Understanding the Basics of SLDPRT and STL File Formats

Image source: https://standaloneinstaller.com/

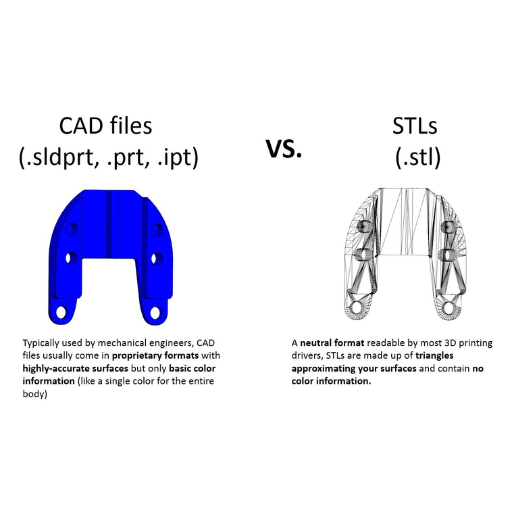

SolidWorks uses SLDPRT files to package its native design data, such as part geometry, material properties and assembly relations. These are mainly employed for creating and modifying 3D models within the SolidWorks application environment. Conversely, STL (stereolithography) files find extensive use in 3D printing because of their simplicity and compatibility. An STL file represents a 3D model as a set of triangular facets that only define surface shape; color, texture or other CAD model attributes are not included. This format with a mesh of triangles simplifies the representation, which is then easily interpreted by 3D printers so that they can process it for printing layer by layer. To achieve accurate and successful 3D prints, one must understand this distinction between formats.

What is an SLDPRT file?

Introduction to STL file format

Differences between SLDPRT and STL formats

You must understand the difference between SLDPRT and STL formats if you want to optimize your workflow with 3D modeling and printing. In other words, SLDPRT format is a SolidWorks proprietary format which saves all information about the part, such as: geometry, materials used or even annotations necessary for complete CAD projects. It means that designers can work with every feature of the part, make accurate adjustments and analyze it right in SolidWorks.

On the contrary, STL (Standard Triangle Language) represents solely surface geometry and serves primarily for 3D printing needs. In this format three-dimensional models are converted into meshes made up by triangles. This reduces complexity of object descriptions for further simplification during 3D printing process. Nevertheless there is some trade-off – STL files do not include any data about material color or other attributes; also they lack parametricity known from SLDPRTs. So it becomes less convenient when you need detailed design modification or engineering analysis during work with such file types like stl.

Furthermore SLDPRTs tend to be bigger and more complicated due to their high level of detail whereas STLS are lightweight and can easily be shared across different software platforms as they are simpler in structure. For this reason final stage of 3D Printing is often conducted using an .STL format – but at first stages it’s better to stick with .SLDPRT because it allows maximum creativity while designing objects. Therefore choice between those two depends on what kind of project you’re working on taking into account requirements towards precision (SLDPRT) or simplicity (STL) necessary for efficient additive manufacturing technology based process completion

Why Convert SLDPRT to STL: Use Cases and Benefits

In the 3D modeling and printing industry, it is common to convert SLDPRT files into STL format mainly because of its benefits and applications. One such reason is that they are compatible with most 3D printers as well as different slicing software which mostly require this kind of files. This change ensures that there is no break between detailed CAD design and physical prototype production where additive manufacturing can take place quickly.

Also, this method saves on time when sharing or transferring across platforms or applications because STL files work universally as they are light in weight thus making them easy for collaboration among teams working on different platforms or clients who may not own SolidWorks CAD software. Additionally, these types of files are good for quick prototyping showing only the basic shape of a model without much detail needed.

Essentially, SLDPRT to STL conversion in SolidWorks takes advantage of its detailed design capabilities during initial development and later adopts the practicality printer friendlyness of STL for manufacturing purposes while fostering collaborations too. This two-pronged approach guarantees accuracy in designing while also enhancing speed in production through sharing.

The role of STL files in 3D printing

In the world of 3D printing, STL files are highly important because they serve as the industry’s standard format for 3D models. Created by 3D Systems, this format stores 3D geometries as a tessellated representation of surfaces described in triangles. This feature makes precision possible at both the high end where industrial level or consumer level 3D printers can be found.

Compatibility with different slicing programs and other software that convert a 3D model into printable layers is one reason why people use STLs so often in their projects. This way it is easier to move from digital designs to physical objects which is what makes prototyping and manufacturing possible through them. Another advantage that comes with this kind of file is its light weight making data transfer faster while also taking up less storage space which only adds onto how useful these types of files are.

Essentially, universally accepted efficiency and accuracy during conversion into readily manufacturable physical models for complex CAD designs is what an STL file provides along with being an efficient format for all stages in between. The significance here lies within streamlining production processes through standardizing everything thereby fostering more innovation and collaboration within the 3D printing industry as a whole.

Enhancing compatibility across different CAD software

To ensure that everything works without interruptions, what is needed is compatibility among various CAD software. This is especially important in projects where many people are involved and they have to work together. Formats like IGES, STEP, and IFC were created as a solution for improving compatibility. These formats can be used with different systems of computer-aided design and allow easy exchange of three-dimensional models between them saving all data integrity as well as functionality.

Interoperability may also be enhanced by adopting open source softwares together with APIs which enable integration or conversion according to need. Also, it would be better if we start using cloud-based platforms for CAD so that different environments of software can get updated automatically during real-time collaborations.

In other words; standardizing file formats, employing open-source solutions and utilizing cloud based systems are some ways through which one can enhance the compatibility between CAD softwares thereby streamlining design processes while promoting collaboration.

Streamlining the 3D modeling to 3D printing process

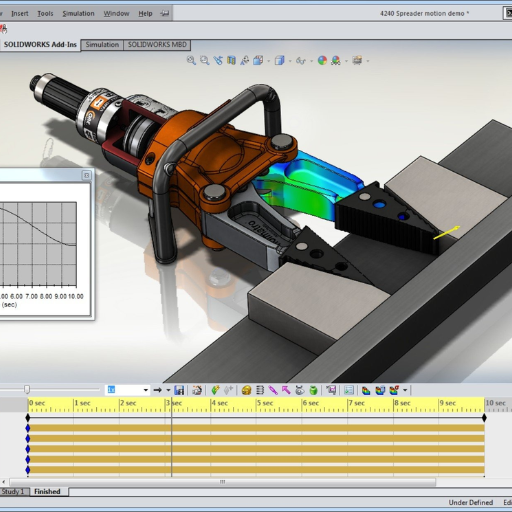

There are a number of important steps in streamlining the process from 3D modeling to 3D printing, all of which are necessary to ensure that the final product is efficient and accurate. First, it is important to utilize a strong and user-friendly CAD software that supports creation and modification of 3D models in a seamless manner. For example, Autodesk Fusion 360 or Blender are among the top platforms which provide wide range tools for designers both newbies and experts.

Afterward, optimizing the model for printing is another crucial step. In this phase one should look out for errors such as non-manifold edges or holes as well as making sure that everything fits within printer’s specifications. Software such as Mesh Repair can be really helpful during this stage along with slicers like Cura, PrusaSlicer or Simplify3D which prepare model by generating G-code required by printer.

Apart from these steps taken based on material selection also matters during printing process because each type of materials (PLA, ABS etc) has its own characteristic features that can affect strength, flexibility or finish of printed objects differently. Therefore having knowledge about these things would greatly impact on final outcomes.

At last but not least post-processing methods contribute much towards overall appearance and functionality of end products through activities like sanding,painting or chemical smoothing among others.By following this streamlined approach to modelling-to-final print process individuals & organizations alike can achieve high quality outputs consistently in their 3D printing undertakings.

Step-by-Step Guide to Convert Your SLDPRT Files to STL

Using different software tools is a direct way of converting your SLDPRT files to STL. To make sure that the process goes on smoothly; follow these steps:

- Open Your SLDPRT File in SolidWorks: Launch SolidWorks and open the SLDPRT file you want to convert by navigating to `File > Open` and selecting the desired file.

- Prepare the Model: Before proceeding, ensure your model is error-free and accurately reflects the final design intended for 3D printing.

- Save As STL:

- Go to `File > Save As`.

- In the `Save as type` dropdown menu, select `STL (*.stl)`.

- Click the `Options` button to adjust the export settings for resolution and quality. Choose the desired settings that best match your 3D printer’s capabilities and press `OK`.

- Export the STL File: Once you have configured the settings, click `Save` to export your file as an STL.

- Verify the STL File: Use mesh repair software or slicer tools like Cura or PrusaSlicer to confirm that the exported STL file is suitable for 3D printing. Verify there are no errors or significant alterations in the geometry.

- Adjust Settings if Necessary: If the STL file needs adjustments, return to SolidWorks, modify your export settings, and re-export the model until satisfied.

By following these instructions, one should be able convert his/her SLDPRT files into STLs successfully hence enabling compatibility with their specific 3D printer which will eventually lead to high-quality prints being produced.

Choosing the right software for conversion

Consider these top-rated choices when picking out the right software for converting SLDPRT files into STL:

- SolidWorks: As the native software for SLDPRT files, SolidWorks offers seamless conversion and various export settings to tailor the STL file for 3D printing.

- Fusion 360: This user-friendly tool from Autodesk provides robust conversion capabilities and is well-suited for both personal and professional use.

- FreeCAD: An open-source alternative, FreeCAD supports file conversion with customizable options, making it a versatile choice for many users.

- Blender: Known for its powerful modeling functionalities, Blender’s import and export features accommodate several file types, including SLDPRT to STL.

- MeshLab: Specially designed for processing and editing 3D triangular meshes, MeshLab ensures fine-tuning and error-checking of STL files.

- Rhino 3D: Renowned for its precision and commercial-grade capabilities, Rhino 3D handles a wide range of file formats and conversion needs.

- Creo Parametric: Developed by PTC, Creo is a professional-grade CAD software ensuring reliable conversions and accurate 3D model exports.

- Onshape: A cloud-based CAD solution, Onshape allows for easy and direct conversion of SLDPRT to STL without the need for local software installation.

- TinkerCAD: Ideal for beginners and educators, TinkerCAD offers simple tools for basic file conversions, making it perfect for quick and easy projects.

- Netfabb: Part of the Autodesk suite, Netfabb provides advanced options for optimizing and repairing 3D print files, leading to high-quality STL outputs.

By evaluating these software tools, you can select the one that best suits your specific needs and ensures accurate and efficient conversion from SLDPRT to STL.

SolidWorks: Using native tools for direct conversion

SolidWorks facilitates the conversion of SLDPRT files into STL format without relying on external software. Here is how you can do it:

- Open the SLDPRT File: Launch SolidWorks and open your preferred SLDPRT file.

- Save As Command: Click on “File” from the main menu, then select “Save As.” From the dialog box that appears, choose the STL (*.stl) file type among others available in the format section.

- Adjust Export Settings:Next to the file type dropdown there is an ‘Options’ button which you need to click so as to be able to modify resolution and precision for this specific STL output required by your work. Various settings provided by SolidWorks allow one to refine tessellation process even more if they want to.

- Preview and Save: When all settings have been made according to preference I can see what my final result will look like before saving anything down permanently by giving me an option called preview where can take a look at it then if everything looks good press okay followed by save and export button at bottom right corner.

This way, SolidWorks enables its users with enough tools for managing their own conversions between different formats which could be necessary during 3D printing among other applications depending on what one needs most out of them- whether better details or compatibility with other devices used

Third-party converters: Features and benefits

When it comes to third-party converters for converting SLDPRT files to STL, there are numerous options available with different features and benefits.

- Enhanced Compatibility: Many third-party converters support a wide array of formats beyond SLDPRT and STL. This makes them incredibly versatile for diverse project requirements.

- User-Friendly Interfaces: Most of these programs come with intuitive interfaces which are easy to navigate thus simplifying the conversion process even for people who do not understand much about technology.

- Customization Options: Advanced user settings in a third party converter provides more control over how conversions are made. Users can decide on what they want by changing parameters like resolution, scale or complexity that will give them exactly what they need as an output file.

- Batch Processing: One major advantage offered by third-party converters is their ability to handle batch processing where large numbers of files can be converted simultaneously which saves time significantly.

- Enhanced Performance: Some of these tools are optimized for faster conversion speeds, providing quick turnaround without compromising on quality.

- Additional Features: Many third-party converters offer extra features like file repair, mesh optimization, and direct integration with other software, adding layers of functionality that native tools may lack.

Therefore using a third party converter can be seen as being flexible, efficient and customizable when it comes to file conversion requirements.

Frequently Asked Questions About Converting SLDPRT to STL

We often encounter many problems converting SLDPRT to STL when designing, but in order to ensure that 3D printing can proceed effectively, we must explore methods related to converting SLDPRT to STL.

How to ensure quality in the converted STL file?

Dealing with issues during the conversion process

Reference sources

Online Article: “A Comprehensive Guide to Converting SLDPRT to STL Files” by All3DP

Link: All3DP – SLDPRT to STL Conversion

Summary: This informative online article by All3DP provides a detailed guide on the process of converting SLDPRT files to STL format. It covers various methods and tools available for this conversion, including software recommendations and step-by-step instructions. The article also discusses the importance of file formats in 3D printing and highlights common issues users may encounter during the conversion process. With practical tips and insights, this source is valuable for 3D printing enthusiasts and professionals seeking to optimize their workflow.

2. Blog Post: “Mastering SLDPRT to STL Conversion for 3D Printing” by Sculpteo

Link: Sculpteo Blog – SLDPRT to STL

Summary: Sculpteo, a prominent 3D printing service provider, offers a blog post focusing on mastering the conversion of SLDPRT files to STL for 3D printing applications. The post delves into the technical aspects of file conversion, emphasizing considerations such as mesh complexity, resolution, and software compatibility. It also provides insights into best practices for optimizing SLDPRT models for successful STL conversion, catering to designers and engineers looking to streamline their design processes for additive manufacturing.

3. Manufacturer Website: “Converting SLDPRT to STL with SolidWorks” by SolidWorks

Link: SolidWorks – SLDPRT to STL Conversion

Summary: SolidWorks, a leading CAD software provider, offers a dedicated resource on converting SLDPRT files to STL within the SolidWorks environment. The webpage provides detailed instructions on how to export designs from SolidWorks to STL format, ensuring compatibility with 3D printing software. It also addresses common queries related to file conversion, such as preserving geometry and maintaining file integrity. This source is particularly relevant for SolidWorks users seeking a seamless transition from design to prototyping in the 3D printing realm.

These sources collectively provide a wealth of information on converting SLDPRT files to STL format, offering practical guidance, technical insights, and industry-specific tips for individuals engaged in 3D printing and additive manufacturing processes.

Frequently Asked Questions (FAQs)

Q: What is the best way to convert your SLDPRT to STL?

A: The best way to convert SLDPRT files to STL files is by using a dedicated sldprt to stl converter. These converters are often part of 3D CAD programs or available as free and fast online tools designed for computer-aided manufacturing purposes.

Q: Can I convert SLDPRT files to STL files online for free?

A: Yes, you can convert SLDPRT files to STL files using free and fast online tools. These stl online converters allow you to upload your SLDPRT file, convert it, and then download the STL version without needing to install any software.

Q: What are the main differences in file format information for SLDPRT and STL?

A: SLDPRT is a file format native to the SolidWorks 3D CAD software, used mainly for computer-aided design, while STL is a file format native to the stereolithography CAD software used for 3D printing. STL files typically contain binary files or ASCII data that represent the outer surfaces of a 3D object.

Q: How do I convert SLDPRT files to STL files in SolidWorks?

A: To convert SLDPRT files to STL files in SolidWorks, open your SLDPRT file in SolidWorks, go to “File” > “Save As,” and select STL as the file type. Before saving, you can adjust the resolution settings to control the detail level of the STL file.

Q: What are the benefits of converting SLDPRT files to binary STL files?

A: Converting SLDPRT files to binary STL files reduces the file size significantly, making it easier to handle and quicker to transfer. Binary files are also more widely accepted by 3D printing software and services.

Q: What file type should I choose when converting a SLDPRT file to an STL file?

A: When converting a SLDPRT file to an STL file, you should typically choose the binary file type option if available since it offers a good balance between file size and fidelity. However, if you need to edit the STL file later or ensure compatibility with a specific software, ASCII may be preferred.

Q: Are there any limitations when converting SLDPRT files to STL files?

A: When converting SLDPRT files to STL files, there may be limitations related to the file size and the complexity of the model. Very detailed models might result in large STL files, and some intricate features of the SLDPRT file may not be perfectly replicated in the STL file depending on the conversion settings.

Q: How can I learn more about SLDPRT and STL file formats?

A: To learn more about SLDPRT and STL file formats, you can research specific CAD and 3D printing resources. These often include detailed guides on the structure, usage, and conversion processes of these file types, along with tips for optimizing your models for 3D printing or design work.

Q: What are some steps to convert SLDPRT files to STL files efficiently?

A: Steps to convert SLDPRT files to STL files efficiently include using a reliable sldprt to stl converter, ensuring your SLDPRT file is optimized for conversion, selecting the appropriate file type (binary or ASCII), and adjusting the resolution settings to match your needs for the final model.