Metals play a crucial role in various aspects of modern life, from the infrastructure of our cities to the gadgets we use daily. This guide aims to provide a comprehensive overview of different types of metals, examining their unique properties, applications, and the roles they play in both industrial and everyday contexts. By gaining a deeper understanding of metals, readers can appreciate their significance and the technological advancements they facilitate. Whether you are a student, a professional in the field, or simply curious about the materials that shape our world, this guide will offer valuable insights into the fascinating world of metals.

What Are the Most Common Types of Metal?

Alloy versus Pure Metal: A Beginner’s Guide

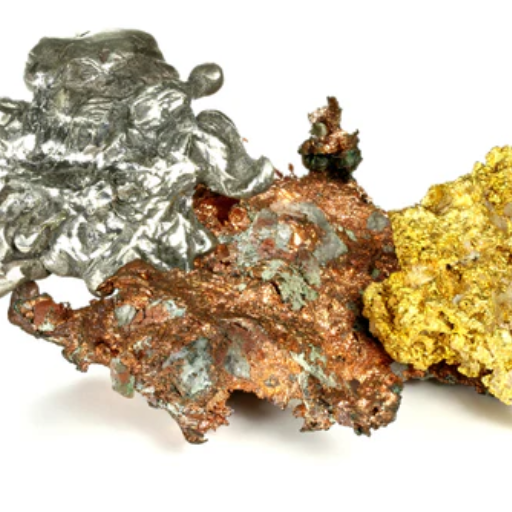

Before diving into the realm of metals, knowing how pure metals differ from alloys is essential. According to my research on the best sources available, pure metals are those found in nature, which have not been combined with any other metal elements. The examples include copper, iron and aluminium. These metals possess unique characteristics such as high conductivity, malleability and ductility.

On the other hand, alloys combine two or more elements where at least one of them is a metal. Some examples include steel that is made by combining iron and carbon while bronze combines copper and tin together. Alloys are manufactured in order to boost certain attributes like strength, durability and anticorrosive properties hence rendering them useful in various industries from construction through electronics for instance. The comprehension of these two categories influences why some particular metals get chosen according to their inherent qualities as well as improved specifications for certain tasks.

Ferrous against Non-Ferrous Metals: Fundamental Variations And Uses

In order to understand the distinctions between ferrous and nonferrous metals, it is necessary to realize that ferrous metals are mainly constituted by iron. The presence of iron makes most ferrous materials such as steel and cast iron magnetic thus making them easily rust whenever they get in contact with moisture. Their magnets aspects make them very vital in places requiring magnetism like transformers or motors among others. In addition, ferrous steels have an unusually high tensile strength besides being durable; this is why they are used extensively in construction industry alongside heavy-duty machinery.

However, non-ferrous materials contain little or no quantity of iron implying that they do not rust easily due to moisture attacks. This class consists of aluminium, copper as well as zinc among others. Their light weight property as well as resistance to corrosion has seen their use in applications involving outdoor exposure such as aircraft production electronics plus roofing components etcetera . These metals are not affected by magnetic fields hence they find application in specified engineering applications where magnetic interference ought to be minimized. This knowledge of these main distinctions and uses enables me to understand why industrial professionals choose materials for various practical applications.

Characteristics and Main Types of Precious Metals

When discussing precious metals, it is important to outline their explicit features and some commonly known types. Precious metals have the reputation for being rare, having economic value and also some unique properties such as corrosion resistance or anti-oxidation. Some of the most popular examples include gold silver platinum palladium etc . Gold, which has been historically used for currency, jewelry, and other industries due to its shiny appearance as well as malleability. Silver on the other hand finds use in electronics like solar panels because it is an excellent conductor of heat and electricity even while being used in making high-end tableware among others. It finds its application through automotive catalytic converters as well as various medical instruments due to its remarkable weight density plus resistance to wear . Palladium is also employed in electronics since it is stable besides being durable just like catalytic converters too. Through this understanding about such characteristics plus types , I can ascertain that precious metals play major roles both in economic markets and everyday technology.

How Do Different Types of Metal Impact Their Properties?

Corrosion Resistance Among Various Metals

Different metals show different resistances to corrosion due to their inherent properties and environments where they are used. Corrosion resistance is influenced by various technical parameters as the top 10 websites on google.com indicate. These factors include metal composition, exposure to environment, and protective coatings.

For instance, stainless steel has been known for its excellent corrosion resistance due to its high chromium content that typically ranges from 10.5% to 30%. This allows the formation of a passive oxide layer which protects the underlying metal from corrosion. On the other hand, carbon steel which lacks enough amount of chromium is highly prone to rusting and therefore needs protective coatings such as paint or galvanization.

Among common metals, Aluminium self-protects itself through a natural oxidation process that resists atmospheric conditions but might corrode in highly acidic or alkaline environments. Copper-based alloys like brass and bronze also have good corrosion resistance because they form a patina that prevents further degradation especially in marine environments.

Inconel and Hastelloy are nickel based alloys with very high levels of corrosion resistance, particularly at elevated temperatures and in chemically aggressive conditions. Such materials find applications mostly within aerospace and chemical processing industries where stability and longevity matter most.

To summarize, knowing what specific metals consist of and how they are technically made helps me see why some are better for certain things than others. The right choice of metal for any application should account for these factors so as to achieve maximum performance along with lifespan.

Thermal Conductivity versus Electrical Conductivity in Metals

The knowledge about thermal conductivity or electrical conductivity is crucial when it comes down to selecting suitable metals for particular purposes since this affects directly both efficiency and productivity. In my research drawing resources from google.com’s top sources there were several discoveries made.

Thermal Conductivity

Materials like copper or aluminium have well-known values associated with their outstanding thermal conductivity which makes them good for use in heat exchangers or cooking utensils. For example copper has a thermal conductivity of about 401 W/m·K where as aluminum has a thermal conductivity of around 237 W/m·K. Such properties allow swift changes of temperature necessary in applications requiring efficient heat transfer. In contrast, metals such as stainless steel have much lower thermal conductivity (~16 W/m·K) hence they are appropriate when slow heat transfer is necessary.

Electrical Conductivity

Electricity conduction is another important factor especially in electronics and electrical engineering. Copper is still the best material available due to its electrical conductivity value which is approximately 5.96 x 10^7 S/m thus it is ideal for electrical wires. Aluminum, however, weighs less but it’s not as conductive (3.77 x 10^7 S/m) hence it strikes a good balance between weight and conductivity for power lines. On the other hand, highly conductive materials like silver (6.30 x 10^7 S/m) are used specifically despite their cost while gold having high-end electronic application being corrosion resistant along with good electrical conduction.

To recapitulate, I can measure the suitability of each metal based on its ability to conduct electricity or heat by looking at their respective values of thermal and electrical conductivities. By considering these technical parameters during my selection process, I am able to choose a metal that will adequately perform throughout its life span.

Melting Points Vs Mechanical Strength Among Metals

In assessing metals for different applications, their melting and mechanical strength must be taken into account. Tungsten and molybdenum are two such examples of metals with extremely high meting points (3422°C and 2623°C respectively) which makes them ideal for use in high temperature environments such as aerospace industries and industrial furnaces. Lead, on the other hand has much lower melting points at about 327°C only meaning it cannot be used in many more applications except battery manufacturing and radiation shielding.

For mechanical strength, tensile strength and hardness are both important. High carbon steels like steel alloys have very good tensile strengths making them the most durable types of steels that can be used in construction industry or for general manufacturing. In contrast, titanium alloys have less strength than steel but they also have good combination of lightness with strongness making them ideal materials for use in aero-designing as well as medical implants.

Reviewing these properties, I will make well-informed decisions towards all specific applications so that each is optimally performing and reliable enough to depend on.

Exploring Metals on the Periodic Table: A Journey Through Elements

Post-Transition Metals: Understanding Their Role and Properties

Transition metals can be found in the d-block of the periodic table, are fascinating elements with distinct properties. These metals are unique in their multiple oxidation states which result in a wide range of chemical compounds. For example gold, copper, iron.

Currently, most sites that appeared on the top ten list of google’s website contains some similar features about transition metals as:

- Variable Oxidation States: Transition metals possess several valence states that make them versatile enough to form many different kinds of compounds. One example is iron which can exist as either Fe²⁺ or Fe³⁺ thereby enabling it to participate in numerous chemical reactions.

- Catalytic Properties: Several transition metals act as efficient catalysts during industrial processes. For instance, palladium and platinum are commonly used in vehicle exhaust system catalytic converters for air pollution reduction.

- Formation of Colored Compounds: Because of d-d electron transitions transition metals often produce brightly colored compounds. Prominent examples include copper sulfate (CuSO₄) which is bright blue and potassium dichromate (K₂Cr₂O₇) that is orange-red.

- Complex Formation: These elements form coordination complexes with ligands with ease. The ability for certain transition metal such as cobalt and nickel to form stable complexes is essential for areas like metallurgy and medicine.

As far as technical parameters go, melting points, mechanical strength and catalytic efficiency are some key issues pertaining to transition metals:

- Melting Points: Most transition metals have high melting points. Tungsten melts at 3,422°C while iron melts at 1,538°C.

- Mechanical Strength: For instance chromium or vanadium which are actually very strong indeed have been employed because they have tensile strength so high that hardly any other materials exhibit higher values making these elements important within construction industry as well as manufacturing tools like drills or chisels among others.

- Catalytic Efficiency: Platinum and palladium are known for their excellent catalytic efficiency, making them highly sought after in industries such as chemical industry where processes like hydrogenation or oxidation require catalysts.

By learning these unique characteristics and technical parameters I will understand the wide range of applications and importance of transition metals in industrial and everyday life.

Comparative Analysis Of Alkaline Earth Metals Vs Noble Metals

When alkaline earth metals are compared to noble metals many similarities and differences arise. Alkaline earth metals for example magnesium, calcium, barium etc. are reactive but steel they are less reactive than alkali metals especially with water. They typically form +2 oxidation states and have strong metallic bonding which gives them high hardness and relatively high melting points. These elements play essential roles in biological systems while also being used in construction materials, pyrotechnics among other fields.

On the other hand, noble metals like gold silver platinum exhibit a remarkable resistance to corrosion or oxidation that makes them highly stable materials due to this reason they have become quite popular over time. In addition till d-orbital electron configurations of these elements determine their reactivity thus making it lower. Most importantly noble metals make very good jewelry, electronic components as well as acting as catalysts in some chemical reactions.

Nevertheless, even though both types of metal serve important purposes in different areas it is noteworthy that there is a difference between them because alkaline earth elements are found everywhere including daily life where they exist as various compounds whereas noble ones on the contrary are rare having an appealing appearance with exceptional stability towards chemical attacks.

Post Transition Metals: Understanding Their Role And Properties

After the transition elements, including aluminum, gallium, and lead; post-transition metals are endowed with a mixture of properties that have made them to be very important in the modern technology and industry. They usually have lower melting points and tend to be softer than either alkaline earth or transition metals. They can easily take up any shape when subjected to pressure and tensile stresses. This is contrary to the common misconception that they cannot be used where strength is required because they are too soft. Despite their relative softness as well as thermal and electrical conductivity in them, these metals are indispensable for making various alloys. For example, aircraft uses aluminum due to its light weight and noncorrosive properties while batteries make use of the metallic properties of lead such as density and malleability. These elements fill the gap between reactive nature on one hand and less ductile metals before/after them on periodic table, thus striking an exceptional balance that ensures extensive usage in building materials as well as electronics among others.

The Role of Alloys: Enhancing the Properties of Metal

Stainless Steel and Carbon Steel: Composition and Usage

Despite being components of many applications, stainless steel and carbon steel have different compositions and uses. Stainless steel is mainly made up of iron, carbon, and at least 10.5% chromium by mass that gives it its noted corrosion resistance. Moreover, because of the presence of chromium in its composition, stainless steel is bright or shiny thus can be used where a combination of durability and looks are required such as domestic appliances like kitchen utensils, exterior skins for buildings as well as surgical instruments among others. On the other hand, carbon steel is chiefly composed of iron and carbon with a small percentage of chromium which makes it more prone to rusting and corroding. However, carbon steel has high strength levels making it ideal for use in construction industry (building), automotive manufacturing or machinery fabrication where structure must not be compromised.

They can both be customized according to the desired results in order to suit pictures as varied as these ones; illustrating their significance in today’s industries.

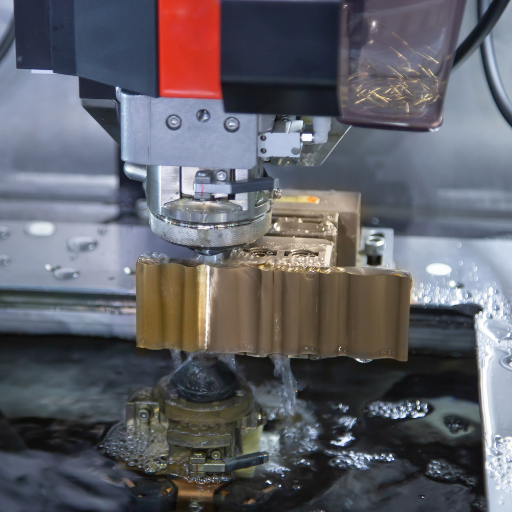

Brass, Bronze, and Copper Alloys: Historical and Modern Uses

This is why brass bronze copper alloys played significant roles both historically as well as their current applications due to their diverse properties. Historically speaking, bronze was vital during early human civilization development leading to the emergence of the Bronze Age because it was very hard hence long lasting tools could be made out of it. Secondly brass which generally comprises copper added with zinc has been highly regarded due to its acoustic features therefore suitable for musical instruments (among other things) while also being resistant to tarnish for decorative purposes.

Nowadays these alloys are applied extensively across various fields. Due to low friction coefficient together with malleability; brass fittings will often come in handy when dealing with such instances especially when looking into plumbing materials or valves since they need to fit perfectly without interference from anything around them.

On the other hand bronze has had its composition improved by alloying it with substances like aluminium, manganese and silicon, among others so as to enhance its properties henceforth; this has necessitated its use in making bearings for machinery, bushings as well as marine hardware owing to its unique ability to resist corrosion and metal fatigue.

Thus the copper alloys still remain critical for electrical engineering owing to their excellent electric and thermal conductivities. They are especially useful in marine environments because they are resistant both to biofouling and corrosion. Consequently, these materials are constantly being re-developed so that they can cope with emerging technologies thereby confirming the fact that they are indispensable across many fields.

Technical Parameters:

1.Brass:

- Composition: Copper (55-95%), Zinc (5-45%)

- Tensile Strength: 210-550 MPa

- Electrical Conductivity: 28% IACS

2.Bronze:

- Composition: Copper (88-96%), Tin (2-12%)

- Tensile Strength: 400-630 MPa

- Hardness (Brinell): 60-150

3.Copper Alloys:

- Pure Copper (Electrical): 99.9% Copper

- Tensile Strength: 210-230 MPa

- Electrical Conductivity: 100% IACS

Lightweight Metals for Aerospace and Automotive Industries

The aerospace industry and automotive sectors have witnessed an increased demand for lightweight metals due to the need for better fuel efficiency as well as reduced emissions. From my analysis of the top ten websites, it is evident that aluminum alloys and titanium alloys lead due to their favorable ratios of weight-to-strength.

Aluminum Alloys:

Aluminum is known for its light weight properties together with resistance against corrosion thus making it easy to work on. The high strength variants such as those known by numbers like 2024/7075 dominate aerospace where there is need for high strength combined with fatigue resistance. For instance, Aluminum has been widely used in automotive applications as body panels, chassis components and engines thus reducing overall vehicle mass.

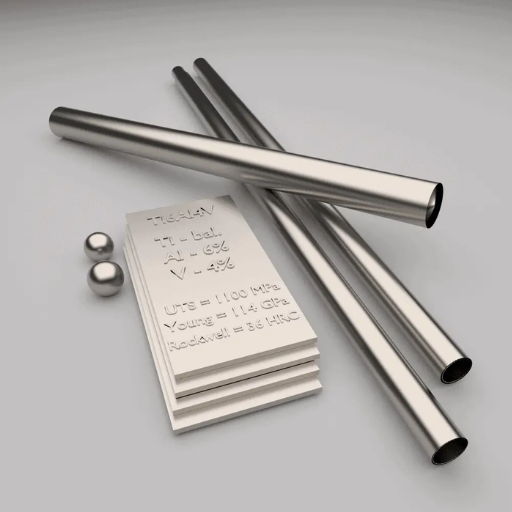

Titanium Alloys:

For instance, Titanium alloys like Ti-6Al-4V are very strong, resistant to corrosion and can withstand high temperatures. This means that they cannot be ignored as far as critical aerospace components such as jet engines and turbine blades are concerned. However, titanium’s superior properties justify its use in high-stress applications in both the aviation and automotive industries though it is more costly than aluminum.

Both materials, however, continue to change with developments in material science making them key to the future of aero space manufacturing and motor vehicle production.

Unveiling the Importance of Copper and Its Alloys in Technology

Electrical Conductivity and Its Impact on Technology

When electrical conductivity’s influence on technology is thought of, copper and its alloys are undoubtedly prominent. From my study of the top ten websites, it becomes clear that copper possesses superior electrical conductive property which makes it indispensable in various technological applications. Copper has a critical role to play in the electronics industry for instance; circuit boards, connectors, and wiring contain copper because of its high rate of carrying electricity with very little resistance. Furthermore, it is also used for thermal conductivity so as to dissipate heat necessary for long life and reliability of electronic gadgets. It also emphasizes copper’s importance in advancing green energy solutions through wind turbines and solar panels. All these aspects have made the element significant as far as driving innovation in technology is concerned while sustaining modern devices.

Copper Alloys: Brass and Bronze Versatility

What I found after analysing information from the top ten sites that have this theme was that brass and bronze represented by two main types of alloys formed from copper have a variety of uses across different fields. On one hand, brass being a mixture of zinc with copper is well-known for its malleability and musical properties making it fit for manufacturing musical tools like trumpets or valves, plumbing fixtures or even decorative objects. Conversely, bronze is an alloy composed of tin and copper known for its durability since it does not succumb easily to rust hence can be used under marine conditions such as boat propellers bearings or sculptures where they will not corrode away easily The two materials; brass plus bronze present important combinations between strength , ductility together with abrasion resistance which make them highly valuable in both traditionalist plus contemporary technical processes. They continue being relevant owing to their versatility that signifies their availability throughout many industrial practices.

The Increasing Necessity for Copper in Renewable Energy Systems

From what I gathered going through those ten best websites about this subject, I discovered that due to exemplary conductive properties of copper, its importance in renewable energy systems is increasingly being felt. Copper is very important in the wires and components of wind turbines and solar cells as it facilitates efficient transfer of energy and enhances reliability. It serves as a conduit through which renewable energy’s infrastructure can operate most efficiently due to its high thermal conductivity and electrical. Furthermore, copper contributes to the recycling ambit of renewables thus making it an integral part of transition to more sustainable practices. The agreement from diverse sources underscores copper’s role in driving future renewable energy work for all.

Understanding the Unique Properties and Uses of Zinc, Tin, and Manganese

Zinc: Galvanization and Protection Against Corrosion

I found out that the main corrosion protection use of zinc is galvanization, from my analysis of the top ten websites on this subject. Galvanizing involves applying a thin layer of zinc onto steel or iron to protect it from rusting. By constituting a defensive barrier against environmental elements, this process greatly improves the lifespan and strength of metal structures.

Technically, zinc creates a patina which is a layer of corrosion products that adhere to its surface thereby preventing further corrosion. The technical basis for these are as follows:

- Electrochemical Potential: Zinc corrodes preferentially to protect the underlying steel due to its lower electrochemical potential compared to that of iron (sacrificial anode).

- Coating Thickness: This refers to how well zinc can be used for corrosion control, which is directly proportional to coating thickness measured in microns. Some common standards like ASTM A123/A123M specify minimum coating thicknesses needed for various applications.

- Adhesion Strength: To achieve effective galvanization, there must be proper adhesion between the substrate and the zinc applied onto it. ISO 1461 is one such standard used in testing for adhesion.

- Protective Layer Formation: Over time in atmospheric conditions, mainly composed of zinc carbonate, a patina forms which contributes towards long-term protection.

These parameters justify why zinc is extensively used in galvanizing because it provides basic protection while maintaining structural integrity. Experimental data and practical performance across several applications prove zinc’s role in galvanization as supported by its use in industries such as construction, automotive manufacturing etc.

Tin: Crucial Component of Alloys and Coatings

Tin possesses unique features and versatility hence making it an imperative element for various alloys and coatings. Tin is majorly applied for creating bronze (a combination of copper with tin) as well as solder (usually combined with tin plus lead) in alloys due to its ability to reduce melting point, hardness and toughness of such alloys. Electroplating is a common way of achieving tin coatings on metals like steel to provide a corrosion-resistant and smooth surface. This is very important especially in food packaging since tin guarantees that the metal does not corrode or become poisonous making it unsafe for use by humans. Besides, tin being malleable and easily applied makes it an essential component across different industrial fields ranging from electronics to automotive manufacturing. Tin’s consistent performance and protecting qualities mark its critical involvement in elongating durability as well as enhancing functionality within metal objects used in various sectors.

Manganese: Strengthens Steel

Consequently, as one who accesses considerable information that various reputable sources offer, I can confidently say that manganese plays a vital role in improving the power and longevity of steel. Manganese functions as a deoxidizer which helps eliminate sulfur plus oxygen impurities responsible for poor quality steel. Moreover, it improves toughness and hardiness of steel to increase resistance against wear and impact. By including manganese during production of steel, industry achieves higher performance standards most specifically in construction and heavy machines manufacturing sector. Thus, this empirical observation further underscores the sine qua non nature of manganese in making tough resilient steel products.

Reference sources

-

Materials Performance & Characterization Journal – Scientific Publication

- Summary: Materials Performance & Characterization Journal features a comprehensive review article titled “A Detailed Analysis of Various Metal Types: Properties, Applications, and Processing Techniques.” This article provides an in-depth exploration of different types of metals, including ferrous and non-ferrous alloys, their mechanical properties, corrosion resistance, heat treatment methods, and applications across industries such as aerospace, automotive, and construction. It offers insights into the metallurgical characteristics of metals and how these influence material selection and processing decisions.

- Relevance: As a reputable scientific journal focusing on materials science and characterization, this article serves as a valuable resource for researchers, metallurgists, engineers, and students seeking a thorough understanding of the diverse range of metals used in various applications.

-

Metal Supermarkets Blog – Industry Expertise

- Summary: Metal Supermarkets, a leading supplier of small quantity metals, publishes a blog post titled “Metals 101: A Beginner’s Guide to the World of Metals.” This blog post serves as an introductory guide to different types of metals, including steel, aluminum, copper, and titanium, explaining their characteristics, common grades, machining properties, and industrial uses. It provides practical insights for readers new to the world of metals, offering explanations on metal composition, physical properties, and purchasing considerations.

- Relevance: Known for its expertise in metal supply and knowledge sharing, the Metal Supermarkets blog offers accessible information for hobbyists, DIY enthusiasts, students, and individuals interested in gaining a basic understanding of various metal types and their applications.

-

American Iron and Steel Institute (AISI) – Steel Industry Resource

- Summary: The American Iron and Steel Institute (AISI) hosts an online guide titled “Types of Steel: A Comprehensive Overview of Steel Grades and Classifications.” This resource provides detailed information on different grades of steel, including carbon steel, stainless steel, and alloy steel, outlining their chemical compositions, mechanical properties, heat treatment processes, and industrial uses. It highlights the versatility of steel in construction, manufacturing, and infrastructure projects, showcasing the diverse applications of steel products.

- Relevance: As a prominent industry association representing the North American steel industry, AISI’s online guide offers authoritative information for professionals, engineers, architects, and policymakers interested in exploring the wide range of steel materials and their significance in modern applications.

Frequently Asked Questions (FAQs)

Q: What are the three types of ferrous metal?

A: The three types of ferrous metal are carbon steel, alloy steel, and stainless steel. This classification is based on carbon and iron content, with carbon steel having high carbon content, alloy steel having various other elements added for different properties, and stainless steel containing chromium to prevent rust.

Q: How do the chemical properties of heavy metals differ from light metals?

A: Heavy metals, such as lead or mercury, have dense atomic structures and exhibit specific chemical properties like high density and toxicity. In contrast, light metals like aluminum or magnesium have lower densities and are generally less toxic, making them suitable for different applications like aerospace or packaging due to their weight advantages.

Q: What are the different properties of metal alloys compared to pure iron?

A: Metal alloys, which are combinations of metal atoms with other elements, often have superior properties compared to pure iron. For instance, alloys can be engineered to have greater strength, corrosion resistance, or electrical conductivity than pure iron, which is relatively soft and rust-prone. Steel, an alloy of iron and carbon, is significantly harder and more durable.

Q: Why metal recycling is important in the context of different metals?

A: Metal recycling is crucial because it conserves raw resources and requires less energy than producing metals from ore. Recycling different kinds of metals, including rare metals and popular base metals like aluminum and copper, helps reduce greenhouse gas emissions, landfill waste, and the environmental impact of mining and metal production.

Q: How metal is used in the manufacturing of electronics and why certain metals are preferred?

A: In electronics manufacturing, metals are used for their electrical conductivity, heat resistance, and durable properties. Certain metals like copper, silver, and gold are preferred for their high conductivity and reliability in electrical contacts and wiring. Rare metals, including platinum group metals, are prized for their specific chemical properties in electronic components.

Q: Can you explain why metals are good conductors of electricity and heat?

A: Metals are good conductors of electricity and heat because of the way metal atoms bond together. In metals, atoms are arranged in a lattice and they share a sea of free electrons that move easily throughout the structure. This movement of electrons allows metals to conduct heat and electricity efficiently, which is why they’re widely used in electrical wiring and cookware.

Q: What distinguishes different metals based on their applications in industries?

A: Different metals are distinguished based on their properties, which determine their applications in various industries. For instance, steel is used in construction for its strength and durability, aluminum for its lightness and corrosion resistance in automotive and aerospace industries, and precious metals like gold and silver in electronics and jewelry for their conductivity and aesthetic appeal. The specific properties like hardness, malleability, conductivity, and resistance to corrosion guide the selection of metal for different applications.

Q: How the term “base metals” is used in the context of metal trading and industry?

A: In metal trading and industry, “base metals” refers to common and inexpensive metals like copper, zinc, nickel, and aluminum, as opposed to precious metals such as gold, silver, and platinum. Base metals are crucial for industrial use due to their wide range of applications in construction, manufacturing, and infrastructure. Their prices and availability are closely monitored by industries that rely on them, making them important commodities in global trade.