Steel extrusion profiles are used in many industries because of their adaptability and strength. This blog post will cover the basics of steel extrusion – its processes, applications, and benefits. It doesn’t matter if you’re an expert or just starting out; this guide aims to give you all the information you need for understanding and using them effectively. We’ll go from how steel is extruded down to different shapes and design principles so that you can choose wisely for your projects.

What Is Steel Extrusion and How Does It Work?

Image source: https://www.stainless-structurals.com/

Steel extrusion refers to a manufacturing process that pushes steel through a die producing objects with constant cross-sectional profiles. The first step involves heating a steel billet until it becomes soft enough to be worked on easily. Next, the heated billet gets forced via a hydraulic or mechanical press into contact with dies having desired shapes. When exiting these openings, the metal takes up forms similar to those of their counterparts thereby creating extended lengths continuously as well as along them being able then cut into required sizes. This approach enables high productivity rates when dealing with intricate geometrical sections hence making it applicable widely across such sectors like construction automotive aerospace due its ability produce stronger materials which can withstand various forces better than other methods would allow for.

Introduction to the Extrusion Process

A few important steps are taken in the steel extrusion process to convert raw steel into usable profiles. Typically, the first step is heating steel billets to a high temperature of about 1,100 degrees Celsius so as to make them more ductile. After reaching the right temperature, they are then fed into an extrusion press where hydraulic ramming forces these metals through dies having desired cross-sectional shapes. It is during this stage that specific profiles required for their intended applications are achieved as they come out from the dies. The next thing done with them will be cooling; usually quenched by air or water then cut into necessary lengths afterwards. Depending on what type of materials and finishes are needed; annealing among other post-processing methods such as surfacing treatment or machining might also be carried out in order to meet certain standards regarding materials used and appearance achieved . This is a fast way of making robust parts which have complicated forms because it can be applied widely across various sectors including but not limited to building construction industry , automobile manufacturing sector as well aviation field among others.

The Basics of Steel Extrusion

Steel extrusion is a technique used to create profiles by forcing steel through a die, usually in the form of billets. It consists of the following steps:

- Preheating: The malleability of steel billets is increased by heating them up to about 1,100 degrees Celsius.

- Extrusion: Then the heated billet is placed into an extrusion press where it goes through a die with required shape under pressure from hydraulic or mechanical ram.

- Shaping: Once passed through the die, steel takes on that opening’s shape and becomes continuous lengths having specific cross-sectional profiles.

- Cooling: Air quenching or water cooling are some methods applied in order to cool down extruded steel.

- Cutting and Post-Processing: After they have cooled off enough; these materials are cut into appropriate lengths before being subjected to additional treatment such as annealing; surface finishing/machining, which may be needed for meeting different standards accordingly.

Steel extrusion allows complex geometrical shapes with high strength to be made easily thus making it applicable widely within construction industry automotive sector aerospace among other fields. This not only improves mechanical properties but also ensures accurate and efficient production of tailored profiles based on this process.

Applications of Extruded Steel Profiles

Among the many industries where they are used, extruded steel profiles stand out due to their flexibility and strength. In constructions, these shapes are commonly employed as support systems or reinforcements which help in stabilizing buildings and infrastructure projects. Vehicle frames for cars and automobile safety improvement through chassis components and crash management systems are some areas that benefit from extruded steel profiles within the automotive industry. On the other hand, aircraft structures lightweightness while being strong enough to withstand extreme conditions can only be achieved with them during aerospace engineering. It is also worth noting that apart from this use alone; machines need accurate movements too thus making extruded steel profiles an important part of every mechanical application.

Why Choose Stainless Steel for Extrusion Profiles?

Corrosion resistance is one of the factors considered when choosing stainless steels for extrusion profiles because it has excellent corrosion resistance, durability, strength among others. Being able to maintain its structural integrity even at very high temperatures or under severe environmental circumstances makes stainless steel suitable for use in harsh environments where other materials may fail to perform up-to the required standards such as offshore oil rigs etcetera.. Moreover, stainless steels have aesthetic values which can enhance appearance especially if polished well enough besides requiring less maintenance thus saving on costs over time; hence becoming more popular not only in construction sector but also automotive industry like aerospace among others involved in food processing where hygiene matters most. Additionally recyclability helps promote sustainability efforts since they align with current environmental expectations.

Benefits of Stainless Steel Extrusion Profiles

- Corrosion Resistance: Stainless steel is naturally resistant to corrosion, so it can be used in areas that are exposed to moisture, chemicals, and acids. This means that they don’t have to be replaced often, leading to long-term savings.

- Strength and Durability: Profiles made from stainless steel extrusion have an excellent strength-to-weight ratio which makes them perfect for applications where high stress is expected. They can bear heavy loads under extreme conditions without bending or breaking hence ensuring the robustness of the end product.

- Aesthetic Appeal: Stainless steel looks sleek and modern which is why it is commonly used in construction, architecture as well as interior design for visible parts. Its ability to keep a polished finish while resisting stains guarantees timeless beauty.

- Low Maintenance: Stainless steel products require little maintenance since they do not easily rust or stain – therefore; these items can remain functional and attractive with minimal care leading to reduced maintenance costs and labor requirements.

- Hygienic Properties: It is easy to clean stainless steel because there are no places where germs could hide thus making this material suitable for use in such industries like food processing, healthcare or pharmaceuticals where cleanliness is important.

- Sustainability: Stainless steel is recyclable thus contributing positively towards sustainability efforts. Being able to recycle ensures efficient reuse of resources in line with current environmental policies thereby cutting down on overall carbon emissions.

Comparing Stainless Steel to Aluminium for Extrusion

When contrasting stainless steel to aluminium for extrusion, there are a number of factors to consider:

- Strength and Durability: One thing that stands out about stainless steel over aluminum is its strength and durability. It is stronger than aluminium which makes it suitable for heavy duty applications where the structural integrity of a product must not be compromised. Conversely, while being lighter in weight but generally cannot match up against stainless steel when it comes to strength nor does it have same levels of durability as stainless steel.

- Weight: Aluminium is significantly lighter than stainless steel, allowing for weight savings in applications where mass reduction is critical. As such, this makes aluminum more preferable choice within industries such as aerospace or automotive sectors which can benefit a lot from increased fuel efficiency achieved by lowering down vehicle weights.

- Cost: Compared with stainless steels aluminum tends to be less expensive on average per unit volume due largely because its initial cost may not involve charges related directly with manufacturing processes other materials require before being put into final shape during production cycle; also there are cases where even though some parts made out of SS may cost more initially but they end up saving money over time due long life span associated with such components coupled low maintenance required since these two factors often offset each other depending upon specific application needs.

- Corrosion Resistance: Both stainless steel and aluminium provide good corrosion resistance although in general terms SS performs better than Al especially under harsher conditions. Al will corrode after sometime particularly when exposed salts or certain chemicals while SS has ability resist rusting caused by acids among other things hence making it ideal choice for extreme environments where high levels of protection against corrosion are necessary.

- Conductivity: Aluminum has higher thermal conductivity compared to that of SS so if heat dissipation efficiency ranks among top priorities then opting for Al would be best decision ever taken likewise electrical conduction should also factor much into consideration since metals like Copper exhibit excellent conductive properties hence finding extensive use within power transmission sector.

- Aesthetic and Hygienic Properties: Stainless steel is known for its sleek modern look and ease of sterilization which makes it perfect choice whenever aesthetics or hygiene needs come first more especially in medical field as well food industry among others where cleanliness paramount.

In conclusion, choosing between stainless steels and aluminum alloys during extrusion process depends entirely upon what exactly you want to achieve out of your product hence one has balance various aspects such as strength, weight, cost, resistance against corrosion among others.

Cost Considerations for Stainless Steel vs. Aluminium Profiles

Several things should be considered when comparing the cost of stainless steel profiles with that of aluminum. According to reliable sources, the initial material costs for stainless steel are generally higher due to its composition and strength while aluminium is cheaper upfront. Nonetheless, in harsh conditions or places where durability matters most like these ones, stainless steels may save you a lot through its low maintenance requirements over time. In addition to this, aluminium is much lighter than steel meaning it can be easily transported from one place to another without much effort being put on weight lifting which also means easy handling during fabrication processes thereby reducing labor cost per unit produced significantly thus making it cheap overall. Finally; the choice here depends purely upon what is needed at hand since we can only compare initial investments vis-à-vis long-term usage.

How to Select the Right Steel Extrusion Supplier?

When choosing a steel extrusion supplier there are many factors that need to be taken into consideration if you want high quality products and services. First look at how long have they been operating in this industry? Suppliers who have been around for some time now tend have good records because people keep coming back whenever they require their goods delivered reliably with uniform levels of quality; therefore such suppliers should always be given priority over new entrants or those without any track records yet since nobody knows what could happen next so better safe than sorry right? Second check out what kind of service does each offer among other things such as whether there is an option for customized extrusions or not plus do provide secondary processing facilities too apart from just materials used e.g plastics etc? Do ensure these practices meet required standards set by relevant bodies otherwise look elsewhere. Also consider lead times vis-a-vis project deadlines so that nothing goes wrong along way as well pricing structures adopted which ought reflect market realities prevailing during sourcing period but without comprising quality otherwise it will turn out expensive affair altogether ; customer support service coupled with after sales care provided also matter a lot more especially if something happens later on after purchase like repairs etc.. This means that there should always be someone ready to assist whenever called upon. By considering all these things one can easily settle for a supplier who will serve them best depending on what their projects require.

Qualities of a Reliable Extrusion Supplier

To obtain a reliable supplier for extrusion, contemplate these qualities:

- Experience and Expertise: Pick out those suppliers who have been in the industry for long and are well-established. They possess vast knowledge and skills required to handle complicated projects besides proposing new ideas.

- Quality Assurance: Make sure that they have certificates such ISO 9001 or its equivalent which shows their commitment towards maintaining high standards throughout production process . The quality control measures of an excellent supplier should involve strict tests as well as inspections so as to keep up with reliability and uniformity of what they manufacture.

- Customization Capabilities: Flexibility counts a lot when it comes down to choosing good suppliers; therefore go only for those capable of giving various options like personalized profiles or even specific alloys depending on what is needed by different clients at particular times during their projects implementation period.

- Advanced Technology and Equipment: Ensure precision by going for those suppliers who use modern machines supported by latest technologies during extrusions thereby increasing not only quality but also speed while producing them.

- Customer Service and Support: A good supplier should be able to offer all-round support services right from the beginning through consultations up to after sales service delivery stage . They must be quick in responding inquiries made by customers through any communication channel provided whether it is email address or phone numbers indicated on website pages where necessary, this will indicate whether they can relied upon always .

- Competitive Pricing: Consider several quotations from different companies before making final decision based on your budget estimate so as to identify most affordable yet reliable one among them without compromising anything concerning price or quality aspect.

By focusing on these qualities, you can confidently select an extrusion supplier that aligns with your needs and ensures the success of your projects.

Questions to Ask Your Extrusion Provider

To make sure that they meet your project requirements, it is very important to ask specific questions when evaluating an extrusion provider. Here are some of the most important ones:

- Can you provide references or case studies of similar projects you have completed?

- This will help determine their level of experience and dependability in handling projects like yours.

- What quality control measures do you have in place to ensure product consistency?

- Knowing their QC processes will give assurance about getting good products all the time.

- How do you handle customization requests and what options are available?

- It’s important to know how flexible or capable they are with meeting unique project needs – be it special finishes, custom profiles among others.

- What technology and equipment do you utilize in your extrusion processes?

- You need them to use modern machines alongside advanced technologies so as not only to enhance accuracy but also efficiency throughout production.

- What level of customer support can we expect throughout the project lifecycle?

- Assessing whether initial consultations will be held or not, plus after sales services among others should prove helpful here especially if these happen before any agreement has been made between two parties involved.

- How competitive is your pricing compared to other suppliers, and what value-added services do you offer?

- Doing so helps one know if indeed what this company charges falls within industry ranges thus optimizing on one’s budget while at it; Also find out if there’re any additional things offered by such organizations which may benefit us financially or otherwise.

These questions will help you evaluate whether an extrusion provider can offer customized solutions that suit your needs while still maintaining high standards of quality.

Supplier Certification and Quality Standards

When selecting an extrusion provider, making sure they meet strict certification and quality standards is essential. Below are the brief answers:

- Can you provide references or case studies of similar projects you have completed?

- Yes, we have an extensive record of accomplished projects available in our case studies section. We can also provide references as requested.

- What quality control measures do you have in place to ensure product consistency?

- Our QC measures comprise ISO 9001 certification, regular audits and advanced inspection methods like X-ray fluorescence (XRF) and coordinate measuring machines (CMM).

- How do you handle customization requests and what options are available?

- We offer a vast array of customization options including bespoke profiles, different alloys, surface treatments and finishes among others. Our team works closely with customers to meet their unique needs.

- What technology and equipment do you utilize in your extrusion processes?

- To ensure accuracy and efficiency in our processes we utilize modernized extrusion presses, CNC machining as well as automated quality control systems.

- What level of customer support can we expect throughout the project lifecycle?

- From initial design consultations through after-sales support; our dedicated customer service representatives are always available to walk with you at every stage of your project.

- How competitive is your pricing compared to other suppliers, and what value-added services do you offer?

- Our pricing is very competitive and besides that we provide such value added services as prototyping, inventory management together with supply chain logistics all aimed at optimizing your project costs.

You can confidently choose a partner who will deliver excellent products coupled with outstanding service by ensuring that your extrusion provider follows these certification standards.

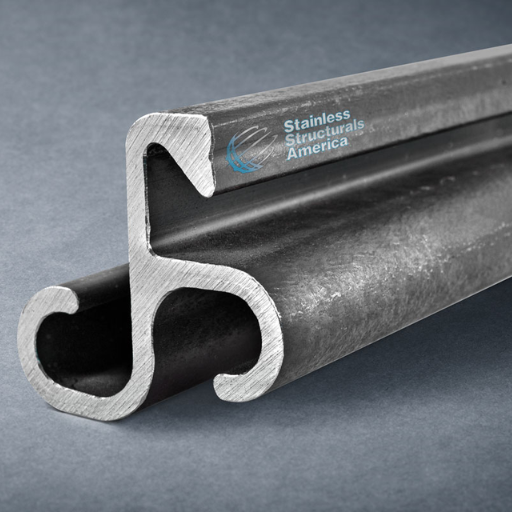

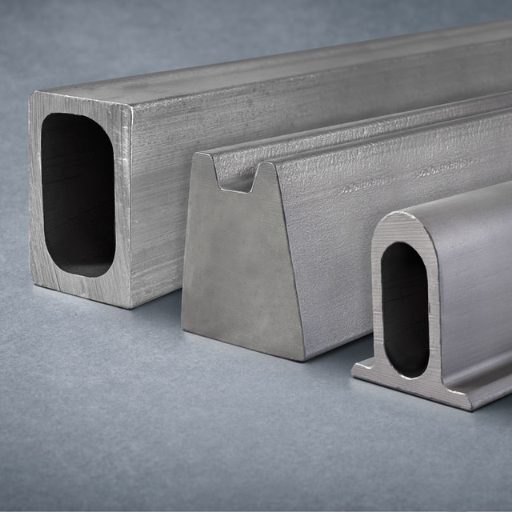

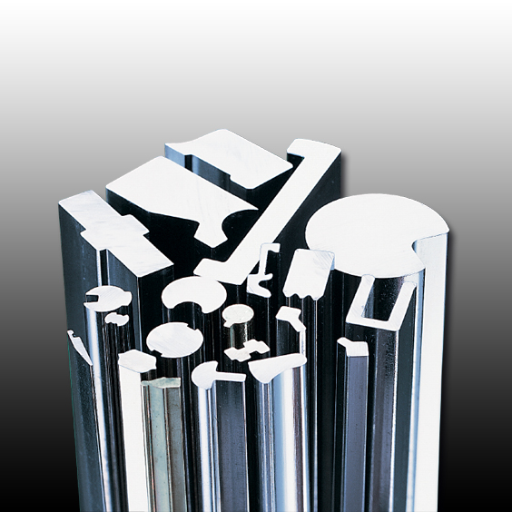

Common Types of Steel Extrusion Profiles

There are many types of steel extrusion profiles that are commonly used. Each one has been made to meet the requirements in different sectors. Below are some of the most popular ones:

- Solid Profiles

- These consist of simple shapes such as rods, bars and beams which find their application mainly in construction industry, manufacturing industry among others due to their strength and versatility.

- Hollow Profiles

- When you need to reduce weight but still maintain structural integrity, then go for hollow profiles like tubes or pipes. This makes them useful in areas like architecture, transport or furniture design.

- T-Profiles

- For frameworks where support and stability is key especially for heavy machines or even structural supports in buildings; T-profiles would be appropriate since they offer these qualities best.

- Angles and Channels

- Structural applications require materials with great support, strength as well as rigidity such as angles and channels which are also widely used during framing process together with braces or tracks construction.

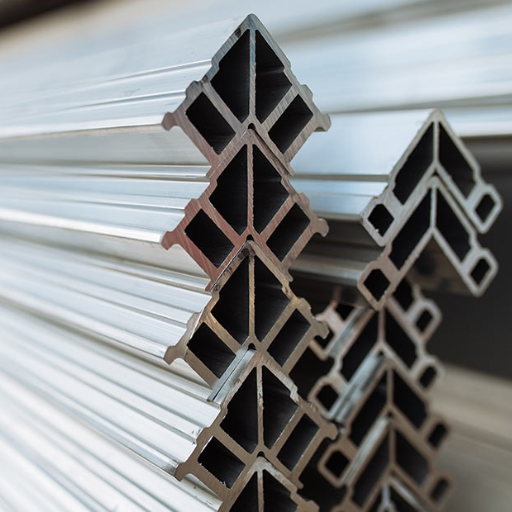

- Complex and Custom Profiles

- In specialized industries there is always need for unique geometries which can only be achieved through intricate details while designing custom shapes according to specific demands. Such kinds of profiles serve niche applications best.

You will be able to optimize the functionality as well as efficiency of your project by choosing the right steel extrusion profile.

Hot Extruded Profiles vs. Cold Extruded Profiles

While selecting between hot extruded sections and cold extruded sections, it is important to take into account what exactly your project requires. Each of these methods has its own unique benefits and suitedness for various applications.

Hot Extruded Profiles:

- Process: This involves heating a steel billet beyond its recrystallization temperature then pushing it through a die. The material flows more easily at high temperatures hence low force is needed.

- Benefits: Can create large and intricate profiles; removes impurities from the metal due to the heat thus making it ductile and tough; best for use in applications where very strong parts are needed.

- Applications: Commonly found in construction industry as well as automotive sector among others that require big heavy-duty machines.

Cold Extruded Profiles:

- Process: This is done at or slightly above room temperature so as to obtain finer finishes by using greater amounts of pressure during extrusion which makes work hardening possible within the processed alloy layers resulting in better mechanical properties such as strength and toughness.

- Benefits: Produces profiles with tighter tolerances & smoother surfaces compared with those made via other means like machining etc.; strain hardens materials leading to increased strengths together with hardnesses after cold forming.

- Applications: This kind suits precision components used in electronics, medical devices, consumer goods where accurate dimensions coupled with excellent surface finish are paramount.

Once you know what each type of profile offers, tailor your selection around them depending on their relevance towards fulfilling specific requirements posed by the task at hand.

Standard vs. Custom Extrusion Profiles

Standard Extrusion Profiles:

- Overview: Standard extrusion profiles are shapes that have been pre-made to fit general industry needs. These profiles are usually stocked by manufacturers and can be obtained immediately.

- Advantages: These are cost-effective because they are produced in bulk quantities, which also leads to shorter wait times and easier sourcing. They work well for applications where it is not necessary to have precise measurements and standard forms will do.

- Uses: Typically used in construction, window frames, door frames, and support structures when universal shapes meet project requirements.

Custom Extrusion Profiles:

- Outline: Custom extrusion profiles are created and manufactured specifically for unique project requirements. This entails making a custom die that produces shapes which match provided specifications exactly.

- Benefits: They are highly tailored towards application need offering different geometries, dimensions as well as properties. Customization can address particular challenges while providing new solutions for complicated designs.

- Applications: Often employed within industries like aerospace or automotive where specialized performance levels cannot be achieved without having accurate representations of them through the use of medical devices too often require very specific profiles achieve desired functionality.

In short terms, you should choose either between standard or custom extrusion profile based on what your project needs. If cost saving is important then go with standards but if time is an issue then consider going for customization since it offers faster solutions though more expensive whereas both provide efficiencies only one may be required depending on the situation.

Industrial Applications for Various Profile Shapes

To understand the many industrial uses of different shapes of profiles, it is possible to choose the perfect material for a certain project. Below are some sectors where aluminum extrusion profiles can be applied:

- Construction and Architecture:

- These types of materials are light in weight and resistant to corrosion which makes them useful in making structures like frames for windows as well as curtain walls.

- Buildings become stronger, flexible and attractive with various forms such as I-beams, channels, angles among others being used during construction processes.

- Transportation:

- The automotive industry heavily relies on this product because they have low mass while still being strong enough hence not compromising their durability especially when it comes to railroads or planes’ manufacture that also requires lightness.

- Rails act as guides while support systems ensure safety measures are adhered to thus saving fuel through efficiency enhancement trim parts designed durable enough withstand frequent use under harsh conditions should also help save on energy by reducing air drag caused from moving objects at high speeds.

- Electronics and IT:

- Heat sinks are manufactured using these profiles due to their good thermal conductivity which helps in dissipating heat produced within electronic devices when they are operational for long periods.

- Efficient cooling can be achieved through improved designs aimed at safeguarding delicate parts since failure may result into poor performance thus preventing optimal utilization of such gadgets.

Different industries should exploit the unique benefits associated with each category contour so that they achieve maximum functionality coupled with effectiveness depending on specific applications required.

The Customization Process for Steel Extrusion Profiles

To make steel extrusion profiles custom, there are a few important steps that need to be followed so as to get the right dimensions and unique features for specific applications. Normally, this process starts with an assessment of the project where engineers work together with designers in order to specify measurements such as sizes or shapes among other mechanical properties too. At this point is when they use CAD programs which help them create accurate designs as well as simulate everything before actual production takes place.

Once everything has been designed properly then comes choosing suitable steel alloy plus preparing necessary extrusion dies whereby these tools should be made carefully until they match exact profile specifications without any single mistake being made during their fabrication stage whatsoever. When it reaches this stage, what happens here next is heating up steel billets at correct temperatures before pushing them through individualised dies using enormous pressure until required shape is achieved.

After extrusion, different finishing treatments like cutting or machining may be done on profiles together with some surface finishes that improve their strength against corrosion while still enhancing overall look since they can also serve decorative purposes in most cases too. At the same time there must always be quality control throughout all these processes so that produced items meet strict standards and satisfy clients’ needs equally well.

If manufacturers adjust every part of customization procedure accordingly; then each product will become very functional just like any other thing which was specifically created for certain tasks only by doing so efficiency increases within various areas thus making projects successful eventually.

Steps to Creating Custom Steel Extrusion Profiles

- Assessment of Project Requirements: At first, engineers and designers have to talk a lot about this project, so that they can define its dimensions, forms as well as mechanical properties.

- Design and Simulation: With the help of CAD software detailed designs are made while simulating at the same time. These digital models are important because it allows for adjustments which may need optimization before production hence solving any potential problems early enough.

- Selection of Steel Alloy and Die Preparation: A steel alloy is chosen with consideration given to what is required by the project. Extrusion dies are prepared carefully so as to match desired profiles’ exact specifications.

- Extrusion Process: High temperatures heat steel billets up until they become malleable enough then they are passed through custom made die under enormous pressure; this shapes them according to design.

- Finishing Treatments: There are several post-extrusion finishing treatments done on profiles such as cutting; machining or applying surface finish. These processes improve their strength properties like corrosion resistance among others aesthetics also being taken into account.

- Quality Control: Throughout this entire process very strict quality control measures have been put in place aimed at making sure that all products adhere to set standards and meet customer expectations.

- Final Inspection and Customization: The completed profile bars undergo inspection after which necessary modifications may be effected in order to satisfy specific requirements of an application thus assuring maximum performance efficiency.

Design Considerations for Custom Profiles

There are many things that should be considered when designing a steel profile. Among these are; the performance, manufacturability and cost of the profile. Designing the custom steel profiles needs one to take into account several important factors so that they can work best for what they were made for.

Firstly, the mechanical properties required for any given application should be identified. This includes things like tensile strength, flexibility and durability which are specific to different applications. In addition to this it also considers environmental factors such as temperature ranges (hot or cold), corrosive elements present in an environment like acids bases salts etcetera or even mechanical stress that may apply on them while still performing their intended function.

Secondly, proper material selection is very crucial during design stage because wrong choice can lead not only poor performance but also higher costs incurred during production process thus affecting overall profitability level realized by organization involved into production activities especially where there is need use steel alloys having high strengths such as those used structural components requiring more ductility like those used profiles with intricate shapes.

Thirdly, manufacturing method itself must be carefully planned from detailed designs and simulations which help identify potential challenges before starting actual production run through die designs used during extrusion process till cooling rates chosen after consideration die’s geometry along its length ensures consistent quality achieved without any defects being noticed at final stage inspection prior shipment out factory gate moreover dimensions tolerances should specified precisely taking into account particularity each designed part so as meet desired level accuracy required by given application while enhancing ease integration among various parts thereby simplifying assembly work done by different operators involved within entire supply chain management system

Finally, finishing treatments are very important steps taken towards improving product properties more specifically those related with protection against corrosion wear impact among others therefore necessary surface treatment procedures coatings applied together thermal processes carried out over a period time enhance resistance ability towards such forces hence prolonging life expectancy alongside boosting performance capabilities displayed throughout service life span projected up completion project under taken so far. In conclusion, it is necessary to maintain stringent control measures during all stages production process ensure that final meets highest standard client expectations.

Examples of Custom Extrusion Applications

Various businesses take advantage of custom steel profiles because they are flexible and strong.

- Construction: Architects use unique extrusions for beams, columns and railings. They can be shaped into intricate designs while remaining structurally sound which makes them perfect for both decorative features as well as functional ones in buildings or houses too!

- Automotive Industry: In the auto industry, a lot of parts such as chassis, frames and reinforcements need to be made from sturdy materials like steel. These items are manufactured with the help of customized extrusions which offer an ideal balance between weight saving measures and required strength levels thus contributing greatly towards safety standards improvement within vehicles.

- Aerospace Industry: When it comes to aerospace applications there is no room for error since everything has got to work perfectly well all times without failure whatsoever mainly due high risk involved. For instance fuselage sections, wing structures among others must be created using strong yet light materials that can only be achieved through custom extrusions having integrity over long periods of time under extreme conditions.

Clearly these uses show just how much variety can come from one type alone thereby indicating versatility beyond belief across various fields; such an element remains critical not only in established but also emerging sectors where innovation thrives most.

Frequently Asked Questions (FAQs)

Q: What is a steel extrusion profile?

A: A steel extrusion profile is a shape formed by pushing or drawing steel through a die to create a specific cross-sectional shape. This method is commonly used for producing custom stainless steel and various steel shapes for construction and industrial applications.

Q: How does hot extrusion differ from cold extrusion in steel profiles?

A: Hot extrusion involves shaping steel at high temperatures, making it more malleable and easier to form into intricate shapes. This process is ideal for creating complex extruded steel shapes. Cold extrusion, on the other hand, is done at room temperature, providing higher strength and more precise tolerances in the final product.

Q: Can you explain the common applications for extruded aluminum and steel profiles?

A: Both extruded aluminum and steel profiles are used in various industries. Aluminum profiles are often used in transportation, architecture, and decoration due to their lightweight and corrosion resistance. Steel profiles are predominantly used in construction, heavy machinery, and industrial applications for their strength and durability.

Q: What is the advantage of using extrusion services for custom aluminum projects?

A: Extrusion services offer the ability to create custom extruded aluminum profiles tailored to specific project requirements. This customization ensures that the profiles meet exact dimensions and specifications, providing a perfect fit for unique applications in fields such as construction and industrial manufacturing.

Q: How do steel extruded profiles compare to rolled steel products?

A: Steel extruded profiles are created by pushing steel through a die, allowing for more complex and precise shapes compared to rolled steel, which is flattened and shaped through rolling. Extruded profiles offer better customization for specific structural and aesthetic needs, while rolled steel is typically used for simpler, more uniform shapes.

Q: What materials can be used in the hot extrusion process?

A: The hot extrusion process can be used with various materials, including carbon steel, stainless steel, and aluminum. Each material provides unique properties that make it suitable for different applications, such as strength, corrosion resistance, and lightweight designs.

Q: Why are door aluminium profiles commonly extruded?

A: Door aluminium profiles are commonly extruded because the extrusion method allows for precise control over the profile’s shape and dimensions. This is essential for ensuring the profiles fit seamlessly into door frames and mechanisms, providing durability and a consistent appearance.

Q: Can extrusion profiles be used for both structural and decorative purposes?

A: Yes, extrusion profiles can be designed for both structural and decorative purposes. For example, industrial aluminium profiles might be used for structural support in machinery, while decoration aluminium profiles could be designed for aesthetic applications like building façades and interior decor.

Q: What are the benefits of using customized aluminum extrusion profiles in construction?

A: Customized aluminum extrusion profiles offer several benefits in construction, including reduced weight, enhanced corrosion resistance, and the ability to create complex shapes tailored to specific architectural requirements. This flexibility leads to improved design possibilities and structural efficiency.

Q: How does the use of stainless steel extruded profiles impact the construction industry?

A: Stainless steel extruded profiles are highly valued in the construction industry for their strength, corrosion resistance, and aesthetic appeal. Using these profiles in construction projects ensures long-lasting structural integrity and a modern appearance, making them ideal for both functional and decorative elements.