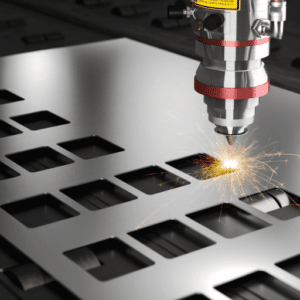

Laser cutters are very versatile tools that have many uses, from manufacturing to fine arts. They are capable of cutting and engraving various materials with extreme precision, however the kind of file you use is what determines the outcome. Whether a person wants to capitalize on a laser cutter’s capabilities or not, it is important they understand which files do what. In this post we will discuss important formats for laser cutting files and their unique features as well as effects on the process of cutting. With this information readers should be able to make an informed decision about which files are best suited for their projects involving laser cutters thereby ensuring efficiency and quality in execution.

What Are the Best File Types for a Laser Cutter?

Image source: https://baisonlaser.com/

In relation to laser cutting, the kind of file that you opt for can largely affect the overall quality of your output. Few among the many great formats for laser cutters are as follows:

Vector Files

- SVG (Scalable Vector Graphics): This format works best for laser cutting because it is scalable and accurate too. SVG files do not lose their quality when resized which makes them appropriate for designs with a lot of details.

- DXF (Drawing Exchange Format): It is common in engineering and CAD applications since most laser cutters support it. DXF files allow 2D drawings hence good for technical and detailed designs.

Raster Files

- PNG (Portable Network Graphics): PNGs may be used occasionally compared to vector files but they are acceptable for engraving projects. These have lossless compression plus wide color support.

- JPEG (Joint Photographic Experts Group): For photorealistic engravings, JPEGs are the best choice. Nevertheless, caution should be exercised while using them due to their lossy compression which may lead to loss of detail in some cases.

CAD Files

- DWG (Drawing): Many CAD programs use this as their native file format so it integrates well with laser cutting software. DWG files contain lots of intricate designs thus suitable for professional purposes.

Efficiency and high-quality outcomes should be the main focus of your laser cutting undertakings; therefore, comprehending these file formats will be helpful in achieving this goal.

Why Should You Use Vector Files?

There are many benefits of using vector files for laser cutting, which can greatly improve the quality and efficiency of your projects. Vector files, for one thing, aren’t made up of pixels like raster images but rather represented by mathematical equations; this allows for perfect scaling up or down without losing any details or sharpness at all. This is especially useful when it comes to complex designs that require high levels of accuracy. Another advantage is that vectors have crisp lines and smooth curves so they provide the most direct route through material while being cut out – resulting in neater finish edges and less wear-and-tear on machinery used for cutting them too. Lastly, because they’re universally supported across different software programs and hardware configurations involved with laser cutting machines; therefore making them a more flexible option among professionals as well as hobbyists. With vector files, you’ll be able to create better looking work more often.

Understanding Raster Files in Laser Cutting

The reason why raster files are different from vector files is that they have pixels which are small parts representing the whole picture. When used with laser cutting, these types of files work best for engraving as opposed to cutting because they can create detailed photorealistic images. Rather than defining paths for the laser to follow like vector files do, this type of file makes the laser move back and forth across the material turning on and off to create patterns of light and dark. This process is similar to how images are printed and allows for engraving complex shading and textures. Some common formats for raster files include JPEG, PNG, and BMP. Although detail may be high in a raster image, resolution is critical; higher resolutions yield finer more accurate engravings while lower ones may produce output showing visible pixelation. In order to achieve optimal results on laser engraved projects therefore it becomes essential that one starts with a good quality raster image.

Popular File Formats: SVG, DXF, and More

SVG, DXF, and other popular files formats are all used in laser cutting and engraving but each has its own place.

- Scalable Vector Graphics (SVG): SVGs are great because they can be scaled without losing quality since it’s an open-standard format. You can also use it for both cutting or engraving because they support intricate designs which most design software can handle effectively.

- Drawing Exchange Format (DXF): When sharing drawings between different CAD programs, DXF files are perfect. They work well for detailed vector designs too and often used in manufacturing processes like laser cutting.

- Portable Document Format (PDF): PDFs aren’t always ideal for laser cutting but they’re great when sharing designs with both raster and vector components. This is because they ensure that the design remains easily accessible across various platforms while still keeping it intact.

Other popular file formats are AI that stands for Adobe Illustrator which is best suited for detailed vector art as well as EPS meaning Encapsulated PostScript designed specifically for high-quality graphic and text designs. The decision on which file format to use largely depends on what kind of project you’re working on and whether or not it’s compatible with your laser cutting machinery/software.

How to Choose the Right File Type for Your Laser Cutting Machine?

When picking the right file type for a laser cutting machine, think about the nature of design, software compatibility and level of detail needed. SVG files are great if scalability and intricate details are required because they can do almost everything. DXF files work very well with detailed vector designs that need to be moved between different CAD programs frequently. If your design includes both vector and raster elements, PDF is the best choice because it ensures easy accessibility across various platforms while preserving integrity of such combination. AI provides immense capabilities for advanced vector art while EPS has good graphics as well as text design quality at higher levels . In the end match up file types with what you want from them in relation to your project requirements and laser cutter capabilities available to you.

Comparing Vector and Raster Files

The use of vector and raster files depend on the demands of your design. SVG and AI are examples of vector files, they are made up of paths represented by mathematical formulas thereby allowing for unlimited scaling without losing quality; this feature is great for designs that require frequent resizing or need to retain sharp edges as well as intricate details.

On the other hand, PNG and JPG are some of the types of raster files created from grids composed with individual pixels having particular color values assigned to them each. Raster files excel in handling complex pictures with smooth gradients between different shades but only at their original size because when enlarged beyond its resolution limit a raster file becomes pixelated. This means that rasters work best for photographs or other highly detailed images where high resolutions are necessary.

To wrap up, vectors should be used if preciseness and scalability matter most while preferring rasters would be logical when dealing with more elaborate photographic representations demanding fine color distinctions. The right choice between these two formats depends on what you want to achieve at the end of your project’s design phase given its specific requirements.

How CAD Files Work with Laser Cutters

Laser cutting depends on the CAD (Computer-Aided Design) files for detailed instructions on design. The software of laser cutting utilizes G-code or CNC (Computer Numerical Control) commands to interpret the drawing into a language that can be understood by a machine. It then maps out coordinates and paths to follow while dictating speed, power as well as movement necessary for correct material cutting or engraving.

These types of files are good because they guarantee precision and repeatability hence all cuts will be made according to specifications. Some common file formats used in laser cutting include DXF (Drawing Exchange Format) and DWG (Drawing), since different CAD software programs and laser cutters support them widely. Even the most complex designs with very fine details can still be reproduced accurately through converting them into digital instructions which is what CAD files do best, making them indispensable in manufacturing industry among other sectors like signage or custom fabrication where intricate patterns may need replication.

Using PDF and Image Files in Laser Cutting

Laser cutting, however it is also possible to use PDFs and image files such as JPEG, PNG, and TIFF, is not always the best choice for certain applications which require vector-based files. In order to make them work with laser cutter software, PDF or image files must be converted into appropriate vector formats. This can be done by means of specialized software designed for this purpose that can “see” outlines and paths in an image file and then creates vectors.

If you want your design path to be followed by a laser cutter accurately you need to ensure that you are using vector graphics. If there are any raster images or bitmap elements included in a PDF they have to be converted first; sometimes this process may result in loss of details or require manual adjustments so that everything would fit perfectly well.

Image files are usually used not for cutting but engraving instead. Black-and-white high-contrast versions of these files are created during processing which helps a laser cutter determine depths of engraving as well as patterns themselves. According to the intensity of different shades grayscale images can be interpreted by software thus making possible more detailed shaded engravings.

Thus we can say that while it’s true that PDFs and image files can be used with lasers cuts , this is often achieved by converting those into vectors or using them mainly for purposes connected with engraving . It has been proven though that ability to manage these kinds of documents greatly broadens possibilities offered by laser cutting technologies enabling realization various artistic ideas.

What Design Software to Use for Laser Cutting?

Design software for laser cutting has quite a number of alternatives that can be considered based on their strong features as well as compatibility with the laser cutting machines. Adobe Illustrator and CorelDRAW are among the best design tools because they offer a wide range of vector graphics so that your designs can be precise and detailed enough. For people who would want free solutions, Inkscape is an open-source tool that has all the necessary functions required by any designer; moreover, it could also generate vector files suitable for laser cutting too. AutoCAD may also be used widely especially in engineering or architectural fields where accuracy is paramount due to its advanced drafting capabilities besides being used for these purposes along with its precision abilities. The ultimate choice will heavily rely upon personal requirements and project types envisioned by individuals.

Benefits of Adobe Illustrator for Designing Laser Cut Files

Adobe Illustrator is popular because of its accuracy & flexibility when creating vector graphics that are necessary for laser cutting. One reason why this happens is because it has many design tools which allow for detailed & intricate vector paths thus ensuring that the projects are precise and uniform when cut by a laser beam. Moreover, the program supports multiple file formats hence can work with different types of laser cutting machines. The pathfinder tool and expansive color management options are among other features included in Adobe Illustrator which make it possible to create complicated designs with good output quality. This software has an easy interface too; besides, there are numerous online resources plus tutorials available making it user-friendly even to starters who may have no experience in designing for laser cutting.

Using Free Programs like Inkscape for Creating Laser Patterns

Inkscape is a strong and flexible freely available vector laptop graphics software perfect for making patterns for lasers. As an open-source tool, this provides each program needed to come up with details intricate exact designs. It can work with variety of file formats hence it is highly compatible with various laser cutting machines. In addition to common utilities including establishment of paths from vectors; modifying nodes so that they may become more precise and Boolean operations that ensure accurate creation of patterns meant to be cut using lasers among others are supported by Inkscape. That’s not all; layers which allow placing one object on top another without affecting them individually along grouping where several items become treated as single item while being moved together but still remain separated when required plus alignment tools useful during handling complex designs too are encompassed by this software package. Through its community involvement coupled with abundance online resources beginners through advanced users looking forward producing fine quality laser patterns at zero or low costs are well catered for in Inkscape unlike proprietary softwares.

How to Engrave Images with a Laser Cutter?

To engrave images with a laser cutter, follow these steps:

- Prepare your image: Use a graphics program like Adobe Illustrator or Inkscape to alter and manipulate the picture. To obtain a better engraving outcome, convert it to black-and-white since grey tones are employed by laser cutters for depth and intensity modulation.

- Modify resolution: Adjust the resolution of the image so that it matches those set within the laser cutter’s limitations. This guarantees that engraved images will be sharp and detailed.

- Import into Laser Cutting Software: Take this edited image and bring it inside any software used for controlling laser cutters. Ensure that you place it correctly on your workspace while also scaling as desired.

- Setting up engraving parameters: Depending on what material is being worked on, adjust settings like speed, power (wattage), dpi (dots per inch) etc, which determine how deep or light an area would appear engraved. Manuals or recommended settings guidebooks have such details targeted towards specific laser machines.

- Test and Adjust: Fine tune your configurations by doing trial engravings on scraps made from similar materials until optimum results are achieved during actual production runs

- Engrave: Kick off engraving process when happy about these parameters. Watch over it until completion so that nothing goes wrong during this stage.

By following these instructions carefully one will be able to effectively use a laser cutter for printing pictures in cases where precision matters most.

Understanding Raster Images for Engraving

Bitmap images, referred to as raster images, are made of a grid of pixels. Each pixel contains a specific color value which collectively creates the image. Raster images are important in laser engraving because they determine the level of detail and shading that can be achieved. The intensity of each pixel is processed by the laser cutter which then converts it into engraving depth and pattern. More complex and accurate engravings are produced with higher resolutions on raster images that have finer details. JPEG, PNG, BMP, and GIF are some common formats for raster images. These formats are popular because they can represent continuous-tone imagery like photographs in great detail. When getting ready for engraving with lasers one must ensure that the resolution matches up with what the system can handle so as not to lose any quality during this process according to this page on preparing raster images for engraving.

Preparing Vector Graphics for Laser Engraving

Vector graphics differ from raster images in that they are not made up of pixels but of paths defined by mathematical expressions, which allow them to be scaled indefinitely without losing quality; this makes them perfect for laser engraving where very sharp and clean lines may be needed especially for intricate designs. SVG, AI, EPS, and PDF are some common vector file formats.

Here is what you need to do to prepare your vectors for laser engraving:

- Design or Import: Use a graphic design program like CorelDRAW, Adobe Illustrator or Inkscape to create or import your own vector design.

- Scale Correctly: Ensure that your design is properly scaled before sending it off to the printer or service provider – so that it will fit onto the material being engraved upon.

- Set Line Weights: The line weights should be defined properly as different line weights are interpreted by the laser cutter to indicate cutting lines or engraving depth. Thin lines (hairline) are typically used for cutting while thicker ones serve as engravings.

- Check for Closed Paths: Verify that all paths and shapes within your design are closed since open paths may result in incomplete cuts or engravings.

- Color Coding: You can use various colors to represent different operations (engraving, cutting, scoring). Refer to the user manual of your laser cutter for specific color coding instructions.

- Optimize for Speed and Power: Depending on what material you’re using along with specifications of your laser cutter adjust speed and power settings in the vector graphic software accordingly.

With proper preparation of vectors one can achieve accurate results easily while doing laser engravings.

Enhancing Quality: Why File Format Matters

It is very important to choose the correct file format if you want your laser engravings to turn out well. Formats like SVG, AI, EPS and PDF are ideal for vector images as they store them as mathematical equations which means that they can be scaled up or down without any loss in quality. Raster formats such as JPEG or PNG on the other hand are resolution dependent so when you resize them there will inevitably be some pixelation going on. Another thing to consider is transparency and layers – AI and PDF both support these features allowing for intricate designs and fine tuning during editing stages. So pick a suitable vector format and your design will stay crisp throughout all those engraving lines.

What’s the Difference Between a CO2 Laser and a Fiber Laser?

CO2 and fiber lasers vary in many important ways, such as their source and what they are used for. For example, while CO2 lasers employ a gas mixture excited by an electrical discharge to generate a laser beam (primarily carbon dioxide), fiber lasers use silica glass fibers doped with rare earth elements. These are particularly good at cutting, engraving or marking non-metallic materials like wood, acrylics, ceramics as well as glasses fabrics etc., but can also be applied on metals such as steel or copper. Fiber lasers are smaller than CO2 ones because they possess higher efficiency levels needed for marking and cutting through different types of metals including aluminum too. The decision between these two mainly depends on the material that has to be processed along with specific task requirements taking into consideration the fact that each one of them is designed for its own range of applications.

Applications of CO2 Lasers

The flexibility of CO2 lasers across industries is widely recognized. These devices are particularly good at cutting through and etching non-metallic materials like wood, acrylics, or plastics which is why they are so necessary in the signage business. Also, since a CO2 laser can cut fabric with extreme accuracy while still being able to produce very detailed designs, it has found many uses within the fashion industry for cutting out patterns on textiles. Another field that benefits greatly from this tool’s precision is medicine – especially dermatology and surgery where doctors need something that can cleanly remove tissue without damaging too much healthy skin around it; hence why they often turn towards using CO2 lasers during certain procedures. Finally we have industrial manufacturing again but now think about engraving glassware or marking ceramics – these tasks would be impossible without some type of powerful light source capable of vaporizing materials so quickly – enter stage left our trusty carbon dioxide powered friend.

Benefits of Fiber Lasers for Precision Cutting

Fiber lasers have many pluses when it comes to precision cutting, hence their popularity across various uses. For one thing, they provide very precise and neat cuts due to their high beam quality and intensity, which reduces the need for post-processing. This accuracy is needed in industries such as aerospace or automotive where everything should be done according to exact specifications. Secondly, fiber lasers are highly electrically efficient thereby lowering operation expenses as well as saving energy. Moreover, they can work longer without breakdowns with little maintenance required thus improving overall productivity. At last but not least fiber lasers are flexible enough to cut different metals including stainless steel aluminum copper among others making them fit for many industrial applications . Apart from this , their size being small together with capability of integration enhances operational efficiencies through simplifying manufacturing processes.

Reference sources

Frequently Asked Questions (FAQs)

Q: What type of file does a laser cutter need for cutting designs?

A: A laser cutter typically requires a vector file format for cutting designs. Common formats include SVG, DXF, and AI files, as they contain precise paths necessary for accurate cuts.

Q: Why is a vector file preferred for laser cutting?

A: Vector files are preferred for laser cutting because they contain mathematical instructions that define lines, curves, and shapes with precision. Unlike raster files that use pixels, vector files ensure clean and accurate cut lines.

Q: Can I use an SVG file for laser cutting?

A: Yes, you can use an SVG (Scalable Vector Graphics) file for laser cutting. SVG files are widely supported by laser cutting software and provide high precision for cutting detailed designs.

Q: Are PDF files suitable for laser cutting?

A: PDF files can be used for laser cutting if they contain vector data. However, it’s important to ensure the PDF includes paths and not just images, as only vector paths can be accurately cut.

Q: What is the most common type of file format used in laser cutting?

A: The most common file formats used in laser cutting include SVG, DXF, AI, and EPS. These vector formats are widely supported by various laser cutting machines and software.

Q: How do I convert an image file to a vector format for laser cutting?

A: To convert an image file to a vector format, you can use vector graphic software like Adobe Illustrator or Inkscape. These programs have tools to trace the bitmap image and convert it into a vector path suitable for laser cutting.

Q: What is a DXF file, and why is it important for laser cutting?

A: A DXF (Drawing Exchange Format) file is a CAD data file format developed by Autodesk. It is important for laser cutting as it provides precise 2D and 3D CAD drawings and is widely supported by laser cutting and CNC machinery.

Q: Can I use CAD files for laser cutting?

A: Yes, CAD files such as DWG and DXF are commonly used for laser cutting. These files are created using CAD software and contain detailed design data suitable for precision cutting.

Q: What role does laser cutting software play in using design files?

A: Laser cutting software is crucial for interpreting vector design files and converting them into instructions that the laser cutter can execute. The software you use ensures that the design is accurately replicated by the laser cutter.

Q: Are AI files compatible with laser cutters?

A: Yes, AI files, which are Adobe Illustrator files, are compatible with many laser cutters. They are vector files that provide high accuracy for cutting intricate designs and are widely used in the industry.