Polyamide is a kind of hydrostatic fabric that drives today’s textile industry, particularly in the outdoor gears and fashion category. This means it is common in products designed to shield the user from water damage. In this article, we are going to look at the key attributes, uses and advantages of Polyamide waterproof fabric. If you are a hiker interested for instance, in changing your gear, as a designer curious about novel materials or simply focusing on latest textile technologies; then you will find here an extensive guide that will offer you invaluable insights on polyamide waterproof.

What Makes Polyamide Effective as a Waterproof Fabric?

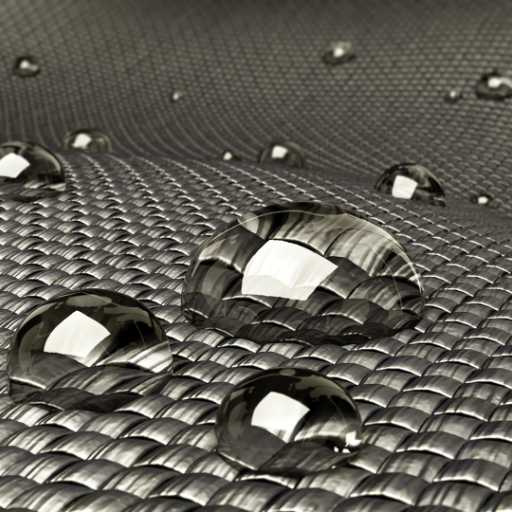

Its dense weave and application of durable water repellent (DWR) coatings majorly make Polyamide fabric effective as a waterproof material. For instance water molecules cannot pass through while the DWR coating causes water to form beads instead of being soaked by it. Moreover these fabrics have strong elasticity and tensile strength which make them very useful under diverse conditions. They give way for polyamide to continue being waterproof even when exposed to normal use and climatic patterns over time.

Understanding the Properties of Polyamide

Nylon, scientifically referred to as polyamide, is known for its wide range of characteristics that make it ideal for waterproof fabrics. Polyamide is extremely strong and tough enough to handle heavy wear and tear without degrading. Consequently, these type of materials have high tensile strength due to their molecular structure characterized by strong hydrogen bonds. Secondly, polyamide has impressive stretchability properties that enable it to return back to its initial form without any damages hence making it suitable for sportswear and camping equipment. In addition, polyamide does not absorb water easily hence enabling it to dry quickly. This aspect is particularly useful in damp regions by ensuring quick drying of clothes while maintaining comfort all through the day. Finally, polyamides are also resistant to chemical attacks thus enhancing the durability of a waterproof fabric against abrasion as well as chemicals such as water and solvents among others. With all these features combined, this makes polyamide a versatile material that can be trusted upon for different uses.

Comparison: Waterproof vs. Water-Resistant

When it comes to outdoor gear and clothing, understanding the difference between waterproof and water-resistant materials is crucial. Waterproof materials are created to withstand even the pressure of water. As a result, they could endure heavy rain as well as submersion without letting any bit of moisture to enter the fabric. Nylon or polyester with special coatings or membranes that completely seal the fabric’s surface represent common waterproof materials.

Otherwise, water-resistant materials are those which can resist some water but not entirely. They are capable of resisting light rains or splashes while if exposed for a long time or put under pressure, water will finally permeate through them. However, in contrast such fabrics only have treatment or coating which causes water to bead up and roll off instead of full protective barrier like in case of waterproof ones.

In sum, though there are certain types of fabrics that may keep away some amount of moisture from coming into contact with our bodies, others provide complete protection against liquid passage; therefore making them ideal for extreme conditions and environments where one might remain wet for a long time.

How Different Nylon Fabric Treatments Work

The approach to improving properties such as water resistance, durability and comfort in nylon fabric varies from one treatment to another. There are several common treatments used on nylon:

- Durable Water Repellent (DWR): This is an ordinary process of making the surface of the fabric water resistant by putting a water-proof coating on it. It makes water bead up and run off so that the wearer is protected against splashing and light rain. Nonetheless, DWR can wear out but this does not mean that it cannot be reapplied to remain effective.

- Silicone Coating: The use of silicon with nylon material results in an incredibly waterproof layer which is still flexible and lightweight. It is therefore quite common in outdoor gears such as tents, tarpaulins, or backpacks made of nylon coated with silicone. This helps in sealing off the fabric from moisture while enhancing its overall strength thereby increasing durability.

- Polyurethane (PU) Coating: In this technique, a PU layer is coated on top of the nylon fabric which makes it waterproof and more long lasting. PU coatings are often used for rain jackets, bags etc among other outdoor equipment’s. A significant merit associated with PU-coated nylons is their cheapness as well as being good at providing waterproof barriers although they add on some weight reducing breathability.

Familiarity with these applications will allow you to make better choices when purchasing nylon-based gear and clothing that meet your needs best.

What Are the Key Features of a Waterproof Polyamide Jacket?

Maximum protection from the elements, long-lastingness and comfort are some of the things a waterproof polyamide jacket is made to offer. Here are some key features:

- Waterproof Membrane: This jacket typically has a breathable yet waterproof membrane that prevents water from penetrating through the fabric but lets moisture vapor escape, keeping you comfortable and dry.

- Sealed Seams: Seams may be taped or sealed to keep water out of stitching which improves overall waterproofing.

- Durability: Polyamide is strong, resistant to scratches and suitable for outdoor uses where it could rub against rough surfaces.

- Lightweight and Packable: Despite being durable, these jackets made of polyamide material are also lightweight and can easily be packed making them convenient for travel and other outdoor activities.

- Windproof Properties: These jackets are not only water-proof but also wind-resistant offering more comfort as well as protection in harsh weather conditions.

- Adjustable Features: To prevent leakage of water or wind, many have adjustable hoods, cuffs, hems etc., thus creating a custom fit.

- Ventilation Options: Some jackets have ventilation zippers or mesh-lined pockets to increase breathability hence enabling one to regulate their body temperature during strenuous physical exercises.

The Role of PU Coating in Waterproof Jackets

Jackets become waterproof by coating them with polyurethane (PU). It is an artificial layer that is applied on the inner side of the cloth to form a strong barrier that will stop water penetration without impeding breathability. The PU forms a microporous structure after undergoing a chemical process; this permits perspiration and moisture vapour to evaporate thus maintaining dryness and comfort from within. Moreover, it enhances garment longevity and resistance against tear and wear. PU coated jackets are notable for their cost-effectiveness as well as dependability under different outdoor circumstances.

Implementing Breathable Fabrics

It is important that outdoor jackets integrate breathable materials as one of their features to allow individuals to feel at ease when engaged in physical activities. Breathable fabrics simply make it possible for water vapour to pass through them while preventing rain from getting inside the jacket. Below are some commonly used materials and technologies:

- GORE-TEX®: A fabric which is known by many people, this material combines waterproofness with breathability through a membrane with micro-pores that will obviate rain but not sweat. As much as GORE-TEX® is well-known for its strength, it is extensively applied in making high-performance outdoor gears.

- eVent® Fabric: Like GORE-TEX®, eVent® fabric uses the Direct Venting™ technique that allows sweat to evaporate rapidly without it gathering within the garment. This keeps a dry and comfortable microclimate.

- Polartec® NeoShell®: With Polartec’s Neoshell technology, this breakthrough material has found a middle ground between breathability and waterproof capability. The soft flexible design of this fabric goes along with an air penetrable layer leading to increased ventilation thus suitable for high intensity activities.

Advanced fabrics like these help in managing moisture effectively on outdoor jackets thus ensuring comfort and performance in various conditions.

Benefits of Using Polyamide Fabric in Outdoor Gear

Polyamide textile, popularly called nylon, is well respected in the manufacture of outdoor clothes due to its unique nature. First, polyamide is known for its great toughness and durability. It does not wear out easily; hence it is useful where the gear undergoes harsh conditions like backpacks meant for hiking and ropes used in climbing. Second, this fabric is light in weight thus making other outdoor gears light without any compromise on toughness. Further still the Polyamide textile has an outstanding capacity to wick moisture away from skin ensuring that perspiration moves through it into outer layers of fabric where evaporation can occur. This factor becomes very vital when one takes part in long-term open-air activities. Lastly, polyamide dries fast which makes it advantageous especially in wet situations since no hazards or discomfort brought about by moist clothes are involved. Combining all these benefits together make polyamides preferable choice for high-performance outdoor gear to keep adventurers comfortable and safe under different environments.

How Does Polyamide Fabric Compare to Polyester?

Polyamide textile and polyester are both options that people make in relation to outdoor gear preferences but have different brands. It is generally observed that polyamide is stronger and last longer than polyester, which makes it more appropriate for gears that will encounter rough or abrasive conditions. Apart from this, the fabric has greater moisture wicking characteristics thus keeping the wearer dry and comfortable even during intense physical activities. On the other hand, polyester tends to be more resilient towards UV damage as well as retaining its shape better over a long period of time. Polyester is also usually cheaper and offers better colorfastness after repeated washing. However, depend on individual needs as well as prevailing factors influencing the outdoor activity; one can choose between polyamide and polyester since both fabrics are lightweight and quick drying.

Durability of Waterproof Polyamide vs. Polyester Fabric

Waterproof polyamide, as a rule, is generally more durable than polyester because of its greater tensile strength and resistance to abrasion. Polyamide fabric is rather tough and can endure harsh conditions which makes it suitable for high-impact activities and equipment that always get worn out. Its flexibility allows it to defy repeated stress without losing structural integrity; this is very important when it comes to use in challenging environments continuously. Conversely, polyester fabric tends to excel in UV resistance, maintaining its strength and appearance under prolonged sun exposure. However, though less strong than polyamide, polyester still has the requisite durability for outdoor uses and is often cheaper as well. In the end, if we are talking about waterproof gear then preference should be given to polyamide for being tougher but polyester provides dependable service at a more affordable price point. Times when polyester suits better include those when wetness or general harsh weather conditions may be avoided or there are budget constraints on buying such clothes.

Cost and Availability of Polyamide and Polyester

Polyester, on the other hand, usually takes the lead when it comes to cost and availability due to its lower production costs and common use. Polyester is produced in large quantities for a variety of uses, so it remains widespread in many forms through various outlets both online and offline. As a result, most consumers as well as manufacturers often choose it since it is pocket friendly.

However, polyamide tends to be more expensive than polyester although it too can be widely found on the market but typically has a higher price due to qualities such as high tensile strength and moisture absorption. Polyamide though less popular than polyester in general consumer markets is still readily available through specialty stores and suppliers serving performance-based applications.

In summary, while they are always around for purchase polyester is commonly cheaper and easier to get whereas polyamide is relatively expensive though mostly used by those seeking specific tastes at its best.

Can Waterproof Polyamide Fabric Be Recycled?

Non-coated textiles have an easier recycling process than waterproof polyamide. This means that the waterproof fabrics must first be stripped of their coatings before the fibers can be reused in an effective manner, rendering the process more complex. Unlike other fabrics for recycling, this process requires specialized facilities that are less accessible and potentially more costly. On the other hand, new ways of recycling are constantly making it easier to recycle waterproof polyamide.

Environmental Benefits of Using Recycled Polyamide Nylon

Recycling polyamide nylon presents a variety of environmental advantages, which make it a preferable choice over virgin nylon. Initially, recycled polyamide involves limited material extraction hence minimizing energy use and reducing greenhouse gas emissions. It also helps in preventing trash from being dumped into landfills thereby decreasing pollution as well. Recycling polyamides also necessitates lesser chemicals and water as compared to manufacturing new nylons thus becoming a more sustainable option. More so by reusing Polyamide materials through recycling we help keep them in use longer reducing the dependency on virgin resources hence promoting responsible resource management within a circular economy.

The Process of Recycling Polyamide and Polyester

Recycling of polyamide and polyester involves some critical stages. The first one is sorting that separates the polyamide and polyester from other forms of plastics and impurities in the collected waste materials. After sorting, the fabric is cleaned to remove any dirt, dyes or coatings.

Polyamide often undergoes cleaning followed by depolymerization which breaks long polymer chains into their monomers. These monomers are then purified, before being repolymerized into new polyamide fibers. On the other hand, polyester usually undergoes a mechanical recycling process where it gets shredded to smaller flakes which are then melted and extruded into new polyester fibers.

Additionally, advanced chemical processes for recycling both polyamides and polyesters have been developed recently in order to improve efficiencies as well as improving quality of recycled products. By so doing, these methods help reduce reliance on virgin raw materials thereby reducing wastefulness and cutting down on environmental footprints in cloth manufacturing.

What Applications Benefit Most from Waterproof Polyamide Fabric?

Particularly useful for outdoor and sports applications is the waterproof polyamide fabric. It is highly resistant to water and its durability makes it perfect for making hiking gears, tents, jackets, pants among others to safeguard against elements of weather. Moreover, this material is commonly used in marine environments where it is made into sails, boat covers and other marine equipment. The automotive manufacturing sector also uses waterproof polyamide for seat covers and interior linings that will withstand different climatic conditions. Besides, it is lightweight yet strong which makes it appropriate for backpacks and suitcases providing long-lasting reliable service.

Outdoor Jacket and Gear

When we think of the use of waterproof polyamide in outdoor jackets and gear, there are a few key benefits that come to mind:

- Water Resistance: Waterproof polyamide fabric effectively repels water, allowing people who enjoy the outdoors to remain dry and comfortable even during damp conditions. It is therefore suitable for hiking jackets, anoraks and other outdoor clothing.

- Durability: The strength and resistance to wear of this material makes it ideal for tough outdoor activities. In any case, whether you are passing through dense forests or moving across rocky terrains, polyamide garments can withstand such elements.

- Breathability: Modern polyamide fabrics are made breathable to allow sweat and moisture out while keeping off raindrops and cold winds. This equilibrium between security and comfort is vital in a physical activity that intends to keep the performance at its best.

Sources:

- REI.com advocates for water resistance and durability in outdoor gear.

- Backcountry.com shows how breathability enables overall comfort in relation with polyamides.

- On Patagonia.com, information about long-lasting performance plus environmental benefits associated with recycling nylon goes into their outerwear line.

This way, manufacturers can make quality, sturdy yet comfortable outerwear like jackets by using Polyamide which meets the requirements of adventure seeking enthusiasts.

Sport and Marine Garments

When it comes to sports and marine clothing, their use of water-resistant polyamide fabric can be of advantage in making sure that performance and comfort are enhanced while operating under wet or difficult conditions. Furthermore, attributes such as water resistance, durability, and breathability highlighted for outdoor jackets and gear are also important for sport and marine applications.

- Water Resistance: This ensures not only that sailors do not get wet because of splashes but it is a way of sailors who engage in regular boat activities staying dry. This feature helps maintain warmth and minimize the likelihood of hypothermia.

- Durability: Marine wear and sports apparel are exposed to some detrimental factors including saltwater, UV rays, physical abrasion among others. As a result, the toughness of nylon fabric makes it an excellent choice with respect to prolonged lifespan despite repeated exposure to these elements.

- Breathability: In addition, breathable materials used in athletic and sea professions help these people avoid moisture resulting from sweat when they are doing their training activities hence creating dryness in them. It becomes even more significant during vigorous exercises which could hinder performance if there is overheating.

Sources:

- Furthermore: West Marine informs us about how important waterproof and durable fabrics are needed for marine clothing.

- Moreover: Helly Hansen states how breathable fabrics increase comfortableness as well as improve the performance achieved by using athletic wears.

- Additionally: Gill Marine points out the significance of the endurance reinforcing waterproof fabrics for marine clothing items’ life span reliability.

Therefore manufacturers can make sportswear products that meet both athletes’ rigorous needs as well as those required by mariners by including waterproof polyamide fabric hence enhancing their safety, convenience and productivity notwithstanding various circumstances.

Everyday Water Resistant Clothing

Waterproof clothes are the bread and butter of people who want a reliable shield against weather conditions yet do not want to forego comfort and style. With modern technologies and substances, water-resistant clothing has become breathable as well as waterproof making it suitable for outdoor activities in unpredictable climates.

- Functionality and Style: Brands like The North Face make jackets that combine water resistance with contemporary aesthetics to ensure you still look good while you keep dry.

- Breathability: Columbia Sportswear shows how important it is to have fabrics that let body sweat evaporate thus keeping them comfortable throughout the day.

- Versatility: Patagonia makes water resistant clothing that can be worn for different activities such as city-to-city commuting or running errands outdoors thus ensuring that your daily gear requirements are met.

Inclusion of these characteristics into everyday water resistant wear enables consumers achieve a perfect mix between functionality and fashion hence making their daily routines manageable irrespective of prevailing climatic factors.

Frequently Asked Questions (FAQs)

Q: What makes polyamide waterproof fabric different from other fabrics?

A: Polyamide waterproof fabric typically incorporates waterproof breathable technologies to prevent moisture from penetrating while allowing vapor to escape. This unique fabric is often used in garments where staying dry is essential, such as jackets and outdoor gear.

Q: How is a polyamide fabric made waterproof?

A: Polyamide fabric is made waterproof by applying a waterproof PU (polyurethane) coating, laminating it with a waterproof breathable layer, or treating the surface with a water-repellent finish. These methods ensure the fabric is waterproof and can withstand wet conditions.

Q: Can polyamide fabric waterproof be recycled?

A: Yes, polyamide fabric waterproof designs can include recycled polyester components, which contribute to eco-friendly practices. Using recycled polyester helps reduce waste and the environmental impact of producing new materials.

Q: What are the benefits of using waterproof breathable fabric in clothing items?

A: Waterproof breathable fabric balances water resistance and breathability, ensuring that the wearer stays dry while preventing overheating. This is particularly useful in jacket fabric and other outdoor clothing designed for active use.

Q: What is the difference between water-repellent and waterproof fabrics?

A: Water-repellent fabrics are treated to resist water but are not completely waterproof. In contrast, waterproof fabrics are designed to prevent water from penetrating the fabric entirely. Understanding waterproof means knowing that a truly waterproof fabric will keep you dry under sustained exposure to moisture.

Q: Is coated nylon the same as polyamide fabric waterproof?

A: Not exactly. Coated nylon is a type of polyamide fabric that has been treated with a waterproof PU coating. While both are resistant fabric types, coated nylon specifically refers to nylon with an added waterproof layer.

Q: What types of garments commonly use polyamide waterproof fabric?

A: Polyamide waterproof fabric is popular in various outdoor and activewear garments, including jackets, pants, and other clothing items. It is especially favored for its durability and water-resistant properties.

Q: How durable is polyamide fabric waterproof compared to other materials?

A: Polyamide fabric waterproof is known for its durability and resistance to wear and tear. Fabrics like ripstop nylon fabric and tear-resistant woven fabric enhance its strength, making it suitable for rigorous activities.

Q: Which is better for stretch waterproof garments, nylon spandex fabric or full dull nylon?

A: Nylon spandex fabric is better for stretch waterproof garments due to its flexibility and comfort. Full dull nylon offers a non-glossy finish but may not provide the same level of stretch, making nylon spandex the preferred choice for activewear that requires range of motion.

Q: How do you care for polyamide waterproof garments to maintain their waterproof properties?

A: To maintain the waterproof properties of polyamide garments, it is advisable to follow the care instructions on the label. Generally, you should wash them with a mild detergent, avoid fabric softeners, and reapply a water-repellent treatment periodically to ensure the fabric remains effective.