Engraving is an age-old jeweler art that has its roots tracing back to ancient civilizations and has remained as a valuable form of artistic representation in both decorative and functional purposes. This is however not an easy process since it involves creating designs by cutting into hard surfaces such as glass or metal thereby leAving behind impressions that are both enduring and beautiful. Engraving, however, still retains its ebullience even as it changes from the traditional methods passed down from generation to generation to adaptive ones used in contemporary times.The different engraving techniques will be explored in this blog post providing readers with insight regarding their peculiarities, uses as well as the requisite skills. With this investigation you can expect to discover how every single method reflects incredible technique along with finesse whether you have been doing this for some time now or just venturing into it.Enjoy our trip to reveal hidden facts about this discipline and reveal the intricacies that make it captivating!

What Are the Different Types of Engraving?

Image source: https://sixsellov.live/

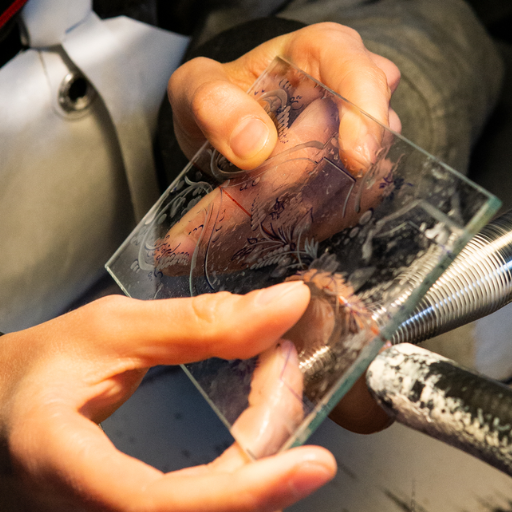

1. Hand Engraving

Hand engraving is an age-old art form that involves etching delicate patterns on a material with manually operated gravers – small tools that are held by hand. Its implementation calls for great skill, precision and attention to detail which means it is possible for individuals to personalize their work.

2. Machine Engraving

Machine etching is performed using computer-driven machines on different materials’ surfaces. This method is usually applied in serial and standard pattern making industries like jewellery and electronics where high flow rates of products have to be achieved.

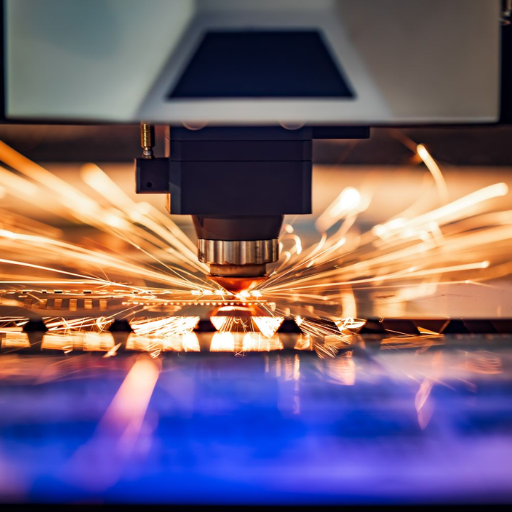

3. Laser Engraving

Laser engraving uses highly focused lasers to cut through the surface material leaving a permanent recess. It is very efficient and flexible on nearly all materials such as metals, woods, glasses or even plastics hence mostly preferred due to its speed and precision.

4. Etching

Acid etching involves covering the material’s surface with acid resistant substances before removing areas exposed through acid erosion and thus leave behind designs thereon. In arts most especially fine ones, this technique has gained popularity because it can bring out detailed drawings.

5. Photo-Engraving

Photogravure refers to the process of making images from chemical methods such as photography on a surface instead of anything else that may be done on it if required in different forms of printing plates or circuit boards because it provides great accuracy and clarity.

How Does Traditional Hand Engraving Work?

Traditional hand-engraving begins with the choice of appropriate types of gravers among which are jeweler’s tools with differently shaped tips used for cutting various kinds of grooves during design work. Mostly, a vise is used to fix the engraved article thereby preventing its displacement while working on it by an artisan . With controlled pressure, these professional designers guide their shapers along these patterns taking care not exceed them more than necessary in depth since this needs steady eye-hand coordination which implies that performance must be accurate. The finest work is usually magnified with a glass. Every item produced in this manner is unique and it illustrates the engraver’s craft as well as artistry.

What Are the Main Types of Machine Engraving?

Various kinds of machine engraving are:

- Laser Engraving: Creating clean, precise engravings on objects like wood, metal, glass and plastic using laser beams that vaporize materials. Laser engraving is chosen for its speed, accuracy, and ability to deliver intricate designs.

- Rotary Engraving: This method involves a tool or cutter that rotates as it cuts into the materials; this process is best for carving deeper and more dimensional works. Rotary engraving is excellent for metals, plastics and other hard materials which can be used for making logos, texts or decorative parts.

- Dot Peen Engraving: Indentations are made on the material by the stylus creating a series of dots; this technique is ideal for marking hard plastics and metals. Dot peen engraving is widely applied in serial numbers barcodes industrial components due to its strength and heavy duty marking capability.

These types of machine engraving offer diverse applications and benefits which suit different materials along with precision requirements.

How Does Laser Engraving Compare to Other Methods?

When compared to other methods, laser engraving is unmatched in terms of precision and versatility. In contrast to the rotary engraving that involves contact with materials, laser engraving uses laser beams which vaporize the surface leading to cleaner and more intricate designs without wearing away the tools. Additionally, this technique is quicker and can produce finer designs that may not be possible with rotary or dot peen engraving. Although dot peen marking is excellent for heavy duty marking and durability, it lacks accuracy as compared to laser engraving which can be used on a wider range of materials such as metals, plastic, wood and glass. Therefore, for highly accurate and detailed jobs, laser engraving is often preferred.

What Is the Laser Engraving Process?

Creating a digital design starts the process of laser engraving, then it is uploaded to a laser engraving machine. Using this design, which serves as the guide for its laser beam to follow, directed towards the material. The high intensity of the laser causes materials to vaporize or burn away and leaves behind an engraved pattern that is very precise. It can be done in various ways including; adjusting different depths, speeds and materials depending on what one wants to meet with it. Cooling mechanisms often help in managing heat produced during engraving so as to get clean lines and precision in the final output. This method is popular because it can quickly produce engravings that are highly detailed and sturdy too.

How Does a Laser Beam Etch Materials?

Material is etched by a laser beam that concentrates high-energy, coherent light onto the material surface. This energy that is concentrated causes the material to melt, burn or vaporize so as to produce very fine patterns. To suit different materials without destroying surrounding materials, it is possible to regulate the wavelength and intensity of the laser used in this process. Consequently, making highly detailed designs and long lasting objects calls for higher precision. In addition, laser etching has no tool wear owing to its non-contact nature which consequently enhance efficiency and durability of an engraving process.

What Are the Advantages of Laser Engraving?

There are many benefits of laser engraving, and that is why it is a preferred method for many applications. First, its extraordinary accuracy allows for intricate patterns and small details which would be difficult to attain by using traditional methods. Second, Laser engraving is noncontact thus there is no physical wear on either the tool or the material; this makes them more durable and resistant to damage. Moreover, one should not overlook the flexibility of laser engraving that can be applied on an array of materials including metals, plastics, wood and glass. It also saves on time and money because it facilitates fast production with minimal waste and can be automated easily for large scale projects. Lastly, through laser engraving high quality results are achieved that will last long without fading hence making sure that engraved designs remain sharp and clear always.

What Materials Can Be Engraved with Different Techniques?

Each material requires a different manner of engraving that could be done with various techniques hence the following are the details of every one:

- Laser Engraving: This is good for metals, as well as plastics, wood, glass and ceramics. It is non-contact and gives precise detailed designs.

- Rotary Engraving: For metal – optimized material and some types of plastics. Employing a spinning tool to cut into the surface so it’s ideal for deeper engravings.

- Chemical Etching: Efficiently works on metals plus glasses. The technique uses chemical solutions to etch the surface thus it is widely applied in large patters and fine details’ implementation.

- Sandblasting: This method mainly used on glass, stone, or metal surfaces. Here an abrasive particle is blasted at high speed onto the surface which creates a textured kind of finish.

Comprehending Metal Engraving

As for various needs and materials, metallic engraving is done using several methods. Laser engraving which specializes in complex and detailed work on metals like stainless steel, aluminum, and brass stands out as one of the commonly used ones. It does not touch anything, hence very accurate and wears out the material minimally.

Rotary engraving is an older technique that relies on a rotating cutting tool to make lines deeper and bolder making it suitable for items that need strength such as data plates or personalized gifts.

Chemical etching also called acid etching entails applying chemical solutions to metals surfaces .Because of its uniformity, this method 9 is most effective in creating fine details and intricate patterns often used in industrial purposes or artworks .All these techniques have their own set of advantages depending on what one wants to achieve with them.

Different Techniques for Engraving Wood

There are a number of ways to achieve wood engraving, each with its own advantages.

- Laser Engraving: The high demand for this method is due to its accuracy and the fact that it can make very complicated designs. This style uses a beam of light from a laser machine to turn the surface of wood into vapor thereby enabling one create detailed images, letters and even pictures. They are best used when making logos, personalized souvenirs as well as decorative pieces.

- Rotary Engraving: In this traditional technique, wood is carved using a spinning tool. This method cuts deeper and is useful for applications that require long-lasting products like signs, plaques or artistic sculptures. Consequently, this process can be applied on various kinds of woods since it is flexible.

- Hand Engraving: Craftsmen use sharp tools manually to carve designs directly onto the wooden material for hand engraving which is more manual and artistic in nature. It allows for high level personalization and detailing but requires great expertise and time investment. Hand engraving finds common application in custom furniture, art works among other delicately designed decorative items.

Wood engraving is a versatile craft suitable for various projects and tastes because each technique has something special about it.

How Paper and Other Materials Are Engraved

Engraving on paper and other materials like wood is a complex process. The conventional way of doing it on paper is through dry point engraving where the design is scratched on to a metal plate using a needle or sharp tool. The plate is then used to print ink onto paper, producing raised areas and fine details.

Laser Engraving is another widely used method. It uses laser beam to inscribe or cut designs on different items such as papers, cardboards, fabrics among others. This machine has been known for its high precision, speed and ability to replicate intricate designs which makes it ideal for industrial labels, invitations and art.

Gravure in metal and glass typically involves diamond tipped tools or CNC machines that are good for precise elaborate creations. For instance there are some intricate designs that need robust and sturdy methods like this one. Also glass particularly can be sandblasted to create frosted designs if necessary.

The recent technological developments have also brought forth 3D Printing Techniques that allow the reproduction of engraved patterns across many types of materials thereby expanding the flexibility and creativity achievable when an artist chooses modern engraving practices. Each approach has its own strengths since they permit customized sophisticated forms using various materials.

What Types of Engraving Machines Are Available?

Diverse engraving machines are available, each designed to work on different materials and purposes. For example, Manual Engraving Machines are very straightforward and value adding as they are used by many hobbyists or for small projects. Laser Engraving Machines use focused laser beams that achieve a high level of accuracy thus can be used on paper, wood, fabric, metal and plastics. As for Rotary Engraving Machines, these have cutters which rotate and thus engrave on the hardest of materials like metals, stones and wooden objects. A CNC (Computer Numerical Control) Engraving Machine has the capability of automated engraving which is highly accurate as well when dealing with complex large-scale projects. In addition to this primary function of creating frosted designs on glass and stone is that of Sandblasting Engraving Machines. Depending on what one wants to achieve in an engraving project each type has its own benefits to offer.

Differences in Laser Engraving Machines

The type of laser, power output, and intended application are different for every laser engraving machine. CO2 Lasers is one kind of them which are Fiber Lasers and Diode Lasers.

CO2 Lasers are most effective on non-metallic materials like wood, acrylic, paper, and plastic. In general they have low power but can cut and engrave with high accuracy making them suitable for many hobbyist and small business purposes.

Fiber Lasers are more powerful and appropriate for marking and engraving metals as well as some plastics. They have the highest power output to efficiency ratio that make them perfect for industrial applications such as barcodes/serial numbers etc., on metal parts.

Diode Lasers are not very common yet cost-effective in performing light duty engraving jobs. These types of lasers work effectively on softer materials thus most people prefer using it at homes or schools because they are cheaper compared to others in the market.

Each type of laser engraver has its advantages and is designed to be used with particular materials taking into account various other parameters thereby allowing users to select according to their needs.

What Is CNC Engraving?

CNC engraving stands for Computer Numerical Control (CNC) manufacturing technology that controls the operation of machine instruments used to make engravings onto different materials such as designs, texts or patterns. It’s superior to the conventional ways of doing it because it’s highly precise and repeatable through computer programming. It is applicable in various mediums like metals, plastics, wood and glass. CNC engraving translates digital designs into exact kinetic moves so that complex and uniform patterns can be done making it a good tool for both small variant production and mass production. This usually involves a spinning device which holds many cutting tools and then engraves on the material basing on what has been programmed thus giving out very smooth surfaces with high precision.

Exploring Diamond Engraving Machines

They are known for their exceptional accuracy and durability, making them the perfect choice for high-end engraving projects. These machines employ diamond with industrial quality that can be used to engrave minute details on a variety of materials such as metal, glass and ceramics. The major benefits of diamond engraving include unmatchable detailing, life-long grinding tool and no need for other finishing treatments as good finishes are achieved without them. Their sharpness and precision can be retained even after long time use due to the fact that diamond is one of the hardest substances in existence; it is thus capable of yielding uniform or improved results. This is because diamond engravings in jewelry designs are preferred by many people since they result into intricate designs with personalized inscriptions that last forever.

How Is Laser Marking Different from Traditional Engraving?

Laser marking is fundamentally different from traditional engraving in a number of ways. To begin with, laser marking employs a concentrated beam of light to mark materials’ surfaces while the latter utilizes a tool to physically cut into the material. This distinction implies that laser marking is typically noncontact, reducing the wearing off of the marking equipment and also minimizing damage to the substrate. Besides this, it allows for higher precision and the creation of more complex designs. Moreover, it can deliver high speed and high contrast results when used on metals, plastics and ceramics among other materials. On the contrary, traditional engraving may be preferable for deeper cuts and offers a finished product that has tactility.

Understanding the Process of Laser Marking

Laser marking involves using a high-powered laser beam to change the surface properties of materials resulting in accurate and permanent marks. It starts with generating the laser beam which is then passed through several mirrors and lenses to concentrate its energy at a small area on the target material. The focused light interacts with the material’s surface leading to localized heating, chemical events or physical changes as may be applicable depending on the material and type of laser.

Several types of laser marking techniques exist including:

- Annealing: This method heats up metal without removing its surface hence resulting to alteration of color due to oxidation.

- Etching: This is where the material melts away and vaporizes thus creating depth.

- Engraving: An intense beam removes material leaving deep lasting marks.

- Ablation: Coatings or films are removed exposing underlying materials while not affecting the substrate.

Laser marking is highly valued for its speed, accuracy, and versatility. In many cases it can mark metals, plastics, ceramics, glass and other materials without requiring further finishing steps. Computer-aided design (CAD) software has made it possible for manufacturers to design complex parts that they can produce with consistently high quality even in large numbers.

Differences Between Laser Marking and Laser Engraving

Laser marking and laser engraving are different methods that people confuse quite often though the differences between them are precise.

Usually, laser marking alters the surface properties of a material without removing material. This leads to chemical or molecular changes due to contact of the laser beam with the material’s surface resulting in marks. The energy is low and thus it results into visible but less deep marks. Such consequences are normally needed for barcodes, serial numbers, etc., when durability and precision matters while depth is not important.

On the contrary, laser engraving entails removal of materials at its surface through vaporization thereby producing deeper and more enduring marks. Increased energy levels are used to cut into the object thus creating a tactile groove or indentation. Laser engraving is commonly employed in personalizing items like trophies, industrial components which must have marks resistant to wearing out.

Summarily speaking, there are two major differences between these two techniques: how deep they go and how visible their marks appear. While laser marking is all about changes within one layer by means of a laser beam, lasers engrave deeply into materials. The two techniques being highly accurate can be applied with versatility depending on what one wants to achieve from an application.

Frequently Asked Questions (FAQs)

Q: What is engraving and how is it used?

A: Engraving is one of the oldest artistic techniques used to create intricate designs on various materials such as metals, glass, and wood. It involves incising or carving designs onto a surface using different engraving tools. This method of engraving is widely employed in creating customized pieces of jewelry and art.

Q: What are the different types of engraving techniques?

A: There are several types of engraving techniques including modern hand engraving, rotary machine engraving, laser engraving, and line engraving. Each technique uses different engraving tools and methods to achieve unique results.

Q: How does laser engraving work?

A: Laser engraving uses a concentrated laser beam to etch designs onto a surface. This laser beam is used to precisely remove material, allowing for high accuracy and detail, making it ideal for small engraving tasks and intricate designs.

Q: What tools are used in modern hand engraving?

A: Modern hand engraving artists often use small engraving tools such as burins and gravers to manually carve designs onto a surface. Pneumatic engraving systems can also be used to provide more control and precision.

Q: How is line engraving different from other techniques?

A: Line engraving is a form of engraving where the image is created using a series of lines incised into a surface. This technique is often used for creating detailed illustrations and can be seen in many classical pieces showcased at museums such as the metropolitan museum of art.

Q: What materials can be engraved using rotary machine engraving?

A: Rotary machine engraving uses a rotating engraving head to cut designs into materials such as metals, plastics, and wood. This method of engraving is commonly used in industrial applications and for producing durable signs and nameplates.

Q: How has the history of engraving evolved over time?

A: The history of engraving dates back to ancient times where it was an important art form for creating decorative items and recording information. Over the centuries, various techniques and tools have been developed, leading to advanced engraving systems that we use today.

Q: What are the applications of laser engraving and laser cutting?

A: Laser engraving and laser cutting are widely used in various industries for applications such as creating detailed artwork, personalizing items, and manufacturing components. Engraving services offering these techniques can produce highly precise and intricate designs on a variety of materials.

Q: How can engraving be used in creating pieces of jewelry?

A: Engraving is also used in the jewelry industry to add personalized touches to pieces such as rings, bracelets, and pendants. Small engraving tools or laser engraving systems can be used to engrave initials, dates, or intricate designs onto jewelry items.

Q: What role does engraving play in museums of art?

A: Engraving plays a significant role in exhibiting the evolution of art and techniques. Many museums of art, including the metropolitan museum of art, showcase historical engraved pieces that illustrate the craftsmanship and artistic styles of different eras.