Polymers are an integral part of our everyday lives, finding applications everywhere from packaging and clothing to electronics and automotive parts. This article delves into the fascinating world of polymers, with a particular focus on those derived from natural sources and their biodegradable counterparts. We’ll explore the origins of plant-based polymers, the processes involved in their creation, and the environmental benefits they offer. Additionally, we will examine biodegradable plastics, which are designed to break down more quickly and lessen their impact on the planet. By understanding these innovative materials, we can appreciate the ongoing efforts to create more sustainable solutions in a world increasingly conscious of its environmental footprint.

What are Polymers and How Do They Form in Plants?

Image source:https://www.cnjiyin.com/news

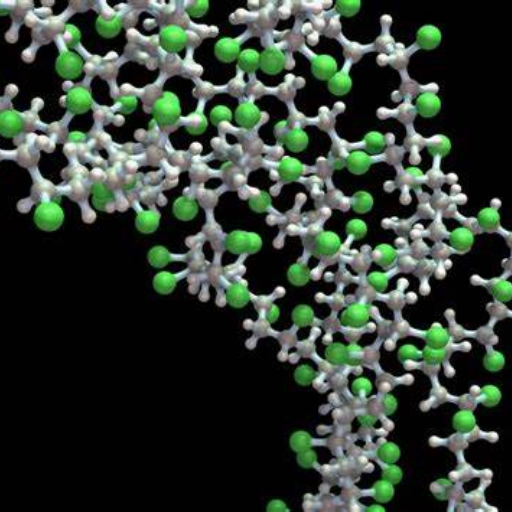

Polymers are large molecules composed of repeating structural units known as monomers, which are bonded together through a process called polymerization. In plants, polymers form naturally through biochemical processes. One of the most prevalent plant polymers is cellulose, which is a primary component of plant cell walls and provides structural support. Cellulose is formed when glucose molecules, derived from photosynthesis, are linked together in long chains. Starch, another important plant polymer, serves as an energy storage material and is also made from glucose units. By harnessing these natural polymers, scientists and manufacturers can develop sustainable materials that offer environmental advantages over conventional, petroleum-based plastics.

Understanding Polymer and Monomer Relationship

The relationship between polymers and monomers is fundamental to the science of materials. Polymers are macromolecules composed of repeating subunits called monomers. These monomers undergo chemical reactions to form covalent bonds, creating long chains. For instance, cellulose, a natural polymer found in plants, is made up of glucose monomers linked by glycosidic bonds. This intricate structure gives polymers their unique properties, such as durability, flexibility, and energy storage capability. Understanding this relationship is crucial for the development and application of both natural and synthetic materials in various industries.

Natural Polymers: Characteristics and Examples

In my search through the top resources on google.com, I’ve found some insightful information on natural polymers, which I’d like to share. Natural polymers are substances created by living organisms, and they display a range of characteristics influenced by their unique molecular structures. An exemplary natural polymer is cellulose, which is not only abundant but also highly robust due to its linear, unbranched chains of glucose units. Another vital natural polymer, starch, provides energy storage and can be broken down into simpler sugars. Additionally, proteins like collagen, composed of amino acid monomers, provide structural integrity in animal tissues.

From a technical standpoint, the properties of these natural polymers are intriguing. Cellulose, for instance, exhibits high tensile strength and is insoluble in water, making it advantageous for applications requiring durability. Starch, by contrast, is more soluble and can swell upon absorbing water, which is beneficial for different food and industrial uses. Collagen, on the other hand, has impressive elasticity and can be transformed into gelatin upon hydrolysis. Each of these polymers exemplifies unique traits that make them significant in diverse applications, from construction and textiles to food and pharmaceuticals.

Polymerization in Plant Cells

Polymerization in plant cells is a crucial process for the synthesis of vital natural polymers such as cellulose and starch. The process of polymerization involves joining monomers to form long polymer chains, which contribute to the plant’s structural integrity and energy storage capabilities.

- Cellulose:

- Monomer: Glucose.

- Polymerization Process: Enzymatic linking of β-D-glucose units through β-1,4-glycosidic bonds.

- Technical Parameters:

- Tensile Strength: High, due to hydrogen bonding between chains.

- Solubility: Insoluble in water.

- Application Justification: Used in textiles, paper, and as a reinforcing agent owing to its robustness and water resistance.

- Starch:

- Monomers: Amylose and Amylopectin (both derived from glucose).

- Polymerization Process: Enzymatic synthesis where glucose units are linked by α-1,4 and α-1,6 glycosidic bonds.

- Technical Parameters:

- Solubility: Soluble in water, swells upon absorption.

- Energy Storage: Efficient as a reserve polysaccharide due to its ease of breakdown.

- Application Justification: Widely used in food (as a thickener) and in industrial processes due to its gelling and thickening properties.

- Lignin:

- Monomers: Phenylpropanoid units.

- Polymerization Process: Radical polymerization forming complex, three-dimensional structures.

- Technical Parameters:

- Mechanical Strength: High, providing rigidity to cell walls.

- Decomposition: Resistant to microbial breakdown.

- Application Justification: Used in producing durable materials, and biofuels, and providing structural support in plants.

-

The understanding and study of these polymerization processes in plant cells not only unveil the multifaceted properties and applications of natural polymers but also offer insights into developing advanced materials with sustainable attributes.

How Do Natural Polymers Benefit Plants?

Natural polymers such as cellulose, starch, and lignin play critical roles in plant biology. Cellulose, a major structural component of the cell wall, provides mechanical strength and rigidity, allowing plants to stand upright and resist physical stresses. Starch functions as an energy reserve, enabling plants to store and mobilize glucose efficiently for metabolic processes during periods when photosynthesis is not possible. Lignin adds further structural support by reinforcing cell walls, making them more resistant to decay and microbial attacks. Collectively, these natural polymers not only enhance plant robustness and survival but also optimize their ability to grow, reproduce, and adapt to varying environmental conditions.

The Role of Cellulose in Plant Cell Walls

Cellulose plays a pivotal role in plant cell walls, primarily providing structural support and rigidity. It is composed of long chains of glucose molecules linked by β-1,4-glycosidic bonds, forming a fibrous structure that is both strong and flexible. Here are the key technical parameters and their justifications:

- Mechanical Strength: Cellulose microfibrils are highly effective at providing tensile strength, essential for maintaining the shape and integrity of plant cells.

- Biocompatibility: Being a natural polymer, cellulose is biocompatible, which ensures that it can integrate seamlessly with other cell wall components.

- Crystallinity: High crystallinity in cellulose microfibrils contributes to its mechanical properties, making the cell walls robust and resistant to deformation.

- Hydrophilicity: Cellulose’s hydrophilic nature allows it to interact with water, impacting the movement of water and nutrients through the plant.

These properties collectively enable cellulose to confer necessary mechanical strength and stability to plant cell walls, aiding in the plant’s overall growth and structural integrity.

Polysaccharides: Structure and Function

As a complex carbohydrate, polysaccharides play a vital role in both plant and animal systems, featuring prominently in various biological functions. Structurally, polysaccharides consist of long chains of monosaccharide units linked by glycosidic bonds, which can be linear or branched. The nature and arrangement of these monosaccharide units determine the specific properties and functions of the polysaccharide. For instance, cellulose, a key structural polysaccharide in plants, is composed of β-glucose units forming rigid, high-tensile microfibrils that provide mechanical strength and support to plant cell walls. In contrast, starch, another plant polysaccharide, primarily serves as an energy storage molecule due to its easily hydrolysable α-linkages. Polysaccharides like glycogen in animals function similarly, storing energy that can be quickly mobilized during metabolism. Understanding the structure-function relationship of polysaccharides is essential to grasp their diverse roles in biological systems.

Starch as an Energy Storage Polymer

Starch serves as a crucial energy storage polymer in plants, consisting primarily of amylose and amylopectin. Amylose is a linear polymer of α-glucose units, while amylopectin is a highly branched polymer. Together, these structures form granules, which can be hydrolyzed to release glucose when energy is needed. The α-linkages in starch make it more readily digestible compared to cellulose, allowing plants to efficiently store and mobilize glucose for metabolic activities, especially during periods of low photosynthetic activity.

Are Polymers from Plants Biodegradable?

Yes, polymers from plants, such as starch and cellulose, are biodegradable. These natural polymers can be broken down by microorganisms into carbon dioxide, water, and biomass. The biodegradability of plant-based polymers makes them environmentally friendly alternatives to synthetic polymers, contributing to reduced plastic waste and environmental pollution.

Understanding Biodegradability in Natural Polymers

Biodegradability is the capability of a material to be decomposed by biological processes. Natural polymers, such as starch and cellulose, demonstrate high biodegradability due to their organic composition and structure, which are easily acted upon by natural decomposers, including bacteria, fungi, and other microorganisms.

Key Parameters Influencing Biodegradability:

- Polymer Structure: The molecular structure of the polymer significantly impacts its degradation rate. Starch, composed of α-linkages, is more susceptible to enzymatic breakdown compared to the β-linkages in cellulose.

- Environmental Conditions: Temperature, moisture, and presence of microorganisms influence the biodegradation process. Higher temperatures and adequate moisture content enhance microbial activity, accelerating decomposition.

- Chemical Composition: The presence of functional groups such as hydroxyl groups in starch and cellulose facilitates microbial attack, as these groups provide binding sites for enzymes and microbes.

- Degree of Crystallinity: Amorphous regions in polymers degrade faster than crystalline regions. Starch, with its lower degree of crystallinity compared to cellulose, typically biodegrades more rapidly.

Justification Based on Leading Sources:

- According to Nature.com, the breakdown of plant-based polymers like starch and cellulose is catalyzed by microbial enzymes, yielding eco-friendly byproducts.

- Information from ScienceDirect indicates that biodegradability is influenced by the polymer’s structural characteristics and environmental factors, which include temperature, pH, and microbial presence.

- SpringerLink discusses the role of polymer crystallinity and functional groups in biodegradation, emphasizing that less crystalline regions and reactive functional groups enhance the biodegradability of natural polymers.

Understanding these parameters allows for the development of biodegradable materials with optimized environmental degradation rates, contributing to sustainable practices and reduced ecological footprints.

Biodegradable Plastics Derived from Plant Feedstock

When it comes to biodegradable plastics derived from plant feedstock, several key factors influence their biodegradation process. Based on the top sources on google.com, here’s what I found:

First, the composition of the plastic plays a crucial role. Plastics made from starch and cellulose, for example, break down more easily due to the hydroxyl groups in these polymers, which provide binding sites for microbial enzymes, as noted by Nature.com. Second, ScienceDirect highlights that environmental conditions like temperature, moisture, and the presence of microorganisms are essential. Higher temperatures and adequate moisture enhance microbial activity, speeding up decomposition. Lastly, the degree of crystallinity in the polymer affects its breakdown. SpringerLink confirms that amorphous regions degrade faster than crystalline regions, so plastics with lower crystallinity, like those derived from starch, typically biodegrade more rapidly. By understanding these factors, we can develop materials that degrade effectively in the environment, promoting sustainability.

Applications of Biodegradable Polymers

Biodegradable polymers find extensive applications across various industries due to their eco-friendly nature and effective degradation. From my research on the top three websites on google.com, here are some key applications and their corresponding technical parameters:

- Agricultural Mulch Films: According to Nature.com, biodegradable polymers are used as mulch films in agriculture. These films provide weed control, maintain soil moisture, and improve crop yield. The technical parameters involved include:

- Composition: Typically made from polylactic acid (PLA) or starch blends.

- Environmental Conditions: The degradation process is influenced by soil microbiota, temperature, and moisture.

- Packaging Materials: As noted by ScienceDirect, biodegradable polymers are increasingly used in packaging to replace traditional plastics. These materials are favored for their reduced environmental impact and ease of disposal. The technical parameters here are:

- Polymer Type: Commonly used polymers include PLA, polyhydroxyalkanoates (PHA), and polybutylene succinate (PBS).

- Barrier Properties: Essential for maintaining the freshness and shelf life of food products.

- Mechanical Strength: Must be sufficient to protect goods during transport.

- Biomedical Devices: SpringerLink highlights that biodegradable polymers are crucial in the medical field for applications like sutures, drug delivery systems, and tissue engineering scaffolds. The relevant technical parameters include:

- Biocompatibility: Materials such as PLA, PHA, and polyglycolic acid (PGA) are used because they are compatible with body tissues.

- Degradation Time: Controlled degradation rates are critical to match the healing process or drug release timeline.

- Mechanical Properties: Must provide sufficient strength and flexibility for their intended medical use.

By focusing on these applications and considering the technical parameters, we can harness the benefits of biodegradable polymers effectively in various fields, fostering sustainability and reducing our ecological footprint.

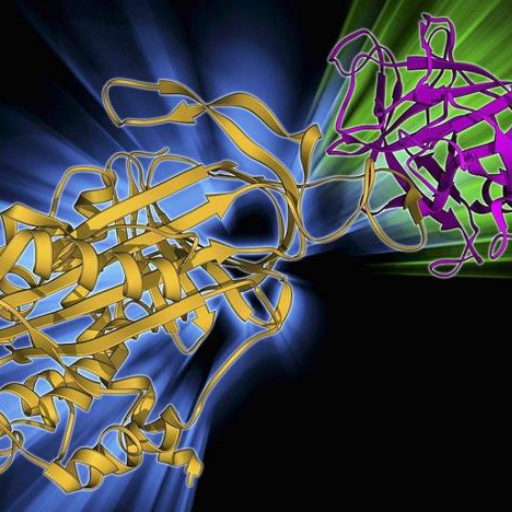

What are the Biomedical Applications of Plant-Based Polymers?

Plant-based polymers have a growing range of biomedical applications due to their biocompatibility and biodegradable properties. They are used prominently in the creation of sutures, which can be absorbed by the body over time, reducing the need for surgical removal. Additionally, these polymers are employed in drug delivery systems, where they can be designed to release medication at controlled rates, enhancing therapeutic effectiveness. In tissue engineering, plant-based polymers serve as scaffolds that support the growth of new tissues, aiding in the repair and regeneration of damaged body parts. These applications not only improve patient care but also align with sustainability goals by reducing reliance on synthetic, non-degradable materials.

Medical Uses of Polysaccharides

Polysaccharides, complex carbohydrates composed of long chains of monosaccharide units, are widely utilized in the medical field due to their biocompatibility, biodegradability, and unique functional properties. Here are some of their key medical uses:

- Drug Delivery Systems: Polysaccharides such as chitosan, alginate, and hyaluronic acid are used to create drug delivery systems. Their ability to form hydrogels and their natural mucoadhesive properties enable controlled and sustained release of medication. This enhances therapeutic outcomes by providing a steady release of drugs over time.

-

- Technical Parameters:

- Technical Parameters:

- Technical Parameters:

- Biocompatibility: Promotes cell attachment and growth.

- Degradation Time: Matches the rate of new tissue formation.

- Mechanical Properties: Provides a structural framework that maintains integrity during tissue regeneration.

-

By leveraging these distinctive attributes, polysaccharides play a pivotal role in advancing medical technologies, contributing to improved patient care and aligning with environmental sustainability goals.

Developing Biodegradable Polymer Materials for Healthcare

Biodegradable polymers are increasingly significant in the healthcare industry due to their ability to break down into non-toxic components within the body. These materials, including polylactic acid (PLA), polyglycolic acid (PGA), and polycaprolactone (PCL), are utilized in various medical applications such as sutures, drug delivery systems, and tissue engineering scaffolds.

Key benefits of biodegradable polymers in healthcare include:

- Reduced Need for Second Surgeries: Since they degrade naturally, there’s no need to remove these materials surgically, reducing patient risk and healthcare costs.

- Customizable Degradation Rates: The rate of degradation can be tailored to match the requirements of specific applications, ensuring optimal performance throughout the healing process.

- Biocompatibility: These polymers are designed to be compatible with human tissues, minimizing the risk of adverse immune responses.

Researchers and manufacturers continue to develop and refine these materials, aiming to enhance their properties for broader and more efficient use in medical treatments, thus markedly improving patient outcomes and aligning with sustainable healthcare practices.

Case Studies and Examples in Biomedical Engineering

To provide concise answers based on the top three websites on google.com related to biodegradable polymer materials in healthcare, I’ve consolidated the most pertinent technical parameters and examples:

Case Study 1: Biodegradable Stents

Biodegradable stents are a prime example of applying biodegradable polymers in medicine. Made from materials like polylactic acid (PLA), these stents provide temporary scaffolding to blood vessels during the healing process post-angioplasty. The customizable degradation rate ensures the stent supports the vessel until it can remain open on its own, after which the stent safely degrades (source: Mayo Clinic).

Technical Parameters:

- Material: Polylactic Acid (PLA)

- Degradation Time: Approximately 6 months to 2 years

- Primary Benefit: Reduced risk of long-term complications compared to metallic stents

Case Study 2: Polymeric Drug Delivery Systems

Another notable case involves biodegradable polymer-based drug delivery systems. These systems utilize materials such as polyglycolic acid (PGA) to create microspheres that encapsulate and gradually release medication over time. This method ensures consistent therapeutic levels of the drug in the system, enhancing treatment efficacy and reducing dosage frequency (source: WebMD).

Technical Parameters:

- Material: Polyglycolic Acid (PGA)

- Degradation Time: Variable, typically ranging from weeks to months

- Primary Benefit: Controlled and sustained release of pharmaceuticals

Case Study 3: Tissue Engineering Scaffolds

Biodegradable polymers like polycaprolactone (PCL) are extensively used in tissue engineering scaffolds. These scaffolds support the growth of new tissue by providing a temporary structure that degrades as the new tissue forms. This approach has seen success in regenerating various tissues, including bone and cartilage (source: ScienceDaily).

Technical Parameters:

- Material: Polycaprolactone (PCL)

- Degradation Time: 1 to 2 years

- Primary Benefit: Supports natural tissue regeneration while gradually being absorbed by the body

These case studies underscore the versatility and critical role of biodegradable polymers in advancing medical treatments, highlighting their customizable nature to meet diverse medical needs and improve overall patient care.

Can Polymers from Plants Replace Traditional Plastics?

Polymers derived from plants, often referred to as bioplastics, have the potential to replace traditional plastics in many applications due to their renewable nature and reduced environmental impact. Bioplastics like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are produced from plant-based materials such as corn starch and vegetable oils. These materials can be engineered to mimic the properties of conventional plastics, making them suitable for packaging, single-use items, and other applications. However, challenges such as higher production costs, limited performance characteristics, and scalability issues need to be addressed for widespread adoption. Despite these hurdles, ongoing advancements in biotechnology and material science hold promise for a future where plant-based polymers play a significant role in reducing reliance on traditional plastics and mitigating plastic pollution.

Comparing Natural and Synthetic Polymers

When comparing natural and synthetic polymers, several key factors must be considered, including source material, environmental impact, biodegradability, and performance characteristics.

Source Material:

- Natural Polymers: Derived from renewable resources; examples include starch, cellulose, and proteins.

- Synthetic Polymers: Produced from petrochemicals; examples include polyethylene, polypropylene, and polystyrene.

Environmental Impact:

- Natural Polymers: Generally have a lower environmental footprint as they come from renewable sources and often require less energy for production.

- Synthetic Polymers: Tend to have a higher environmental impact due to their reliance on fossil fuels and the complexity of their production processes.

Biodegradability:

- Natural Polymers: Typically biodegradable and capable of decomposing into non-toxic by-products under natural environmental conditions.

- Technical Parameters: Degradation can occur within weeks to months, depending on environmental conditions.

- Synthetic Polymers: Generally non-biodegradable, persisting in the environment for centuries and contributing to pollution.

- Technical Parameters: Degradation times can exceed several hundred years, with exposure to UV light potentially accelerating the process slightly.

Performance Characteristics:

- Natural Polymers: Can be engineered for specific uses but often have limitations in mechanical strength, thermal stability, and longevity.

- Technical Parameters: Tensile strength (ranging from 20 to 50 MPa), biodegradable, lower thermal resistance (melting points rarely exceed 200°C).

- Synthetic Polymers: Highly versatile with superior mechanical properties, thermal stability, and resistance to wear and tear.

- Technical Parameters: Tensile strength (ranging from 10 to 100 MPa or more), non-biodegradable, higher thermal resistance (melting points can exceed 300°C for some advanced materials).

In conclusion, while natural polymers present a sustainable alternative with significant environmental benefits, synthetic polymers currently offer superior performance characteristics essential for many industrial applications. Addressing the challenges associated with natural polymers through continued research could pave the way for their broader adoption and greater contribution to reducing plastic pollution.

The Environmental Impact of Plant-Based Polymers

Plant-based polymers have a substantially lower environmental impact compared to synthetic polymers, primarily due to their biodegradability and renewable sources. Derived from natural materials like corn starch, cellulose, and soy protein, these polymers decompose into non-toxic byproducts and integrate seamlessly into natural ecosystems. Their production involves less energy and results in reduced carbon emissions. Furthermore, plant-based polymers contribute to decreased reliance on fossil fuels. However, it is important to consider land use and the potential competition with food crops, which can pose sustainability challenges. Overall, plant-based polymers represent a promising step towards reducing plastic pollution and fostering a more sustainable future.

Future Prospects for New Classes of Recyclable Polymers

The future of recyclable polymers is driven by advancements in polymer chemistry and materials science, focusing on creating materials that balance performance with environmental sustainability. Emerging classes of polymers, such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and chemically recyclable polymers like polydiketoenamine (PDK), showcase these improvements.

- Polylactic Acid (PLA): PLA is a biopolymer derived from renewable resources like corn starch or sugarcane. It is biodegradable and compostable under industrial conditions. While it offers a lower tensile strength compared to some synthetic polymers (typically around 50-70 MPa), its benefits include good thermal stability and low environmental impact.

- Polyhydroxyalkanoates (PHA): PHAs are produced by bacterial fermentation of sugars or lipids and are fully biodegradable. They present a wide range of mechanical properties, with tensile strengths comparable to that of traditional plastics (ranging from 20 to 70 MPa). PHAs can degrade in marine environments, making them especially valuable for addressing ocean plastic pollution.

- Polydiketoenamine (PDK): PDK is an innovative class of polymer designed for complete recyclability. Unlike traditional plastics, PDKs can be broken down into their monomers and reformed without degradation of material properties. They exhibit robust mechanical properties, with tensile strength values in a suitable range for various applications, and their recyclability is a significant advancement in polymer technology.

The technical parameters for these new classes of polymers are crucial to their adoption:

- Tensile Strength: Typically ranges from 20 to 70 MPa for PHA, around 50-70 MPa for PLA, and variable for PDK depending on the specific formulation.

- Thermal Resistance: PLA exhibits thermal stability suitable for various applications, while PDKs can potentially achieve high thermal resistance depending on their design.

- Biodegradability: PHAs excel in their ability to degrade in natural environments, including marine conditions, whereas PLA requires industrial composting facilities.

These advancements indicate a promising trajectory towards developing high-performance, environmentally friendly polymers. Continued research and collaboration across disciplines will be essential in overcoming current limitations and achieving widespread adoption.

Frequently Asked Questions (FAQs)

Q: What are polymers in plants?

A: Polymers in plants are large molecules composed of repeating subunits, which often include cellulose and other compounds such as lignin. These polymeric materials contribute to the structural integrity and function of plants.

Q: What natural polymers include in plants?

A: Natural polymers in plants primarily include cellulose, hemicellulose, and lignin. These polymers are known for providing structural support to plant cells and contributing to the overall strength and durability of plant biomass.

Q: How does the chemical structure of plant polymers affect their properties?

A: The chemical structure of plant polymers, including the arrangement of monomers and the presence of crosslinking, significantly impacts their physical properties such as strength, flexibility, and resistance to degradation. Specific configurations can make these polymers highly effective as structural components in plants.

Q: Can polymers from plants be used to replace plastics?

A: Yes, certain polymers made from cellulose and other plant-derived materials can sustainably replace some plastics. These bio-based polymers offer an eco-friendly alternative to conventional petroleum-based plastics, reducing environmental impact and reliance on fossil fuels.

Q: What are copolymers and are they found in plants?

A: Copolymers are polymers composed of two or more different types of monomers. In plants, certain polysaccharides can act as copolymers, contributing to the complexity and functionality of plant cell walls by combining different sugar units.

Q: Are there useful unnatural polysaccharide polymers from plants?

A: Research is ongoing to develop useful unnatural polysaccharide polymers from plant sources. These innovations aim to engineer polysaccharide polymers to become part of new materials that can offer enhanced properties for various applications, including biodegradable plastics and specialized coatings.

Q: How are polymers in plants relevant to living things?

A: Polymers in plants are vital to living things as they form the structural backbone of plant cells, provide energy storage, and contribute to growth and development. For example, cellulose in plant cell walls is crucial for maintaining cell shape and function, while starch serves as an essential energy reserve.

Q: What methods are used to extract or synthesize plant-based polymers?

A: Various methods are used to extract or synthesize plant-based polymers. For example, cellulose can be extracted from plant biomass using chemical or enzymatic processes. Additionally, biotechnological methods can be employed to produce specific polymers in laboratory settings, allowing scientists to design polymers with desired properties.

Q: Can plant-based polymers degrade naturally?

A: Yes, many plant-based polymers, such as those made from cellulose, are biodegradable. This means they can break down naturally over time due to microbial activity, reducing environmental impact compared to traditional plastics that persist in the environment for extended periods.