The importance of efficient and customizable manufacturing solutions continues to grow in today’s fast-paced manufacturing world. These services revolutionize the way lead times and costs are reduced while quality is maintained. This blog will familiarize you with rapid injection molding as an influential process that can improve your production capacities in terms of its benefits, applications, etc. The information in this comprehensive guide will be useful to both those who are already experienced in the field and those who are beginners.

What Is Rapid Injection Molding and How Does It Differ from Traditional Injection Mold Processes?

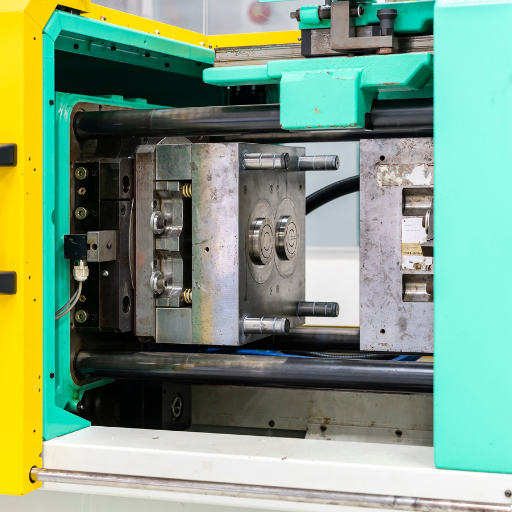

Image source: https://www.3erp.com/

Rapid injection molding is a faster, less expensive method of making plastic parts than traditional injection molding techniques. Rapid injection molding involves new fabrication techniques including 3D printing for molds that shorten lead times to a few days instead of weeks or months compared to conventional methods involving tooling and setup time. The materials used here are often of high quality and durability that suit both prototyping and low-to-mid volume production purposes. Quick turnaround designs, lower upfront costs and faster ability to manufacture resulting in fast trial runs make rapid injection molding ideal for industries where flexibility and speed matter most.

Understanding Rapid Tooling and Its Importance

Rapid tooling, which is also known as prototype tooling or soft tooling, is used in the rapid injection molding process. In this method, molds are made faster and at a lower cost than traditional methods. Usually, 3D printing, CNC machining or urethane casting are the advanced manufacturing techniques that can be employed in the making of these molds for limited production runs.

The most important benefit of rapid tooling is that it reduces mold construction time and cost significantly. By reducing long lead times for production and costs associated with tooling manufacturers can quickly try out different designs, test new ideas and bring new products into the market. Additionally, through rapid tooling one can vary the material selection in prototyping such that even production grade materials can be utilized. This assists in more accurate testing and validation before embarking onto mass production hence minimizing risks as well as maintaining high quality results.

Comparing Rapid Injection Molding with Standard Production Methods

Speed, cost and flexibility are some of the major differences between rapid injection molding and standard production molding. Small to medium volumes can be rapidly produced through rapid injection molding at low costs. Use of advanced methods such as 3D printing in mold making contributes to reduced time lag and tooling costs in contrast with conventional methods.

On the contrary, for large-volume manufacturing, standard production molding is considered due to its capability of consistently producing high-quality parts over millions of cycles. However, initial tooling investment and production set-up are significantly higher while lead times are lengthier. This method is best suited in economies of scale where cost per part drops when production volume increases.

Broadly speaking, rapid injection molding suits industries that value quickness along with flexibility to facilitate prompt iteration and market response. Standard production molding serves well long-term high volume manufacturing where huge investments during start-up processes can be justified by extensive runs of productions resulting into cost effectiveness over time.

Advantages of Using Rapid Prototyping for Quick Turnarounds

For rapid project turnaround, rapid prototyping presents several important benefits. First and foremost, it drastically shortens the time of development by allowing for the production and testing of many different versions of designs in a very short period. Rapid identification and troubleshooting is essential at this stage. In addition, compared to theoretical models or drawings that only illustrate design concepts, rapid prototyping aids in enhancing communication as well as collaboration among stakeholders through providing real working models. Finally, this technique minimizes tooling requirements and long production runs leading to lowered costs as well as less risk of expensive design mistakes being made. By speeding up product development cycles and cutting down on time-to-market, quick iterative refinements of prototypes enable companies to retain competitiveness.

How to Choose the Right Mold Materials for Your Prototype Injection Molding?

When selecting the right materials for your prototype injection molding, there are several important factors to consider. The first is that you must look at thermal properties of the material like thermal conductivity and heat resistance; this will affect how well the mold can maintain dimensional stability and surface finish during injection process. For prototypes, aluminum molds are usually preferred due to their high heat conductivity and ease of machinability which allows rapid prototyping with shorter cycle times. Secondly, one should think about the durability of a mold as well as number of cycles it can withstand. Steel molds made from either P20 or H13 steel are more tough and are thus fit for higher volume prototyping runs. Finally, examine whether the material is cost-effective vis-à-vis your project’s budget and timeframe. Although steel moulds may be quite expensive and take longer time to make, they have better accuracy hence more long lasting therefore suitable for projects that require many iterations Aluminum moulds for example are cheaper to make and quicker in production thus good for initial prototyping as well as low volume production runs.

Factors to Consider in Material Selection

When selecting materials for prototype injection molding, there are three factors that need to be considered:

- Thermal Properties: Material’s thermal conductivity and heat resistance play a significant role. Materials with good thermal conductivity such as aluminum enable uniform temperature distribution, thereby reducing cycle times and improving final product quality. They also help maintain dimensional stability and achieve higher surface finish.

- Durability and Cycle Life: The ability of the material to withstand repeated use is more important especially for high volume production. Steel molds made from durable grades like P20 or H13 can go through many cycles without substantial wear hence suitable for projects needing multiple iterations.

- Cost-Effectiveness: Material selection is heavily influenced by budgetary constraints and time limitations. Compared to steel molds, aluminium molds are cheaper and faster to produce thus ideal for initial prototyping as well as low volume runs. Conversely, steel molds take long to manufacture and cost more but they offer improved precision and durability which can be more cost-effective in the longer term when targeting higher volumes.

The above mentioned considerations should help you choose the best mold material based on your specific project requirements.

Impact of Wall Thickness on Mold Durability and Product Quality

Both the durability and quality of the products made by a mold depend on its wall thickness. In general, thicker walls reinforce the structure and life span of a mould, making it cope with bigger loads and multiple uses. This guarantee of durability results in long cycle lives and cost effectiveness for high volume production.

On the flip side, different wall thicknesses can affect the final product quality. A consistent wall thickness ensures that there is even cooling during cooling, thereby minimizing chances of defects like warping, sink marks or internal stresses. Improved dimensional accuracy and surface finish are among the benefits provided by uniform cooling. Conversely, thinner walls may lead to faster cooling times but can compromise the product’s strength and durability hence calling for a careful balance depending on desired application and production volume. Effective mould design often looks at strategic positioning of wall thickness as part of improving both durability and finished product quality.

What Are the Typical Applications of Rapid Injection Molding in Production Injection Molding?

Rapid injection molding is used in many places of production injection molding because of its unique advantages. It is widely used in prototyping, where parts are made quickly to test fitting, forming and function before embarking on full scale manufacturing. This speeds up product development cycles hence making it easy for fast iteration and adjustment. Rapid injection molding also has great value for small to medium sized production runs where the cost and time involved in conventional mold making cannot be justified. Also it’s employed in bridge production that fills the gap between initial prototyping and full-scale manufacturing this ensures a seamless transition within the manufacturing process. This approach is vital for reducing lead-times and costs whilst maintaining flexibility and quality at early stages of product development.

Real-World Examples of Plastic Parts Manufactured by Injection Mold Processes

Injection molding is employed to fabricate a wide variety of plastic parts in various fields because of its adaptability and efficiency. Below are some examples from the real world:

- Automotive Components: Molding injection on the other hand helps in producing different types of vehicle parts like dashboards, bumpers, grills as well as interior trims. In this regard, these components benefit greatly from such attributes since it leads to the production of durable parts that maintain their quality consistently.

- Consumer Electronics: Injection molding is commonly used to produce many consumer electronics components including smartphone casings, laptop cases and remote controls. This enables the complex geometries and intricate features that are required for most modern electronic devices.

- Medical Devices: Syringes, inhalers and vial caps are among other items made using injection molding which is highly prevalent in medical field. The process ensures impeccable precision and cleanliness; two prerequisites for any medical application.

These examples illustrate how versatile injection molding can be when it comes to manufacturing high-quality, long-lasting plastics at low costs across sectors.

The Role of Bridge Tooling in Volume Production

In the transition from prototype to full-scale production, bridge tooling acts as an important go-between. It allows makers to provide lesser amounts of parts fast while they finalize design and production details for final, full-scale tooling. This is very appropriate in speeding up time-to-market since it enables one make money from a product at the development stage. In addition, with bridge tooling one can change designs inexpensively without having to alter whole scale production molds that are very costly. Thus, this has particular application in those industries where speed and adaptability are essential because it allows products to be refined and brought into market more efficiently and at lower costs.

How Can Rapid Injection Molding Services Accelerate Your Molding Project?

Lead times can be shortened considerably, iteration cycles sped up drastically by Rapid Injection Molding Services. These services employ advanced materials and techniques that allow them produce molds rapidly enabling you move from concept to prototype in less time than traditional methods would require. For instance faster iterations mean quick testing and verification of designs which lead to rapid adjustments or refinements. Moreover small production runs are supported by rapid injection molding meaning that there is room for assessing market response without huge initial investment capital requirements. All in all, this strategy improves your ability to take your product on a market quicker but also enhances efficiency while reducing costs.

Key Benefits of Partnering with Injection Molding Services

- One way in which the injection molding services are economical is that they make intricate and high volume products while minimizing waste. This process is automated, hence reducing labor costs and ensuring uniformity of outcomes thereby reducing overall production expenses.

- Partnering with specialized injection molding services allows for rapid production and scalability and it helps to bring a product quickly to market through advanced technologies and streamlined processes, which enable quick turnaround times from design to finished product. It also allows the business to scale production up or down based on demand.

- These services avail a wide range of materials for use as well as various plastics, rubber-like materials etc…, so as to ensure ideal material choice for different applications. High precision levels combined with stringent quality control measures ensure that the final products not only meet the set standards but also perform satisfactorily in their intended uses.

Ways to Reduce Lead Time and Turnaround Time

Reductions in lead time and turnaround time within the manufacturing industry can be achieved by strategic planning, efficient utilization of technology and optimization of processes. Here are some crucial strategies:

- Adopt Lean Manufacturing Principles: By getting rid of waste, smoothing work and improving methods a lot of time can be taken out of production processes. Lean methods focus on reducing non-value added activities such as excess inventory or unnecessary transportation.

- Implement Advanced Technology and Automation: The use of modern manufacturing technology includes automated machinery and robotics that increases efficiency as well as speed. This reduces manual intervention, minimizes errors, offers shorter production cycles.

- Improve Supply Chain Management: A strong supplier relationship and an effective supply chain guarantee timely receipt of raw materials thereby leading to reduced delays. On the other hand implementing just-in-time (JIT) inventory management keeps stock levels low enough so that components are there when they need it but not overstocked.

- Optimize Design and Prototyping Phases: Quick validation of designs is made possible through rapid prototyping coupled with iterative design processes which in turn contribute to faster development process iterations. Digital tools like 3D modeling and simulation enable faster design changes during the development phase.

- Enhance Communication and Collaboration: Effective communication among all stakeholders including designers, engineers, suppliers, manufacturers etc., ensures that everyone involved understands production timelines as well as requirements. Collaborative platforms also facilitate updates in real-time for quick decision-making purposes.

Businesses therefore need to adopt these strategies in order to improve their production efficiency, reduce lead times, accelerate time-to-market thus enhancing their competitiveness in the market at large.

The Future of Injection Molding Production with Rapid Technologies

The future of molds production is being transformed by emerging technologies like 3D printing, industry 4.0 advancements and material innovation. In recent times, 3D printing also known as additive manufacturing has been fused with conventional injection molding processes to enable fast tooling and prototyping thereby greatly reducing development time and costs involved in the process. The use of Internet of Things (IoT), artificial intelligence (AI) and machine learning among others as part of Industry 4.0 technologies is enhancing efficiency in the production process through smart factory concepts. To ensure high quality products and optimal machine performance, these smart factories employ real-time data for machine optimization purposes. Moreover, addressing environmental concerns involving biodegradable or sustainable polymers enables manufacturers to take on eco-friendly standards such as those that apply to matter innovations industry-wide. By capitalizing on these rapid technologies, injection molding sector will attain an unprecedented level of efficiency, adaptability and sustainability.

What Are the Cost Considerations in Rapid Molding?

In rapid molding the factors that are considered when estimating the cost of this process can be broken down into several aspects. At first, investment in such cutting-edge technologies as 3D printers and AI-driven software can seem expensive; however, these machines have a positive impact on long-term production costs by minimizing waste and accelerating operations. Secondly, as some polymers and other initial materials are expensive, materials costs should also be taken into account. Also, there is need to consider the labor cost which is very important because running and maintaining modern machines requires highly trained personnel. Finally, energy use by rapid molding technologies contributes to overall expenses although most of these systems are built to save energy. By carefully evaluating these issues companies will reduce spending while maximizing profits from rapid molding.

Breakdown of Costs Between Traditional Injection Molding and Rapid Methods

It is important to consider different factors that contribute to the cost of traditional injection molding and rapid molding when you compare them:

- Initial Tooling Costs:

- Traditional Injection Molding: This method requires production of steel or aluminum molds which are usually expensive. Steel molds are costly but will last longer, on the other hand aluminum molds wear out quickly.

- Rapid Molding: Modern technologies such as 3D printing are used in this method hence lowering the initial tooling costs. These can be produced within a short time frame and for a fraction of what it would take in traditional methods.

- Production Volume:

- Traditional Injection Molding: Most suitable for large scale production as cost per unit decreases significantly with high volumes making it possible for mass production.

- Rapid Molding: This is most economical for low to medium production volumes. The decreasing rate in the cost per unit is not so sharp when in higher volumes implying that it’s excellent for prototyping and small-scale productions.

- Material Costs:

- Traditional Injection Molding: It often employs cheap common plastics on higher volume manufacturing thus limiting freedom of choice of materials.

- Rapid Molding: Nevertheless, this process allows wide range of materials to choose from including sustainable and specialty polymers although these may be relatively expensive than standard ones.

- Labor and Maintenance:

- Traditional Injection Molding: Mold creation, machine operation, and maintenance activities require skilled workforce. At times labor costs increase because there is an involvement of complexity and precision.

- Rapid Molding: Usually less specialized skills are needed due to automation and AI driven systems during its operation leading to reduced labour overtime associated maintenance costs over time.

- Energy Consumption:

- Traditional Injection Molding: In cases where there is high volume part production, energy consumption could be huge thereby affecting overall operational costs.

- Rapid Molding: They tend to use more optimized machines which lead to low energy bills thus being considered energy conservative as compared to traditional ones.

By evaluating these elements businesses can decide on the most cost effective method for their production based on their specific production requirements and financial situations.

Long-Term Savings through Cost-Effective Rapid Injection Molding

Certainly, businesses can save a lot of money in the future if they utilize rapid injection molding techniques. The first advantage is that its low initial tooling costs make it more viable for small and medium production runs rather than traditional ones which require high upfront investments. Secondly, faster turnaround times mean quicker time to market so as to enable companies to respond promptly to market demands and thus minimize inventory outlays. Furthermore, though it may appear costly initially, the flexibility in material choice can bring about savings by allowing application of superior quality materials that decrease product failures and return rates. Lastly, modern rapid molding machines are energy efficient hence help reduce operational costs. In conclusion, these things collectively result into significant savings over a period of time making it a wise financial decision for various manufacturing situations such as rapid injection molding.

Economic Benefits of Low-Volume Production Runs

In today’s business environment, low-volume production runs have numerous economic benefits that cater to the changing needs of businesses. This is because they significantly reduce the risk of financial loss that comes with holding large inventories and unsold stocks. In place of fixing themselves to huge amounts, businesses can manufacture and test smaller lots thus giving them room for more flexibility and adaptability in dealing with market changes. Secondly, low-volume runs enable faster time to market, which is essential for the quick launch of new products or responding to shifting consumer preferences. When done properly it can give a competitive advantage and increased customer satisfaction. Additionally, low-volume production often entails less cost on tooling and setup as compared to high-volume ones hence lowers initial investment costs. This way this strategy is especially useful for startups or small companies that must be very cautious about cash flows; thus it assists them in managing their operations effectively through cost reduction methods. Moreover, this allows for more frequent inclusion of user’s comments thereby improving product iterations and reducing wastage. In conclusion low volume production runs lead to reduced financial risks as well as drive innovation and market responsiveness.

Frequently Asked Questions (FAQs)

Q: What is Rapid Injection Molding and how does it differ from standard injection molding?

A: Rapid Injection Molding is a manufacturing process that uses rapid tooling techniques to produce injection molded parts quickly and cost-effectively. While standard injection molding involves creating long-term production tooling, rapid injection molding focuses on speed and cost efficiency for lower volumes, often using aluminum tooling rather than steel.

Q: How does part design affect the Rapid Injection Molding process?

A: Part design is crucial in the Rapid Injection Molding process. Efficient design for manufacturability (DFM) can ensure that molds are made correctly and can withstand the rapid tooling injection molding process. Designs that consider cavity layout, resin flow, and tolerance are more likely to produce high-quality injection molded parts.

Q: What materials can be used in Rapid Injection Molding?

A: A wide range of injection molding materials can be used in Rapid Injection Molding, including various types of resin, thermoplastics, and elastomers. The choice of material will affect the production mold, tool life, and the overall efficiency of the manufacturing process.

Q: How quickly can Rapid Injection Molding services deliver parts?

A: Rapid Injection Molding services can deliver parts in as little as a few days to a couple of weeks, depending on the complexity of the part design and the tooling services required. This rapid turnaround is one of the key advantages over traditional production tooling methods.

Q: What is the role of mold tooling in the Rapid Injection Molding process?

A: Mold tooling in the Rapid Injection Molding process involves creating the molds that will shape the final injection molded parts. Proper mold tooling ensures that the parts meet design specifications and are manufacturable within specified tolerances. This includes considering factors like cavity layout, use of EDM techniques, and selecting suitable tooling materials.

Q: Can Rapid Injection Molding accommodate custom injection molding projects?

A: Yes, Rapid Injection Molding is highly flexible and can accommodate custom injection molding projects. This capability allows for creating unique injection molded parts tailored to specific needs, facilitating on-demand manufacturing and rapid prototyping.

Q: How does Rapid Injection Molding ensure precision and quality in parts?

A: Rapid Injection Molding uses advanced techniques such as EDM for detailed mold tooling, high-precision injection molding machines, and strict quality control measures. These efforts ensure that the final parts meet required tolerances and maintain high quality.

Q: What is DFM, and why is it important in Rapid Injection Molding?

A: DFM stands for Design for Manufacturability, which involves designing parts in a way that makes them easier and more cost-effective to manufacture. In Rapid Injection Molding, DFM is essential to ensure that the injection molded parts can be produced quickly and efficiently without compromising quality.

Q: How is rapid tooling different from traditional production tooling?

A: Rapid tooling often uses materials like aluminum, which allow for faster and more cost-effective mold creation compared to traditional steel molds used in production tooling. This approach reduces lead time and cost, making it ideal for short-run and prototype molding while still delivering high-quality components.

Q: What is the lifespan of a mold used in Rapid Injection Molding?

A: The tool life of molds used in Rapid Injection Molding varies depending on the tooling materials and the complexity of the part design. Generally, molds made from aluminum can produce several thousand parts, which is sufficient for low-to-medium volume production and prototyping. For higher volumes, more durable materials may be used to extend the mold’s lifespan.