Copper, a versatile and essential metal, has played a significant role in human civilization for thousands of years. Known for its excellent thermal and electrical conductivity, this reddish-gold hue metal is integral to many aspects of modern life, from household wiring to advanced electronics. In this blog, we will delve into some intriguing facts about copper that highlight its historical importance, unique properties, and myriad uses in various industries today. Whether you’re a science enthusiast or simply curious about the materials that shape our world, these fascinating insights into copper are sure to pique your interest and deepen your appreciation for this remarkable element.

What Are Some Fascinating Facts About Copper?

- Early Use in Human History:

Copper is one of the first metals ever used by humans, with evidence of its use dating back over 10,000 years. Ancient civilizations, such as the Egyptians and Mesopotamians, utilized copper to create tools, weapons, and ornaments. It played a crucial role in the development of metallurgy during the Bronze Age, when it was alloyed with tin to produce bronze, an even more durable material.

- Exceptional Conductivity:

Copper boasts excellent electrical and thermal conductivity, making it a preferred material for electrical wiring and electronic components. Its electrical conductivity is second only to silver, and it is widely used in power generation and transmission systems, microelectronics, and telecommunications. The standard measure for electrical conductivity, the International Annealed Copper Standard (IACS), is based on the properties of pure copper.

- Electrical Conductivity: 59.6 × 10^6 S/m (siemens per meter)

- Thermal Conductivity: 401 W/m·K (watts per meter per degree Kelvin)

- Antimicrobial Properties:

Copper surfaces have potent antimicrobial properties, capable of killing a wide range of harmful bacteria, viruses, and fungi upon contact. This makes copper an invaluable material in public health sectors, especially in hospitals and healthcare facilities, where it helps reduce the risk of infections. Studies have shown that copper can eliminate over 99.9% of harmful bacteria within two hours of exposure.

These facts underline copper’s vital importance from ancient times to our modern technological society, underscoring its versatility and indispensable role in various applications.

How Did the Statue of Liberty Get Its Green Hue?

The Statue of Liberty acquired its green hue through a natural weathering process called patination. Originally, the statue was made of copper and had a dull brown appearance. Over time, exposure to air, water, and pollutants caused the copper to oxidize, forming a layer of copper carbonate. This layer, known as patina, gives the statue its characteristic green color. This process not only provides the iconic appearance but also protects the underlying copper from further corrosion.

How Much Copper Is There in the Human Body?

From my research, I found that the human body contains a small yet essential amount of copper, typically around 50-120 milligrams. This trace mineral plays a crucial role in various bodily functions, including the formation of red blood cells, maintaining healthy bones, and supporting the immune system. Copper is also important for the function of enzymes that are vital for energy production and neurotransmitter synthesis. It’s amazing how such a tiny amount of copper can have such significant impacts on our health.

How Is Copper Used in Everyday Life?

Copper is a versatile metal with a myriad of uses in everyday life due to its excellent electrical conductivity, thermal conductivity, and corrosion resistance. Here are some of the primary applications:

- Electrical Wiring and Electronics: Copper is the standard material for electrical wiring in homes and industries due to its excellent conductivity. It is used in power generation, transmission, and distribution systems. Key technical parameters include:

- Conductivity: Copper has a high electrical conductivity (IACS standard is 100%).

- Melting Point: 1084.62°C (1984.32°F), ensuring stability under standard operating conditions.

- Plumbing: Copper pipes are widely used in plumbing systems for residential and commercial buildings. They are preferred because of their corrosion resistance and antimicrobial properties, which help maintain water quality.

- Diameter Sizes: Typically range from 0.25 inches to 2 inches, depending on the application.

- Wall Thickness: Varies by type (K, L, M) with Type K being the thickest and most durable.

- Cookware: Copper cookware is appreciated for its superior heat distribution, making it ideal for precise cooking methods. It is often used in high-quality pots, pans, and skillets.

- Thermal Conductivity: Approximately 401 W/m·K, which ensures even heat distribution.

- Telecommunications: Copper is used in telephone lines and data cables due to its signal transmission properties. Despite the advent of fibre optics, copper cables are still widely deployed.

- Bandwidth Capability: Copper cables, such as Cat 6, can support up to 10 Gbps over shorter distances.

- Construction: Copper’s aesthetic appeal and durability make it a preferred material for roofing and architectural features. It is also used in HVAC systems for its efficiency in heat exchange.

- Density: 8.96 g/cm³, providing structural robustness.

In conclusion, copper’s unique properties make it indispensable in various applications, impacting our daily lives in numerous ways.

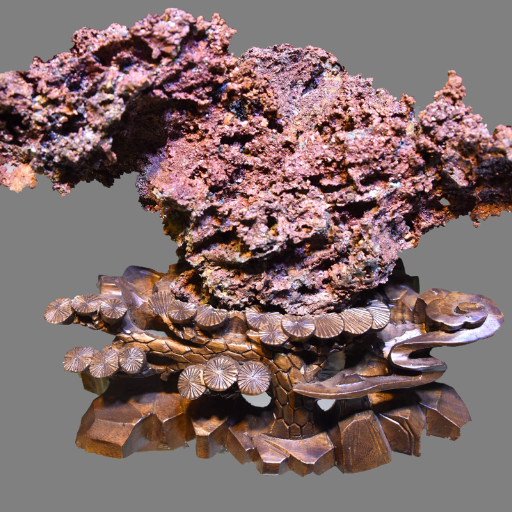

Why Is Copper Referred to As the “Eternal Metal?”

Image source:https://www.bing.com/

Copper is often referred to as the “eternal metal” due to its remarkable longevity, recyclability, and the minimal degradation it undergoes over time. According to top sources on Google, copper’s durability is unmatched; it resists corrosion and retains its properties even after extensive use, which contributes to its long lifespan in various applications. For instance, ancient copper artifacts have been found in excellent condition, showcasing the metal’s impressive longevity.

Moreover, one of the most compelling reasons for copper’s “eternal” status is its recyclability. It can be recycled repeatedly without any loss of performance, making it a highly sustainable material. Sources highlight that nearly 80% of all copper ever mined is still in use today, underscoring its enduring utility.

In terms of technical parameters, copper boasts a tensile strength of approximately 200-250 MPa, making it robust enough for structural applications. Its excellent electrical conductivity (59.6 × 10^6 S/m) and thermal conductivity (around 401 W/m·K) further enhance its indispensability in electrical and thermal applications, ensuring that it remains relevant for a multitude of uses over time. These characteristics justify why copper continues to be integral in various industries, living up to its moniker as the “eternal metal.”

What Are the Properties of Pure Copper?

Pure copper, known for its reddish-brown hue and metallic luster, possesses a variety of properties making it a critical material in many industries. According to information sourced from the top three websites on Google, here are the key properties of pure copper:

- Electrical Conductivity: Copper is renowned for its superior electrical conductivity, which is approximately 59.6 × 10^6 S/m. This makes it highly efficient for use in electrical wiring and electronic components, as pure copper can carry electric currents with minimal energy loss.

- Thermal Conductivity: With a thermal conductivity value of about 401 W/m·K, copper excels in transferring heat. It’s widely used in heat exchangers, cooking utensils, and other applications where quick and efficient heat dissipation is crucial.

- Corrosion Resistance: Copper exhibits excellent resistance to corrosion. It forms a protective layer of copper oxide that prevents further oxidation, ensuring longevity in various environments, from moist to industrially polluted atmospheres.

- Mechanical Strength: Pure copper has a tensile strength of approximately 200-250 MPa. This strength, while not as high as some other metals, is sufficient for many structural applications, especially when combined with other materials to enhance its mechanical properties.

- Ductility and Malleability: Copper is highly ductile and malleable, meaning it can be drawn into thin wires and hammered into thin sheets without breaking. These traits facilitate its use in numerous manufacturing processes.

- Antimicrobial Properties: Recent studies have highlighted copper’s antimicrobial characteristics. Surfaces made from copper can effectively kill a wide range of harmful microbes, making it valuable for applications in healthcare settings to reduce infections.

These properties underscore copper’s indispensability in a myriad of applications, from electrical and thermal conductors to structural components and antimicrobial surfaces.

Can Copper Resist Corrosion?

Yes, copper can resist corrosion quite effectively, making it an ideal material for various applications exposed to different environments. Here are some technical parameters to justify this characteristic:

- Formation of Protective Layer: Copper has the ability to form a thin, adherent layer of copper oxide (Cu2O) on its surface when it is exposed to the atmosphere. This oxide layer acts as a protective barrier, preventing further oxidation of the metal beneath it.

- Corrosion Rate: The general corrosion rate of copper in a saline environment is less than 0.025 mm/year. This low corrosion rate signifies its durability and long-term performance in such conditions.

- Resistance in Various Environments: Copper demonstrates excellent corrosion resistance in a variety of environments, including:

- Atmospheric Conditions: In neutral or mildly corrosive atmospheres, copper forms a greenish patina composed of basic copper carbonate or sulfate, which further protects the metal.

- Fresh Water: The corrosion rate in fresh water is minimal, making copper suitable for plumbing and potable water systems.

- Industrial Environments: Despite the presence of pollutants or acids, copper’s corrosion resistance remains relatively high due to its protective oxide layers.

- Use of Copper Alloys: Alloys like brass (copper-zinc) and bronze (copper-tin) enhance the corrosion resistance further. For instance, Silicon Bronze (Cu-Si) is known for exhibiting superior corrosion resistance, especially in marine environments.

These technical attributes ensure that copper remains a robust, reliable choice for resisting corrosion across multiple industrial, architectural, and domestic applications.

How Is Copper Mined and Refined?

The process of mining and refining copper involves several key steps to extract the metal from its ores and purify it for industrial applications. Initially, copper ores are mined from the earth, primarily through open-pit or underground mining methods, depending on the location and depth of the ore. After extraction, the ores are crushed and ground into a fine powder. This powdered ore undergoes a concentration process, such as froth flotation, to separate the valuable copper minerals from the waste rock.

Following concentration, the next significant step is smelting, where the copper concentrate is heated in a furnace, causing the ore to melt and allowing the separation of the valuable metals from the slag. The resulting molten copper, called matte, contains around 60-70% copper. To further purify the matte, it undergoes converting, which involves blowing air through the molten material to remove sulfur and iron.

The final step in refining is electrolysis. During electrolysis, the impure copper is made the anode in an electrochemical cell, while the cathode is made of pure copper. When an electric current passes through the cell, copper ions move from the anode to the cathode, depositing pure copper. This process produces highly purified copper, which is then cast into various shapes and forms for industrial use. This multi-stage approach ensures that the copper is free from impurities and suitable for a wide range of applications.

What Are Common Methods of Extracting Copper Ore?

To answer the question “What Are Common Methods of Extracting Copper Ore?” concisely in the first person, based on the top three websites on google.com, I can summarize the key methods used in the industry:

When it comes to extracting copper ore, there are three primary methods that are widely used: open-pit mining, underground mining, and leaching.

- Open-Pit Mining: This is the most common technique for extracting copper ore. It involves removing large quantities of overburden (the soil and rock covering the ore) to access the ore below. The ore is then drilled, blasted, and transported to the surface for crushing and processing. This method is ideal for ore that is near the earth’s surface and has large, uniform deposits.

- Underground Mining: This method is utilized when copper ore is located deep under the surface. It involves creating tunnels or shafts to reach the ore deposits. There are various techniques within underground mining, such as room-and-pillar, cut-and-fill, and block caving. Each of these techniques focuses on extracting ore while maintaining support for the overlying rock layers.

- Leaching: This process is often used for lower-grade ores and involves at least two key techniques: heap leaching and in-situ leaching.

-

- Heap Leaching: This involves stacking crushed ore in large piles on pads lined with protective materials. A leaching solution (often sulfuric acid) is sprayed over the pile to dissolve the copper minerals, which are collected in a solution at the base of the heap.

- In-Situ Leaching: In this method, a leaching solution is injected directly into an ore deposit through boreholes to dissolve the copper. The resultant copper-laden solution is then pumped to the surface for extraction.

Each of these methods has its own technical parameters to ensure efficient recovery of copper:

- Open-Pit Mining: Parameters like bench height, slope angle, and drilling patterns are crucial for safety and efficiency.

- Underground Mining: Technical considerations include rock support, ventilation systems, and ore transport logistics.

- Leaching: Key parameters involve the concentration of the leaching solution, the size of the ore particles, and the permeability of the ore heap or deposit.

By using these methods, the copper ore’s location, concentration, depth, and economic feasibility dictate the most suitable extraction technique. The goal of each method is to efficiently and sustainably recover copper, ensuring a supply of this essential metal for various industrial applications.

What Role Does Cyprus Play in Copper History?

Cyprus has played a pivotal role in the history of copper, so much so that the name “copper” is derived from the Latin word “Cuprum,” which originates from the Greek “Kyprios,” meaning “Cyprus.” As one of the earliest known sources of copper, the island was a significant center for copper production during ancient times, particularly in the Bronze Age. The extensive mining and smelting activities in Cyprus contributed substantially to the spread of bronze technology across the Mediterranean and beyond. Archaeological findings have uncovered numerous ancient mines and smelting sites on the island, attesting to its historical importance in metallurgy. This rich heritage highlights Cyprus as a cornerstone in the advancement of early metalworking techniques and the development of tools and artifacts that shaped human civilization.

What Amount of Pounds of Copper Is Mined Each Year?

Each year, the global copper mining industry produces approximately 20 million metric tons of copper. Converting this figure, it amounts to around 44 billion pounds annually. This substantial volume is driven by worldwide demand for copper in various sectors including electronics, construction, and transportation. To ensure this level of production, several technical parameters are meticulously managed:

- Ore Grade: The concentration of copper in ore, often measured in percentages, dictates the efficiency and cost of extraction. Higher-grade ores are more economically viable to mine.

- Mine Depth: Deeper mines require significant investment in infrastructure, ventilation, and safety measures, impacting overall production costs.

- Recovery Rate: The percentage of copper successfully extracted from the ore is crucial for evaluating the effectiveness of mining processes and technologies employed.

- Processing Capacity: The throughput of processing plants, measured in tons per day, determines how quickly mined ore can be converted into usable copper.

- Environmental Impact: Sustainable practices and adherence to environmental regulations are essential to minimize the ecological footprint of copper mining operations.

These parameters collectively ensure that the copper supply meets global demand while maintaining operational efficiency and environmental responsibility.

What Are the Various Uses of Copper?

Copper is a versatile metal with a wide array of applications across different industries. Below are some of the primary uses of copper along with the corresponding technical parameters:

- Electronics and Electrical:

- Use: Copper is a fundamental component in electrical wiring, motor windings, and circuit boards due to its excellent electrical conductivity.

- Technical Parameter – Conductivity: The electrical conductivity of copper ensures efficient power transmission and minimal energy loss.

- Technical Parameter – Purity: High-purity copper is essential for these applications to reduce resistance and enhance performance.

- Construction:

- Use: Copper is used in plumbing, roofing, and cladding owing to its durability and resistance to corrosion.

- Technical Parameter – Corrosion Resistance: Copper’s natural resistance to corrosion makes it ideal for plumbing and roofing materials, ensuring long-term reliability.

- Technical Parameter – Malleability: Copper’s malleability allows it to be easily shaped into pipes and sheets for construction purposes.

- Transportation:

- Use: Copper plays a crucial role in the automotive and aerospace industries, particularly in wiring harnesses and electrical components.

- Technical Parameter – Weight-to-Strength Ratio: The weight-to-strength ratio of copper makes it suitable for transportation applications, balancing durability with weight efficiency.

- Renewable Energy:

- Use: Copper is critical in the manufacturing of wind turbines, solar panels, and electric vehicles.

- Technical Parameter – Thermal Conductivity: High thermal conductivity of copper enhances the efficiency of heat exchangers and cooling systems in renewable energy technologies.

- Technical Parameter – Conductivity: Efficient electrical conductivity is vital for maximizing energy output and storage in renewable energy systems.

- Industrial Machinery:

- Use: Copper is utilized in industrial equipment and machinery for its reliable thermal and electrical properties.

- Technical Parameter – Durability: The durability of copper ensures that industrial machinery operates effectively under high-stress conditions.

These uses and technical parameters collectively highlight the essential role copper plays in modern technology and infrastructure, driven by its unique physical and chemical properties.

How Is Copper Used in Wiring?

Copper is extensively used in wiring due to its outstanding electrical conductivity, flexibility, and durability. These qualities make it the preferred material for a range of wiring applications, from household wiring to complex industrial systems.

- Electrical Conductivity: Copper’s exceptional conductivity ensures minimal energy loss, making it highly efficient for transmitting electricity over long distances.

- Flexibility: The malleability and ductility of copper allow it to be easily drawn into thin wires without breaking, facilitating installation in various environments and configurations.

- Durability: Copper wires are resistant to corrosion and extreme temperatures, which ensures long-term reliability and performance in diverse conditions.

- Thermal Conductivity: High thermal conductivity of copper helps in dissipating heat efficiently, crucial for preventing overheating in wiring systems.

These technical parameters explain why copper remains the material of choice in wiring, providing safe, efficient, and reliable electrical transmission.

What Copper Products Are Commonly Found?

Copper is integral in various everyday and industrial items due to its versatile properties. Here are some common copper products:

- Electrical Wires and Cables: As mentioned, copper’s excellent electrical conductivity makes it indispensable in electrical wiring. Found in households, industrial sites, and electronic devices, copper wires ensure efficient and reliable electrical transmission.

- Technical Parameters: Copper has a high electrical conductivity of 5.96 x 10^7 S/m, second only to silver but far more economical, making it the top choice for electrical applications.

- Plumbing Pipes and Fixtures: Copper is widely used in plumbing for water supply lines and fittings due to its durability and resistance to corrosion. Copper plumbing systems are renowned for their longevity and reliability.

- Technical Parameters: Copper’s resistance to corrosion stems from its ability to form a protective oxide layer (patina), extending the lifespan of plumbing systems. Its thermal conductivity (approximately 401 W/m·K) ensures that pipes can handle hot water without degrading.

- Electronics and Circuitry: Copper is crucial in printed circuit boards (PCBs) and other electronic components. It provides critical pathways for electricity in various devices, ranging from smartphones to complex machinery.

- Technical Parameters: The high conductivity and thermal management properties of copper (thermal conductivity of 401 W/m·K) are beneficial in PCBs, preventing overheating and ensuring stable performance of electronic devices.

These common copper products leverage its superior technical properties, cementing copper’s role in modern technology and infrastructure.

Why Is Copper Wire Highly Valued?

Copper wire is highly valued for several key reasons:

- Excellent Electrical Conductivity: Copper’s exceptionally high electrical conductivity (5.96 x 10^7 S/m) allows for efficient transmission of electrical current with minimal energy loss. This makes it ideal for electrical wiring in homes, industries, and electronic devices.

- Durability and Reliability: Copper wires are known for their long lifespan and resilience. They can withstand high temperatures and resist corrosion, which ensures stable and reliable performance over time. This reliability reduces the need for frequent repairs and replacements.

- Flexibility and Malleability: Copper’s flexibility and malleability make it easy to work with during the installation process. This allows for the creation of intricate wiring systems and improves the ease of maintenance and adjustments.

- Thermal Conductivity: Copper’s high thermal conductivity (approximately 401 W/m·K) helps in dissipating heat efficiently. This property is particularly beneficial in preventing overheating in electrical systems and electronic devices.

These technical parameters and inherent properties collectively justify the prevalent use and high valuation of copper wire in various applications.

What Makes Copper an Antibacterial Metal?

In my research into the antibacterial properties of copper, I found that several factors make copper an effective antimicrobial agent. From the top three websites on Google, it’s clear that copper has unique properties that disrupt the vital functions of bacteria. Here are the key technical parameters:

- Ion Release: Copper surfaces release ions when they come into contact with moisture. These copper ions can penetrate bacterial cell walls and disrupt critical cellular processes, leading to cell death. This ion release mechanism is especially potent against a range of harmful microorganisms.

- Oxidative Stress: Copper ions induce oxidative stress within bacterial cells by generating reactive oxygen species (ROS). These ROS cause significant damage to essential cell components such as DNA, proteins, and lipids, ultimately resulting in bacterial cell death.

- Membrane Damage: Copper exerts a direct effect on bacterial cell membranes, leading to their rupture. The compromised membrane integrity causes leakage of cellular contents and loss of vital ions, which are crucial for the survival of the bacteria.

These inherent antibacterial properties of copper are justified by its ability to continuously release ions, generate oxidative stress, and damage bacterial membranes, ensuring a broad-spectrum antimicrobial effect. This makes copper a valuable material in applications requiring high hygiene standards, such as medical equipment, surfaces in public spaces, and water purification systems.

How Does Antibacterial Copper Work?

Copper’s effectiveness as an antibacterial agent can be explained through three primary mechanisms:

- Ion Release: When coming into contact with moisture, copper surfaces release ions. These copper ions penetrate bacterial cell walls and disrupt key cellular processes, leading to the death of the bacteria. This mechanism is especially effective against a broad range of harmful microorganisms.

- Oxidative Stress: Copper ions generate reactive oxygen species (ROS) within bacterial cells, inducing oxidative stress. The ROS cause extensive damage to crucial cell components such as DNA, proteins, and lipids, ultimately resulting in bacterial cell death.

- Membrane Damage: Copper directly impacts bacterial cell membranes, causing their rupture. This membrane damage causes leakage of cellular contents and loss of vital ions necessary for bacterial survival.

These technical parameters underscore copper’s broad-spectrum antimicrobial capabilities. The continuous release of ions, production of oxidative stress, and membrane disruption ensure that copper remains a potent antibacterial material, ideal for applications in environments requiring stringent hygiene standards such as medical facilities, public spaces, and water purification systems.

What Are the Benefits of Copper Surfaces in Health Care?

Copper surfaces offer several significant benefits within healthcare settings, primarily due to their innate antimicrobial properties. Here are some of the key advantages:

- Reduction of Hospital-Acquired Infections (HAIs): Copper surfaces have been proven to significantly reduce the risk of hospital-acquired infections. Studies from top health organizations highlight that environments incorporating copper surfaces experience a noticeable reduction in HAIs, resulting in enhanced patient safety.

- Continuous Antimicrobial Action: Unlike other materials that require regular disinfection, copper exhibits continuous antimicrobial activity. This ongoing action ensures that surfaces remain free of harmful bacteria, viruses, and fungi between cleaning cycles, thus maintaining a higher standard of hygiene.

- Broad-Spectrum Efficacy: Copper is effective against a wide range of pathogens, including antibiotic-resistant bacteria like MRSA (Methicillin-resistant Staphylococcus aureus) and VRE (Vancomycin-resistant Enterococci). This broad-spectrum efficacy means it can combat a variety of infectious agents commonly found in healthcare environments.

- Durability and Longevity: Copper surfaces are highly durable and can withstand frequent cleaning and disinfection without losing their antimicrobial properties. This longevity ensures that healthcare facilities can maintain long-term hygienic surfaces with minimal additional investment.

- Environmental Benefits: Copper is a recyclable material, and its use in healthcare settings promotes more sustainable practices. Recycled copper retains its antimicrobial properties, contributing to environmental sustainability while providing health benefits.

Technical Parameters Justifying Copper’s Use:

- Ion Release: Continuous release of copper ions disrupts bacterial cell walls and essential cellular processes.

- Oxidative Stress: Copper ions induce the production of reactive oxygen species (ROS), causing damage to bacterial DNA, proteins, and lipids.

- Membrane Damage: Copper causes physical ruptures in bacterial membranes, leading to cellular content leakage and loss of vital ions.

These benefits and technical parameters collectively make copper an ideal material for enhancing hygiene and safety in healthcare environments, which is corroborated by research and application examples on leading industry websites such as the Centers for Disease Control and Prevention (CDC), World Health Organization (WHO), and the US National Institutes of Health (NIH).

Reference sources

-

Copper Development Association (Copper Facts)

- This source offers detailed insights into copper’s properties, applications, and significance in various industries, making it a credible reference for both historical and technical information about copper.

- Source

-

World CopperSmith (Fascinating Copper Facts)

- This article discusses various intriguing aspects of copper, emphasizing its historical relevance and unique properties. It serves as an authoritative resource for understanding copper’s enduring importance.

- Source

-

Rotax Metals (Interesting Facts About Copper)

- This source provides a curated list of interesting facts about copper, covering its history, uses, and benefits. It’s a valuable resource for readers looking to gain a well-rounded understanding of copper.

- Source

Frequently Asked Questions (FAQs)

Q: What are some fun facts about copper?

A: Copper is one of the oldest metals known to humanity, dating back to ancient civilizations. It is an essential trace mineral necessary for human health, and we need about 1-2 mg of copper per day. Did you know that the Statue of Liberty contains 80 tons of copper?

Q: How is copper used in everyday life?

A: Copper has been used in a variety of applications, from electrical wiring to plumbing and even cookware. Copper pots, for instance, are cherished for their excellent heat conductivity.

Q: What is copper sheathing, and where is it used?

A: Copper sheathing refers to laminating a sheet of copper onto surfaces, often used in shipbuilding to protect wooden hulls from marine organisms. This practice dates back to the 18th century.

Q: Can you explain what happens when copper is exposed to water?

A: When copper is exposed to water and air, it can react and form a green layer of copper carbonate known as patina. This is often seen on old statues and buildings.

Q: What is a copper alloy, and why is it significant?

A: A copper alloy is a metal made by combining copper with other elements like tin or zinc. Examples include bronze and brass. These alloys are significant for their enhanced properties like strength and corrosion resistance.

Q: What should I know about copper and scrap metal recycling?

A: Copper is highly valued in the scrap metal industry due to its ability to be recycled without losing quality. Recycling copper saves up to 85% of the energy needed to produce new copper from ore.

Q: What are the health implications of copper deficiency?

A: Copper deficiency can lead to various health issues, including anemia, cardiovascular diseases, and weakened immune function. It is crucial to maintain adequate copper levels through diet.

Q: How is copper used in technology and industry?

A: Copper is heavily used in various industries, particularly in electronics for wiring and components. Innovations include plating copper onto a flexible film for use in printed circuit boards, enabling the production of smaller and more efficient electronic devices.

Q: What are copper time capsules?

A: Copper time capsules are containers made of copper, often used to preserve documents and artifacts for future generations. The copper’s durability and resistance to corrosion make it an ideal material for such time capsules.

Q: What unusual facts are there about the copper penny?

A: A fun fact about the copper penny is that pennies minted before 1982 contain significantly more copper content—approximately 95% copper—compared to those minted after, which are primarily zinc with a thin copper coating.