris. Avoid using harsh chemicals that could damage the powder-coated finish. Second, inspect and touch up any chips or scratches in the finish to prevent rust. Lastly, during off-seasons or extreme weather, consider storing the furniture indoors or using protective covers to shield it from the elements. With these simple maintenance steps, your cast aluminum patio furniture will remain a stylish and durable addition to your outdoor space.

Best Practices for Selecting Cast Aluminum Patio Furniture

When selecting cast aluminum patio furniture, there are a few best practices to follow to ensure you make an informed decision. Based on insights from the top-rated websites on google.com, here are the key considerations:

- Check the Quality of the Cast Aluminum: Ensure the furniture is made from high-grade cast aluminum. High-quality cast aluminum will be thicker and more durable, providing better longevity and resistance to weather conditions. Look for specific grades; for example, industrial-grade cast aluminum like 356.0 is known for its strength and corrosion resistance.

- Examine the Powder-Coated Finish: A robust, high-quality powder-coated finish will provide a protective layer that shields the furniture from UV rays, rust, and scratching. Verify if the coating meets standards such as Qualicoat Class 2 which offers enhanced weather resistance.

- Assess Comfort and Design: Comfort should be a priority, so look for furniture that offers ergonomic designs with contoured seats and backs. Additionally, intricate patterns and styles should not just appeal aesthetically but also seamlessly blend with your outdoor setting. Many premium options feature hand-crafted designs that add a luxurious touch.

- Check for Maintenance Requirements: Opt for furniture that requires minimal upkeep. The best choices will be those that only need occasional cleaning with mild soap and water and offer easily replaceable parts if needed. This information can often be confirmed by checking user reviews and product specifications.

- Weather Resistance: Ensure the furniture is resistant to various weather conditions. High-quality cast aluminum furniture should withstand rain, snow, and sun without deteriorating. Features like weather-resistant cushions and fabrics enhance longevity and comfort.

- Verify Warranty and After-Sales Service: Reliable warranties and after-sales service are indicative of the manufacturer’s confidence in their product. Look for options that come with at least a 5-year warranty, covering both structural integrity and finish.

By following these best practices, you can select cast aluminum patio furniture that not only meets your aesthetic preferences but is also durable, low-maintenance, and a valuable addition to your outdoor living space.

Reference sources

-

Sunrise Metal: Difference Between Cast Aluminum and Extruded Aluminum

- This source offers a comprehensive comparison of cast aluminum and extruded aluminum, detailing their respective advantages and disadvantages. It provides valuable insights into the manufacturing processes and applications of each type of aluminum.

-

Howard Precision: What is the Difference Between Extruded Aluminum and Cast Aluminum?

- Howard Precision’s article explains the fundamental differences between casting and extrusion processes for aluminum. It also describes the characteristics and common uses of cast aluminum in contrast to other forms of aluminum.

-

AccuBrass: The Differences Between Machined Aluminum vs. Cast Aluminum

- This blog post from AccuBrass explores the distinctions between machined aluminum and cast aluminum, making it a useful resource for understanding the specific properties and benefits of cast aluminum compared to other metalworking techniques.

Frequently Asked Questions (FAQs)

Q: What is cast aluminum?

A: Cast aluminum is a type of aluminum that has been melted and poured into a mold to achieve a particular shape. This process is often used to produce complex and intricate aluminum parts and components.

Q: How is cast aluminum different from aluminum extrusion?

A: Aluminum extrusion involves forcing aluminum through a die to create uniform cross-sectional shapes, whereas cast aluminum is made by pouring molten aluminum into a mold. The extrusion process is suitable for creating continuous profiles, while casting is ideal for more intricate and detailed shapes.

Q: Cast aluminum vs cast iron: which is better?

A: Cast aluminum is generally lighter than cast iron and offers better corrosion resistance. However, cast iron is stronger and more durable. The choice between cast aluminum and cast iron depends on the specific requirements of the application, such as weight constraints and durability needs.

Q: What are the common uses of cast aluminum?

A: Cast aluminum is often used to produce parts for the automotive, aerospace, and construction industries. It is also popular for making cookware, engine blocks, and outdoor furniture such as cast aluminum patio furniture.

Q: What is the process of aluminum die casting?

A: Aluminum die casting involves injecting molten aluminum into a steel mold under high pressure. This method allows for high precision and is often used to produce intricate and complex shapes that require tight tolerances, such as die cast aluminum parts.

Q: Can you weld cast aluminum?

A: Yes, cast aluminum can be welded, but it requires specialized techniques and equipment. The welding process can be challenging due to the presence of impurities and the material’s high thermal conductivity.

Q: What is the advantage of using cast aluminum over cast iron?

A: One major advantage of using cast aluminum over cast iron is its lighter weight, which makes it ideal for applications where reducing weight is essential. Additionally, cast aluminum offers better resistance to corrosion and is easier to machine.

Q: What types of products are made using cast aluminum?

A: Products made using cast aluminum include engine blocks, cookware, hydraulic components, and outdoor furniture. The casting process allows for flexibility in design and detailed shapes, making it suitable for a wide range of applications.

Q: What is a common aluminum casting alloy?

A: A common aluminum casting alloy is A356, which offers good castability, mechanical properties, and corrosion resistance. This alloy is often used for automotive, aerospace, and industrial applications.

Q: How does metal fabrication differ from aluminum die casting?

A: Metal fabrication typically involves cutting, bending, and assembling metal parts and components through processes like welding and machining. In contrast, aluminum die casting involves pouring molten aluminum into molds to create specific shapes. Each method has its own advantages and is chosen based on the desired outcome and application.