When it comes to plastics, there are many types, and knowing the difference is crucial when selecting the right one for specific applications. In this article, we explore three of the most commonly used plastic types found in the industry: polyolefin, polyethylene, and polypropylene. Each of these polymers have unique properties and applications, as will be revealed in this guide. Our aim is to explore the characteristics that make these plastics unique: their chemical structures, how they are produced and their common uses. Hopefully, this guide will help you better understand the plastics you work with, are developing, manufacturing or simply curious about.

What Is Polyolefin and How Does It Compare to Polyethylene and Polypropylene?

polyolefin vs polypropylene

As an expert in this industry, I would say that polyolefin is a class of polymers that are made from simple olefins, which are hydrocarbons containing at least one carbon-carbon double bond. Polyolefins include polyethylene (PE) and polypropylene (PP) and also some other types of polymers. The reasons for the popularity of polyolefins are its high range of applications and the fact that they are very chemically resistant, durable and inexpensive.

For instance, the most common polyolefin is polyethylene with its chemical formula CH₂ – CH₂ – O – CH₂. This plastic is almost ubiquitous: low-density polyethylene (LDPE) and high-density polyethylene (HDPE) are present in almost everything from plastic bags to water pipes. Compared with polyethylene, polypropylene (above) is harder and has a higher melting point and tensile strength. It is, therefore, added to polyethylene to make the plastic more rigid and thermally resistant, and used to make products such as automotive parts and medical devices.

When comparing the two, the differences become clearer, showing how they are suited to different applications. So, if flexibility and toughness is what is required, polyethylene is the better choice, whereas if strength and heat resistance are more crucial, then polypropylene will be the better choice. How many tons of unnecessary plastic are destroyed each year by simply not taking the time to consider whether the material is suitable for the job?

Polyolefin family and its polymers

Being a member of the polyolefin family, being a polymer, being specialised, I’d like to delve deeper into the polyolefin discussing the members of the polyolefin family which are polyethylene and polypropylene and stating what is the difference between polyethylene and polypropylene literally. Let’s divide the main parameters when comparing polyethylene and polypropylene:

1.Chemical Resistance:

Polyethylene (PE): Very good chemical resistance for use with containers and tubing that may hold all kinds of chemicals.

Polypropylene (PP): Equally good at resisting chemicals, but more suitable for more demanding applications, such as in automotive or industrial environments.

2.Durability:

Polyethylene (PE): It’s tough and flexible and does an excellent job in applications where the material has stretch, or bending or impact.

Polypropylene (PP): It has the same amount of durability, but since it’s a bit more rigid (its tensile strength is a little higher), it is used for products that need to be a bit more rigid.

3.Thermal Resistance:

Polyethylene (PE): Temperature range suitable for most general-purpose applications (eg, packaging, consumer goods).

Polypropylene (PP): PP has a higher melting point than PE, making it more useful in high-temperature applications where it can retain its properties while PE would start to melt.

4.Cost-Effectiveness:

In this regard, polyethylene has similar properties to polypropylene, though specific choices also depend on application-specific requirements. For example, although PE is cheaper in everyday use, PP can incur slightly higher costs, especially due to its strength and thermal superiorities.

5.Applications:

Polyethylene (PE): Soft, pliable, and transparent, perfect for plastic bags, flexible packaging, squeeze bottles, and toys.

Polypropylene (PP): Used for reusable containers, cars, and medical devices where strength and resistance to heat are vital.

Overall, for users who wish use to polyethylene and polypropylene, much depends on the specific needs of your projects. If you want to achieve flexibility and toughness in your project, polyethylene is pretty much a go-to product for you. On the other hand, if you need a product that can withstand higher temperatures and stress, polypropylene has got your back. Finally, it is clear that insisting on these parameters will enable you make the right choice for your journey of material application. As a result of this, your product will be of durable nature and in perfect function. Thanks.

Distinctive characteristics between PE, PP, and other polyolefins

As an expert in this area, I wish to share the main differences between polyethylene (PE), polypropylene (PP) and other polyolefins in a comprehensible manner. Let us start with each and the associated parameters:

1.Polyethylene (PE):

Flexibility and Toughness:PE exhibits high flexibility and toughness. The application of this polymer covers a wider field, including all kinds of soft packaging, plastic bags, squeeze bottles, toys, and many other products. Good flexibility, can be bent, stretched without breakage.

Thermal Resistance: PE runs well in a regular temperature range for general purpose tasks, but it won’t be the best option for high heat environments.

Cost-effectiveness: PE is cheaper than PP and is the go-to material of choice for many day-to-day applications.

2.Polypropylene (PP):

Strength and rigidity: PP is much stronger and stiffer than PE. This is important for certain products where the shape must be maintained under stress, such as reusable containers and car body parts.

Thermal Resistance: PP melts at a higher temperature than PE, which allows it to retain its properties at higher temperatures. This gives it an advantage in applications exposed to heat, such as the internal parts of medical devices or certain kinds of food service containers.

Cost-Effectiveness: While PP is more expensive than PE, the difference in cost is frequently worth it given the enhanced strength and thermal properties of PP.

3.Other Polyolefins:

Ethylene-Vinyl Acetate (EVA): This material blends flexibility with abrasion-resistance and it’s well suited for applications such as foam products, flexible hoses and insulating films. EVA copolymers can tolerate moderate stress and temperature but they don’t have the strength of PP or the resilience to heat.

Polybutylene (PB): For a long time in plastic water pipes, PB is the go-to plastic for long-term water contact. It had good flexibility and better heat resistance than PE, but isn’t as good for long-term high-stress use as PP.

Polybutene-1 (PB-1): Similar to PB but less widely used; also used in niche applications as piping and film for its excellent creep resistance and flexibility; niche, high-value speciality polymer; no inferior composition of PE and PP.

In conclusion, the choice between PE, PP and other polyolefins will depend on the type of project:

Opt for PE if flexibility and cost savings are your primary concerns.

Choose PP for its heat resistance and structural integrity.

For these more specific niche applications, where the properties of a particular polyolefin such as EVA, PB or PB-1 are needed, those instances ought to be selected.

In conclusion, with a clear knowledge of these parameters, you are able to determine the best material for your particular application, ensuring optimal performance and longevity.

Chemical structure and molecular weight differences

As a technical personnel, I want to explain the chemical structures and molecular weights of polyolefins differ greatly and accordingly, they have different application feasibility and performance.

1.Polyethylene (PE):

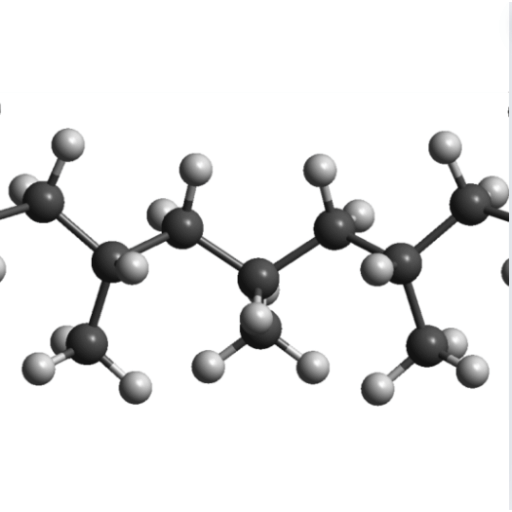

Chemical Structure: PE comes from a repeating series of ethylene (C2H4) monomers, strung into a long chain, using a simple backbone structure of carbon and hydrogen atoms.

Molecular Weight: PE has a wide range of molecular weights, from a few thousand to several million g/mol. Higher molecular weights can lead to higher strength and impact resistance.

2.Polypropylene (PP):

Chemical Structure: PP is produced by the polymerisation of propylene (C3H6) monomers. The methyl group (CH3) is attached to every other carbon in the backbone, making the structure more complicated compared to that of PE.

Molecular Weight: The molecular weight of PP is usually between 40,000 g/mol and 300,000 g/mol. Compared with ordinary PE grades, it has higher mechanical strength and thermal stability.

3.Ethylene-Vinyl Acetate (EVA):

Chemical Structure: EVA is a copolymer of ethylene and vinyl acetate (C2H3O2) units. The copolymerisation of the vinyl acetate groups disrupts the ordered regularity of the chain giving EVA a unique combination of flexibility and toughness.

Molecular Weight:The molecular weight is between 20,000-300,000 g/mol. Its properties depend on the percentage of vinyl acetate content.

4.Polybutylene (PB):

Chemical Structure: PB is a polymer of butene-1 monomers. Since its chemical structure gives this type of polymer higher crystallinity, it has excellent flexibility and resistance to creep.

Molecular Weight: Often ranging from 50,000 to 300,000 g/mol, the molecular weight allows customers to select the material to fit their needs, such as plumbing.

5.Polybutene-1 (PB-1):

Chemical Structure PB-1 has the same chemical structure as PB but with slight modifications in the monomers so as to improve its processability and mechanical properties for film applications.

Molecular Weight: Like PB, PB-1’s molecular weight varies from 50,000 to 300,000 g/mol, which makes it useful in specialised applications requiring high flexibility and low residual stress.

And with a grasp of these two fundamental variables, chemical structure and molecular weight, you can chart your way across the polyolefin material landscape for your projects. As a result of their different combinations of properties, certain polyolefins will be better matched to particular performance needs, thus enabling the appropriate selection and application of polyolefins to your activities.

Understanding the Physical Properties of Polyolefins, Polyethylene, and Polypropylene

I will introduce a product known as “polyolefins” among experts and their categories: polyethylene and polypropylene. Furthermore, I will elaborate on the physical properties of these materials and highlight how they differ in various practical applications.

Polyolefins are polymers derived from olefins, and are among the most versatile and durable plastics. Polyethylene (PE) and polypropylene (PP) are probably the best-known examples in this group. Polyolefins are generally characterised by good chemical resistance, low density and good electrical insulating properties. They are essential for many applications ranging from packaging materials to automotive parts.

Polyethylene also comes in several varieties: low-density (LDPE), linear low-density (LLDPE) and high-density (HDPE). PE is valued for its flexibility (LDPE), its rigidity (HDPE) and its ease of processing (LLDPE). LDPE is amorphous with low crystallinity that provides elasticity and bounce, which makes it ideal for film and packaging needs. In contrast, HDPE is characterized by high crystallinity, which translates to high tensile strength, making it good for applications where strength and robustness are essential, such as piping and containers.

The polymer called polypropylene (PP) is singular among polyolefins because it combines high tensile strength, excellent resistance to chemicals, and a fairly high melting point. These properties make PP a good choice for medical equipment that needs to be sterilised, or automotive parts that need to be durable. Isotactic PP and syndiotactic PP provide a different balance of these properties and are used in industries where those different properties are advantageous.

Indeed, these physical properties allow us to choose the right polymer for a job depending on performance requirements and cost: the flexibility for regular use of PE; the robust strength of HDPE for roadside bollards; the toughness of PP that can withstand a shelf-life of 30 years; the ratty nonchalance of LDPE for life-saving tubing in a hospital. The intricate subtleties of the polyolefin make it practically indispensable in the modern industrial setting.

Impact resistance and tensile strength

When choosing polymers for different applications, we need to know whether they have good impact resistance, tensile strength, both or neither. I am frequently asked about the impact and tensile properties of materials by people in the industry.

Impact resistance is a material-science term for a polymer’s ability to withstand sudden, violent impacts without shattering or fracturing; it’s a critical property for all products that are subject to frequent or severe physical trauma, such as automotive bumpers, or protective gear such as helmets. Here’s how a polymer’s impact resistance is defined:

- Molecular Structure: Polymers with more flexible molecular structure such as Polymethylene (PE), especially low-density version (LDPE), were found to absorb and dissipate energy more.

- Crystallinity: Lower crystallinity in materials like LDPE provides superior toughness and resilience.

- Additives: Certain additives can enhance a polymer’s impact resistance by improving its energy-absorbing characteristics.

Tensile strength, on the contrary, is a measure of the maximum tensile (pulling or stretching) stress a polymer material can withstand before it breaks. This property is essential for materials subjected to long periods of force or constant load, such as cables, ropes and structural components. Factors that significantly affect tensile strength include:

- Length of polymer chains: Longer chains mean higher tensile strength as there are more inter-molecular forces.

- Crystallinity: High-density forms (HDPE) of polyethylene have a high crystallinity, resulting in a higher tensile strength.

- Temperature and Processing Conditions: The tensile strength could be greatly influenced by the manufacturing process, and the operating temperature of the final product could also influence it.

It is the balancing act between these properties that is key. While HDPE is particularly strong when stretched (tensile strength), its crystallinity works against its impact resistance. PP, by contrast, manages to combine both good tensile strength and good impact resistance: it can be used to make a strong, long-lasting bag, as well as a water bottle with good rigidity but a softer feel.

By knowing and using these parameters, we can then select the best polymer for a given industrial task, putting performance on a cost-effective footing.

Temperature tolerance: Comparing melting points

Temperature tolerance is one of the aspects of the coating’s performance. The melting point of the polymer is a good place to start. It is the most common question that I get from the industry: ‘What is the best polymer for high-temperature application?’ This is my short, one-liner answer.

- Polyethylene (PE): This polymer has a low melting point range, between 115°C and 135°C for high-density polyethylene (HDPE), and works quite well when’s it isn’t too hot or cold.

- Polypropylene (PP): The next step from PE in terms of melting point would be polypropylene, with an intermediate melting point between 160°C and 170°C. It can be used for those mild-heat applications.

- Polytetrafluoroethylene (PTFE): Our third and final resin grades also has a very high melting point which is around 327°C or 620°F. PTFE makes one of the best extreme temperature settings because its properties remain unchanged, not just after the extrusion, but even after prolonged use.

- Polyethylene Terephthalate (PET): PET is a common packaging material but it is also of use in applications where good temperature tolerance is required as the melting point is around 250°C. It’s useful for items that are needed to withstand mechanical strength and to be subject to heating.

- Polyamide (Nylon): Its melting point depends on the type and is in the range of 190°C to 350°C. Nylon is suitable for applications subject to high thermal loads when exposed to large temperature swings.

With these parameters in mind, one can make an informed choice of which polymer to use in any given industrial application. Keep in mind that increasing the temperature resistance of a polymer comes at a cost. Often one needs to sacrifice other properties – tensile strength, impact resistance, or something else – in order to help the material survive the heat, but still perform well in its function.

Chemical resistance and durability of PE vs. PP

however , in terms of chemical resistance and durability, polyethylen (PE) and polypropylen (PP) varies in both positive and negative aspects.In my personal view, it is necessary to consider the application requirements to conclude which one is better in regard to PE or PP.

First, chemical resistance. PE is resistant to many solvents, acids and bases – particularly HDPE, which is particularly resistant. For example:

- Resistance to Acids and Bases: HDPE is highly resistant to acids and alkalis, which is why it is used to make containers for chemical transport as well as pipes that carry chemicals.

- Solvent Resistance: It also performs well against solvents, further broadening its application scope.

Polypropylene also offers good chemical resistance but with some nuanced differences:

- Chemical Stability: It’s more chemically resistant than HDPE, but less chemically resistant than PE to concentrated acids and bases.

- Solvent Interaction: It has better resistance to organic solvents compared to PE.

Moving on to durability, let’s break it down:

- Tensile Strength: PE and PP both have comparable tensile strength, making them both acceptable for applications requiring mechanical endurance.

- Impact resistance: PE, and therefore HDPE, is better able to resist breaking under stress.

- Thermal Durability: As stated before, because PP melts higher than PE, it can survive mild heat much better.

When choosing between PE and PP, also consider the following relevant parameters:

- Environmental Stress-Cracking: PE has lower susceptibility to environmental stress-cracking compared to PP.

- Flexible and strong: PE is generally flexible and tough which makes it a good choice for use in flexible applications.

- Cost-Effectiveness: PP is more expensive than PE and unaffordable for many purposes.

Taking all these precise parameters into consideration will help you make a decision on whether PE or PP is the right polymer for your application. In other words, weighing these factors will help you to select the polymer that will be most chemically resistant as well as the most durable for your application.

Exploring the Applications of Polyolefin, Polyethylene, and Polypropylene

I have been very often asked about applications of polyolefine families like polyethylene (PE) and polypropylene (PP). These materials are really multifunctional and used in a lot of different industries, for their specific characteristics. I will like to share with you some of their most common applications with my experience.

Next up, Polyethylene (PE) is ubiquitous in packaging thanks to its moisture resistance and flexibility. LDPE, for example, is most commonly used in plastic bags and film wraps due to its flexibility and toughness. HDPE is used in rigid applications such as plastic bottles, corrosion-resistant piping and geomembranes because the material needs to be resilient and durable.

In addition to its resistance to moisture, PP is the best known example of the broad range of semi-crystalline polymers. It has a higher melting point than PE (temperature of 165°C-170°C), making it usable for applications requiring some resistance to heat. For instance, it is used for automotive parts such as bumpers and interior car compartment parts, in substitution of heavier metallic materials, but ensuring similar strength and resilience. It is also a traditional polymer used in medical applications and, in particular, in the synthesis of syringes and other lab equipment thanks to its chemical resistance and the fact that sterilisation processes do not affect its stiffness.

The applications of Polyolefin in general, not just PE and PP, are more diverse. Their fibres are widely used in textiles for carpets, curtains, athleisure, etc. Many products in agricultural use, for example greenhouse films and irrigation piping, contribute to improved water use efficiency and protection of crops.

In conclusion, be it packaging, automotive, medical, agricultural or other application, PE and PP demonstrate a wide range of solutions with well-defined properties for matched performance and further development. Once the different material characteristics are understood, polyolefins can be employed to bring out innovation and efficiency to your chosen area of interest.

Widely used applications in packaging and food industry

As a professional in this field I can affirm that polyolefins such as polyethylene (PE) and polypropylene (PP) are extensively used in packaging and food industry for various reasons. I want to provide some reasons why the properties that can justify its wide use in packaging and food industry:

- Barrier Properties: PE and PP are also the best materials for packaging food products, because they have good barrier against moisture, oxygen and other contaminants. This helps to preserve the freshness and extend the shelf life of food products. Commercial film structure – right side : PE film, left side: PPThe diagram shows that PE film is widely used as a liner for cereal box to protect the crispness. Besides, PP bears better resistant to moisture, so it is more common in the packaging of snacks to protect its dryness and freshness.

- Low Weight: Both PE and PP are extremely lightweight compared with other packaging materials. This translates to low cost for shipping, and low environmental impact. Their good packaging performance helps to reduce the overall product weight, which means lower shipping cost and more efficient transportation.

- Durability: These materials are very resilient with high resistance to physical damage during handling and transportation. PE is used in stretch wraps and shrink films for pallet wrapping, and PP’s toughness makes it a good material for rigid containers such as yogurt cups and takeaway boxes.

- Chemical resistance: PE and PP can tolerate many chemicals. Why is this important? Because food packaged in these plastics won’t be tainted by their surroundings. That’s why you’ll see PP being used to package condiments and dairy products, both of which might otherwise degrade cheaper materials.

- Transparency (aesthetics): Transparency (and hence aesthetic appeal) can be important for some grades of PE and PP because consumers can see how much of the product inside is left. This can make a big difference in a sales situation. Transparent films and clear containers are a good example.

- Cost effectiveness: These packaging materials are available at relatively low cost of production and are the best bet for producers to achieve mass production without compromising on price.

- Recyclability: Both PE and PP are fully recyclable, which is a key consideration nowadays due to the growing emphasis among industry and consumers on environmental factors. Recycling systems are inherently more mature for both materials, and so provide a good measure of environmental friendliness, if used properly.

- Versatility: The extreme variability of polyolefins — which can be blended, co-polymerised or modified by adding additives right from the start — means, for instance, that they can be tailored to make flexible pouches or rigid and sturdy containers.

In conclusion, I want to say that the use of polyolefins by the packaging and food industry is so dispersed because of its unique properties, as it offers barrier protection, weightlessness, durability, chemical resistance, aesthetic value, cost effectiveness and recyclability, and overall versatility. It is for this reason that both PE and PP remain the prime materials of choice for packaging solutions.

The role of PP and PE in medical devices and automotive parts

Here, I would like to give an professional opinion that PP and PE are two of the most important materials used by the medical and automotive sectors for their properties. Here, I am going to give details on these roles:

Medical Devices

- Biocompatibility: PP and PE are biocompatible, which means they are suitable for biological systems, such as living tissues. That is very important for medical devices, which can contact directly with human parts, such as syringes, surgical trays and implantable devices.

- Sterilisability: PP and PE are able to survive many forms of sterilisation, such as autoclaving and gamma radiation, without being degraded. This makes them a good fit for medical-grade tools and devices.

- Chemical Resistance: These plastics are resistant to a wide range of chemicals, so that they don’t react adversely when they are exposed to saliva, blood, urine, stool or cleaning agents. This is important in equipment such as IV bags and tubing.

- Durability: Consistent with its ready durability, this plastic offers the medical field, for instance, the long-term reliability of performance it demands.

Automotive Parts

- Reduced vehicle weight: Both PP and PE are light weight. Reduced weight means more fuel efficient vehicles so they cause fewer emissions.

- Flexibility/Toughness A balance between flexibility and toughness in these materials, which make them perfect for parts that must be both durable and resistant to impact, such as bumpers and dashboards.

- Thermal Stability: Polypropylene and polyethylene don’t deteriorate much at extreme temperatures, an important feature for automotive components exposed to wide swings in conditions, such as those that happen under the hood. Examples include air ducts and fluid reservoirs.

- Cost-Effectiveness: As with packaging, cost-effectiveness is an important benefit of PP and PE in the automotive field: they helped carmakers produce good-quality components at a lower cost, which has translated into cheaper vehicles for consumers.

- Ease of Moulding: These polymers can be shaped relatively easily into complex shapes. This allows the manufacture of in many cases, virtually impossible to produce, intricate geometries needed for new and innovative automotive parts with the highest degree of precision.

In conclusion, the reason behind using PP and PE in wide range of medical devices and automotive parts can be contributed to their biocompatibilty, sterilizibilty, chemical resistance, longevity, lightweight, flexible, thermal stability, cost effectiveness, and moldibility. All of these features guarantee the performance of the materials according to the standards in these two demanding areas, thus providing consumers with a reliable, safe and efficient option.

Innovations in polymer technology: From textiles to tech

And if you are someone who works in the field, you probably get a lot of questions regarding the latest developments in polymer technology and how they are potentially going to change other industries. There have been many such innovations in recent years, here are some of the most important ones, and their applications.

Biodegradable polymers are emerging as a new frontier, especially in textiles, where degradable polymers may break down over time, minimising the environmental damage. Polylactic acid (PLA) is one of the most popular material, but there are others that could potentially replace non-biodegradable polymers, such as polyhydroxyalkanoates (PHA). These materials are durable and flexible, but will not leave a long-term environmental footprint.

The second is about smart textiles based on conductive polymers, so called ‘e-textiles’. Such ‘e-textiles’ can detect changes in the environment and monitor physiological parameters, as well as generate energy. For example, using polyaniline (PANI) or polypyrrole (PPy) composites, one can integrate electronic components such as heart rate monitors or physical activity trackers into textiles.

How can scientists successfully construct flexible electronics, allowing us to interact more dynamically with technology? Advancements in polymer technology have paved the way for more innovative uses in flexible electronics. Two specific polymers that are being widely explored are polyethylene terephthalate (PET) and polyimide (PI), each of which is a primary ingredient in our increasingly bendable and foldable displays. The benefits of flexible electronics are already evident in consumers’ handheld electronices (think smartphones and wearable devices).

In addition, 3D printing has been greatly assisted by the development of high-performance polymers, such as polyether ether ketone (PEEK) and thermoplastic polyurethane (TPU) which can be formed into complex, high performance, lightweight components. Such components have particular advantages in aerospace and medical implant applications.

Thirdly, recyclable and sustainable polymers are catching up. New chemical recycling technologies make it possible to again decompose polymers back into the monomers from which they were originally created, opening the doors to fully closed-loop systems. For example, polymers such as polyethylene terephthalate glycol (PETG) can be easily recycled and made again into something new multiple times.

In sum, recent innovations in polymer technology – spanning from biodegradable fibres and smart textiles to flexible electronics and advanced 3D printing – are enabling radical changes in both the textile and tech industries. Each one employs a different set of unique advantages and allows us to live a more sustainable, connected and efficient life.

Properties of Polyolefins: Dive into Their Chemical Resistance and Flexibility

They are known for their chemical resistance and flexibility, and have a wide range of applications in food packaging, engineering and pharmaceuticals. Having worked with a variety of polyolefins, I can explain why certain properties like their chemical resistance or flexibility are so widely appreciated. Through their non-polar molecular structure, I think polyolefins are very resistant to water, acids and alkalis. Therefore, compounds like polyethylene and polypropylene do not degrade or react in the presence of harsh chemical environments, which makes them suitable for applications such as packaging, the storage of chemicals or the manufacturing of medical devices.

In addition, flexibility is another important property that I often make use of. It is the result of polyolefin chains having the ability to stretch and can deform up to several hundred per cent before breaking which makes polyolefins impact-resistant and durable. They are the backbones of most flexible tubing application such as those used in pharmaceutics or infusions, but they are also used to make rigid applications in the automotive industry. The design and mechanical properties can be tailored by copolymerisation or blending, making them useful for different and specific manufacturing requirements. In brief, chemical resistance and flexibility are the two major performance characteristics of polyolefins found in high-performance applications.

How chemical structure impacts resistance to solvents and chemicals

Being a specialist in the field, I can tell you that the key property that determines the resistance of a polymer such as polyolefin towards a solvent and a chemical is its chemical structure. Let us analyse the important parameters that influence this chemical resistance:

- Molecular Polarity: Polyolefins (polyethylene, polypropylene) are non-polar molecules; that is, they do not contain polar functional groups, and so they have little affinity for water or other polar substances. They are therefore inherently immune to many solvents and chemicals.

- Crystallinity: The higher the degree of crystallinity of a polyolefin, the lower its chemical resistance – in most cases. The high degree of packing of the catenated chains in a polymer with high crystallinity makes it more resistant to chemical solvents, since these solvents find it harder to penetrate. This is the case, for instance, with high-density polyethylene (HDPE), which is more resistant than low-density polyethylene (LDPE) because of its higher crystallinity.

- Molecular Weight: The higher the molecular weight of a polymer, the more chemically resistant it is. Because long chains are less likely to be solubilised and disrupted by solvents.

- Cross-Linking: When polyolefins are cross-linked by interconnecting the polymer chains, they become less soluble in common solvents and less likely to dissolve or deform under stress. This stiffening of the macromolecular conformation explains why cross-linked polyethylene (PEX) is used in highly stressful applications such as plumbing.

- Additives – Chemicals: Sometimes, during the processing of the polymer, one aims to enhance the chemical resistance even more by adding specific additives such as antioxidants or UV stabilisers that protect the polymers molecules from being degraded by oxidation in the environment or UV radiation.

Knowing these parameters lets us predict how a polyolefin will perform in different chemical environments, and could be tweaked to enhance performance. The chemical structure of polyolefins dictates how resistant they are to chemical attacks, but it also presents a unique opportunity for modification and improvement.

The flexibility of polyolefins in various applications

As someone who knows a lot about this topic, I would say that the polyolefins’ versatility stems from some particular intrinsic properties and from some modifiable attributes. At the same time, this flexibility enables the use of polyolefins in many applications, from packaging to the automotive industry.

- Chemistry: As I previously mentioned, the chemical structure of polyolefins can make them highly resistant to many different substances; HDPE is an example of high crystallinity that is very difficult to dissolve, and is often used as a chemical storage tank liner, whereas LDPE has a lower crystallinity and greater flexibility, making it ideal for use in film.

- Mechanical Properties: Depending on the process, polyolefins can be produced with widely varying mechanical properties (tensile strength, impact strength and flexibility) by adjusting the molecular weight and degree of cross-linking. For example, cross-linked polyethylene pipes (PEX) are sturdy and flexible.

- Processability: Polyolefins are easily processed and hence mouldable to create a range of products, from plastic toys to car parts. Injection moulding, blow moulding or extrusion are some of the most common manufacturing processes used. This processability allows for a greater degree of freedom in product design and manufacture, according to the demands of the end function.

- Cost-effectiveness: The low cost of polyolefins manufacture means that they are highly cost-effective: the low price does not compromise their quality, such that producing a large number of goods – including for packaging materials – is always feasible.

- Environmental Footprint: Although polyolefins have some environmental issues during the production and disposal stages, the recycling technologies recently developed are also increasing. This is because of the high recyclability of polyolefins, specially polyethylene and polypropylene, can easily be used as feedstocks for many applications. For example, recycled polyolefins are being used to make green packaging and construction materials.

Understanding and then controlling these parameters allows us to tune polyolefins to the specific needs of each application, keeping these materials relevant and even improving them for their intended uses.

The role of additives in enhancing properties

Since I’ve spent my life working for one of the large polyolefin producers, I can tell you that additives do something very important to polymers: they change their properties. Let me describe some of the operation parameters that we consider when selecting and using additives:

- Stabilisers: These additives help enhance the resistance of polyolefins to deterioration caused by heat, light, and oxygen. For example, stabilisers may help to prevent polyolefins from breaking down during processing and use.

- Fillers: Talc, calcium carbonate and glass fibres are examples of fillers that are used to enhance the mechanical properties (strength, rigidity, wear resistance) of polyolefins. In this way, the material can be tailored to certain applications that require increased durability.

- Plasticisers: These improve the softness and flexibility of polyolefins, for example in applications where a softer, more pliable material is required. Here plasticisers help to make the polyolefin more pliable and effective in the application.

- Colourants: These are pigments and dyes that are added to polyolefins to improve the product’s aesthetic qualities by providing colour, or for functional purposes (providing, for example, a means of identifying different types of material in a manufacturing process).

- Antioxidants: Antioxidants are included to prevent oxidation of the polyolefins that might occur either in the processing of the resin or in the end-use environment. Oxidation causes brittleness, loss of strength and shortens the useful life of the product, and so this additive is important for providing long-term utility.

- UV absorbers: UV absorbers are used to prevent ultraviolet light-induced degradation of polyolefins, which could affect their performance and appearance – critical issues in applications requiring extended outdoor use.

- Antimicrobial Additives: These are additives that confer antimicrobial characteristics to the polyolefin. They are useful for medical devices and food packaging, for example.

By selecting and combining the additives, we can improve the performance of polyolefins and extend the life of products made from them, while increasing their versatility and functionality.

The Characteristics of Polypropylene: Versatility and Uses

Having worked in the industry, I know that polypropylene is one of the most versatile polymers, which is used in such a wide range of industries; and for a good reason: it has to be really very good at a lot of things before it can be used both for simple everyday items as well as highly specialised applications. Polypropylene exhibits exceptional resistance to many chemicals, it is fatigue-resistant as well as mechanically strong.

I have mostly encountered polypropylene in packages in which its clarity, lightness and moisture-barrier properties help to keep goods unspoiled during transport and storage. Its high melting point also makes it suitable for sterilisation, such as medical instruments or containers that need to be steamed or autoclaved.

This strength, in combination with relatively low density, helps polypropylene to save fuel in automobile use. In fact, polypropylene is ubiquitous in cars – it is used for dashboards, car batteries and car bumpers, where its high toughness and flexible strength are valuable for both safety and durability.

Its versatility shines through in the variety of ways it is harnessed in consumer goods, from containers meant for reuse to textiles; but also in the way it has found a place in the building industry through its use in piping systems and components.

Taking advantage of the inherent properties of polypropylene, we can create products with high performance but also very sustainable, as it is recyclable. The extended field of applications and the good reliability of the properties guarantee its important role in modern manufacturing and industrial processes.

Injection molding and copolymer variants

Injection moulding is by far the most used process to convert polypropylene into a finished part. As an industry veteran, I can confirm that injection moulding is a fantastic way to convert molten polypropylene into a high-quality, precise part, time after time. In the injection moulding process, a quantity of polypropylene is heated to the point where it is molten, injected into a mould to cool and solidify, and then ejected from the mould. Some of the key process parameters for injection moulding are:

- Temperature control: Ensuring that the molten polypropylene is at the correct temperature (usually between 420°F to 470°F) to maintain a consistent flow and avoid material degradation.

- Injection speed and pressure: One of the more important variables but also a bit of an art is how fast to fill the mould with the material at the proper pressure, typically somewhere between 15,000 to 20,000 psi, ensuring complete filling while avoiding warping or what are called sink marks.

- Cooling time: Cooling time should be sufficient to allow the part to cool to below the temperature range for the cloud-point and spinodal curves for the material used to fabricate the part. If cooling is too rapid, internal stresses can be created, resulting in a part that is more brittle and prone to flashing and warping. Dimensional tolerances are also affected.

Most propylene copolymers also add to that versatility. Copolymers are a special form of polypropylene, which combine propylene with other monomers (like ethylene) to create new improvements on the basic form. The primary varieties of copolymer and their parameters follow:

- Random Copolymers: Comprising a random sequence of ethylene, these copolymers have enhanced clarity and flexibility, and are therefore suited to applications such as packaging films and medical devices. Typically, ethylene content is between 1 per cent and 7 per cent.

- Block copolymers: Blocks of ethylene give a high-impact, tough formulation. These polymers are especially suited to parts that must resist stress and impact, such as automotive parts and other industrial components. Typically, block copolymers have between 5 and 15 per cent ethylene content.

These parameters tell us how to manipulate polypropylene and its copolymer varieties in order to develop products that meet exact specification and performance needs. By understanding the exact properties of polymer products via molecular engineering, it can be used to not only ensure the desired functionality but also enable sustainable manufacturing processes.

Polypropylene’s role in everyday products

Having worked with polypropylene and its copolymers extensively, I know from experience just how pervasively polypropylene has improved the products we rely on in our everyday lives. So, let’s examine how this versatile polymer can improve the things we use every day.

First, think of the plastic wrapping of food. Random copolymers are highly transparent, potentially stretchy or rigid, and excellent covers for clear wraps or trays. The critical parameter here are the ethylene molecules – the greater the ethylene content (usually between 1 per cent and 7 per cent), the better will be these desired properties.

Meanwhile, a second everyday use is in household appliances. Here, the block copolymers’ hardness and impact resistance, created by the high proportion of the hard blocks, is advantageous for components with long lifetimes, such as parts of washing machines or vacuum cleaners. The ethylene content in the polyethylene blocks is the crucial ingredient: it needs to be between 5 and 15 per cent for the desired high hardness to occur.

Medical devices too rely on polypropylene. The clear and sterile quality of the copolymers make them ideal for syringes and laboratory equipment. Once again, getting the balance of ethylene right – just 1-7 per cent of the monomers for the random copolymers – is vital to delivering this.

With those specifications in hand, we can make polypropylene and its derivatives fit the needs of a particular product and of the design as a whole – both for the good of the object, and for the good of our planet.

Comparing the environmental impact of PP, PE, and other plastics

An expert in this field I’m often asked about the environmental impact of polypropylene (PP) and polyethylene (PE) plastics compared with other ‘common plastics’. Since we are currently in a time of concern about sustainability and environmental impact, this is a highly relevant question.

1.Polypropylene (PP):

- In terms of production: PP uses much less energy than most other plastics in production – this is because the specific polymerisation process used is particularly efficient.

- Recyclability: one of PP’s great points is that it has high recyclability – it can be reprocessed and reused many times, maintaining much of its quality.

- Waste management: Although PP does have waste management issues, improvements in recycling technology will make it less troublesome in the future.

2.Polyethylene (PE):

- Flexibility in Forms: PE is produced both as high-density (HDPE) and as low-density polyethylene (LDPE) each with different environmental impacts, HDPE being highly recyclable.

- Biodegradability: In general, PE is non-biodegradable, and this raises an environmental problem that forms the major part of the total waste problem, ie, in the long term.

- Production Efficiency: This is similar to PP in being relatively energy-efficient, but the environmental impact will vary depending on the type of PE produced.

3.Other Plastics:

- Polystyrene (PS): Mostly used for packaging and insulation, PS is one of the most polluting types of plastic – usually not recyclable and takes hundreds of years to decompose.

- Polyvinyl Chloride (PVC): PVC production has a huge carbon footprint, more crude oil is needed and its manufacturing process involves other harmful chemicals. Particularly, waste management of the product is a huge problem because it is not easily recycled like PP and PE.

- Biodegradable Plastics: Although an improvement on conventional plastics that are not biodegradable, these plastics often require conditions that are not naturally present for them to degrade.

Relevant Parameters:

- Energy Consumption During Production: Measures the amount of energy required to produce the plastic.

- Recyclability: Refers to the ease and effectiveness of recycling the material.

- Biodegradability: Indicates whether and how quickly the material breaks down organically.

- Chemical composition: Refers to the use of materials and chemicals in the production process which can cause environmental problems.

- Waste Management Practices: Refers to whether waste from production processes, as well as waste from the post-consumer life cycle of the plastic is managed in a sustainable manner.

With this in mind, it becomes easier to see how each type of plastic affects the environment. Polypropylene and polyethylene have the lowest energy footprint, and are also the most recyclable – as long as a country has adequate processing facilities to treat its waste. Nevertheless, even these two plastics continue to rely on expensive recycling technologies – the very same ones that have been developed using fossil fuels.

Decoding the Types of Polyethylene: LDPE vs. HDPE

A question barely a month does not go by without someone asking me the following question: What is the difference between Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE)? Actually, this is an important question for a professional in the plastics industry when selecting materials and provides an opportunity to understand the basics.

Low-Density Polyethylene (LDPE): LDPE is very flexible, much less dense than high-density polyethylene, and therefore thinner, more pliable, often made into plastic bags, cling wraps, and flexible lids to containers. It strikes me from personal experience that LDPE is very flexible and great for products that need to be durable and flexible but that the fact that it is so thin and flexible also means that it is not very strong, so it would not be used in high-stress applications.

High-Density Polyethylene (HDPE): HDPE is higher in strength and rigidity and has higher density so it will be tough and more resistant to impact. I use HDPE as a more durable replacement for low density polyethylene in more demanding applications such as milk jugs, detergent bottles and piping systems that must bear mechanical stress. Its higher holding strength also develops a higher melting point, which is why we use it more often than LDPE.

From an environmental perspective, both LDPE and HDPE are recyclable. Yet HDPE has a much higher recycling rate, for the simple reason that it is used for rigid, high-value products such as bottles. Understanding their properties and applications can make a big difference to environmental and economic outcomes, helping us to make more sustainable choices for a range of industrial applications.

Low-density vs. high-density polyethylene: Applications and properties

Many of the questions I get as an industry commentator are the same. From how LDPE can assist you with different applications, or how it compares to HDPE, but the most common is how it is made and what are its advantages.

1. Flexibility and Strength:

LDPE: If you’re looking for a flexible package, look no further – LDPE is soft, plastic and will bend without breaking under tensile strength. It’s commonly used in products such as plastic bags and squeeze bottles because flexibility is key.

HDPE: On the other hand, HDPE have more density than LDPE, which means they are much stronger and stiffer. The difference in density allows for better impact resistance and durability, allowing HDPE to be used for products that require more intensity, such as industrial pipes and big plastic containers or bottles.

2. Melting Point:

LDPE: In LDPE, the polymer chains are shorter than in HDPE. This makes the melting point lower than in HDPE, and hence LDPE is easier to process and mould. This property is very important if the material is to be formed quickly and easily, as is the case with plastic films and coverings.

High-density polyethylene (HDPE): When it comes to heat resistance, the melting point of HDPE makes it higher than that of LDPE. This is why in applications where high heat resistance is desired, HDPE is commonly used. Industrially, you’ll find HDPE used in the manufacturing of piping systems and chemical containers.

3. Environmental Impact:

LDPE: while LDPE and HDPE are both recyclable, often LDPE is not recycled since it is used for single-use products especially, so much plastic is made out of less durable LDPE. However, this plastic is still harmful to the planet and should be disposed of rather than just thrown away.

High-density polyethylene (HDPE): Unlike the above, HDPE enjoy much higher rate of recycling because, being used for more durable and heavy-duty products, it is easy to collect and recycle through the process of remanufacturing into new items. This leads to the formation of a circular economy.

Knowing these numbers helps make better decisions about the material when we know how it is to be used. That’s because each type of polyethylene is highly effective for that type of use – and that material is selected to fit the specific needs of the application.

Molecular structure differences and their implications

Discuss the structural difference between Low-Density Polyethylene(LDPE) and High-Density Polyethylene(HDPE) and the impact of this difference in choosing the right material for the right applications. I will start with talking about the structure of HDPE and LDPE.

1. Degree of Branching:

LDPE: The high degree of short and long chain branching in LDPE makes it impossible for the polymer chains to pack tightly against each other. LDPE’s lower density compared with HDPE is the result of having a less compact molecular structure. Since LDPE is bendable or stretchable, it is often used to produce items like plastic bags, films and containers.

HDPE: On the other hand, the branching is minimal, leaving the HDPE structure more linear and tightly coiled, hence denser and stronger. The structure is more crystalline, which gives HDPE strength for robust applications such as industrial pipes and heavy-duty bottles.

2. Crystallinity:

LDPE: Branching generates amorphous areas of polymer, lowering the crystallinity. This in turn results in a material with lower tensile strength and impact resistance, and greater transparency and softness. LDPE is easier to process than HDPE.

HDPE: The crystalline structure of HDPE is higher, as it is linear and it gives it rigidity and strength. HDPE is more dense and opaque. It can withstand impact and tensile stresses better than LDPE, which is necessary for applications that require strength and durability.

3. Density and Mechanical Properties:

LDPE: This latter has a lower density and is also mechanically less strong. This explains why LDPE is frequently used for lightweight, flexible packaging, but is less used in more demanding applications.

HDPE: The higher density of HDPE means it has superior mechanical properties – it’s tougher, resistant to impact, wear and environmental stressors. This is why it’s the preferred plastic for manufacturing products that require benign handling and conditions, such as milk bottles.

In conclusion, the main molecular difference, which determines the property and the applicable field for LDPE and HDPE, is branching and crystallinity. We must always be mindful of our requirements when choosing the material and ensure the selected polyethylene can meet our specific, targeted purposes. With this additional knowledge about how the molecular nuances of polyethylene affect the ultimate properties of the material, we can fully utilise the different strengths of LDPE and HDPE.

Environmental considerations and recycling of HDPE and LDPE

For me, as an expert in the field, the question of environmental impact is an important one to consider, especially when it comes to the recyclability of HDPE versus LDPE and their relative lifecycle performance. Let’s take a look at some of the key considerations.

1.Recyclability:

HDPE: Recyclable: HDPE is one of the easiest plastics to recycle. It’s collected as part of the curbside recycling programme and can be recycled into new items very easily and many times- it just needs to be cleaned, shredded, and melted down back into pellets which can be used to create new items. Due to its strength, HDPE is commonly recycled into new piping, plastic lumber, and other containers.

LDPE: Low-density polyethylene is not easy to recycle, either. Although it is technically recyclable, LDPE’s light weight and greater flexibility mean that it is less often collected by municipal recycling programmes. Still, certain facilities can recycle LDPE into items such as bin liners, floor tiles and shipping envelopes.

2.Environmental Impact:

HDPE: HDPE has one of the best footprints among the plastics, especially if recycled. Being recyclable many times, it will reduce impact by lowering the need for primary raw materials and the amount of plastic going into waste.

LDPE: LDPE is problematic because it is less recyclable (especially when compared with other types of polymers) and it ends up in landfills more. When not recycled, LDPE takes several hundred years to decompose and thereby pollutes for a long period of time. If you care about the effects of plastic pollution, then you should support attempts to improve recycling technologies for LDPE and to increase the availability of LDPE recycling programmes.

3.Energy Consumption:

HDPE and LDPE: Both polyethylene variants require a lot of energy to produce in the first place. Generally, it takes less energy to recycle HDPE and, where possible, LDPE than it does to make new plastic from virgin materials. So encouraging the recycling of HDPE and, where possible, LDPE, helps to reduce energy use.

4.Biodegradability:

Both HDPE and LDPE are non-biodegradable, that is they do not break down in the environment, which makes recycling them even more important to reduce their ecological footprint.

In conclusion, the two kinds of plastic HDPE and LDPE, are not without their problems and advantages, but conscious recycling can go a long way in reducing their impact on the environment. Recycling technologies can be improved and collection infrastructure can be expanded, that way we can better manage such materials, prevent harm to our ecosystems, and find uses for them.

Reference sources

- “Understanding the Differences Between Polyethylene and Polypropylene” – PlasticsToday

- Medium: Online Article

- Summary: This article provides a detailed comparison of the two commonly used plastics, polyethylene (which includes polyolefin) and polypropylene. It discusses their chemical structures, physical properties, and typical applications. By presenting key differences and similarities, the article helps readers understand where each material excels and the unique benefits they offer.

- Link: PlasticsToday Article

- “Polyolefins: The North American Polypropylene Market” – Journal of Polymer Science

- Medium: Academic Journal

- Summary: This peer-reviewed journal article delves into the scientific and economic aspects of polyolefins, focusing particularly on polypropylene. It covers the polymerization processes, properties, market trends, and future outlook. The in-depth analysis makes it highly relevant for researchers and industry professionals looking for comprehensive technical details.

- Link: Journal of Polymer Science

- “Material Properties and Applications of Plastics” – Manufacturer Website (Dow Inc.)

- Medium: Manufacturer Website

- Summary: This resource from a leading plastics manufacturer offers an extensive overview of both polyolefin and polypropylene. The website provides technical data sheets, application guidelines, and sustainability practices related to these materials. It’s particularly useful for engineers and product designers seeking practical insights and performance data.

- Link: Dow Inc.

These sources provide a well-rounded education on the distinctions and applications of polyolefins and polypropylene, suitable for both beginners and experienced professionals in the field.

Frequently Asked Questions (FAQs)

Q: What are the primary differences between polyethylene and polypropylene?

A: Polyethylene and polypropylene are both types of polyolefins, but they differ in their chemical structure, properties, and applications. Polyethylene is generally more flexible and has a lower melting point, making it suitable for applications like plastic bags and films. Polypropylene, on the other hand, has a higher melting point and offers greater rigidity and chemical resistance, making it ideal for automotive parts, containers, and medical devices.

Q: How are polyethylene and polypropylene manufactured?

A: Both polyethylene and polypropylene are manufactured through polymerization processes. Polyethylene is typically produced via the polymerization of ethylene monomers, using processes such as Ziegler-Natta polymerization or metallocene catalysis. Polypropylene is produced from the polymerization of propylene monomers, most commonly using Ziegler-Natta or metallocene catalysts as well.

Q: What are the environmental impacts of polyethylene and polypropylene?

A: Both polyethylene and polypropylene are plastics with significant environmental footprints due to their petroleum-based origins and challenges in biodegradability. Efforts are being made to recycle these materials more effectively, and research is ongoing into bio-based alternatives. However, improper disposal of these plastics can lead to pollution and harm to wildlife and ecosystems.

Q: Can polyethylene and polypropylene be recycled?

A: Yes, both polyethylene and polypropylene can be recycled, though the processes and feasibility can vary. Polyethylene (typically denoted as PE) is often recycled into products like plastic lumber, pipes, and containers. Polypropylene (PP) can be recycled into items such as automotive parts, consumer goods, and textiles. However, recycling rates and facilities available for these materials can differ widely by region.

Q: What are some common applications of polyethylene and polypropylene?

A: Polyethylene is used in a variety of applications including packaging films, plastic bags, containers, and household products. Polypropylene’s common uses include automotive components, food containers, medical devices, and textiles. Each material’s unique properties make it suitable for specific applications where flexibility, rigidity, chemical resistance, or temperature endurance are required.