Among the machining operations in manufacturing, slab milling is a basic one and it finds its significance in shaping strong materials because of its resourcefulness. The article explains the main aspects of slab milling, including techniques, applications and advantages that can be considered by readers. It does not matter if you are an experienced machinist who wants to refresh their minds or a beginner who just needs to know the basics; this exhaustive guide will help you understand more about slab milling. In this write-up, we will discuss what slab milling entails and suggest some guidelines for making this process more effective as well. We invite you join us in discovering nebulousness behind a critically important material processing operation and how you can improve your industrial capabilities through increased knowledge on slab-milling.

Understanding Slab Milling: The Basics

What is Slab Milling?

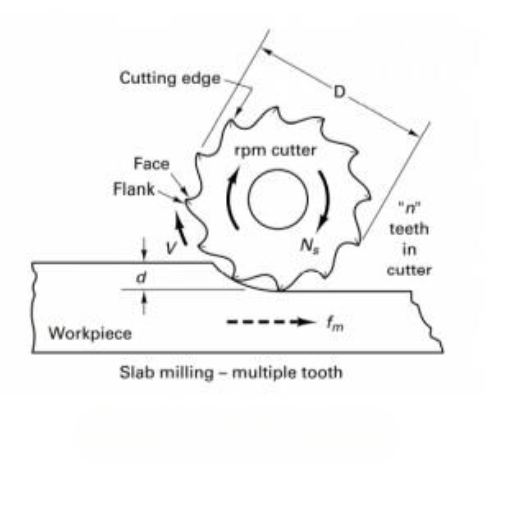

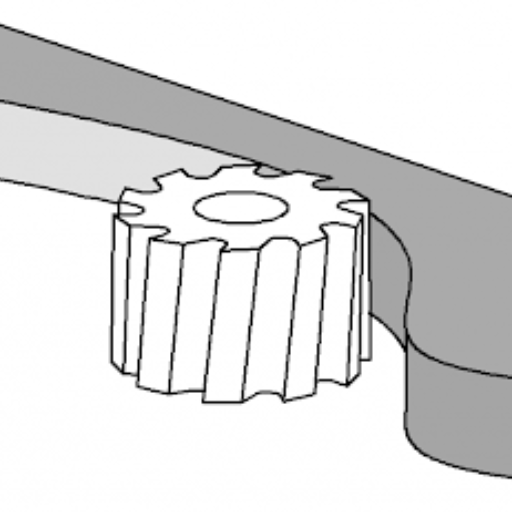

To me slab milling is a method involving cutting flat surfaces of large area with the help of a milling cutter. The technique is crucial in removing vast quantities of material rapidly, typically from workpieces demanding high precision finishing. The cutter has numerous cutting edges to provide an even removal of the materials hence ensuring smooth surface. It is mostly used in the production of large machine components, metallic slabs and other structural elements thus making it fundamental in manufacturing industry.

Differentiating Slab Mill from Other Milling Processes

Based on what I have gathered from reading several sources differentiating between slab milling and end milling it clearly does not involve complex shapes, contours and cavities. Broad material removal over large work pieces calls for this process unlike end mills which are designed for making 3D objects or shaping complex geometries within a given surface. Face milling can also be confused for slab as it also operates on wide areas but generally uses a cutter with larger diameter than that used by slab mill. In addition, face milling allows machining surfaces at different angles while slab milling primarily works for horizontal surfaces. Among all the primary methods of milling, slab millings efficiency in eradicating substantial volumes of materials quickly and rendering them uniformly finished makes it stand out.

The Role of the Slab Milling Cutter in Manufacturing

Slab Milling Cutters are important tools because they are efficient and accurate in removing materials during manufacturing processes. These cutters usually have many cutting edges that allow them to work on large flat areas appropriately ideal for producing accurately finished parts through machining (production). Being able to remove huge amounts of material quickly reduces production times and increases throughput necessary for high scale production activities. Heavy duty machinery parts like metal slabs need uniformity and consistency among others; hence require slab milling cutters that will meet such standards set by their producers. Their construction robustness guarantees long service life as well as predictable performance therefore qualifying them for an indispensable aspect of the manufacturing process in any field.

Choosing the Right Cutter for Slab Milling

Mesopotamian Plain Cutter vis-à-vis Slab Milling Cutters

When it comes to comparing plain milling cutters versus slab milling cutters, it is important to concentrate their specific uses and gains. Normally plain milling cutters are used for general purpose milling of horizontal surfaces that have helical or straight teeth enabling them to undertake a wide range of milling operations. On the contrary, slab millings cutters are specifically designed to remove a lot of materials efficiently from flat surfaces. In most cases they have a larger diameter with several cutting edges which enhances their ability to give high accuracy as well as smooth finishing. At the same time, plain milling cutters offer flexibility in different types of milling but slab milling cutters outperform them in tasks where uniformity and rapid material removal is required thus making them preferred for heavy duty manufacturing of large flat components.

Significance of Cutter Diameter and Material

In my opinion, choosing the right cutter diameter and material is crucial to achieving success in slab milling procedures. Bigger diameters enable efficient removals of bulk amounts of materials during each pass thereby improving productivity significantly while producing excellent finish on the work piece respectively. Conversely, the choice between cutter materials affects its performance and durability; for example, high speed steel and carbide tipped ones have varying wear resistance properties as well as cutting abilities too. It therefore means that we need to consider all these features so that our cutter can withstand all machining requirements such as cutting speeds , surface roughness level desired and type of material being machined . This method does not only boost efficiency but also elongates life span of tools hence lowering operational costs.

Helical Cutters vs Straight Cutters: What’s Better?

Based on what I know about this issue, an option needs to be made whether one should use helical rather than straight ones depending on project specifics. For instance more often helical cutters are chosen since their oblique angles provide a more gentle and silent cutting process. This helps in reducing cutting forces and enhancing surface finish especially in case of harder materials or when high precision is required. On the other hand, straight cutters are more suitable for cutting aggressively decreasing tool wear and tear and they are also easier to re-sharpen. They should be used in less complicated milling work where surface quality is not a priority. Therefore by examining specific requirements of the milling operation such as roughness, machining speed, hardness of material we can decide which type will benefit us most in terms of performance and lifetime simultaneously.

Optimizing the Milling Process: Tips and Techniques

Superior Finish through Adjusting Feed and Speed

Milling operations with a better surface finish require adjusting feed and speed. High feed rates could result to high tool loads which cause chatter, leaving rough surfaces in the workpiece. On the contrary, reduced feed rates allow for more refined finishes but extend machining time. Spindle speeds need to be determined by material type and cutter’s nature; higher velocities generally mean better finish but at a quicker rate of tool wear. Performance is optimized when a balance between feed rate and spindle speed is struck: first, go through manufacturer’s instructions concerning both figures then do fine adjustments with reference to surface finish. A good finishing requires using the right cutting fluid on sharp cutters.

How to Flatten Broad Slabs

To ensure that wide slabs are flat, certain procedures must be followed correctly for accuracy. The first thing that needs to be done is starting from a well planned working area that is level and firm enough. High point elimination on slab will involve use of good quality planer or jointer run along the entire surface with overlapped passes. A skilled operator may also use a sharp hand plane as an alternative hand tool for this purpose so as not to get an uneven surface. The best technique for sanding starts with lower-grit up to higher grits in order to get a smooth, even plane. Check flatness regularly using straight edges and winding sticks throughout the operation stage or process of work done on it from time-to-time by using straightedges or winding sticks. It is important that you clamp your slab properly onto your bench so that it does not move during routing sledding/ rabbeting procedure done across its entire expanse at once for consistent depth of cuts made all over it instead of many you might take longer if each one has different depths on particular parts compared with others under such circumstances where solid timber slab you have cannot stay stable once fastened down tightly enough after being cut through with router. Lastly, keeping tools sharp and consistent, methodical passes on the wood will ensure that a superior flat surface is achieved.

Exploring Advanced Slab Milling Operations

Straddle Milling vs. Slab Milling: What’s the Difference?

Straddle milling, as well slab milling both fundamental machining processes that are used in manufacturing with each having distinct applications and advantages.

For straddle milling, two side milling cutters are used on the same arbor to machine two parallel surfaces simultaneously. This method is highly efficient for producing components with closely spaced parallel surfaces like square or hexagonal parts. The parameters that drive it include width and depth of cuts which are governed by spacing and diameter of the cutters, feed rate and spindle speed. Straddle Milling has typical technical parameters such as:

- Cutter Diameter: Vary between 50mm to 200mm.

- Cutting Width: Depends on the particular part needed.

- Feed Rate: Usually around 50 – 150 mm/min.

- Spindle Speed: Adjusted depending on the material hardness from about 500-1500 RPM.

On the other hand, Slab Milling helps create wide flat surfaces. It uses a cylindrical cutter through workpiece width and allows for large areas to be milled in single pass. This process is ideal for reducing thickness of slabs and can be used in roughing or finishing operations too. Typical parameters for effective slab milling include:

- Cutter Diameter: Ranges from 100mm to 300mm.

- Cutting Width: Corresponds to the width of work piece.

- Feed Rate: Between about 60-200 mm/min

- Spindle Speed: Generally ranging from about 600 to1800 RPM, depending on material being milled

Both methods require careful tool maintenance and selection according to machining requirements. While straddle milling is good for small features requiring precision; extensive surface machining would be more suited by slab milling Proper setting of technical parameters ensures optimized balance between cutting efficiency and finish quality

Using CNC Machines in Slab Milling

There are several advantages of using CNC machines in slab milling as far as precision, efficiency and repeatability is concerned. Based on the latest information from credible sources, I can authoritatively say that through automated control, CNC machines enhance slab milling process which reduces human error and allows for intricate programming of cutting paths. This level of accuracy guarantees high quality surface finish and consistent cutting depths. Additionally, productivity is boosted by a feature that allows modifications to the cutting parameters without stopping the operation. Furthermore, they have versatility since they can handle different types of materials for various applications. In general, this technology does not only facilitate higher levels of accuracy and speed but also raises overall production efficiency.

Interpreting Slot Milling: Slab Milling’s Limitations

Slot milling is an important machining technique that compliments slab milling by enabling accurate creation of slots and grooves. Such method employs specific kinds of cutting tools such as end mills which are capable of fabricating straight or complex slot geometries. Given its applications in keyways, intricate part features and pathways for wiring into components among others, it is well-known for its adaptability.

Even more importantly however, CNC machines have shown effectiveness in slot milling through these advanced programming features which are accompanied by automatic control over cutting paths. They can be used to make complicated slot designs very quickly with great precision as well. It also helps computerized automation to reduce the possibility of human faults occurring throughout the manufacturing process hence uniformity across production batches becomes achievable at all times when using CNC technology to carry out slot machining processes as well as other activities related thereto under consideration . Also there is no limit on what material can be machined with it; metal composites or plastic among others that could be milled on them including metals like brass making it versatile enough for different industries.

Manufacturers can attain improved product quality and faster turnaround times by integrating CNC technology into the slot and slab milling processes, leading to higher precision, increased productivity and improved versatility.

The Advantages of Slab Milling in Modern Manufacturing

Material Removing on a Mass Scale at High Efficiency

The reason for this is that slab milling can remove in one pass a lot of material effectively, which greatly enhances productivity in manufacturing. The large cutting area of the slab mill enables quick and efficient removal of extra materials reducing the number of passes needed to achieve required dimensions. This efficiency is particularly good when working with big or heavy workpieces because it reduces machines time and operating costs.

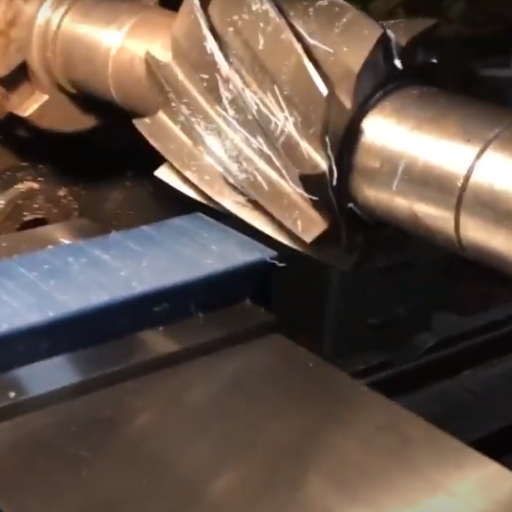

These advanced materials may include carbide tools that are now used as cutting instruments in modern slab milling operations that involve high feed rates. These tools maintain their edges over longer periods and withstand the intense forces created during the slab milling process. Furthermore, the integration of CNC technology into sliding processes has increased rates of material extraction by allowing accurate control of cutting attributes and real-time changes while working.

Essentially, this means that with slab milling, huge amounts of raw materials can be taken away quickly resulting to higher throughput, cost savings, and improved effectiveness in today’s manufacturing settings.

Advantages of HSS and Carbide Cutters

Thus, High-Speed Steel (HSS) and Carbide cutters have significant advantages over other materials in modern manufacturing environments hence making them widely used for various machining applications. Toughness, flexibility, resistance to chipping is some properties associated with high-speed steel, it makes these cutters suitable for general-purpose cutting tasks and also those operations requiring complex tool geometries. Consequently, HSS tools get resharpened easily thus prolonging their lifespan while being economical for use in relatively slow speed or low precision demanding operations.

Alternatively, carbide cutters are praised because they do not only possess incomparable hardness but also heat resistant capabilities that allow them run at much higher speeds than HSS cutters. They stay sharper longer which is important for very precise cuts and hard-to-cut materials such as hardened steels or superalloys. In addition to less downtime required for tool changeovers and higher rates of productivity, carbide tools have recently undergone improvements through use of coatings like titanium nitride (TiN) and aluminum oxide (Al2O3) that minimize wear while enhancing heat dissipation.

In conclusion, unlike the HSS cutters which are versatile and cheap to use, carbide cutters are faster, more accurate and last longer hence cannot be done without in high performance manufacturing setups where demand is high.

A Summary of Slab Milling: Process, Tools, and Applications

Key Takeaways from the Slab Milling Process

Definition and Purpose:

- Slab milling is a process where material is removed by a cutting tool that rotates on the surface of the workpiece. It is often used to make large surfaces flat.

Types of Milling Cutters:

- Popular tools are cylindrical cutters and they often have teeth at their edges, which enable them to cover large areas simultaneously.

- Face mills are also commonly employed because they give high material removal rates and better surface finish.

Material and Tool Selection:

- Tools’ choice depends on what the workpiece is made from. Carbide and high-speed steel materials are preferred in many cases while carbide can be preferred for harder materials or high speeds.

Operation Parameters:

- The critical parameters include cutting speed, feed rate, depth of cut which need to be optimized considering the type of material, type of tool and desired surface finish.

- Right coolant and lubrication is vital in order for the usefulness of the cutter to be prolonged as well as preventing overheating.

Machining Strategies:

- Climb milling versus conventional milling: Climb milling gives much better finishing look; it extends the service life of a cutter although more robust machinery is required.

- Conventional milling should generally be done if rigidity of machine tools or presence of backlash will affect accuracy adversely.

Applications:

- This technology has found use in various sectors including automobile, aerospace as well as manufacturing industries that require large flat surfaces.

- Mostly it is used during planing operations where there are big cast iron or steel plates requiring flatness such as blocks and other components.

Quality and Precision:

- To carry out slab milling with precision requires setup stiffness validation, stable tool condition, accurate machine set-up adjustments among others

- Modern CNC technology allows for this parameterized control so that consistent results can always be obtained

Tool Maintenance:

- It is important to regularly check up mill cutters with regard to sharpening since dull ones tend to hinder efficient cutting action.

- By utilizing modern coated tools, service life of the cutter can be significantly increased.

Safety Considerations:

- For instance, operators are expected to strictly adhere to safety guidelines which include machine guards, personal protective tools and adherence to operational guidelines which help in preventing accidents

Technological Advancements:

- Slab milling efficiency and productivity has been improved recently by digital twins and adaptive control systems that provide feedback in real-time.

Future Trends in Slab Milling Technologies

There are two factors which appear to be driving slab milling technologies into the future – artificial intelligence (AI) and the Internet of Things (IoT). AI-powered systems can analyze large data sets to forecast tool wear and optimize cut parameters on a real-time basis, thereby raising efficiency and accuracy. The integration of the IoT will pave way for machine-to-machine communication, allowing remote supervision and predictive maintenance. Additive manufacturing in combination with conventional slab milling is also probably going to gain popularity thus offering hybrid solutions that will streamline production as well as reduce material wastage. Advanced materials like enhanced coatings for milling cutters shall keep on improving, therefore lengthening their lifespan while enhancing performance, in addition more sustainable, accurate and efficient slab milling practices.

Reference sources

1. Online Article: “Understanding Slab Milling: Techniques and Applications” – Modern Machine Shop

- Source: Modern Machine Shop

- Summary/Annotation: This article from Modern Machine Shop provides an in-depth overview of slab milling techniques and applications. It explains the fundamentals of slab milling, including the operation of horizontal milling machines and the types of cutters used. The article discusses the advantages of slab milling for producing flat surfaces and large workpieces, as well as providing tips for optimizing milling efficiency and surface finish quality. Modern Machine Shop is a reputable publication in the machining industry, ensuring the content is accurate and well-researched. This source is valuable for readers seeking practical insights and techniques for effective slab milling operations.

2. Academic Journal: “Analysis of Cutting Forces and Tool Wear in Slab Milling” – International Journal of Advanced Manufacturing Technology

- Source: International Journal of Advanced Manufacturing Technology

- Summary/Annotation: Published in the International Journal of Advanced Manufacturing Technology, this peer-reviewed paper investigates the cutting forces and tool wear experienced during slab milling processes. The study uses experimental data to analyze the impact of various cutting parameters on tool life and machining performance. It also examines the relationship between cutting forces and surface finish quality. As an academic journal, this source provides high credibility and technical depth, making it essential for readers interested in the scientific aspects of slab milling, particularly regarding tool wear and process optimization.

3. Manufacturer Website: “Slab Milling Cutters and Solutions” – Sandvik Coromant

- Source: Sandvik Coromant

- Summary/Annotation: Sandvik Coromant’s website offers detailed information about their range of slab milling cutters and solutions. The site features technical specifications, application guidelines, and case studies demonstrating the effectiveness of Sandvik’s slab milling tools in various industrial applications. It also provides insights into the benefits of using their advanced cutting technologies for improving productivity and extending tool life. Sandvik Coromant is a leading manufacturer of cutting tools and solutions, ensuring authoritative and practical insights. This source is crucial for professionals and engineers seeking reliable information on selecting and using slab milling cutters for optimal performance.

Frequently Asked Questions (FAQs)

Q: What is slab milling and how does it differ from face milling?

A: Slab milling, also called peripheral milling, removes materials off the surface of the workpiece parallel to the axis of a cutter. Saliently, a plain mill or end mill creates a flat surface in this method. By contrast, whereas slab milling employs cutters that travel along their edges with respect to their axis in order to make large cuts as well as create flat surfaces lying parallel to the tooling axis, face milling is done using cutters that are positioned perpendicular to the work piece’s surface hence creating flat surfaces using cuts made by ends of cutter.

Q: What tools are commonly used in slab milling?

A: The most common tools used in slab milling process include plain mills and end-mills. Plain mills are best suited for many slab-milling operations and they come in different sizes that usually have large diameters with cutting teeth around them. End-mills can also be used during end-milling processes but may be required for slab milling where more intricate or precise cuts must be made. Slab-metal-removal rates coupled with planeness depend on these kinds of cutters applied.

Q: How does peripheral milling work?

A: Peripheral Milling rotates a cutting tool about its own axis while moving it along a prescribed path over the job; this cutting action takes place over its circumference making it mostly useful when slabs have to be flattened and considerable metal removed. The number of teeth on the cutter is small enough so that chips will not clog up and hinder smooth operation. This motion allows cutting through all lengths of the part perpendicularly towards its own shank line thereby producing an axial planar surface.

Q: Can slab milling be used for woodworking?

A: Certainly, woodworkers utilize slab-milling widely for flattening slabs and preparing big blocks of wood. It involves removing top layers thus making them flat, hence ideal for furniture and cabinet making in woodworking. Craftsmen can mill down the large pieces of wood efficiently and make them perfectly parallel and smooth with the help of milling machines fitted with suitable milling attachments.

Q: Why are there advantages of using slower feed rates in slab milling?

A: There are several advantages to using slower feed rates during slab milling. This allows for a finer surface finish as the cutter gets more time to create a smooth cut on the workpiece’s face. In addition, slower feed rates help preserve tool life, as they produce less heat and wear on cutting edges. They also provide for more accurate material removal which is necessary for achieving flat surfaces parallel to the axis of workpiece within given tolerances.

Q: What does the number of teeth on a cutter have to do with slab milling?

A: The number of teeth that appear on a cutter has an important role in slab milling. A cutter with fewer teeth results in larger chip load per tooth that is suitable for removing large volumes of material quickly but may give rise to a rougher surface finish. Conversely, more teeth make lighter cuts with less material removed per tooth resulting into a finer finish, which is good for finishing operations. While choosing between coarse and fine finishes depends upon particular requirements of job being milled and surface finish required.

Q: How can you ensure flatness when slab milling?

A: Ensuring flatness during slab milling includes several factors. Machine calibration and maintenance is crucial first off all; one should use properly calibrated and maintained milling machines. Equally important is considering diameter, number of teeth and flute design while choosing cutters. Appropriate level adjustment in feed rate and depth of cut aids in achieving desired flatness that slow feed rates combined with shallow cuts seem to yield better results on most occasions. Finally, coolant or lubricants should be used whenever possible to reduce heat generation and warping effects due to temperature changes that can occur during machining processes like this one here.”