Understanding the Shore D Hardness scale is crucial for professionals across various industries, from manufacturing to engineering, as it measures the hardness of polymers, elastomers, and rubbers. This guide aims to demystify the complexities surrounding the Shore D Hardness scale, providing a clear and accessible overview for all readers. Whether you’re a seasoned engineer looking to refresh your knowledge or someone new to the field trying to understand the basics, this comprehensive guide will explore key concepts, testing methods, and the practical applications of Shore D Hardness measurements. By unpacking the significance of these measurements, we’ll reveal how they influence material selection and product design, ensuring you’re well-equipped to make informed decisions in your projects.

Understanding the Shore D Hardness Scale

What Is Shore D Hardness and How Is It Measured?

Shore D Hardness is a measure employed to appraise the hardness of hard rubbers, plastics, and other non-flexible substances. The value is obtained with the aid of a durometer, and it comes in a form of a number from zero to hundred. Higher numbers show harder materials. Thus, this scale, referred to as ASTM D2240 standard in some cases, is important in industrial applications where material hardness affects product performance and durability.

- Measurement Device: A durometer is the instrument that measures Shore D Hardness. It typically contains a spring-loaded pin or indenter that is forced into the surface of the material at a fixed pressure.

- The Scale: For Shore D Hardness, there are readings within 0-100 range whereby 0 means very soft while 100 denotes extreme hardness. Numerically this range allows for precise scaling of different hardness levels between materials.

- Measurement Procedure: Using standardized periods (usually 15 seconds), one should press an indenter of the durometer into the material thereby turning its depth into a Shore D value.

- Units: Although labeled as ‘Shore D Hardness,’ these figures do not carry any absolute values but instead possess relative information regarding how hard or soft a given substance feels compared to others on said scale.

Professionals can ensure that their project’s chosen materials meet required durability and performance standards by understanding what Shore D Hardness is and measuring it correctly. This knowledge proves especially critical when selecting materials for high impact resistance, stiffness/rigidity or wear resistance applications such as automotive components, industrial seals or protective covers.

Deciphering the Difference Between Shore A and Shore D Hardness

Shore A and shore d hardness both have scales for measuring material hardness; however these scales differ depending on how firm substances are. Understanding these differences helps in choosing appropriate materials for specific applications. Here’s an elaborate comparison:

Material Type:

- Shore A: It is meant for softer materials like rubber, elastomers and other flexible materials. The hardness value represents a measurement of the ability to dent a material but not break it.

- Shore D: It is for tougher plastics and rigid polymers. This type encompasses materials that will resist penetration under similar conditions as those used in the Shore A scale for soft materials.

Scale Range:

- Shore A: Whereas the scale goes from 0 to 100, with something very soft (like gum rubber) being at 0 and harder but still relatively flexible (such as shopping cart wheel) at 100.

- Shore D: Also having zero to hundred span, in which case zero is moderately hard (like some Shore A rubbers), while one hundred denotes extreme hardness (similar to a hard hat).

Application Examples:

- Shore A: Automotive tire treads, conveyor belts, and various sealing rings all require flexibility and resilience.

- Shore D: On the other hand, there are products that demand greater resistance to stress or wear so such items include protective coverings, plastic parts on automobile interiors and industrial machinery components made of rigid polymers.

By comparing Shore A and Shore D hardness, professionals can more accurately determine material suitability for their specific project requirements, ensuring optimal performance and longevity. Each scale provides a vital tool in the material selection process, enabling precise specification according to the demands of the application.

Importance of Shore Hardness in Material Selection

The importance of shore hardness in material selection cannot be overemphasized as it directly affects products’ durability, flexibility, resistance to wear and specific use conditions. Therefore, understanding and measuring shore hardness gives engineers, designers and manufacturers critical data they must have to ensure that the materials chosen meet required specifications and performance standards. Here is why selecting right shore hardness is important during material choice:

- Durability and Lifespan: Products made from materials with appropriate shore hardness can stand daily abuse as well as environmental stresses that may extend their functional life span. For instance, shores D are commonly used materials for heavy duty or high impact applications so that product remains operational over time without significant degradation.

- Flexibility and Elasticity: Shore A hard materials are essential when flexibility is a primary requirement. This helps seals or gaskets or flexible hosepipes maintain their integrity without breaking when bent or stretched thus preventing leaks or failures during operations.

- Wear Resistance: There is close relationship between wear resistance and ability of a material to resist wearing out due to its shore hardness values. To ensure long component life under abrasive conditions, hard (High value of Shore D) materials are frequently used for high wearing applications such as gears or bearings.

- Impact Resistance: Higher rating on shore D scale means higher resistance against sudden impacts; hence it becomes suitable for protective equipment like housing/casing where the aim is minimizing destruction caused by shocks.

- Compatibility with Application Requirements: Different kinds of applications require different properties in materials. Designers can use shore hardness measurements to match appropriate materials with particular applications including cases where either rigidity or flexibility is necessary.

- Cost-effectiveness: Significant savings related to cost can also be realized by selecting appropriate materials based on shore hardness. Consequently, using very hard or too soft materials for the intended application leads to premature failure, increased need for maintenance and higher costs of replacement.

Thus, detailed and accurate shore hardness data can help make better informed choices. This will not only ensure appropriateness of the chosen material but also contribute towards safety, performance and satisfaction of end users. Material selection guided by shore hardness is hence a primary concern during design and manufacturing processes that influences the product’s quality, dependability and general success in the market.

Delving into Durometers: The Tools for Measuring Hardness

How Does A Durometer Work?

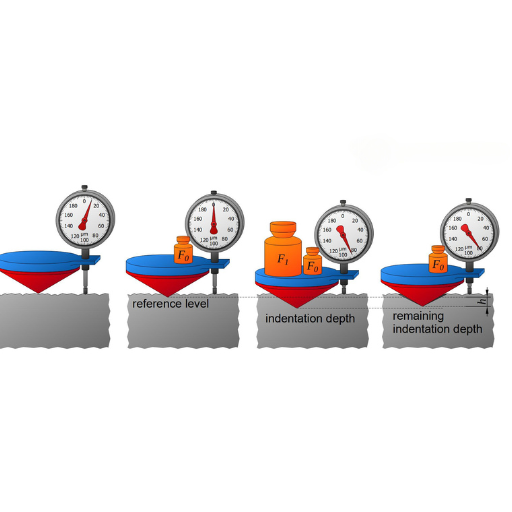

A durometer is a tool used to measure the Shore hardness of different materials and give a quantitative figure for their resistance to indentation. The following is how it works in detail:

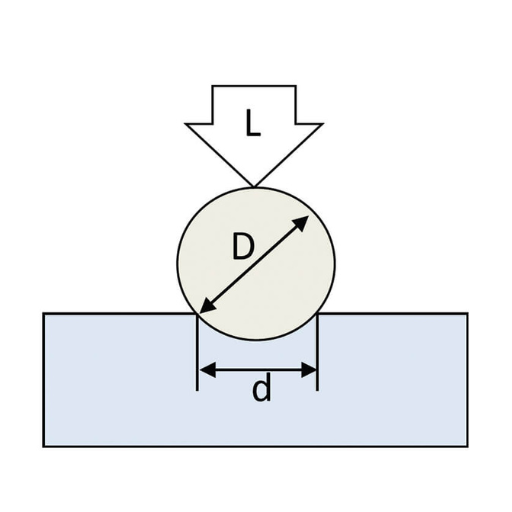

- Force Application: A standard force is applied through a specific indenter onto a material in the primary mechanism of a durometer. The tip of the indenter may be flat or pointed, depending on what type or variation of the Shore scale that the measurement will be made on (e.g., Shore A, D).

- Indentation Measurement: After applying the force, the depth of indentation created by the indenter in the material is determined by the durometer. This depth is inversely related with hardness of substance meaning that softer substances will cause deeper indent.

- Shore Hardness Scale Reading: Next, this depth of indentation is matched up against a given range on the Shore hardness scale which goes from 0 (very soft) to 100 (very hard). For instance, taking 0 reading along Shore A scale points to extremely soft material while 100 indicates extreme composite stiffness.

- Digital or Analog Display: Contemporary durometers may have digital screens showing directly the hardness value thus making it easier for users to read and increase accuracy. Conversely, an analogue dial provides values for hardness in analogue durometers.

- Repeatability and Precision: Highly reliable durometers are designed to assure measurements repeatability as well as precision. These are calibrated according to national or international standards so that they could maintain accuracy throughout their use repeatedly.

These principles allow for accurate measurement of material science’s crucial property-hardness; this relates indirectly choosing materials most suitable for specific tasks. This equipment offers detailed information which can also be relied upon due its reliability when it comes data concerning stress-driven properties.

Choosing The Right Durometer For Your Material

Getting accurate results that pertain only to your application begins with selecting an appropriate durometer for assessing hardness of a material. Here is a simple guide to help you with your decision making:

- Material Type Understanding: The general category of hardness for the material should be determined first. Shore A durometer may be needed for very soft materials, such as certain types of rubbers, gels, or foams. On the other hand Shore D durometer might become more suitable for harder plastics or rigid materials.

- Shape and Thickness of Material Consideration: The size and shape of the material may also determine what kind of durometer is used. Smaller indentor foot on the durometer would therefore be selected as required in case of thin or small materials to give correct measurements.

- Application Of Material: You need to know what purpose the material will serve. In comparison to those products that have less severe applications, those designed for high impact and abrasive conditions require more specific hardness specifications.

- Precision Required: For digital durometers with advanced features like repeatability and accuracy when it comes to precision demanding applications select as may be appropriate where precision is important. Analog durometers can indicate general hardness or work well for less critical situations.

- Standards Compliance: It is essential that your chosen material complies with relevant industrial standards. Such compliance ensures accurate measurement results while ensuring product conformity with industry regulations.

To select a durometer that matches your material’s characteristics and matches your specific measurement needs, you have to consider these parameters. This selection process is deliberate in order to maintain quality control and make sure the material serves its purpose as expected.

Importance of ASTM D2240 in Hardness Testing

ASTM D2240 is vital for hardness testing of rubber and plastic materials. This standard provides a common way of determining substance indentation hardness using durometers. Here’s how it breaks down in simple terms:

- Standardization: It ensures that all hardness testing done across different labs and industries is uniform. By following ASTM D2240, companies can be confident that their hardness measurements are comparable to those of others.

- Measurement Scale: There are various scales (A, D etc.) provided by the standard each suited to different levels of hardness. By selecting the right scale, you can get accurate readings for your material whether it is a soft rubber or a hard plastic.

- Test Procedure: The test must be carried out as specified by ASTM D2240 including how the durometer should be applied on the material thus consistent implementation of procedure irrespective of who does it gives dependable results.

- Quality Control: Following this standard is essential for quality control purposes. This enables manufacturers to ensure that their materials meet the necessary specifications regarding hardness for their intended use thus avoiding issues with final product.

- Regulatory Compliance: For products that need to meet regulatory requirements, following ASTM D2240 can be essential. Therefore it indicates that the determination was based on globally acknowledged standards concerning this aspect.

Thus, through adherence with ASTM D2240, industries uphold high-quality standards which guarantee performance expectations of materials and products alike. It’s not just about measuring hardness; this standard ensures uniformity, reliability and compatibility among diverse application materials across myriad fabrication processes.

Exploring the Shore Hardness Scale: From Rubber to Hard Plastics

Spectrum of Hardness: From Soft Rubber to Hard Thermoplastic

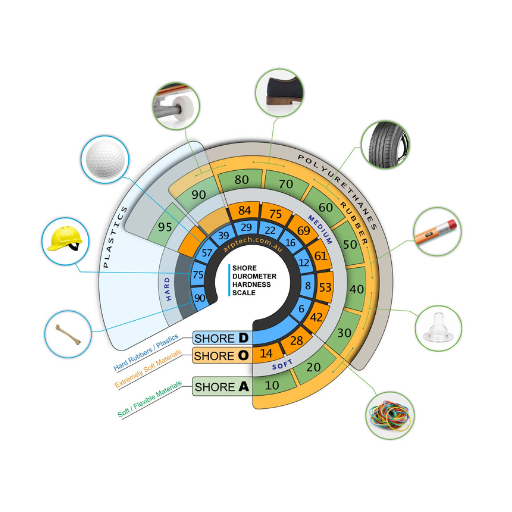

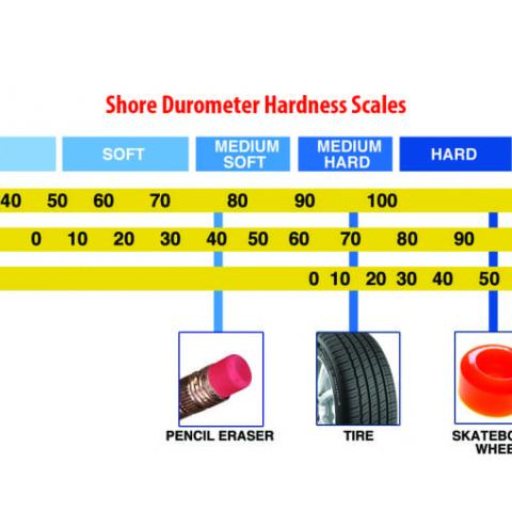

Materials can be classified using Shore hardness scale by their resistance to indentation, a measure that helps in understanding their flexibility or rigidity. The Scale is divided into a number of ranges such as , but not limited to, Shore A and Shore D which are the most commonly used for soft and hard materials respectively.

Shore A Hardness Scale

- Soft Rubber (20-40 Shore A): This group includes things like soft rubber bands and gel insoles. They are extremely flexible and easily compressed.

- Medium Rubber (41-60 Shore A): Examples include car tires and regular rubber bands among others having some level of flexibility with resistance to indentations.

- Hard Rubber (61-80 Shore A): Hockey pucks and some types of shoe heels are examples of hard rubber products which have little flexibility compared to other categories.

Shore D Hardness Scale

- Soft Plastics (20-40 Shore D): These might include softer plastic caps and lids. They experience some indentation but they nevertheless remain more flexible than higher shore D materials.

- Medium Hard Plastics (41-60 Shore D): For instance, there are hard hats and several container types such as shampoo bottles, among others. This means that they have harder texture compared to medium-to-hard_ thermoplastic products resulting in higher resistance toward indentations.

- Hard Thermoplastic (61-80 Shore D): Examples of this category include the hardest plastics such as those employed in bowling balls, some high-performance engineering components etc., exhibiting minimal flexibility with maximum resistance towards indentations..

The Shore scale hardnesses for each material provide crucial information about how these substances perform under different loads and stresses where performance matters. Knowing the whole range from soft rubbers till hard thermoplastics enables designers’ decisions about suitable choices for any application ensuring it will withstand time, operate efficiently without incidents.

Comparison between Shore A, B, C, D and Other Hardness Scales

When comparing shore A, B, C, D and other hardness scales one should also consider the specific applications and the types of substances they are best suited for. Shore hardness scales are mainly divided into Shore A and shore D which are designed to measure the hardness of different kinds of materials.

- Shore A Scale: It is used mainly for softer materials such as rubbers and elastomers down to very soft or flexible polymers. It ranges from 0 to100 Shore A; where higher numbers indicate harder materials. Automotive, footwear and general rubber goods industries benefit a lot from this scale.

- Shore D Scale: This is used for harder plastics also scored on zero to 100. Higher score materials on the scale of shore D are hard ones that offer more resistance towards indentations. The significance of this scale in manufacturing process lies in hard plastics employed in protective equipment including mechanical parts as well as high performance items.

- Other Hardness Scales: Besides the shore A and D scales there are several others used for various materials/applications:

- Rockwell Hardness Scale: Used to measure metal hardness it has different scales identified by letters (A,B,C etc.). In contrast with Rockwell test, depth comparison between big load than smaller one.

- Brinell Hardness Test: It is applied to materials with non-uniform structure or surface, by measuring the diameter of the indentation left after a hard sphere has been pressed on it under a known load.

- Vickers Hardness Test: Applicable to thin materials and small parts, this test gives a broad hardness range from very soft materials to very hard ones. It measures the diagonal length of a square indent made by a diamond pyramid under an applied specified force.

Each hardness scale tells us something specific about material properties. The Shore A and D scales are for elastomers and polymers whilst the Rockwell, Brinell, and Vickers scales are for metals and stronger materials. Knowing these details helps in selecting appropriate material considering its application so as to achieve desired performance and lasting longer.

Case Studies: How Shore Hardness Measurements Have Been Applied in Real World Situations

Protective Gear Manufacturing: By utilizing Shore D hardness measurements, a leading sports equipment manufacturer was able to optimize their helmet shells and pads. They found that materials with a shore d hardness between 60-70 provide an ideal balance between impact resistance and comfort thus considerably reducing concussion rates among contact sport players.

- Automotive Tire Development: In efforts to enhance tire life span and improve fuel consumption, an automobile firm carried out extensive research. After assessing tires having shore A hardness values ranging from 50 to 70, they developed a compound offering better wear resistance while lowering rolling resistance resulting in 5% increase in fuel efficiency across the whole fleet of vehicles.

- Medical Device Innovation: In order to make surgical tubing more durable and flexible, one medical device manufacturer utilized Shore A hardness testing. Choosing tubes with shore A hardness of 80 allowed resistant against kinking whilst still allowing flexibility suitable for fine surgical procedure in patients thereby improving patient outcome.

- Consumer Electronics Casings: Through using Shore D hardness tests this consumer electronics producer identified the right type of material that should be used for smartphone and tablet casings. With a hardness level of 75 Shore D, these devices are strong enough to resist cracking during fall or while in contact with objects that may scratch them but still appear stylish.

These case studies all highlight the importance of Shore hardness measurements in product development and improvement. Companies can considerably enhance the quality, usability, and life expectancy of their products by selecting materials with appropriate hardness levels.

Materials on the Shore D Scale: Thermoplastics and Elastomers

Determining the Hardness of Semi-Rigid and Hard Plastics

To ensure that materials are in line with their intended use, rather than making them too complicated in terms of manufacturing or their functionality, hardness is important when it comes to semi-rigid and hard plastics. The Shore D scale is particularly useful here; it addresses materials which are harder than those measured by Shore A scale. When assessing these plastics, here are key parameters to consider:

- Application Requirements: Know what your application needs. For instance, is resistance to constant rubbing or heavy impacts needed? The required level of hardness depends on the application.

- Material Compatibility: Although some plastics may be sufficiently hard, they may not be compatible with other materials used in the product or manufacturing procedures (e.g., injection molding temperatures).

- Environmental Factors: The impact of temperature changes, variations in humidity as well as exposure to chemicals and ultra violet on plastic hardness and durability.

- Product Lifecycle: While harder plastics might have a longer wear life, they can also be brittle at specific circumstances. Check for how long you expect your product to last and whether its hardness will affect its durability throughout time.

- Compliance and Safety: Regulatory standards applicable in different markets can limit the range of acceptable levels of hardness for a material therefore check if it meets safety standards required by law.

Through systematically going through these parameters we can determine the appropriate level of hardiness for an application using Shore D scales so that we choose semi-rigid and hard plastics that would be most efficient under such conditions anticipated.

The Role of Shore D Hardness in Thermoplastic Elastomer Selection

For industrial designers and engineers looking for suitable thermoplastic elastomers (TPE) for their projects, the scale is very useful. Think about it as a “toughness” rating system for plastic – higher numbers indicate harder materials. Stiffness like this affects almost everything from toughness to flexibility as used on things. Let’s see how it fits into those important considerations we had:

- Application Requirements: If your project is something that’ll get knocked around a lot or needs to slide smoothly without wearing down, you’ll want a TPE with the right balance of hardness. A high Shore D rating means the material is hard and can handle impacts better, but might not be as forgiving in environments requiring flexibility.

- Material Compatibility: Not all plastics play nice together. The hardness you choose must not only meet your application needs but also be compatible with other materials in your product. For example, a very hard plastic might resist bonding with other components.

- Environmental Factors: TPEs face everything from scorching sun to chemical spills. Some materials can become harder or more brittle with exposure to certain conditions. Matching the Shore D hardness to your environment ensures the material stays strong and functional, no matter what’s thrown at it.

- Product Lifecycle: A tougher plastic may last longer in terms of usage but consider its aging process. Will it become brittle with age and cold weather? The right Shore D rating will keep your product functional throughout its lifecycle, balancing hardness with enough flexibility to prevent breakage.

- Compliance and Safety: Finally, the hardness may be governed by legislation for items that come into contact with food or are intended for children. Hard plastics do not bend easily hence they are unlikely to cause injuries if they break but on the other hand, each application has specific safety requirements.

Understanding these points helps you determine the right Shore D hardness of TPEs that is safe, durable and perfectly matched to its intended use.

Understanding How Shore D Hardness Affects Polymer Performance

Shore D hardness determines a polymer’s overall behavior and how it can be used. The following outlines how Shore D hardness affects different aspects of polymer performance:

- Wear Resistance: Generally, materials with higher Shore D hardness have better durability against frequent use and physical wear. They are less likely to scratch, abrade or lose shape hence useful in high contact areas.

- Flexibility versus Rigidity: Lower Shore D values indicate a material is more flexible. This is critical for jobs using substances that must flex without breaking. Conversely, higher values imply increased rigidity; this means that under stress parts retain their shape well.

- Impact Resistance: Material toughness influences how it absorbs and dissipates energy when struck. Therefore softer materials at low shore d absorb impact better thus reducing chances of cracking or breaking on impact.However, if it becomes too soft then there will be no security for the internal components.

- Temperature Sensitivity: Different materials have specific shore d which react uniquely to changes in temperature.When temperatures drop below freezing, some highly hard material become brittle whereas lower hard ones might become too flexible or melt even at elevated temperatures.

- Chemical Compatibility: Also referred as the chemical resistance of a polymer may also be connected to its hardness.Some chemicals may not affect harder materials but can corrode others.Thus, the hardness of a material should be matched with its chemical load in order to make it last.

- Compression Set: It tells how much a material becomes permanently deformed when subjected to a specific load over time. Harder ones might have higher compression set so that they are more reluctant to return back to their original thickness after being compressed.

Understanding these parameters enables product developers and engineers to select the optimal Shore D hardness for their applications, balancing factors such as flexural fatigue resistance, durability and environmental resistance.

Conducting Effective Hardness Tests: Techniques and Tips

How to do Shore D Hardness Test

Shore D hardness test is done to help understand the material properties needed for durability and performance of a product. This is how I go about it:

- Prepare the Sample: First, I ensure the sample material is flat and at least 6.4mm thick as specified by the standard method. If not, I prepare several pieces of similar materials that add up to the required thickness.

- Calibrate the Durometer: To ensure accuracy, I begin by calibrating my Shore D durometer in line with manufacturer’s instructions. Most times this involves using a calibration block provided by the durometer to run tests on such device.

- Take Measurements: With both material and durometer ready, I put down my sample on a rigid flat surface. Then, still holding its vertical position in my hand, I place it on top of that sample until it presses tightly onto it. The durometer should be held steady for exactly fifteen seconds before recording anything.

- Record the Reading: After waiting for some time here, we slowly read what value has been shown on shore D scale by our instrument. Its readings vary between 0 and 100 indicating materials are becoming harder as values increase.

- Repeat for Accuracy: As precautions against unreliable data obtained from one indentation or edge of an item being tested five tests are performed in different areas of sample every time avoiding any former indentations or edges which can make data interpretation quite difficult due to possible inhomogeneity.

- Analyze Data: Once all measurements have been taken into account, I find out average Shore D hardness of a specimen under consideration. And that’s why such an average offers more exact information about overall hardness of materials.

- Report Findings: Finally, I provide detailed reporting with inclusion of details like type of durometer used, date when calibration was made conditions (temperature and humidity) during testing process and averaged Shore D hardiness value. Such report can be used for further product development or quality control.

Thus, this systematic approach to performing Shore D hardness test ensures that a company has complete information required for making decisions on materials and design.

How to avoid common mistakes in hardness testing

Avoiding common errors during hardness testing is important for the accuracy and reliability of the results. First, it is essential to ensure that the durometer is properly calibrated. I always confirm the date of calibration before every series of tests and if there are any remaining ones, recalibrate as per manufacturer’s guidelines. This minimizes any problems caused by instrument errors. Second, environmental conditions can affect readings considerably. A stable testing environment with room temperature around 23°C and relative humidity about 50% is maintained. Any deviations from these levels lead to changes in material hardness temporarily. Thirdly, it is critical to choose the right spot for testing. Results should not be taken near edges or previous tests marks on material that may distort them but instead they have to come from homogenous parts that are found at material core regions only. Lastly, proper application of pressure with timing must be observed when using a durometer. Inconsistent pressure or timing leads to variations so that stopwatches are set ensuring each examination lasts exactly fifteen seconds without any doubt about this particular time period being elapsed accordingly by me while conducting my tests . These considerations have curtailed usual pitfalls thereby improving data credibility significantly.

Interpreting Your Hardness Testing Results

Shore D hardness test results interpretation is as important as the examination itself. Over a period of time, I came to learn that the number within a range of 30-100 on the Shore D scale gives more than just surface hardness of a material. The higher number means that the material is harder and therefore can be very useful when one needs to select materials for an application requiring great strength and resistance to mechanical deformations. On the other hand, a lower Shore D value implies softer materials which may prove beneficial in cases where flexibility and compression are necessary.

As such, it is essential for me to compare these hardness values with industry standards and material specifications. In addition, this comparison helps determine whether or not an intended purpose for which the required criteria have been set will be met by any given material. Moreover, varying patterns in these values among different samples or batches could either expose consistency in production processes or indicate possible defects related to material integrity.

Thus, reading Shore D hardness results should go beyond mere figures; it should capture their significance based on individual project requirements and general principles of materials science. This understanding aids in making well-reasoned choices regarding both material choice and design features so as to maximize longevity and effectiveness of final products.

Reference sources

- Source: ASTM International – Standard Test Method for Rubber Property—Durometer Hardness

Summary: The ASTM D2240 standard is a critical document that outlines the methods for determining the Shore Hardness of materials, including Shore A and Shore D hardness levels. This source is invaluable for researchers, engineers, and quality control professionals seeking to understand or measure the hardness of elastomeric materials accurately. It offers detailed procedural guidance, ensuring consistency and reliability in hardness testing across industries. The credibility stems from ASTM International’s worldwide recognition as a leader in developing and delivering voluntary consensus standards. - Source: Thomasnet – Understanding Shore D Hardness

Summary: Thomasnet provides an accessible, user-friendly guide to understanding Shore D Hardness. The article explains what Shore D Hardness measures, how it compares to other hardness scales, and its significance in material selection and product design. It’s particularly useful for those new to material science or needing a quick reference to explain Shore D hardness in practical terms. Thomasnet’s reputation as a comprehensive resource for finding suppliers and learning about manufacturing materials adds to the article’s reliability. - Source: Polymerscience.com – Shore Hardness Explained

Summary: Polymer Science’s explanation of Shore Hardness offers a deep dive into the nuances of Shore A and Shore D hardness scales. It includes practical illustrations of where these measurements apply in real-world applications, such as in various industries using polymers and elastomers. Additionally, the post discusses the limitations and considerations when interpreting Shore Hardness values. Given Polymer Science’s expertise in engineered materials, this source is particularly relevant for readers interested in the application of Shore D Hardness in product development and material specification.

Frequently Asked Questions (FAQs)

Q: How is the Shore D Hardness related to the durometer scale?

A: The Shore D Hardness measures the hardness of semi-rigid plastics and other materials using a device known as Shore durometer. Developed by Albert Ferdinand Shore, this scale ranges from 0 to 100 and is used to determine how hard or soft a material is. The Shore D scale specifically relates to harder plastics while softer materials like rubber are measured with different shore scales such as shore A.

Q: How can you measure the hardness of a rubber material using shore durometer?

A: Using a shore durometer which is customized for each type of rubber, it can be determined how hard a particular rubber material is. For measuring, the presser foot on the shore durometer should force against the standard sample of rubber. Thereafter, one consults the hardness from the durometer scale that usually has values lying between 0 and 100 inshore which denotes indentation resistance.

Q: Can Shore D Scale be applied to flexible mold rubbers?

A: Usually, Shore D Scale was for tougher stuffs; hence it may not be proper for flexible mold rubbers that are usually softer than these ones. In such cases however, it would be better if we adopted Shorc A Scale since it was designed to examine various degrees of hardness across categories ranging from extreme flexibility (like chewing gum) through mild elasticity (like silicone rubber and rubber molds.

Q: Who was Albert Ferdinand Shore and what is his role towards measurement of material hardness?

A: Invented in early twentieth century by Albert Ferdinand who came up with an invaluable instrument called Durometer essential in measuring hardness of different materials. His work forms basis for legislation on how hard something should be recognized worldwide through adaptation into various types such as Shorc A and Shorc D commonly used today in different sectors to ensure uniformity of matter production and quality assurance.

Q: Are there standards for using the durometer scale to measure the hardness of semi-rigid plastics?

A: There are specific standards and protocols available for measuring the hardness of semi-rigid plastics and other materials by using the durometer scale. These standards help in achieving uniformity and accuracy across diverse applications and industries. They list how to carry out a shore durometer test, what must be complied with during testing, and how the readings must be interpreted. International bodies such as ASTM International often publish such guidelines.

Q: How can one use the durometer chart to interpret hardness scores?

A: To effectively utilize this durometer chart in order to decode its hardness scores, first trace from this material’s measured score on either Shore A or D depending on its rigidity. This is usually a numerical score that converts into a descriptive hardness level going from very soft to very hard on this graph. It is useful in making comparisons between different materials’ hardness or determining which materials meet specific criteria of hardness needed for particular applications.