Stainless steel, a widely used material in various industries, is renowned for its impressive durability, corrosion resistance, and aesthetic appeal. Among its many grades, SS 316L stands out due to its exceptional properties and versatility. This article aims to provide a comprehensive overview of SS 316L sheet stainless, exploring its key characteristics, advantages, and common applications. Whether you’re a professional in the manufacturing sector, an engineer, or simply someone interested in material science, this blog will equip you with valuable insights into why SS 316L is a preferred choice for many demanding environments.

What is a 316L Stainless Steel Sheet?

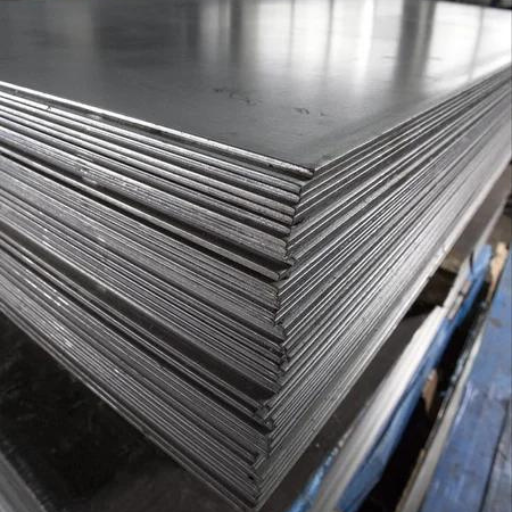

316L Stainless Steel Composition

There is an addition of molybdenum in 316L stainless steel, which makes it an austenitic chromium-nickel stainless steel with a high corrosion resistance particularly to chlorides and other industrial solvents. The typical chemical composition of 316L consists approximately 16-18% chromium, 10-14% nickel and 2-3% molybdenum. In addition, its carbon content is slighter due to this fact that it has been compared to the 316 stainless steel, generally about0.03 percent or lower hence less possibility of sensitization during welding and improvement in weldability. Among other trace elements are silicon, phosphorus, manganese and sulphur all contributing towards improving the strength, ductility as well as their ability to resist various forms of corrosion.

Key Properties of 316L Stainless Steel Sheet

Its corrosion resistance is excellent especially in the presence of chlorides and salts since molybdenum has been added to it. Therefore even under harsh conditions that can be experienced within certain marine environments; this material will definitely last for a long time while still being durable. Secondly, thanks to its low carbon content (which prevents carbide precipitation), type L has good weldability unlike other types which undergo degradation following the welding procedure. Hencefor use in fabrication and structural applications, the above mentioned feature makes it one of the best materials among others.In summary, remarkable mechanical characteristics such as high tensile strength & yield strength together with superior toughness & ductility down to cryogenic temperatures are features exhibited by this metal besides chemicals & acids inertness hence suitable for application across multiple industries including pharmaceuticals processing food marine etc.

Differences between Sheets Made from 316 and 316L Stainless Steels

What differentiates sheets made from 316 stainless steel from those made from type L is only the amount of carbon they have on them: while 316L stainless steel has less than 0.03% carbon, 316 stainless steel can have as much as .08%. Therefore, it is more resistant to sensitization or the formation of chromium carbides at grain boundaries during welding that can cause intergranular corrosion. The element reduces the possibility of carbide precipitation and intergranular corrosion due to lower carbon content in its structure. Therefore, the joint retains its corrosion resistance because the 316L is used in applications involving welding. Furthermore, both grades usually contain similar amount of molybdenum thus showing a good resistance to pitting and crevice corrosion particularly in chloride containing environments.The mechanical properties and overall applications are also quite similar, with 316L’s enhanced weldability and reduced risk of sensitization making it advantageous for specific fabrication and structural applications.

What are the Main Applications of 316L Stainless Steel Plates?

Corrosive Environment and Marine Applications

Their resistance to corrosion in harsh, salty conditions especially harsh saltwater has made 316L stainless steel plates a popular choice for marine use; it is highly valued in corrosive environments. The low amount of carbon in 316L steel minimizes the chances of it being corroded at welded joints, which makes it suitable for building boats’ hulls, deck hardware and coastal architectural features. Furthermore, its resistance to pitting and crevice corrosion guarantees longevity when used in chloride rich marine areas. In offshore oil rigs and desalination plants, this material can withstand extreme conditions as well as chemical exposure that are essential for maintaining safety as well as operational efficiency.

High-Temperature Application

The structural integrity and performance under thermal stress are maintained by 316L stainless steel plates even if they are exposed to high-temperature environments. This means that the material remains with mechanical properties even at temperatures of up to 1,400°F (760°C). Therefore 316L is also a material often selected for use in industry such as industrial heating equipment chemicals production or power generation that deal with situations characterized by high temperatures. Consequently, the minimal level of carbon in 316L eliminates chances of carbide precipitation during heat treatment thereby preventing any compromising effects on the steels’ corrosion resistance. These qualities ensure that heat exchangers furnace components and other high-temperature applications operate reliably over extended periods.

Typical Industrial Applications

Due to their great toughness, ability to withstand extremely stressful conditions or work at high temperature levels; their exceptional durability; remarkable corrosion resistance; a wide range of industrial applications were it is an indispensable material which can be used effectively especially since they have exceptional durability; these include the aerospace sector where it is employed in producing items such as jet engines parts requiring high strength combined with anti-corrosion capabilities like exhaust manifolds. It is preferred for surgical instruments and implants used in the medical field because of its biocompatibility and resistance to body fluids. It has a high tolerance for frequent cleaning or sterilization processes which is why 316L stainless steel is used in the food and beverage industry for example processing tanks and piping systems can be made from it. Also, chemical storage tanks, reactors, pipelines exposed to harsh chemicals as well as solvents are often constructed using this type of stainless steel. This demonstrates that there are many different uses for this material making it a versatile option across demanding industries that need reliability.

How Does the Processing of 316L Stainless Steel Sheet Affect Its Properties?

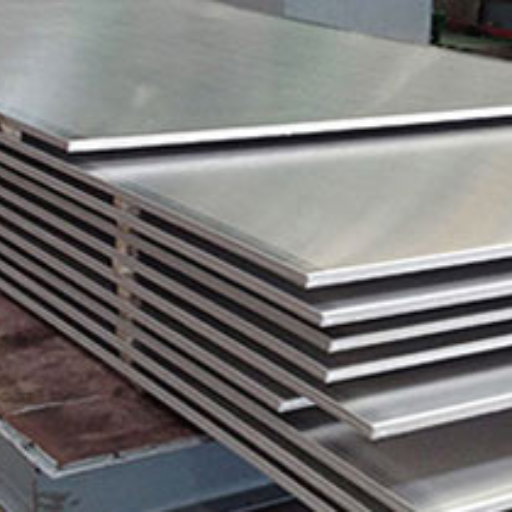

Annealing and Cold Rolling Process

Annealing and cold rolling are the two most important processes that highly influence the properties of 316L Stainless Steel Sheets.

Annealing involves heating to a temperature above its recrystallization point, typically about 1900°F – 2100°F (1040°C -1150°C) followed by slow cooling down. This process is used to relieve internal stresses, improve ductility and enhance formability of steel in general. Furthermore, it helps improve corrosion resistance which could have been reduced during prior processing stages by refining grain structure through annealing.

In order to harden the steel via work hardening, cold rolling is performed at or near room temperature on the 316L stainless steel. The process involves passing the steel sheet through rollers to achieve desired thickness and surface finish. As such, cold rolling results in higher tensile strength as well as yield strength while giving a smoother even surface. However, this can also lead to more internal stresses thus why cold rolled steels frequently undergo subsequent annealing so as to reduce brittleness thereby improving mechanical properties.

Manufacturers can utilize these two processes together in order to customize the physical characteristics and surface properties of 316L stainless sheets towards specific applications for better performances in various industrial contexts.

Effect on Mechanical Properties and Strength

The annealing procedure has significant effects on mechanical properties of 316L stainless metal. Annealing relieves internal stress’; it refines grains which make material more ductile with improved formability; it makes steel easier to machine especially complex shapes or deep draws where large amount of deformation is needed; further, restores any previous loss of corrosion resistance due other forms of processing steps employed.

On the contrary, cold rolling improves appreciably hardness along with strength by way of work hardening. Increasing tensile and yield strengths render materials suitable for structural applications requiring high-strength-to-weight ratios like light weight building applications. However, cold rolling may result into internal stress that can compromise material’s toughness and ductility. As a remedy to this, subsequent annealing is often used to reduce brittleness thereby balancing strength with ductility and toughness.

Through careful combination of annealing and cold rolling, the mechanical properties of 316L stainless steel can be improved to meet specific performance requirements. This kind of approach ensures that the material survives even under severe environments and applications such as in medical devices or architectural components.

The Importance of ASTM Standards

The American Society for Testing Materials (ASTM) plays a key role in ensuring quality, safety, and durability of 316L stainless steel. These standards provide full details about chemical composition, mechanical properties and testing methods that are essential in production and evaluation of these materials. Therefore, adherence to ASTM specifications including ASTM A240 for plate, sheet or strip means that the 316L SS is met acceptable standards which have been documented giving clear directions towards uniformity within various industries it finds use. Moreover, these standards make global trade easier by providing common ground upon which manufacturers, suppliers or consumers meet together so that they produce goods as prescribed by quality assurance bodies present internationally across all countries

What Sizes and Specifications are Available for 316L Stainless Steel Sheets?

Variations in Size of Plates and Sheets

When it comes to industrial needs, a wide variety of sizes and thicknesses of 316L stainless steel sheets and plates are available. Thicknesses can vary from 0.018 inches (0.5 mm) to 2 inches (50 mm). Standard widths are usually from 36 inches (914 mm) to 72 inches (1,828 mm), while lengths can be between 96 inches (2,438 mm) and 240 inches (6,096 mm). Custom dimensions can also be fabricated as needed. These sheets may come in various finishes like No.1, BA or even the famous and common number ‘2B’ giving you an option on what to choose when you need them for various purposes that require different surfaces types including those suitable for construction use up to medicine.

Understanding ASTM A240 Specifications

ASTM A240 is a specification covering plate, sheet, and strip chromium-nickel stainless steel used in pressure vessels and general applications. The standard is inclusive of information about chemical composition mechanical properties heat treatment etc., which should be observed for making good quality stainless steel materials. In particular, ASTM A240 ensures that highly resistant and high performing corrosion-resistant materials such as 316L can withstand tough conditions without losing their strength or becoming brittle This guide contains substantial information on allowable stress tensile strength elongation which makes this material appropriate for harshly corrosive environments including chemical processing plants or shipyards by the sea.Hereby astm a240 guarantees that the most widely used austenitic grade of stainless steel known as type 316l complies with several requirements concerning durability and structural integrity.

Options for Custom Sizes and Thicknesses

With regards to customizing sizes & thicknesses of plates/sheets made out of 316L stainless steel; many suppliers offer various choices tailored towards meeting precise specifications This customization allows project-specific demands which call for nonstandard dimensions not found in the standard sizes. Suppliers also offer a range of cutting and finishing services to achieve desired thicknesses as well as surface finishes. This flexibility is especially useful for applications where non-uniform dimensions or specific performance qualities are needed; say, in individualized architecture or custom-built industrial machines.

How Does 316L Stainless Steel Sheet Perform in Corrosive Environments?

Other Alloys versus Corrosion Resistance

Comparing this alloy to the rest of them, 316L stainless steel is particularly known for its corrosion resistance. It contains a lot more molybdenum which makes it resistant to pitting and crevice corrosion in chloride environments better than many other stainless steels as compared to say 304. In applications like chemical processing or marine where there is high corrosiveness, 316L remains stronger even with time since it will not have corroded structurally by then. Its risk of intergranular corrosion through precipitation of carbide has also been lowered by low carbon content. Thus, generally speaking, 316L stainless steel provides a higher degree of protection against corrosive elements thus becoming the material of choice when dealing with highly exposable situations.

The Significance of Molybdenum in its Corrosion Resistance

In my experience, molybdenum plays a great role in enhancing the ability of 316L stainless steel to resist corrosion. This element greatly increases the alloy’s ability to withstand pitting and crevice corrosion specifically in chloride containing areas. When bonded together with chromium and nickel contained within the steel, molybdenum develops stable protective layers that can withstand chemicals and salty conditions as well. This implies that 316L stainless steel remains strong despite persistent exposure to harsh environments such as those found in marine settings or chemical factories thus making it suitable for such applications.

Long-Term Durability And Maintenance

In my experience the long term durability of this alloy is commendable especially under conditions that encourage rusting. Its composition is rich in molybdenum and nickel which help it resist many types of corrosion including pitting and crevice type ones among others. Regular maintenance, particularly during extreme weather requires routine checks for any wearing or damage seen on it but more significantly cleaning using non-abrasive materials guarantees that the protective layer will be preserved longer thereby prolonging the life of material. Thus, minimal maintenance and excellent durability make 316L stainless steel an ideal choice for use in environments like those in marine industries or chemical plants where there is high stress on materials used.

Frequently Asked Questions (FAQs)

Q: What are the essential features of SS 316L sheet stainless?

A: The SS 316L sheet stainless is known for its improved corrosion resistance, making it a great choice for various applications. It is a low-carbon version of type 316 stainless steel, which means it has reduced susceptibility to carbide precipitation during welding.

Q: What applications benefit from using 316 stainless steel sheet?

A: Applications that benefit from using 316 stainless steel sheet include environments exposed to salt water, chemical plants, petrochemical industries, and food processing facilities due to its superior resistance to corrosion and pitting.

Q: How does chemical composition affect the performance of 316 stainless steel sheets?

A: The chemical composition, particularly the presence of molybdenum, improves the corrosion resistance of the metal, especially against chlorides and other industrial solvents.

Q: What thickness range is available for 316 stainless steel sheets?

A: The thickness range for 316 stainless steel sheets typically varies from as thin as 0.5mm to up to 48mm, allowing for a wide selection of applications from delicate to heavy-duty needs.

Q: Why is SS 316L considered over standard 316 stainless sheets for some applications?

A: SS 316L is considered over standard 316 because it has lower carbon content, reducing the risk of intergranular corrosion or carbide precipitation, especially in welding applications.

Q: Are SS 316L sheets suitable for marine environments?

A: Yes, SS 316L sheets are highly suitable for marine environments due to their enhanced resistance to salt water corrosion, making it a great choice for maritime applications.