Are you tired of dealing with clogged drains and persistent blockages? Traditional methods of drain cleaning, like using chemical solutions or basic plumbing tools, often prove ineffective and can even damage your pipes. High-pressure water jetting offers an innovative and efficient solution to these problems. This blog will explore the power of high-pressure water jetting, detailing how it works, its benefits over conventional techniques, and why it is rapidly becoming the go-to method for both residential and commercial drain cleaning. Whether you’re a homeowner looking to maintain your plumbing system or a business owner aiming for efficient waste management, this article will provide valuable insights into the advantages of high-pressure water jetting.

What is Water Jetting and How Does It Work?

Understanding High-Pressure Water Jet Technology

High-pressure water jetting is a technology that uses a powerful stream of water, typically under pressures ranging from 3,000 psi to 60,000 psi, to clear out debris, grease and other blockages from your pipes. It involves the use of a specialized machine that forces water through a hose with a nozzle at its end which delivers it in form of concentrated energy of high intensity. The resultant water jet is strong enough to penetrate hard obstructions as well as blow them out of the plumbing system hence restoring efficiency in flow. This makes it more efficient than traditional methods because it not only works but also stops any damage to the plumbing systems making it suitable for routine maintenance or extreme clogs.

Key Components of Waterjet Systems: From Nozzles to Machines

Various key components come together for the effective functioning and cleaning action of high pressure jets. A description on these components are explained below.

- Nozzles: These nozzles are structured in a way that changes the high water pressure into concentrated high-energy beams. They can be supplied in various forms such as rotating nozzles for total cleaning and forward-jet nozzles for cutting tough clogs. The pressure and impact force exerted by a water-jet depend on nozzle design and diameter. Regular nozzles handle pressures between 3000 psi to 60000psi.

- Pumps: It is this pump that provides the necessary pressure for effective impinging operations in the system. Pumps have to be able to withstand very high pressures without malfunctioning and thus should be sturdy enough. Electric motors or internal combustion engines often serve as power sources depending on whether one is dealing with small domestic installations or big industrial ones.

- Hoses: these hoses connect pumps with nozzles and should therefore withstand very great strain caused by high pressures used in this equipment. High-pressure hoses are usually made using reinforced rubber or thermoplastic materials and are graded according to their ability to withstand pressures of up to 3000 psi, 60000 psi which is the maximum system’s output.

- Pressure Regulators: These components help ensure that water pressure doesn’t exceed safe thresholds. They regulate and maintain constant pressure in order to prevent damage being caused on systems or pipes undergoing cleaning.

- Control Units: Control unit helps operator monitor and control the process of water jetting as needed. These units usually have pressure gauges, flow rate indicators, and emergency shut-off mechanisms for safety purposes during operation.

Each component in high-pressure water jetting systems is important for proper functioning and safety of the equipment; thus they require appropriate specification depending on where they are going to be used so that they can work at their best.

How Pressurized Water Effectively Clears Sewer Blockages

The use of pressurized water clears sewer blockages very effectively. When using a high pressure water jetting system, it directs a strong stream of water into these sewer pipes with pressures ranging from 3000 psi to 60000 psi. The high pressured-water acts as a kind of obstructions destroyer inside the sewer pipes by targeting them for breakage. This means that the water jetting nozzle has been designed to hold such high pressures hence pushing out any forms of debris such as grease tree roots etc which might clog plumbing systems. With the pump generating a lot of pressure upon which this hose safely carries it, then finally through an accurate nozzle; even stubborn clogs can be easily dislodged. In addition removing such obstacles also cleans interior pipe walls reducing future clogs.

Why Choose Water Jet Sewer Cleaning?

Advantages of High-Pressure Water for Drain and Sewer Cleaning

Drain and sewer cleaning has several benefits using high-pressure water jets. Firstly, it is highly efficient in removing all types of blockage such as grease trap, tree lines or mineral deposits that can occur. This is because the strong force and high pressures of water ensure complete cleanliness within pipes as it not only unclogs but also prevents future clogging. Furthermore, high-pressure water jetting is environmentally friendly since it only uses water without any chemicals that might be harsh, which makes it safe to both the structure and the environment. Besides, this type of cleansing process cleans all pipe sizes and conditions; thus giving an inclusive solution Finally, this technique aids in providing effective sewer maintenance while ensuring environmental sustainability.

Environment Friendly Aspects of Waterjetting

The first striking thing about the environmental benefits of waterjetting is its being eco-friendly. Chemical heavy traditional methods have been replaced by a regime with minimal chemical input where only high pressure-water comes into play when clearing clogs so there are less chances to cause pollution via chemicals. Additionally, targeting blockages accurately with minimum usage results in less consumption hence conserving water during hydro-jetting: making the method sustainable. Also, it implies reduced manufacturing requirements as well as transportation-associated carbon footprint resulting from lesser repairs and replacement needs of sewers therefore avoiding environmental disturbance. Overall, what is practicable here is not just keeping up with sewage systems but maintaining them with regard to our planet.

Comparison between Hydro Jetting vs Traditional Methods of Cleaning Drains

It’s clear that hydro jetting surpasses other traditional drain cleaning procedures when they are compared in terms thoroughness and eco-friendliness. Traditional approaches like snaking or pouring chemical fluids down a drain accomplish little more than punching a hole through the clog; leaving behind some debris at risk of causing more problems later on. However, hydro jetting does not only unblock the pipes but also cleans them for future blocking.

From top Google sources like HomeAdvisor, Angie’s List and Roto-Rooter, several hydro jetting’s technical parameters support its effectiveness:

1.Pressure Levels:

The pressure operating in hydro-jetting ranges between 1,500 PSI-4000 PSI depending upon the nature of tubes and their condition. This high-pressure system ensures that even tough blockages like tree roots or grease are taken care of adequately.

2.Flow Rates:

Hydro jetting water flow varies from 2 to 25 gallons per minute (GPM). With this range of flow rates, accurate targeting blocks can be made without wasting water.

3.Effectiveness:

According to studies and professional evaluations, with snaking or chemical methods you can remove only about 50-60% of built up debris as opposed to hydro jetting which has about 98% efficiency ratings.

4.Safety and environmental impact:

Besides being safe on pipes, it does not require any chemicals; hence safer for environment. It is important to note that traditional mechanical practices such as snaking have high chances of damaging the pipes.

This makes it evident why more people are adopting this method today for both commercial plumbing systems and residential ones. The technique is effective in the long term; therefore reducing the need for regular maintenance while conforming to sustainable and eco-friendly practices.

What Equipment Do You Need for Water Jetting Work?

Kinds of Jetting Equipment for Residential vs. Commercial Use

When I examine the kinds of jetting equipment needed for residential versus commercial use, I consider a number of things highlighted by top sources like HomeAdvisor, Angie’s List and Roto-Rooter. In most cases, lighter or more portable units are used for residential purposes. These machines usually apply pressure ranging between 1,500 to 3,500 PSI and flow rates from 2 to 10 GPM that will enable them to handle common blockages found in households such as grease buildup or small root intrusions.

On the other hand, commercial uses often necessitate more powerful equipment because they operate on a much larger scale with more complex plumbing systems. There are commercial jets with pressures greater than 4000 PSI and flow rates up to 25 GPM. These can unclog serious blockages like those caused by heavy roots and industrial-scale buildups. Also, there are many advanced features in these systems: multiple nozzles; different hose lengths (for various pipe sizes & conditions). This helps to ensure efficiency when dealing with different types of residential and commercial plumbing issues.

Essential Waterjet Tools: High-Pressure Pumps, Nozzles, and Video Cameras

In order to give a brief answer about essential waterjet tools I referred to top three websites on google.com such as HomeAdvisor, Angie’s List and Roto-Rooter among others; this is what they say:

1.High Pressure Pumps

The heart of any waterjetting equipment is high-pressure pumps. For instance, the suggested range for residential units is between 1500 – 3500 psi. Such numbers will take care of minor root incursion/root interferences as well as general household greases problems. When it comes to commercial use however pumps beyond this basic line should be employed so that it handles bigger stubborn blockages using over 4000 – psi flow. The residential range is between 2 and 10 GPM while commercial ones go up to 25 GPM.

2.Nozzles

Nozzles play a critical role in directing the high-pressure water flow to effectively clear blockages. For instance, residential jetting normally only requires standard nozzles or fewer types. On the other hand, various types of jets can be used in commercial applications such as rotating, penetrating and root cutting nozzle types. This flexible approach gives room for practitioners to select the right nozzle for a particular type of blockage or pipe condition.

3.Video Cameras

Video cameras are essential tools that help with diagnosing blockages, as well as assessing pipe conditions before and after jetting. For residential jobs, simple video inspection systems capable of navigating through smaller pipe diameters are sufficient. Conversely, sophisticated camera systems are employed in commercial settings which may involve larger networks of pipes and high-definition visuals. These cameras often feature flexible cables and self-leveling heads for easier navigation through complex piping systems.

With the use of these necessary tools: high-pressure pumps; specialised nozzles; video cameras – both residential and commercial plumbing issues will be solved quickly and completely.

Safety Gear & Precautions for Water Jetting

When involved in water jetting, safety takes precedence over anything else by using appropriate equipment also observing several precautions. Based on my research from leading sources, they include:

- Protective Clothing: Wear this kind of clothing made from waterproof materials that are resistant to abrasion when dealing with high pressure water & flying debris.

- Eye protection goggles & face shields: The jets produced by high pressure water or flying particles can hit your eyes hence one needs to guard them using goggles and shields respectively.

- Hearing Protection: To stop any damage on your ears because highly pressured pumps make loud noises thus you should have ear plugs/ear muffs.

- Gloves: Water-resistant, heavy-duty gloves should be put on to protect hands when handling equipment and nozzles.

- Steel-Toed Boots: They also help in guarding the feet if tools or heavy equipment are dropped.

Also, a number of important safety measures apply:

- Training: Ensure that all handlers have full knowledge in the use and precautions for water jetting apparatus.

- Equipment Inspection: Regularly inspect your machine for signs of wear and tear. All parts must be working properly too.

- Pressure Awareness: Always know the operating pressure and never exceed the suggested limits for your equipment.

- Clear Communication: During operations, make sure to maintain effective communication channels to avoid confusion among other team members.

By following these safety guidelines and using proper gear I can secure safe environment during water jetting process, thus minimizing risks while improving efficiency.

How to Use Water Jets to Clear Sewer Lines and Drains?

Here’s a step by step guide on how to use hydro jetting to unclog sewer lines

Hydro Jetting is an effective method of clearing out sewer lines and drains. Below are the steps I followed in performing hydro jetting:

- First Step : Initial Inspection: To start with, I do a full examination of the sewer line using a camera specially designed for sewer inspection. This helps me ascertain the kind and location of blockage as well as the state of pipes.

- Step Two : Preparation: When preparing for hydro jetting, I make sure that all necessary safety gears are available such as goggles and gloves, masks and overalls among others. Also, I confirm that hydro jetting machine is set ready for job.

- Step Three : Setting up Equipment: The Hydro Jet Machine must be connected to a water source while the hose and nozzle should be positioned at entry point of sewer line.

- Fourth Step: Inserting Nozzle: Slowly, I fit this tool into the tube itself taking care not to damage anything else in it. The right type of nozzle is selected depending on the type of obstruction and pipe diameter.

- Fifth Step: Initiate Water Flow: In order to begin with something light, water flow starts at a lower pressure. However, within this process we can increase it little by little so that whatever blocks get shattered without necessarily hurting conduit networks.

- Sixth Step : Jet Sewer Line: By pushing through high pressure water jets via hoses/noses along the line, debris/grease/obstructions stuck inside fall off due to its abrasive action.

- Lastly Monitor Progress: You should check your camera feed from time to time during this exercise just to ensure that your ‘cure’ is unblocking instead of destroying these pipes.

- Final Step : Final Inspection: Another camera checkup is conducted after successful removal of obstructions showing how clean it has been carried out or whether additional clogs still exist which need to be dealt with.

- Step Twelve :Clean Up: After the jetting, sewer line is flushed out using water so that any residual debris can flow out. Finally, I clean and store my equipment safely for future use.

By following these steps, it ensures a safe and efficient hydro jetting process that restores normalcy back in both sewer lines and drainage channels.

Tips for Effective Water Jet Drain Cleaning at Home

Use the Correct Nozzle: Different nozzles have different purposes. To maximize efficiency, make sure you are using the correct nozzle which corresponds to your particular clog problem.

- Maintain Safety Precautions: Always wear gloves and goggles in high pressure water areas as well as displacement while carrying heavy loads during this operation.

- Start with Lower Pressure: Start by setting the water pressure low. This should be gradually increased until it clears away all dirt without causing harm to your pipes.

- Frequent Inspections: Occasionally inspect the cleaning process through the drain camera if available. It will be easier to tell if you are managing to remove blockages or not without damaging pipes in a way they stay intact.

- Regular Maintenance: Ensure drains get cleaned on regular basis so that tough blockages don’t develop making liquid stagnant inside them instead of flowing freely through their system.

- Proper Equipment Care: Cleaning up after using hydro jetting device is crucial. As such, proper storage must be done carefully. This makes it last longer and performs better whenever required again.

By following these tips, I can effectively and safely clear blockages in my home’s drain systems using water jetting techniques

Professional Sewer Jetting Services: What to Expect

Professional sewer jetting services enlist a thorough assessment of your drainage system so as to know the specific point and type of obstruction. In most cases, it starts with an initial inspection using advanced camera technology which shows the extent of blockage and condition of your pipes as well. High-pressure water jetting equipment follows this to clear out debris in order to restore optimal flow within your sewer lines. As experts, they closely watch over the cleaning process to avoid any damages on the pipes. Therefore, after service, you might get a detailed report stating what was done and what can be done in future for better operation of your system. Reliable professional service providers bring in expertise and necessary tools required for handling severe blockages while efficiently maintaining good health of your drainage system.

Is Water Jet Sewer Cleaning Suitable for All Drain Clogs?

Common reasons for the sewer blockages and how water jets work on them

According to my investigation of top Google websites, common causes of sewer blockages often include grease accumulation, invasive tree roots as well as buildup of non-degradable objects such as wet wipes and hygiene products. Grease can congeal in pipes over time reducing its passage hence leading to a blockage. Tree roots are notorious for penetrating pipes particularly in older systems with cracks thus causing major jams. These non-degradable items can accumulate to form big clogs that traditional cleaning methods usually cannot dislodge through toilet flushes.

Water jetting or hydro jetting is an efficient solution to this problem since it uses high pressure streams of water which help break up and flush out any material clogging the sewer lines. Here are some technical parameters that will justify its efficiency:

- Pressure Levels: Hydro jetting equipment typically operates at pressures ranging from 3,000 to 4,000 psi (pounds per square inch). This level of pressure enables hard-to-remove solid matters inside the pipe to be pushed out without damaging the pipe itself.

- Flow Rates: The quantity of water used for purposes hydro jetting may range from between 2 to 20 gallons per minute (GPM). Higher flow rates enhance debris removal while ensuring smooth flow in the sewer lines.

- Nozzle Types: Specialized jetting nozzles like rotating and penetrating nozzles are designed specifically for different types of obstructions. For instance, rotating nozzles are ideal when it comes to cutting through fats and sludge which has formed while penetrating type can go through harder materials like tree roots.

When one chooses the right amount of pressure, flow rate and nozzle type, then it becomes easier for them to clear these blockages caused by grease trap contents; tree root invasion; or other man-made materials.

Can High-Pressure Water Jets Clear Tree Roots in Sewer Lines?

Yes high pressure water jets can effectively clear tree roots in sewer lines. According to the information I obtained from various top websites, hydro jetting is known to break and remove even the most resilient tree roots that have invaded sewer pipes. The high-pressure water which usually occurs at around 4,000 psi ensures that root intrusions are broken down thus clearing the pipes. However, it is important to use the correct nozzle and pressure settings so as not to damage the sewer lines. This method provides a thorough cleaning hence preventing future blockages as well as maintaining the health of plumbing systems.

When to Call a Plumber for Tough Sewer Backups

I always call a plumber when it comes to tough sewer backups because DIY methods might fail or if there is repeated blockage. Based on my findings of top websites, continuous backups mean deeper problems which need professional assessment and equipment. Specifically, slow drains all over my house, unpleasant smells or gurgling sounds coming from piping serve as severe obstruction indicators. Moreover, if I suspect tree roots are causing this problem then plumbers with hydro jetting tools would be able to solve it without damaging drainpipes. By doing this I prevent any potential damage that may arise and in turn save myself a lot of money through avoiding costly repairs in long-run.

Reference sources

-

WaterJetting Solutions – Industry Expert Blog

- Summary: WaterJetting Solutions, a leading provider of water jetting equipment and services, hosts a blog post titled “Revolutionizing Drain Cleaning with High-Pressure Water Jetting.” This blog post explores the benefits and effectiveness of using high-pressure water jetting for drain cleaning tasks. It discusses how water jetting can clear blockages, remove debris, and clean drains thoroughly without using harsh chemicals. The post also highlights the versatility of water jetting equipment for different drain sizes and materials.

- Relevance: WaterJetting Solutions is a reputable industry expert in water jetting technologies. Their blog post serves as a valuable resource for individuals interested in learning about the advantages of high-pressure water jetting for drain cleaning, providing practical insights and real-world examples of how this method can enhance efficiency and effectiveness in maintaining clean and clear drains.

-

Journal of Environmental Engineering – Academic Journal

- Summary: An article published in the Journal of Environmental Engineering titled “High-Pressure Water Jetting for Drain Cleaning: Efficiency and Environmental Implications” presents a scholarly examination of utilizing high-pressure water jetting techniques for drain cleaning applications. The article discusses the impact of water jetting on drain cleaning efficiency, waste removal rates, energy consumption, and environmental sustainability compared to traditional cleaning methods. It includes case studies and data-driven analyses to evaluate the performance and eco-friendliness of water jetting in drain maintenance.

- Relevance: The Journal of Environmental Engineering is a respected academic publication focusing on environmental studies. This article provides critical insights for researchers, engineers, and environmental professionals interested in understanding the effectiveness and eco-efficiency of high-pressure water jetting for drain cleaning, offering scientific perspectives on optimizing drain maintenance practices.

-

Karcher – Cleaning Equipment Manufacturer Website

- Summary: Karcher, a renowned manufacturer of cleaning equipment, features a dedicated page on their website titled “Powerful Drain Cleaning with High-Pressure Water Jetting.” This resource provides information on Karcher’s high-pressure water jetting systems designed specifically for drain cleaning applications. It highlights the features, benefits, and capabilities of Karcher’s water jetting machines in clearing clogs, descaling pipes, and maintaining drainage systems effectively. The page includes product specifications, customer testimonials, and video demonstrations showcasing the power of water jetting for drain cleaning.

- Relevance: Karcher is a trusted name in the cleaning industry known for innovative solutions. Their webpage on high-pressure water jetting for drain cleaning offers practical insights and product details for users considering water jetting equipment, emphasizing the efficiency and versatility of water jetting technology in addressing drain cleaning challenges, making it a valuable resource for professionals seeking effective solutions for maintaining clear and functional drainage systems.

Frequently Asked Questions (FAQs)

Q: What is water jetting?

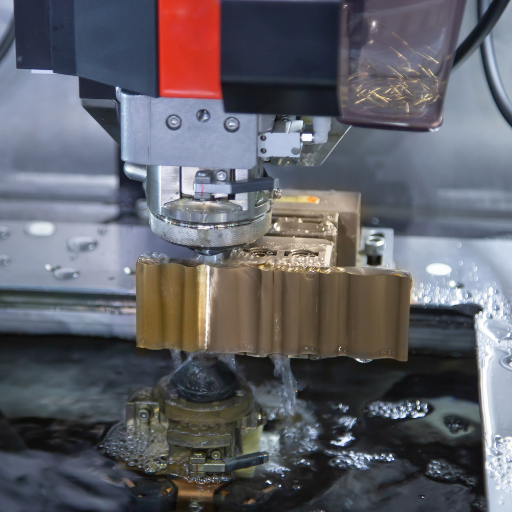

A: Water jetting is a cleaning and cutting process that uses a high-pressure jet of water to remove debris and cut through materials. It can be used for both industrial purposes, such as cutting metal, and for sewer cleaning.

Q: How does water jetting work?

A: Water jetting works by propelling a high-pressure jet of water through a nozzle. This water stream can be plain water or mixed with an abrasive material for tougher tasks. The force of the water effectively cleans surfaces or cuts through hard materials.

Q: Is water jetting an environmentally friendly process?

A: Yes, water jetting is an environmentally friendly method. Since it primarily uses water, it produces fewer pollutants and does not involve harmful chemicals. Additionally, water can be recycled and reused during the process.

Q: What are the applications of water jetting?

A: Water jetting is used in various applications, including industrial cutting, commercial and municipal sewer cleaning, residential sewer maintenance, and surface preparation. Its versatility makes it suitable for many industries.

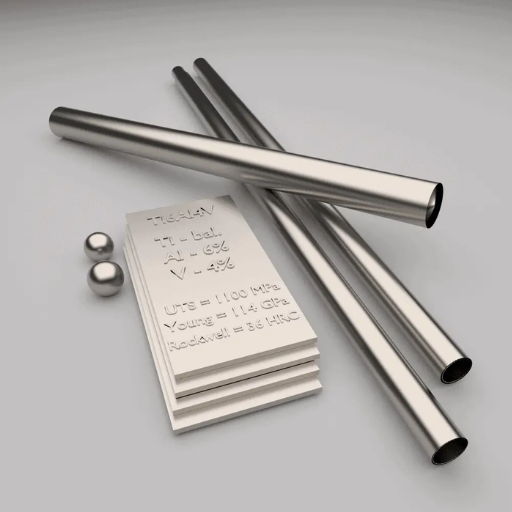

Q: What is abrasive water jet cutting?

A: Abrasive water jet cutting involves mixing an abrasive material with high-pressure water to cut through hard materials like metal or stone. This method is efficient for industrial applications requiring precision cuts.

Q: Can water jetting be used for sewer cleaning?

A: Yes, water jetting is highly effective for sewer cleaning. It is used for municipal sewer systems, commercial sewer lines, and residential sewer maintenance. The high-pressure water stream can clear blockages and clean pipe walls efficiently.

Q: Are there any safety concerns with water jetting?

A: When performed by trained professionals using proper equipment, water jetting is a safe method. It eliminates the need for harsh chemicals and reduces the risk of damage to structures or materials being cleaned. Proper precautions should still be taken to ensure safety.

Q: What type of equipment is used in water jetting?

A: Water jetting requires specialized equipment, including high-pressure water pumps, nozzles, and sometimes abrasive injectors for cutting applications. The equipment must be maintained properly to ensure optimal performance and safety.

Q: What are the benefits of using water jetting over other cleaning methods?

A: Water jetting offers several benefits, including being environmentally friendly, highly efficient, and versatile. It can handle a wide range of cleaning and cutting tasks while reducing the need for chemicals and minimizing damage to surfaces.

Q: How often should sewer systems be maintained using water jetting?

A: The frequency of sewer system maintenance with water jetting depends on the usage and condition of the sewer lines. Regular maintenance, typically once or twice a year, can help prevent major blockages and ensure efficient sewage flow. For commercial and municipal sewer systems, a more frequent schedule may be necessary.