When it comes to selecting the right phone case, it is important to know the material used for informed decision making. Phone cases made of Thermoplastic Polyurethane (TPU) and silicone are among the leading choices, with each having different advantages and disadvantages particularly in regard to shock absorption. We will discuss the actual qualities of TPU and silicone comparing their durability, flexibility, as well as general performance when shielding your handset. Consequently upon finishing this guide you will have more information concerning which materials are suitable for you and can guarantee an ultimate safety cover for your gadget.

What is Silicone and How is it Made?

Image source: https://www.the7electronics.com/

Silicone is an artificial polymer that comprises of silicon, carbon, hydrogen and oxygen. The latter one is obtained from silica by the method of polymerization where it is usually found in sand as a starting material to which petroleum hydrocarbons are added. This ultimately yields a versatile substance that can withstand high temperatures; at the same time it remains resilient and tough. A silicone phone case is ideal because it has specific features making it absorb most of the impact yet remaining soft and pleasant to touch.

Understanding Silicone as a Polymer

The flexibility and toughness that silicone polymers exhibit are well-known. Silicone, as a polymer, is made out of long chains of repeating units which give it its unique physical characteristics. Silicone has many chains with the ability to stretch greatly before snapping back to their original lengths. The silicon phone cases are therefore ideal for any environmental conditions because they maintain good protection regardless of the prevailing weather conditions. Equally important, silicone’s inherent water and chemical resistance make it durable and adding to its protective qualities. In brief, silicone material exhibits some specific properties like versatile polymer structure that allows it to withstand pressure from different quarters hence making strong phone coverings.

The Manufacturing Process of Silicone

The process of manufacturing silicone starts with silicon extraction from silica, commonly found in sand. The silicon is then purified and combined with petroleum-derived hydrocarbons to form siloxane. Polymerization of the siloxane in a series of chemical reactions leads to long chains of silicone polymers. Fluids, gels and solid rubbers are but some forms under which these can be further treated for more suitability. Additives may be introduced during final stages of production to improve specific features like flexibility, color or thermal stability. After shaping, silicone products such as phone cases undergo molding and curing processes that ensure that they possess their last particular form while also maintaining durability standards along with performance levels required.

Uses of Liquid Silicone Rubber

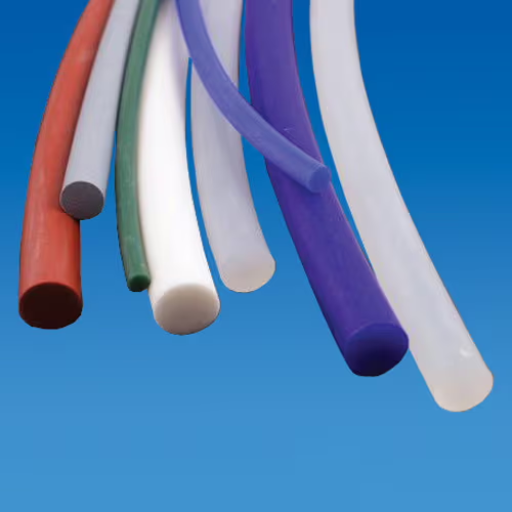

Across various sectors, Liquid Silicone Rubber (LSR) is one of the most adaptable materials with unique properties and easy manufacturing. Due to its biocompatibility, flexibility and ability to resist bacteria, it is frequently used in medical field to produce prosthetics, implantable items and medical device. Gaskets, seals and electrical connectors are produced using LSR in the automotive industry which offer high performance under mechanical stress as well as during extreme temperature fluctuations because of its resistance to those variations. Also, LSR is used for making kitchenware materials like baby products among others due to its non-toxicity and ability to withstand higher temperatures. Consequently, its outstanding qualities make LSR a suitable option where durability is crucial along with precision and safety considerations.

What is TPU and How is it Made?

TPU is one of elastomers that is characterized by its very high flexibility, durability and versatility which makes it useful for wide range of applications. TPU is made through polymerisation process where various raw materials primarily diisocyanates and polyols react with each other to form long chains of molecules. This reaction in most cases require catalysts and can be manipulated to get different levels of hardness as well as elasticity. The resulting TPU can be further processed using methods like injection moulding, blow moulding or extrusion so as to produce items such as shoe soles, mobile phone covers and car components. Unique features like excellent mechanical properties, low temperature flexibility, resistance to abrasion amongst others make it ideal for use in highly demanding applications.

Understanding TPU as a Thermoplastic Elastomer

TPU is a thermoplastic elastomer, implying it combines the best features of rubbery elasticity and processability of thermoplastics. TPU can be melted and remolded many times when heated as a thermoplastic material without undergoing significant degradation, which makes it suitable for manufacturing processes such as injection moulding and extrusion. Key attributes that contribute to TPU’s versatility are its excellent abrasion resistance, high tensile strength and great flexibility at low temperatures. Such properties have made TPU a good choice for applications ranging from industrial components through consumer goods to medical devices. Furthermore, TPU maintains functionality in varied surroundings, which supports its use in numerous industries as a high-performance material.

The Manufacturing Process: Injection Molding and 3D Printing

Injection Molding

Injection molding is a very effective process that is used in manufacturing to create intricate and accurate components from TPU. In this process, TPU granules are melted and then injected into the mold cavity under intense pressure. After cooling down and solidifying, the mold opens up to release the finished part. With its short cycle times, ability to hold tight tolerances, and ability to make complex shapes injection molding can be beneficial for mass production as well. It also makes use of recycled TPU which reduces wastage.

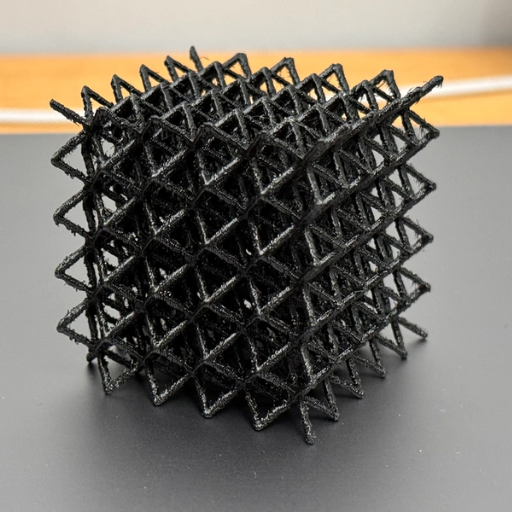

3D Printing

Additive manufacturing or 3D printing provides a versatile and cost-effective method for producing TPU parts mostly for prototyping and small-batch production. The process involves depositing layers of TPU based on a digital model, allowing for a high degree of customization difficult to achieve using traditional methods. Therefore, Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) are common 3D printing techniques used with TPU because they can handle flexible nature of the material while it is more resistant than other materials.. This technique supports quick iteration and design flexibility thus suitable for innovative applications as well as custom-fit products.

Applications of TPU

TPU has a remarkable set of properties including flexibility, abrasion resistance and durability that make it useful in many industries. Some of them are:

Footwear

Its excellent elasticity, transparency and wear resistance explain why TPU is widely used in the making shoe soles. This makes them comfortable and long lasting hence suitable for sports as well as casual footwear.

Medical Devices

Biocompatibility and flexibility characteristics of thermoplastic polyurethane has made it to be very common in production of medical tubing, catheters among other medical devices which needs some amount of softness together with resilience.

Automotive

Automotive sector utilizes TPU in making airbag covers, instrument panels, door trims etc. thus ensuring that they can withstand tough environments with oil or grease.

Consumer Electronics

Commonly found on most consumer electronics cases or covers like smartphones, tablets laptops etc., TPU aids the protection process by absorbing impacts during drops thereby preventing scratches.

Textiles and Apparel

In textile industry, waterproof breathable fabrics are made from TPU; also clothing such as sportswear and outdoor cloths are manufactured using a stretchable strong fabric (TPU).

Industrial Applications

The mechanical properties of TPU make it possible to produce conveyor belts, seals gaskets and wheels for various industrial applications hence providing wearing resistance even when subjected to harsh environmental conditions for a long period.

These uses explain how versatile and strong TPU is, which is why it is used extensively across various sectors.

Comparing the Physical Properties of Silicone and TPU

In examining the physical characteristics of silicone and TPU, several differences become noticeable. In fact, silicone has incredible heat resistance; it is stable in a temperature range from -60°C to +230°C, while TPU can only be used within -40°C to +80°C. Of course both types of materials are flexible even though silicone surpasses all when it comes to stretchiness and staying in shape for a long time period. As concerning hardness silicon can be either soft or firm, just as TPU is; still, however, TPU excels at abrasion and tear resistance. Moreover, silicon is inherently more biocompatible than TPU that makes it ideal for medical implants while TPU’s durability and impact-resistance make it desirable for high-wear applications. These distinctions underline how complementary silicon and TPU can be since they both have distinct advantages in diverse areas depending on specific needs of their target usages.

Shock-Absorbing Capabilities

When comparing the shock-absorbing capabilities of silicone and TPU, these two materials possess unique characteristics that suit distinct uses. Silicone is famous for its great ability to absorb vibrations as well as being smooth to touch, which makes it perfect for applications that need cushioning and gentleness like in medical devices or consumer electronics. In contrast, TPU has higher resilience and durability than any other material that is useful in hard hitting environments. In most cases, TPU is used in sports equipment, shoes or industrial products where resistance to repetitive impacts is important. All in all, although both of them are good at absorbing shocks, TPU usually offers better strength and impact resistivity whereas silicone has more flexibility and suppleness.

Durability and Abrasion Resistance

TPU is usually better than silicone in terms of durability and resistance to abrasion. It has a remarkable ability to resist wear and damage, which makes it suitable for hard applications like car parts, industrial stuffs as well as protectors. Its structure never undergoes deformation even under high energies produced by impacts or corrosive atmospheres. Comparatively, TPU tends to be harder-wearing than silicone although the latter can outlast it under some conditions. Silicone is still useful in places where suppleness and compatibility with living tissues are important but if one needs long-lasting protection against scratches, TPU wins over this material.

Soft to the Touch: Feel and Flexibility

Silicon is well-known for its soft, supple feel, which makes it ideal for applications needing gentle handling and comfort. The material’s inherent suppleness enables it to take on various forms thus enhancing sensory experience. Moreover, this tenderness corresponds to lower durometer ratings that enable silicone to have a rigidness lesser than TPU does hence, making it more popular in consumer products and medical devices where contact with the skin is direct.

TPU may also be somewhat flexible; nevertheless, it tends to be harder than silicones. Rightly balancing between flexibility and ruggedness, it keeps its shape while giving solid support. Such properties make TPU perfect for items like protective covers or skins as well as athletic shoes for people who flex their feet too much during walking or sports activities. Notwithstanding not being as squishy as silicone, TPU’s minor firmness makes certain of its durability since it can retain its outline and structural robustness through multiple uses.

What are the Differences Between TPU and Silicone?

The distinction between TPU (thermoplastic polyurethane) and silicone lies in their endurance, feel, flexibility and suitability for use. TPU is highly resistant to wear and tear as well as impact which makes it suitable for uses that require sustained structural integrity. It is tougher than silicone thus offering a blend of elasticity and strength that is useful for protective cases, shoes, or sports gear. On the other hand, silicone feels more gentle and is more adaptable hence providing a smooth haptic experience perfect for skin touch consumer products or medical devices. Nonetheless, while having lesser surface wear resistance than TPU does; silicone works better in scenarios where malleability and biocompatibility are critical issues.

TPU vs Silicone: Strength and Flexibility

Speaking about toughness and adaptability, TPU and silicone have distinctive traits that make them applicable in various areas. On the one hand, TPU is known for its remarkable resistance to abrasion and ability to withstand impact yet remain intact even under pressure. This is why TPU is preferred for products such as industrial components, safety equipment and sports items which require toughness and consistent functional performance over time.

As opposed to this, silicone has unrivaled suppleness and softness that provides a gentle cozy feel. Its flexibility does not imply weakness though, thus it can be used in medical instruments, electronic devices with frequent bending or stretching among others like kitchen utensils. Although softer than TPU, silicone has a high heat resistance capability maintains its stability over wide range of situations that broadens its applications.

In conclusion, in terms of strength and durability you may choose TPU as your best preference. However when looking at applications where bloggers want increases flexibility and softness their choice should turn to silicones.

Heat and Chemical Resistance Comparison

TPU versus silicone for various purposes should be selected on the basis of heat and chemical resistance. Normally, TPU will withstand temperatures that range between 80-120 degrees Celsius, which gives it a moderate resistance to heat. However, if exposed to temperature conditions beyond this range for prolonged periods, it may become brittle or decompose. In relation to chemical resistance, oils, greases and certain types of solvents can be resisted by TPU but it might not do well with more aggressive chemicals.

On the other hand, silicon purposes excellently survive in high temperatures without losing its physical properties as they allow it to withstand temperatures ranging from -60 to 230 degrees Celsius. Thus making it ideal for automotive components and baking molds utilized in high temperature applications. Silicone also has excellent chemical resistance making it resistant to acids, alkalis and solvents among others. Also, this makes them highly suitable for use in harsh environments such as medical and industrial uses.

In conclusion therefore silicone is generally a better option for applications requiring superior heat and chemical resistance. Whereas TPU is strong in many respects; however when compared with silicone its resilience in highly heated environment or places that are exposed to heavy chemicals cannot be matched by any means.

Abrasion Resistance: Hard Plastic vs Liquid Silicone

When comparing hard plastic and liquid silicone in terms of their wear resistance, the former generally proves to be more durable. These are materials like polycarbonate and ABS that can withstand a lot of abuse, and this makes them useful for applications requiring robust surfaces. They are frequently used in products such as protective equipment, electronic casings as well as other items often held and hit.

This means that it can wear away over an extended period though liquid silicone is softer and more flexible. In respect to resisting wear on its surface silicon’s key benefit is not in this property but chemical resistance, thermal stability and flexibility. The latter is therefore better suited to situations where gentleness or high temperature performance is needed rather than those calling for increased scratch protection.

In summary, hard plastic outperforms liquid silicone in abrasion resistance because of its harder surface characteristics making it the preferred material for applications that demand durability or longevity when subjected to frequent stress and touch moments.

Why TPU Phone Cases are Popular?

The unique combination of flexibility, durability and impact resistance have made TPU phone cases very popular. Thermoplastic polyurethane (TPU) is inherently bendable which enables it to absorb impacts efficiently and keep the phone safe from both falls and bumps. Furthermore, TPU cases are designed to fit snugly in order to keep them on the device and to ensure that buttons and ports remain accessible. Its oil, grease and abrasion resistance coupled with its transparency makes good looking sleek designs that reveal the smartphone’s beauty. All these features make TPU phone cases an ideal choice for many who want a practical and stylish case for their smartphones.

The Appeal of TPU in Smartphone Accessories

TPU is a beloved material in smartphone peripherals as it boasts of durability, malleability and versatility. The elastic nature of TPU enables it to effectively absorb and dissipate impacts thus providing strong protection against falls and scratches. It fits perfectly and is easily moldable ensuring that the cases stick closely to the phone without blocking any ports or buttons, making it user-friendly. In addition, TPU resists oil, grease and other atmospheric conditions which can ensure longer lasting accessories. Moreover, the fact that this substance is transparent while being able to produce many colors and finishes allows for a wide variety of designs for differing customer tastes. Therefore, what makes TPU so popular with smartphone peripherals is its all-round protection, functional convenience as well as stylishness flexibility.

Sustainability and Environmental Factors

The materialization and application of Thermoplastic polyurethane (TPU) in mobile phone accessories are the sources of sustainability and environmental concerns. It can be recycled unlike some plastics, thus minimizing waste and sustaining circular economy interventions. Research is also being done to come up with biosourced TPUs that are made from raw materials that can be regrown hence diminishing the dependence on fossil fuels and decreasing carbon footprints from its manufacturing process. However, one should note that TPU is comparatively environmentally friendly than other types of plastics though it faces challenges related to degradability as well as disposal impact in an ecological sense. So, continual innovation and responsible consumption are important for enhancing the sustainability of TPU-related items.

When to Choose Silicone Case over TPU Case?

In choosing between a silicone case and a TPU, there are several factors to consider. An excellent shock resistant soft material that is more flexible and pliable, prioritizes the case made from silicone. The silicon materials make them ideal for individuals who frequently drop their phones as they offer strong impact protection. Further still, silicon cases have better grips meaning they are less likely to accidentally fall. However, one should be aware that compared to TPU cases from silicon such cases may gather more dust and lint. While TPU might be a better option in terms of comfort and stretchability but for maximum cushioning and grip advantage is with silicon case which is recommended.

Best Scenarios for Using a Silicon Case

1. Daily Use and Drop Protection: According to today’s most visited websites, silicone cases are ideal for day to day use, especially when it comes to people who drop their phones often. Silicone is soft and pliable hence absorbs shock well and resists impact thus providing effective protection against accidental falls.

2. Outdoor Activities: Silicone cases offer a better grip when participating in outdoor activities thus reducing the chances of unintended slips. They are particularly useful in humid or rainy conditions where holding on to your phone firmly becomes challenging.

3. Enhanced Comfort and Tactile Experience: For individuals looking for enhanced comfort as well as tactile experience, they should consider using silicone cases. The material has a good touch feel that adds some fun to using your phone over long periods of time.

Specific Use Cases for Silicone vs TPU Choices

Silicone Cases:

- Work Environments: People working in places where things keep changing, such as construction sites or warehouses, benefit from silicone cases that have increased shock absorption. The flexible material is essential in preventing drops, impacts and bumps on hard surfaces.

- Children’s Devices: With regard to the devices used by children, silicone cases are particularly beneficial due to their superior cushioning characteristics. They are capable of providing maximum protection against frequent mishandling and falling off often associated with young users.

- Cold Weather: In colder climates where other materials tend to become brittle, silicon cases remains flexible and still maintains its protective qualities which makes them ideal for use in these conditions.

TPU Cases:

- Professional Settings: Where a slim sleek profile is required like professional environments, TPU cases work best. The combination of stiffness and flexibility allows a perfect fit that enhances the looks of the device without compromising on safety issues.

- Active Lifestyles: TPU cases are an optimum solution for individuals who live actively because they offer a balanced mix between being too bulky while ensuring adequate protection against shocks and scratches. Ideal for individuals who value function as well as fashion sense at the same time.

- Customization and Variety: However, there is generally more variety in designs and colors for TPU cases hence making them more suitable for people who like to personalize their phones. This means that it can be designed into intricate patterns or made transparent so as to showcase the original design of the phone’s backside.

Frequently Asked Questions (FAQs)

Q: What is TPU in phone cases?

A: TPU, known as Thermoplastic Polyurethane, is a class of polyurethane plastics that combines hard and soft segments, making it a robust and flexible compound often used in smartphone cases.

Q: What are the main differences between silicone and TPU phone cases?

A: The key differences between silicone and TPU phone cases lie in their chemical composition and physical properties. Silicone is an inorganic compound that is flexible and has excellent heat resistance, while TPU is a class of polyurethane plastics that is also flexible but generally has better abrasion and impact resistance.

Q: Which material is better for protecting against drops, TPU or silicone?

A: Both materials offer good protection, but TPU is generally considered better for impact resistance due to its combination of hard and soft segments. Silicone, while also protective, may not offer the same level of shock absorption.

Q: Can TPU and silicone phone cases withstand ultraviolet light?

A: TPU can withstand ultraviolet light better than silicone. Silicone material may degrade faster when continuously exposed to ultraviolet light, impacting its durability.

Q: What are the similarities and differences between polyurethane and silicone phone cases?

A: Both polyurethane (TPU) and silicone are used in mobile phone cases because they provide durability and flexibility. The main difference is that TPU is generally harder and offers better impact resistance, while silicone is softer and can offer better grip and heat resistance.

Q: Are there different types of silicone used in phone cases?

A: Yes, there are different types of silicone used in phone cases, each with varying levels of flexibility, durability, and heat resistance. The specific type of silicone used can affect the overall performance of the phone case.

Q: How does the flexibility of TPU and silicone compare?

A: TPU is flexible but not as soft as silicone, which can stretch more without tearing. Silicone’s flexibility often makes it feel softer in the hand, while TPU’s flexibility provides a firmer, more controlled grip.

Q: Is it safe to charge your phone with a TPU or silicone case on?

A: Yes, it is generally safe to charge your phone with either a TPU or silicone case on. However, both materials may cause slight heating, so it is advisable to ensure your phone does not overheat during charging.

Q: Are there any environmental considerations between using TPU and silicone in phone cases?

A: Silicone is an inorganic compound and recyclable, whereas TPU can be more challenging to recycle due to its chemical makeup. Consideration of environmental impact may lead some to prefer silicone over TPU when choosing mobile phone cases.

Q: Which material, TPU or silicone, offers better long-term durability for phone cases?

A: TPU generally offers better long-term durability due to its superior resistance to abrasion and impact. However, silicone has excellent heat resistance, making it durable in different ways. The choice between the two materials will depend on the specific needs and preferences relating to the case material.