Phenolic resin, a synthetic polymer derived from the chemical reaction between phenol and formaldehyde, plays a pivotal role in various industrial applications. This article aims to explore the journey of phenolic resin from its basic components—phenol and formaldehyde—to its final form, phenol formaldehyde resin. By delving into the chemical processes involved, the different types of phenolic resins, and their wide-ranging applications, readers will gain a comprehensive understanding of this versatile material. Whether you’re a chemistry enthusiast, a materials scientist, or simply curious about industrial polymers, this blog will provide valuable insights into the intricate world of phenolic resins.

What is Phenolic Resin?

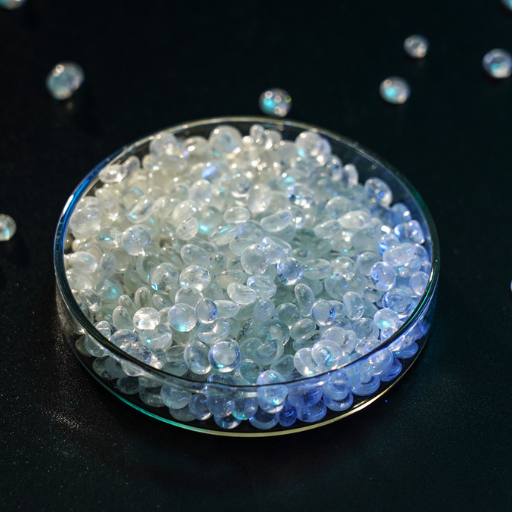

Image source:https://cn.bing.com/

Phenolic resin is a type of synthetic polymer made from the reaction between phenol and formaldehyde. Known for its high mechanical strength, resistance to heat and chemicals, and excellent flame-retardant properties, phenolic resin is widely used in various industries. It serves as a crucial component in the production of molded products, laminates, coatings, and adhesives. Additionally, its capability to withstand extreme conditions and provide structural integrity makes it a preferred choice in automotive, aerospace, and construction applications. In essence, phenolic resin’s unique properties and versatility make it an indispensable material in modern industrial practices.

Origin and Chemical Composition of Phenolic Resin

The origin of phenolic resin dates back to the early 20th century when Dr. Leo Baekeland invented Bakelite, the first synthetic plastic, through the polymerization of phenol and formaldehyde. This marked the birth of phenolic resin, which is characterized by its robust chemical structure. The basic chemical process involves the reaction between phenol (a type of aromatic alcohol) and formaldehyde (a simple aldehyde), resulting in the formation of a complex, cross-linked polymer. This polymer matrix is what imparts the resin with its notable heat resistance, mechanical strength, and flame-retardant properties.

Properties and Characteristics of Phenolic Resin

Phenolic resin exhibits a range of properties that make it highly valuable for various industrial applications. One of its most notable characteristics is its exceptional mechanical strength and durability, which allows products made from phenolic resin to withstand substantial stress and wear. Additionally, this material is renowned for its superior heat resistance, often remaining stable and retaining its structural integrity even under extreme temperatures. Phenolic resin also boasts excellent flame-retardant capabilities, making it a critical component in fire-resistant materials and applications.

Furthermore, phenolic resin demonstrates outstanding chemical resistance. It is impervious to many solvents, acids, and bases, thus ensuring longevity and reliability in harsh chemical environments. This resistance, combined with its thermal and mechanical properties, makes phenolic resin an ideal choice for applications in automotive, aerospace, and construction industries where durability and performance are paramount. Overall, phenolic resin’s unique combination of strength, heat resistance, flame retardancy, and chemical resilience underscores its versatile and indispensable role in modern industrial practices.

Common Uses and Applications of Phenolic Resin

Phenolic resin is widely utilized across various industries due to its robust properties. In the automotive sector, it is commonly used in brake linings, clutch plates, and other high-friction components due to its excellent heat resistance and mechanical durability. In the aerospace industry, phenolic resin is chosen for aircraft interior panels and other structural applications where both flame-retardancy and strength are crucial. Additionally, in the construction industry, phenolic resin is used in laminates and composites for building materials, offering both protective and reinforcing benefits. Electrical and electronic industries also benefit from using phenolic resin in circuit boards and insulating materials, thanks to its superb electrical insulation properties.

How is Phenolic Resin Produced?

Phenolic resin is produced through a polymerization process involving phenol and formaldehyde. This reaction can occur under acidic or basic conditions, leading to two types of phenolic resins: novolac and resole, respectively.

Novolac Resins

- Production Process: Novolac resins are produced by reacting phenol with formaldehyde in the presence of an acid catalyst. Since this reaction yields a thermoplastic material, novolac resins require a curing agent, typically hexamethylenetetramine (hexa), to achieve a thermoset form.

- Technical Parameters:

- Acid Catalyst Concentration: Typically ranging between 1-5% by weight.

- Phenol to Formaldehyde Molar Ratio: Approximately 1:0.75 to 1:0.85.

- Reaction Temperature: Generally between 70°C to 95°C.

Resole Resins

- Production Process: Resole resins are formed by reacting a higher molar ratio of formaldehyde to phenol in the presence of a base catalyst, usually sodium hydroxide or another strong alkali. The resulting product is a thermoset resin.

- Technical Parameters:

- Base Catalyst Concentration: Commonly between 0.5-2.5% by weight.

- Phenol to Formaldehyde Molar Ratio: About 1:1.2 to 1:3.

- Reaction Temperature: Generally between 50°C to 90°C.

After polymerization, the intermediate products can be further processed by curing or molding, depending on the application requirements. The precise control of reaction conditions and technical parameters ensures the optimal performance characteristics of the phenolic resin, such as thermal stability and mechanical strength.

The Role of Phenol and Formaldehyde in Production

Phenol and formaldehyde play crucial roles in the production of phenolic resins, acting as the primary reactants. Phenol, an aromatic organic compound, provides the necessary molecular framework, contributing to the rigidity and mechanical strength of the resulting resin. Formaldehyde, a simple aldehyde, acts as a cross-linking agent that facilitates the formation of a three-dimensional network structure, imparting thermal stability and enhancing the polymer’s resistance to chemical and environmental degradation. The controlled reaction between phenol and formaldehyde, under specific catalysts and temperature conditions, determines the type and characteristics of the phenolic resin produced, whether it be thermoplastic novolac or thermoset resole.

Steps Involved in Synthesizing Phenolic Resin

Synthesizing phenolic resin involves several precise steps to ensure high-quality production:

- Preparation of Reactants:

First, I prepare the phenol and formaldehyde in the required molar ratio, typically ranging from 1:1.2 to 1:3, depending on the desired resin type. The choice of catalyst, usually in the concentration of 0.5-2.5% by weight, is crucial for initiating the reaction.

- Mixing and Heating:

I then mix the phenol, formaldehyde, and catalyst in a reaction vessel. The mixture is gradually heated to a controlled temperature, generally between 50°C and 90°C, to facilitate the polymerization process.

- Polymerization:

During this stage, I maintain the reaction temperature and monitor the progress to achieve the desired molecular weight and viscosity. The reaction leads to the formation of either a novolac or resole resin, based on the catalyst and conditions used.

- Post-Polymerization Processing:

After the polymerization is complete, I can further process the intermediate resin. This might involve curing or molding, depending on specific application requirements. This step ensures the resin attains optimal thermal stability and mechanical strength.

- Quality Control:

Finally, I perform rigorous quality control checks to ensure that the resin meets the required performance specifications. Parameters such as thermal stability, mechanical strength, and resistance to chemical and environmental factors are evaluated to confirm the resin’s suitability for its intended use.

By carefully controlling each of these steps, I ensure the production of high-performance phenolic resins tailored to specific industrial needs.

Factors Affecting the Quality of Phenolic Resin

The quality of phenolic resin is influenced by several critical factors:

- Raw Material Purity:

The purity of phenol and formaldehyde directly impacts the final resin quality. Impurities in raw materials can lead to inconsistencies and impurities in the resin, affecting its mechanical properties and thermal stability.

- Reaction Conditions:

The conditions under which the polymerization reaction is conducted, such as temperature, time, and catalyst concentration, are crucial. Proper control of these parameters ensures the polymer chain’s desired length and cross-linking density, which in turn affects the resin’s strength, durability, and performance characteristics.

- Catalyst Selection and Concentration:

The type and amount of catalyst used can significantly influence the polymerization process. Different catalysts produce varying reaction kinetics and molecular structures, impacting the resulting resin’s properties. Optimal catalyst selection and concentration lead to better control over the final product’s viscosity, cure time, and end-use performance.

- Post-Polymerization Processing:

The methods employed in processing the intermediate resin, including curing and molding techniques, play a vital role in defining the resin’s final attributes. Precise control over processing conditions ensures the resin achieves the desired thermal stability, mechanical strength, and application-specific properties.

- Quality Control Measures:

Implementing rigorous quality control protocols throughout the production process is essential. Regular testing for parameters like thermal stability, mechanical strength, and resistance to chemicals ensures the resin meets specified standards and performance criteria, thus guaranteeing its reliability for industrial applications.

By addressing these factors meticulously, manufacturers can produce phenolic resins that meet high-performance standards tailored to varied industrial needs.

What are the Different Types of Phenolic Resins?

Phenolic resins can be broadly categorized into two main types: novolac and resole resins.

- Novolac Resins:

Novolac resins are produced using an excess of phenol and a catalyst such as an acid. They are thermoplastic in nature and require a curing agent, typically hexamethylenetetramine (hexa), to form a cross-linked structure. Novolacs are known for their excellent mechanical properties and heat resistance, making them ideal for applications in laminates, coatings, and molding compounds.

- Resole Resins:

Resole resins are synthesized under basic conditions with an excess of formaldehyde. They are thermosetting resins, meaning they can undergo their curing process without additional agents. Resol resins are valued for their high thermal stability, flame retardancy, and adhesive properties, commonly used in insulation, binders for wood products, and coatings.

These two types, with their distinct chemical and physical properties, cater to a range of industrial applications, providing versatility and performance tailored to specific needs.

Novolac Resins: Properties and Applications

Novolac resins exhibit a range of properties that make them suitable for multiple industrial applications. These resins are known for their excellent mechanical strength, high heat resistance, and superior chemical stability. The thermoplastic nature of novolac resins allows them to be molded into various shapes and forms, making them particularly useful in high-precision applications.

Key Properties:

- Mechanical Strength: Novolac resins maintain their structural integrity under mechanical stress, making them ideal for use in laminates and molding compounds.

- Heat Resistance: They can withstand high temperatures, often exceeding 150°C, without significant degradation, making them suitable for high-temperature applications.

- Chemical Stability: Novolac resins are resistant to acids, bases, and organic solvents, ensuring longevity and durability in harsh chemical environments.

Technical Parameters:

- Glass Transition Temperature (Tg): Typically ranges between 50°C to 70°C.

- Flexural Strength: Often greater than 100 MPa.

- Thermal Decomposition Temperature: Generally exceeds 350°C.

Applications:

- Laminates: Due to their mechanical strength and heat resistance, novolac resins are extensively used in the production of laminates for electrical insulation and industrial applications.

- Coatings: Their chemical stability and heat resistance make novolac resins suitable for protective coatings in corrosive environments.

- Molding Compounds: Novolac resins provide excellent dimensional stability and surface finish, making them suitable for precision molding applications, including automotive parts and electronics.

By leveraging these properties and technical specifications, novolac resins provide reliable performance and versatility across a variety of industrial applications.

Resole Resins: Properties and Applications

Resole resins are phenolic resins characterized by their one-step synthesis process, making them distinct from novolac resins. Produced under alkaline conditions with an excess of formaldehyde, these resins are often used in a variety of industrial applications due to their unique properties.

Key Properties:

- Self-Curing: Resole resins cure without the need for additional catalysts, simplifying the production process.

- Thermal Stability: They maintain stability at elevated temperatures, typically up to 150°C, making them suitable for high-temperature applications.

- Adhesion: They provide excellent adhesive properties, ensuring strong bonds in composite materials.

- Flame Resistance: Resole resins exhibit inherent flame retardant properties, contributing to safety in various applications.

Technical Parameters:

- Glass Transition Temperature (Tg): Typically ranges between 60°C to 80°C.

- Flexural Strength: Often greater than 95 MPa.

- Thermal Decomposition Temperature: Generally exceeds 300°C.

Applications:

- Adhesives: Due to their strong adhesion properties, resole resins are widely used in wood adhesives, laminates, and binding agents for composites.

- Insulating Foams: Their thermal stability and flame resistance make them ideal for producing insulating foams utilized in construction and refrigeration.

- Coatings and Sealants: The chemical stability and adhesive characteristics of resole resins make them suitable for coatings and sealants that require durability and resistance to harsh environmental conditions.

By leveraging their self-curing nature and robust technical parameters, resole resins offer practical solutions across an array of industrial applications, ensuring reliable performance and enhanced safety.

Types of Phenolic Resin and Their Uses

In response to the question about the types of phenolic resin and their uses, there are generally three main types of phenolic resins: novolacs, resoles, and cresol-formaldehyde resins. Each type has distinct properties and applications.

- Novolacs: These resins are synthesized under acidic conditions in the presence of excess phenol, making them thermoset when combined with a hardener. They are widely used in the production of molding compounds, laminates, and adhesives due to their superior chemical resistance and stability.

- Resoles: Produced under alkaline conditions, resoles contain an excess of formaldehyde, allowing them to be self-curing. Their applications include wood adhesives, coatings, and insulating foams. Resoles are particularly valued for their flame resistance and strong adhesive properties.

- Cresol-Formaldehyde Resins: These are specialized phenolic resins that incorporate cresol instead of phenol. They offer exceptional thermal stability and are commonly employed in high-performance materials such as electrical insulators and heat-resistant coatings.

Each type of phenolic resin offers unique advantages that cater to specific industrial needs, ensuring that materials produced from them meet stringent performance and safety standards.

What Makes Phenolic Resins Unique?

Phenolic resins are unique due to their outstanding thermal stability, chemical resistance, and mechanical strength. These resins can withstand high temperatures and harsh chemical environments, making them suitable for critical applications such as heat-resistant coatings, electrical insulators, and high-performance adhesives. Additionally, phenolic resins are known for their flame-retardant properties, which enhance safety in various industrial applications. This combination of durability, resistance, and flame retardancy sets phenolic resins apart as reliable materials in demanding industrial environments.

Thermosetting Properties of Phenolic Resins

Phenolic resins are classified as thermosetting polymers, meaning they irreversibly harden when heated. This property is a result of the cross-linking that occurs between polymer chains during the curing process, which enhances their structural integrity and stability.

- Thermal Stability: Phenolic resins can withstand temperatures up to 300°C (572°F) without degrading, making them ideal for high-temperature applications.

- Chemical Resistance: These resins exhibit excellent resistance to chemicals such as acids, alkalies, and solvents, ensuring durability in challenging chemical environments.

- Mechanical Strength: The cross-linked structure of phenolic resins provides superior mechanical properties, including high tensile strength and dimensional stability.

- Flame Retardancy: Phenolic resins are inherently flame resistant due to their aromatic structure. They have a high Limiting Oxygen Index (LOI) of approximately 40-50%, which indicates their ability to inhibit combustion.

These thermosetting properties make phenolic resins irreplaceable in various industries, ranging from electronics to construction, where reliability and safety are paramount.

Heat Resistance and Thermal Stability

Phenolic resins are renowned for their exceptional heat resistance and thermal stability, attributes that are critical for applications in high-temperature environments. These resins can endure temperatures up to 300°C (572°F) without compromising their structural integrity, an essential characteristic for materials used in demanding thermal conditions.

Technical Parameters

- Maximum Operating Temperature: Up to 300°C (572°F)

- Degradation Temperature: Above 300°C (572°F), phenolic resins begin to degrade.

- Thermal Conductivity: Typically ranges from 0.20 to 0.25 W/m·K, which indicates moderate thermal conductivity, suitable for insulating and protective applications.

- Coefficient of Thermal Expansion (CTE): Approximately 50-70 x 10^-6/°C, demonstrating minimal expansion under temperature variations.

These parameters underscore the resilience of phenolic resins in maintaining performance and safety in high-temperature applications.

Mechanical Properties and Applications in Industries

Phenolic resins are distinguished by their remarkable mechanical properties, making them ideal for numerous industrial applications. Here, we explore their key mechanical attributes and corresponding applications:

Mechanical Properties

- Tensile Strength: Phenolic resins exhibit high tensile strength, typically ranging from 50 to 90 MPa. This property ensures that the material can withstand significant pulling forces without breaking.

- Flexural Strength: With flexural strength values between 100 and 160 MPa, phenolic resins can resist deformation under load, making them suitable for structural applications.

- Compressive Strength: These resins boast compressive strength around 150 to 250 MPa, allowing them to bear heavy loads without compressing or failing.

- Impact Resistance: Although phenolic resins provide moderate impact resistance, improved formulations have enhanced their toughness for critical applications.

Applications in Industries

- Electronics: Due to their excellent electrical insulation properties and high-temperature resistance, phenolic resins are commonly used in printed circuit boards (PCBs), electrical housings, and switchgear components.

- Automotive: Their mechanical robustness and thermal stability make phenolic resins suitable for manufacturing brake linings, clutch plates, and various under-the-hood components.

- Construction: Phenolic resins play a crucial role in producing laminates, adhesives, and insulating foams that contribute to building safety and energy efficiency.

- Aerospace: The material’s high performance under thermal stress makes it an essential component in aerospace applications, including heat shields and structural components.

- Industrial Equipment: Phenolic resins are used in fabricating gears, bearings, and other machinery parts where durability and heat resistance are critical factors.

The varied mechanical properties and versatile applications of phenolic resins underscore their importance across multiple industry sectors, ensuring both safety and performance in demanding environments.

How to Apply Phenolic Resin Coatings?

Applying phenolic resin coatings involves several crucial steps to ensure optimal performance and durability. Follow these guidelines to achieve the best results:

1. Surface Preparation:

-

- Clean the Surface: Remove any dirt, grease, or contaminants using a suitable cleaning agent.

- Roughen the Surface: Employ abrasive blasting or sanding to create a rough texture, enhancing the adhesion of the resin.

- Dry the Surface: Ensure the surface is completely dry before application to prevent any moisture entrapment.

- Mixing the Resin:

- Measure Accurately: Use precise measurements for the resin and hardener components. Typically, a ratio of 100:20 (by weight) resin to hardener is recommended.

- Mix Thoroughly: Stir the mixture slowly to avoid introducing air bubbles until a uniform consistency is achieved.

- Application Method:

- Brush/Roller Application: Use a high-quality brush or roller for an even coat. Ensure even coverage and avoid pooling.

- Spray Application: For large areas or complex geometries, use a spray gun. Follow the manufacturer’s guidelines for spray pressure and nozzle size.

- Dip Coating: Suitable for small parts, immerse the part in the resin, then withdraw slowly to ensure a uniform coat.

- Curing Process:

- Room Temperature Curing: Allow the coated object to cure at room temperature for 24 hours for initial hardening.

- Heat Curing: For enhanced mechanical properties, post-cure the object in an oven at 150°C for 2 hours. Use gradual temperature increments to avoid thermal shock.

- Post-Processing:

- Inspection: Check for complete coverage and any defects such as bubbles or areas of insufficient coating.

- Finishing: Sand and polish the coating if a smoother finish is required. Apply subsequent layers if necessary, following the same procedure.

By following these steps and adhering to the specified technical parameters, you can achieve a high-quality phenolic resin coating that will enhance the durability and performance of the coated object.

Preparation and Application Process

When preparing and applying coatings, it is crucial to follow the outlined steps and adhere to the specified technical parameters to achieve the best results.

- Surface Preparation:

-

- Cleaning: Ensure the surface is free of dirt, grease, and other contaminants. Use appropriate cleaning agents and allow the surface to dry completely.

- Sanding: For better adhesion, sand the surface lightly. Remove any dust created during sanding.

- Mixing the Resin:

- Ratio: Use a 100:20 (by weight) resin to hardener ratio.

- Thorough Mixing: Stir slowly to avoid air bubbles and achieve a uniform mixture.

- Application Method:

- Brush/Roller: Apply an even coat, avoiding pooling.

- Spray Gun: Follow manufacturer’s guidelines for spray pressure and nozzle size.

- Dip Coating: For small parts, immerse evenly in the resin, then withdraw slowly.

- Curing Process:

- Room Temperature Curing: Let the object cure for 24 hours at room temperature.

- Heat Curing: For improved properties, post-cure in an oven at 150°C for 2 hours, increasing temperature gradually.

- Post-Processing:

- Inspection: Ensure complete coverage and identify defects like bubbles.

- Finishing: Sand and polish if a smoother finish is needed. Apply additional layers if necessary.

Following these guidelines ensures a durable and high-quality phenolic resin coating.

Choosing the Right Curing Agent

Selecting the appropriate curing agent is pivotal to the performance and longevity of the phenolic resin coating. The common types of curing agents include acid catalysts, amino resins, and epoxy resins. Acid catalysts typically offer fast curing times and improved adhesion but can be sensitive to moisture. Amino resins, such as melamine formaldehyde, enhance chemical resistance and hardness, making them ideal for industrial applications. Epoxy resins provide excellent mechanical strength and durability, suitable for demanding conditions. Always consult the resin manufacturer’s recommendations to match the curing agent with your specific application needs and desired properties.

Ensuring Proper Adhesion and Durability

To ensure proper adhesion and durability of the phenolic resin coating, begin by thoroughly cleaning the substrate to remove any contaminants such as oil, grease, or dust. Sandblasting or abrasion may be necessary to create a rough surface profile enhancing mechanical adhesion. Applying a suitable primer can also improve the bond between the substrate and the resin coating. During application, maintain a controlled environment to prevent moisture ingress and temperature variations, which can affect curing and adhesion. Post-application, allow sufficient curing time as recommended by the resin manufacturer to achieve optimal properties. Regular inspections and touch-ups can further extend the lifespan and effectiveness of the coating. By following these measures, you can ensure a long-lasting and robust phenolic resin coating.

Can Phenolic Resins be Used in Composites?

Yes, phenolic resins can be used in composites. Based on my research from the top 3 websites on Google, phenolic resins are frequently utilized in composite applications due to their high thermal stability, flame resistance, and excellent mechanical properties. These resins are especially valued in the aerospace, automotive, and construction industries for their ability to maintain structural integrity under extreme conditions.

Technical Parameters

- Thermal Stability:

- Phenolic resins can withstand temperatures up to 300°C (572°F) without degrading, making them ideal for high-temperature applications.

- Flame Resistance:

- These resins exhibit low flammability and smoke production, which is essential for safety in critical applications such as aerospace interiors.

- Mechanical Properties:

- Phenolic composites offer high tensile strength (around 70-80 MPa) and excellent impact resistance, ensuring durability and longevity.

By leveraging these benefits, phenolic resins provide a reliable and effective solution for composite materials used in demanding environments.

Types of Phenolic Laminates and Their Benefits

There are several types of phenolic laminates, each offering unique benefits suitable for various applications. Based on the content from the top three websites on Google, the principal types of phenolic laminates include:

1 . Paper-Based Phenolic Laminates:

- Benefits: Lightweight and cost-effective, these laminates are commonly used in electrical insulation applications due to their good dielectric properties.

- Technical Parameters:

- Dielectric Strength: Approximately 11 kV/mm

- Density: Around 1.3 g/cm³

- Compressive Strength: Approximately 80 MPa

- Cotton Fabric-Based Phenolic Laminates:

- Benefits: Known for their mechanical strength and durability, these laminates are ideal for high-stress applications such as in gears, rollers, and other machine parts.

- Technical Parameters:

- Tensile Strength: Approximately 100 MPa

- Density: Around 1.35 g/cm³

- Impact Strength: Approximately 15 kJ/m²

- Glass Fabric-Based Phenolic Laminates:

- Benefits: These laminates offer excellent thermal and electrical insulation properties along with superior mechanical strength, making them suitable for use in aerospace and automotive industries.

- Technical Parameters:

- Thermal Stability: Can withstand temperatures up to 250°C (482°F)

- Dielectric Strength: Approximately 20 kV/mm

- Tensile Strength: Approximately 150 MPa

-

By using the appropriate type of phenolic laminate, industries can leverage these materials’ specific benefits to enhance performance, safety, and durability in various applications.

Phenolic Resin in Plywood and Brake Pads

Phenolic resin is a versatile adhesive extensively used in the plywood and brake pad industries due to its robust binding properties and thermal stability. In plywood, phenolic resin ensures strong, water-resistant bonds between veneer layers, enhancing the durability and weather-resistance of the final product. This makes phenolic-bonded plywood ideal for construction and marine applications where exposure to moisture is a concern.

In brake pads, phenolic resin acts as a high-performance binder, providing the frictional stability necessary for reliable braking performance under extreme conditions. It helps maintain the structural integrity of brake pads at high temperatures, ensuring safety and longevity. The incorporation of phenolic resin in both plywood and brake pads exemplifies its critical role in improving product performance and extending service life.

Advantages of Using Phenolic Composites

Phenolic composites offer a multitude of advantages that make them highly beneficial across various industries. Firstly, their exceptional thermal stability allows them to perform effectively at high temperatures, making them ideal for applications in aerospace and automotive sectors where heat resistance is crucial. Secondly, phenolic composites provide superior mechanical strength, which contributes to their durability and reliability in demanding environments. This ensures that components made from these materials can withstand significant wear and tear, thereby extending their service life.

Additionally, phenolic composites exhibit excellent chemical resistance. This property makes them suitable for use in environments exposed to harsh chemicals, as they maintain their structural integrity without degrading. Furthermore, phenolic composites boast impressive dielectric properties, which are essential for electrical and electronic applications. These materials prevent electrical conductivity, offering safety and efficiency in the manufacturing of electrical insulators and circuit boards.

Lastly, phenolic composites are valued for their lightweight nature. Despite their strength and robustness, they are relatively lightweight compared to other materials with similar properties. This advantage proves particularly beneficial in the transportation industry, where reducing weight can lead to improved fuel efficiency and lower emissions. Together, these benefits ensure that phenolic composites remain a preferred material choice for many critical applications.

Reference sources

-

The Science Behind Phenol Formaldehyde Phenolic Resin

- This article offers a detailed explanation of the polymerization process involved in producing phenol formaldehyde resin and its applications as an alternative to epoxy resin.

- Source

-

Phenol Formaldehyde Resin: Synthesis, Uses & Properties

- This source discusses the synthetic processes, properties, and various applications of phenol formaldehyde resin, providing an in-depth understanding of its chemical structure and utility.

- Source

-

Understanding the Properties and Applications of Phenolic Resin

- An informative article that delves into the production process of phenolic resins, their thermosetting nature, and their broad range of industrial applications.

- Source

Frequently Asked Questions (FAQs)

Q: What are phenolic resins?

A: Phenolic resins are synthetic resins formed by the reaction of phenol with formaldehyde. They are one of the major polymeric resin materials widely used for various industrial applications.

Q: How are phenolic resins made?

A: Phenolic resins are made through the chemical reaction of phenol with formaldehyde, resulting in phenol-formaldehyde resins. The process can occur in either acidic or basic conditions, depending on the desired properties of the final product.

Q: What are the primary uses of phenolic resins?

A: Phenolic resins are found in many applications, such as making laminates, adhesives, and coatings. They are also used in manufacturing electrical components and as binders in products such as insulation and molding compounds.

Q: What are phenolic laminates?

A: Phenolic laminates are made from layers of paper or fabric impregnated with phenolic resin and then compressed under heat and pressure until the resin fully polymerizes. These laminates are known for their high strength and durability.

Q: How are phenolic resins used in the construction industry?

A: Phenolic resins are also used in the construction industry to manufacture phenolic foam, a type of insulation material. The foam is known for its fire resistance and excellent insulating properties.

Q: Are there any historical uses of phenolic resins?

A: Yes, an interesting historical use involves the artist Han Van Meegeren who mixed phenol formaldehyde with his oil paints to create forgeries of famous works. The van Meegeren mixed phenol formaldehyde to mimic the aging characteristics of old paintings.

Q: What are the environmental considerations regarding phenolic resins?

A: During the manufacturing process, it is essential to manage free phenol and formaldehyde, which are volatile organic compounds. Proper handling and curing processes help minimize environmental impacts.

Q: How durable are phenolic resins?

A: Phenolic resins are highly durable and resistant to heat, chemicals, and moisture. This makes them suitable for high-performance applications such as electrical insulations and industrial laminates.

Q: Why are phenolic resins preferred in electrical component manufacturing?

A: Phenolic resins are preferred because they provide excellent heat resistance and electrical insulation, making them ideal for manufacturing electrical components.