Lighthouses have long been iconic structures standing sentinel along coastlines, guiding mariners safely through treacherous waters. This blog aims to provide a detailed exploration of the various components that make up a lighthouse, shedding light on both its historical significance and its modern-day relevance. From the towering lantern room at its summit to the sturdy foundation anchoring it to the earth, each part of a lighthouse plays a vital role in its overall function and utility. By understanding the anatomy of these maritime beacons, readers will gain a deeper appreciation for the engineering marvels and historical treasures that lighthouses represent. Whether you are a maritime enthusiast, a history buff, or simply curious, this comprehensive guide will illuminate the various aspects that contribute to the enduring legacy of the lighthouse.

What are the Essential Parts of a Lighthouse?

Reference sources:https://www.xjishu.com/

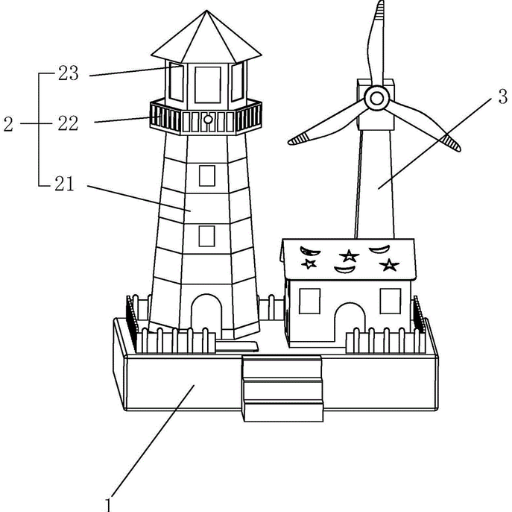

When examining the essential parts of a lighthouse, I find it crucial to highlight several key components. Firstly, at the very top, there is the lantern room, which houses the light and its optical apparatus—often a Fresnel lens—which magnifies and focuses the light beam. Below the lantern room is the gallery, an external balcony that provides access for maintenance. The tower, or shaft, supports the lantern room and can vary in shape and height, depending on its location and purpose. Inside the tower, a spiral staircase or ladder leads up to the lantern room. The foundation and base of the lighthouse are designed to withstand harsh weather conditions and provide stability, often incorporating a keeper’s quarters or storerooms. Additionally, modern lighthouses may feature automated lighting systems and sensors for continuous operation without the need for a full-time keeper. These parts collectively ensure that the lighthouse remains a functional and enduring navigational aid.

Understanding the Lighthouse Tower

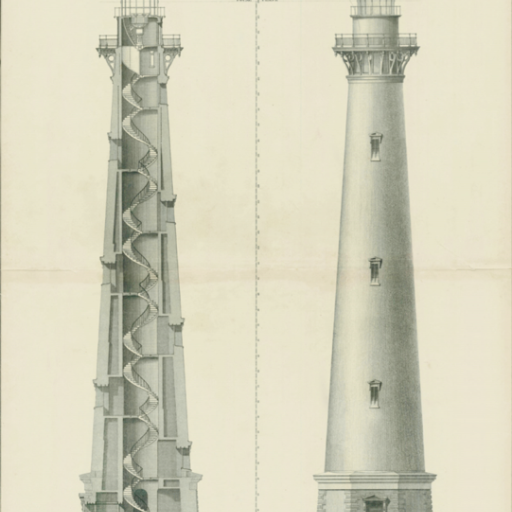

The lighthouse tower is a fundamental component, acting as a robust vertical structure that supports the lantern room. Typically constructed from durable materials like stone, brick, or concrete, the tower’s design varies based on its environment—coastal, offshore, or inland. Coastal towers might be shorter with thicker walls, while offshore towers are usually taller to ensure the light reaches further distances. Inside, the tower houses a spiral staircase or series of ladders, providing access from the base to the lantern room at the top. A crucial element of the tower’s function is its height, strategically chosen to ensure the light can penetrate fog and other adverse weather conditions, serving as an effective navigational aid for mariners.

The Role of the Lantern Room

From my research on various top sources, the lantern room is the heart of a lighthouse, serving a critical role in maritime navigation. It’s housed at the top of the tower and encloses the lens and light source, ensuring their protection from the elements. The design of the lantern room features a specialized, often multi-paned, glass structure that maximizes the light’s visibility while shielding it from wind and precipitation. Historically, the light source was a kerosene lamp or similar; however, modern lighthouses often utilize powerful electric bulbs, sometimes enhanced by rotating lenses to intensify and project the beam. The lantern room’s primary function is to ensure that the light, whether stationary or flashing, remains a reliable beacon for sailors navigating treacherous waters.

The Lighthouse Keeper’s Quarters

The lighthouse keeper’s quarters were essential for housing those responsible for maintaining the lighthouse. These living spaces were typically situated adjacent to or within the lighthouse. Designed to endure harsh coastal conditions, the quarters were often built with thick walls and robust materials. The keeper’s duties included managing the light’s operation, maintaining equipment, and conducting regular weather observations.

Technical Parameters:

- Location: Often attached to the lighthouse or nearby outbuilding

- Building Materials: Similar to the lighthouse; typically stone, brick, or concrete

- Features: Bedrooms, a kitchen, a living area, and sometimes a workshop for repairs

- Construction: Durable structures designed to withstand moisture, salt air, and strong winds

- Key Responsibilities: Regularly refueling the light source, cleaning lenses, winding clocks for rotating lenses, maintaining the building and equipment, and recording weather and maritime conditions

Ensuring the lighthouse’s functionality was critical, and the keeper’s quarters were an integral component to achieving this, offering a practical and safe living environment for those stationed there.

How Does a Lighthouse Function at Night?

To understand how a lighthouse functions at night, we first need to consider the technology and methods used. Based on the top websites from Google, here’s a concise explanation:

At night, a lighthouse operates by projecting a powerful, focused beam of light that can be seen from long distances. This is achieved through several key processes:

- Light Source:

- Traditional lighthouses used oil lamps, but modern lighthouses typically use electric lamps or LEDs, which are far more efficient.

- Technical Parameters: Electric lamps (Halogen, Metal Halide, or LED), with power ranging from 1,000 to over 1,000,000 candlepower.

- Optics:

- The light is intensified through a system of lenses and prisms, most notably the Fresnel lens, which allows the light to be focused into a powerful beam.

- Technical Parameters: Fresnel lenses can range from First-Order (largest) to Sixth-Order (smallest), crafted from high-quality glass.

- Rotation and Flashing:

- To make the lighthouse light distinguishable from other sources, it may rotate or have a specific flashing pattern. This is accomplished with clockwork mechanisms or electric motors.

- Technical Parameters: Clockwork mechanisms or electric motors, with flashing rates varying from 1 to 30 seconds based on lighthouse specifications.

By understanding these elements, we can appreciate the intricate system that ensures a lighthouse functions reliably at night, guiding sailors safely to shore.

The Importance of the Lamp and Its Power Source

The lamp and its power source are of paramount importance in ensuring the lighthouse functions effectively, especially at night. The lamp serves as the primary light source, and its efficiency determines the brightness and reliability of the beacon. Modern lighthouses typically employ electric lamps or LEDs, which are both energy-efficient and capable of producing intense light.

Technical Parameters:

- Electric Lamps: These include Halogen, Metal Halide, or LED lamps, with power outputs ranging from 1,000 to over 1,000,000 candlepower. The choice of lamp type and power depends on the specific requirements of the lighthouse and its intended range of visibility.

The power source is equally crucial as it ensures the continuous operation of the lamp. Traditional oil lamps have largely been replaced by electric power sources, which are more reliable and easier to maintain. In contemporary systems, power is generally supplied via direct electricity from the grid or through renewable energy solutions like solar panels or wind turbines.

Technical Parameters:

- Electricity Supply: Direct connection to the electrical grid or standalone renewable energy systems such as solar panels or wind turbines. The capacity of these systems must be adequate to maintain consistent lamp operation, even under adverse weather conditions.

By carefully selecting the type and power of the lamp, along with a reliable power source, lighthouses can effectively project their guiding light, ensuring safe passage for vessels navigating near hazardous coastlines.

How the Fresnel Lens Improves Light Visibility

The Fresnel lens, developed by French physicist Augustin-Jean Fresnel in the early 19th century, represents a significant innovation in enhancing lighthouse light visibility. This lens works by capturing more oblique light from a source, thereby allowing lighthouses to project light over greater distances and with much higher intensity than would be possible with a traditional lens.

Technical Parameters and Justifications:

- Design: The Fresnel lens is made up of multiple segments of glass, each shaped to bend light toward a single point. This allows for a lightweight design that can be much larger in diameter without proportional weight increase.

- Optical Efficiency: By using concentric grooves, the Fresnel lens can achieve nearly 85% optical efficiency. This means that a large portion of the light emitted from the source is directed into a focused beam.

- Light Intensity: The stepped design of the Fresnel lens allows for the concentration of light into a narrow, high-intensity beam. This results in a light that is visible up to 20 miles or more, depending on atmospheric conditions and the lighthouse’s location.

- Reduction of Material: Traditional lenses of comparable size and capability would be exceedingly heavy and cumbersome. The Fresnel lens achieves high performance with less material, reducing the strain on the lighthouse structure.

Technical Parameters for Fresnel Lens:

- Efficiency: Up to 85% of the light is focused into a beam.

- Size: Can be several meters in diameter while remaining relatively lightweight.

- Range: Capable of projecting light up to 20 miles or more, depending on conditions.

By utilizing a Fresnel lens, lighthouses optimize both the reach and the power of their light, ensuring that their guiding beams are visible to ships navigating treacherous waters. This advancement not only improves maritime safety but also exemplifies the ingenious application of optics in practical technology.

The Mechanism Behind Light Rotation

The mechanism behind light rotation in lighthouses is a crucial element that ensures the distinct and recognizable patterns of light that mariners rely on for navigation. This process involves rotating the Fresnel lens or the light source itself, which creates the sweeping beam of light that can be seen from miles away.

How Light Rotation Works:

- Rotating Lens Assembly: A motorized mechanism is employed to rotate the entire lens assembly. This rotation causes the light passing through the lens to create a sweeping beam effect.

- Clockwork Mechanism: Some older lighthouses use a clockwork mechanism powered by weights and gears. The weights are wound up to provide the energy needed to rotate the lens.

- Electric Motors: Modern lighthouses typically use electric motors to achieve rotation. These motors offer precise control over the speed of rotation.

Technical Parameters for Light Rotation:

- Rotation Speed: The speed at which the lens rotates is calibrated to ensure that the flashing pattern is distinct and identifiable. Typically, this speed ranges from one revolution every few seconds to one revolution per minute.

- Power Source: Depending on the lighthouse, the power source for the rotation mechanism can vary. It may utilize electricity from the grid, batteries, or even solar panels in remote locations.

- Weight and Balance: Given the size of some Fresnel lenses, the rotation mechanism must be capable of handling significant weight while maintaining smooth, consistent motion. Balancing the lens assembly is critical to reducing wear and tear on the mechanical components.

By understanding and implementing these mechanisms, lighthouses can maintain their vital role in maritime navigation, ensuring that their light signals are both reliable and effective in guiding ships safely through challenging waters.

How is the Lighthouse Structure Built to Withstand Harsh Conditions?

From my understanding, lighthouses are engineered to withstand some of the most punishing environments. They are often situated in isolated, rugged locations where they face relentless waves, high winds, and corrosive saltwater. The construction materials chosen are highly durable; traditionally, sturdy stone or bricks were used, but modern lighthouses may incorporate reinforced concrete and steel. The foundations are deeply anchored into bedrock or solid ground, providing stability against powerful ocean surges. Moreover, the cylindrical shape of many lighthouses is not just iconic but functional, enabling them to better deflect the wind and minimize resistance. Waterproofing and corrosion-resistant coatings are essential to preserve the structure over time. Through these meticulous engineering practices, lighthouses remain robust and operational in the face of harsh weather conditions.

Choosing the Right Materials: From Masonry to Metal

When selecting materials for constructing a lighthouse, several factors, including durability, resistance to environmental conditions, and structural integrity, must be considered. Traditionally, lighthouses were built with masonry materials such as granite, limestone, or brick, which provided the necessary strength and longevity. However, with advancements in construction technology, modern lighthouses often utilize reinforced concrete and steel, significantly enhancing their ability to withstand harsh maritime environments.

- Masonry:

- Granite and Limestone: Naturally resistant to weathering and erosion, these materials have historically been used in lighthouse construction due to their ability to withstand strong waves and high winds.

- Bricks: Brick masonry has been a popular choice for its robustness and thermal mass properties, which help in regulating internal temperatures.

- Reinforced Concrete:

- Durability and Strength: Reinforced concrete combines the high compressive strength of concrete with the tensile strength of steel reinforcements, making it an ideal choice for constructing lighthouses that need to endure continuous wave impact and extreme weather.

- Technical Parameters: Properly designed reinforced concrete can achieve a compressive strength of 30 MPa (megapascals) and tensile strength up to 2 MPa, ensuring a resilient structure.

- Steel:

- Corrosion Resistance: Modern lighthouses often incorporate weathering steel, known for forming a stable rust-like appearance after exposure to the elements, which subsequently reduces maintenance needs.

- Structural Integrity: Steel’s high strength-to-weight ratio allows for taller and thinner structures without compromising stability. High-tensile steel used in lighthouse construction can have a tensile strength above 400 MPa.

In summary, the choice of materials is critical in lighthouse construction, ensuring they remain operative in extreme conditions. By integrating masonry’s traditional durability with modern materials like reinforced concrete and corrosion-resistant steel, lighthouses can continue their vital role effectively for decades.

Dealing with Wind and Waves: Structural Design Considerations

Designing lighthouses to withstand wind and wave forces involves several key considerations. Firstly, the foundation must be robust and firmly anchored to the bedrock to resist wave action and prevent erosion. Additionally, the shape of the lighthouse often tapers or curves to deflect wind and reduce surface pressure. The use of reinforced concrete and weathering steel, appreciated for their combined tensile and compressive strengths, ensures structural integrity against both lateral wind forces and the repetitive impact of waves. The height and diameter are carefully calculated to balance visibility needs with stability, taking into account local wind speeds and wave heights. Finally, regular maintenance and inspections are essential to address any wear and tear, bolstering the structure’s longevity in a harsh marine environment.

What is the Historical Significance of Lighthouses?

Lighthouses have played a pivotal role in maritime navigation, guiding ships safely to shore and preventing countless accidents. Historically, they served as critical navigational aids before the advent of modern technologies like GPS. Ancient civilizations like the Egyptians and Greeks constructed early lighthouses, including the Pharos of Alexandria, one of the Seven Wonders of the Ancient World. During the Age of Exploration, their significance grew as sea routes expanded, with lighthouses marking dangerous coastlines, hazardous shoals, and guiding mariners through treacherous waters. They also symbolize human ingenuity and resilience, often situated in remote, storm-battered locations. Though many are now automated or decommissioned, lighthouses remain iconic structures, rich in history and maritime heritage.

The Evolution from Whale Oil to Electric Lights

The evolution of lighthouse illumination technologies reflects significant advancements in engineering and energy efficiency. Initially, whale oil was the primary fuel source, chosen for its availability and bright, steady flame. These whale oil lamps were later replaced by kerosene lamps in the mid-19th century, which burned cleaner and were easier to manage.

With the advent of the 20th century, lighthouses began transitioning to electric lights. This shift offered several advantages, including a more reliable and powerful light source. For instance, the introduction of the Fresnel lens amplified the efficiency of electric bulbs, allowing the light to be visible over greater distances. Here are some key technical parameters that highlight this evolution:

- Whale Oil Lamps:

- Fuel Efficiency: Moderate, prone to soot buildup.

- Light Output: Approximately 15-20 candlepower.

- Maintenance: High, requiring frequent trimming and refilling.

- Kerosene Lamps:

- Fuel Efficiency: Improved over whale oil, less soot.

- Light Output: Up to 50 candlepower.

- Maintenance: Moderate, requiring regular refilling and cleaning.

- Electric Lights:

- Fuel Efficiency: Highly efficient, minimal waste.

- Light Output: Ranges from hundreds to thousands of candlepower depending on the bulb type.

- Maintenance: Low, mostly involving electrical upkeep.

The switch to electric lights significantly enhanced the functionality of lighthouses, providing a brighter, more reliable, and easier-to-maintain source of illumination. This transformation underscores the ongoing commitment to improving maritime safety through technological advancements.

Iconic Lighthouses Around the World: From France to the United States

Lighthouses have long stood as beacons of hope, safety, and guidance across the globe. Below are three of the most iconic lighthouses, spanning from Europe to North America, each with unique historical and architectural significance.

1. Phare des Baleines (France)

- Location: Île de Ré, France

- Year Built: 1854

- Technical Parameters:

- Height: 57 meters

- Range: 50 kilometres

- Light Source: Initially oil lamps, now electric

- Description: The Phare des Baleines is known for its elegant design and towering presence. It utilizes a powerful Fresnel lens that ensures its light reaches vast distances, guiding ships safely to shore.

2. Portland Head Light (United States)

- Location: Cape Elizabeth, Maine, USA

- Year Built: 1791

- Technical Parameters:

- Height: 24 meters

- Range: 39 kilometres

- Light Source: Originally whale oil, currently electric with fourth-order Fresnel lens

- Description: As one of the oldest lighthouses in the U.S., Portland Head Light has a rich history and picturesque scenery. It has undergone several upgrades to maintain its operational effectiveness, including transitioning to electric power while retaining its historic charm.

3. Tower of Hercules (Spain)

- Location: A Coruña, Galicia, Spain

- Year Built: Roman times, reconstructed in the 18th century

- Technical Parameters:

- Height: 55 meters

- Range: 32 kilometres

- Light Source: Originally candles, now electric

- Description: The Tower of Hercules is the world’s oldest active lighthouse and a UNESCO World Heritage site. Its ancient origins and continuous use symbolize the enduring importance of maritime navigation.

These lighthouses not only represent technological advancements in navigation but also stand as historical monuments, reflecting the rich maritime heritage of their respective regions.

How Lighthouses Assist Mariners: Direction and Distance

Lighthouses perform critical functions in maritime navigation by providing visual cues for direction and distance to mariners. They serve as reference points along coastlines, guiding ships safely to their destinations, especially during challenging weather conditions or in areas with dangerous terrain.

Lighthouses assist mariners primarily through their powerful and distinctive light beams, which can be seen from great distances. These beams help sailors determine their position relative to the shore and aid in navigating through hazardous waters. The light’s intensity, range, and characteristic flash pattern (known as the light’s signature) are unique to each lighthouse, allowing mariners to identify their exact location.

Technical Parameters:

- Phare des Baleines (France)

- Height: 60 meters

- Range: 50 kilometres

- Light Source: Electric with Fresnel lens

- Portland Head Light (United States)

- Height: 24 meters

- Range: 39 kilometres

- Light Source: Originally whale oil, currently electric with fourth-order Fresnel lens

- Tower of Hercules (Spain)

- Height: 55 meters

- Range: 32 kilometres

- Light Source: Originally candles, now electric

By using these technical parameters, mariners can estimate their distance from the lighthouse based on the visibility of the light. The height of the lighthouse also factors into the visible range; the higher the light source, the further it can be seen over the horizon. Additionally, the unique signature of each lighthouse’s light pattern helps sailors in determining their direction and confirming they are on the correct course.

What Maintenance Activities are Required for Lighthouses?

Maintaining lighthouses requires a combination of routine and specialized tasks to ensure their optimal performance. First, regular inspections are essential to check the structural integrity of the lighthouse, including the tower, stairways, and surrounding areas. This involves looking for signs of wear and tear, such as cracks or corrosion, and addressing these promptly to prevent further damage. Second, the light source and lens, often a Fresnel lens, need to be kept clean and free of debris, which could obstruct the light beam. This involves cleaning both the inside and outside surfaces and ensuring that the electrical components are functioning correctly. Additionally, any backup systems, such as generators or backup bulbs, should be tested regularly to ensure they are operational in case of primary system failure. Finally, it’s important to maintain the lighthouse’s exterior, which often includes painting and sealing to protect against the harsh marine environment. This helps in preserving the structure and preventing moisture ingress, which could otherwise compromise the lighthouse’s overall integrity.

Cleaning the Lens and Windows for Maximum Visibility

Cleaning the lens and windows of a lighthouse is critical for ensuring maximum visibility. Start by using mild detergents and soft cloths to gently clean the lens’ surface, avoiding any abrasive materials that could cause scratches. For windows, a mixture of water and vinegar or a specialized glass cleaner can effectively remove salt spray and grime without leaving streaks. Ensure that all cleaning solutions are thoroughly rinsed off to prevent residue build-up. Regular maintenance should also include inspecting the seals around windows and lens casings to prevent moisture ingress, which can fog up surfaces and impede light transmission. Finally, periodic professional inspections are recommended to address any hard-to-reach areas or to perform more intensive cleaning as needed.

Regular Checks of the Power Supply and Fuel Systems

Regular maintenance of the power supply and fuel systems is crucial for the seamless operation of the lighthouse. Here are the key steps to ensure reliability:

- Visual Inspection:

- Regularly check for any signs of wear, corrosion, or damage to power cables, connections, and fuel tanks.

- Testing and Monitoring:

- Test backup generators and battery systems routinely to ensure they are functioning correctly.

- Monitor fuel levels frequently and top up to prevent shortages.

- Cleaning and Maintenance:

- Keep the power supply and fuel system components clean and free from debris.

- Perform necessary maintenance as per manufacturer’s guidelines to avoid potential malfunctions.

- Record Keeping:

- Maintain a detailed log of all inspections, tests, and maintenance activities to track the system’s health and anticipate future needs.

By adhering to these measures, one can maintain an uninterrupted power supply, thereby ensuring the lighthouse remains operational and effective in guiding maritime traffic.

Preserving the Structure: Paint and Repair

To preserve the structural integrity and appearance of the lighthouse, regular painting and timely repairs are essential. Over time, harsh weather conditions and the saline environment can cause paint to deteriorate, leaving the structure vulnerable to corrosion. Here are key steps to ensure the lighthouse remains in pristine condition:

- Surface Preparation:

- Thoroughly clean the surface to remove any existing rust, peeling paint, and grime.

- Use appropriate cleaning agents and tools to achieve a smooth and clean surface for painting.

- Painting:

- Apply a high-quality, marine-grade primer to protect against rust and corrosion.

- Follow with multiple coats of weather-resistant, UV-protective paint designed for marine environments.

- Ensure even coverage and allow sufficient drying time between coats.

- Regular Inspections and Repairs:

- Conduct regular inspections to identify any areas of the structure that may require repairs such as cracks, leaks, or rust.

- Use durable, weather-resistant materials to repair any identified damage promptly.

- Documentation and Planning:

- Keep a detailed maintenance log documenting all painting and repair activities.

- Plan for routine maintenance based on the environmental conditions and expected wear and tear.

Implementing these measures ensures the lighthouse remains structurally sound and visually appealing, safeguarding its operational efficiency and historical value.

Frequently Asked Questions (FAQs)

Q: What is the source of light in an island lighthouse?

A: The source of light in an island lighthouse can vary from the traditional wick and fire to modern electric lamps. Older lighthouses used lamp chimneys with parabolic reflectors to focus the light.

Q: What is the purpose of the service room in a lighthouse?

A: The service room in a lighthouse is where maintenance and logistical activities are managed. It houses tools, spare parts, and other necessary equipment to ensure the lighthouse operates smoothly.

Q: What materials are used in constructing the top of a lighthouse tower?

A: The top of a lighthouse tower can be constructed using various materials, including wood, rock, and steel. It is designed to be durable and weather-resistant, with glass storm panes to protect the light source.

Q: How does the National Park Service contribute to the maintenance of lighthouses?

A: The National Park Service often oversees the preservation and maintenance of historic lighthouses. They ensure structures remain safe and operative for many years to come, often by restoring and keeping them in good condition.

Q: What are leading lights and rear lights in a lighthouse system?

A: Leading lights are two lights placed to form a line to guide ships. The rear light is positioned higher and further back than the front light, leading vessels safely into a channel or port.

Q: What safety features are included in the design of a lighthouse during fog or low visibility conditions?

A: Lighthouses feature foghorns and powerful lights to ensure they remain visible and audible in fog or low visibility conditions. Modern lighthouses may also use radar and automated systems to enhance navigation safety.

Q: How high does a lighthouse need to be to be visible on the horizon in nautical miles?

A: The height of a lighthouse determines its visibility over the horizon in nautical miles. Generally, the higher the lighthouse, the further its light can be seen. This is calculated using the formula for the line of sight in nautical miles.

Q: What role does the platform beneath the high cliff play in lighthouse construction?

A: When built on a tall cliff, a platform can provide a stable foundation for the lighthouse, reducing the risk of erosion and weather damage. This ensures the structure’s stability and longevity.

Q: Can you explain how the design of lamp chimneys has evolved over the years?

A: Over the years, lamp chimneys have evolved from simple, hollow designs to more advanced models that incorporate parabolic reflectors and advanced ventilation systems. This evolution has improved the efficiency and brightness of the lighthouse light.

Q: Why is wood or wooden materials used horizontally in some parts of the lighthouse?

A: Wood or wooden materials are sometimes used horizontally in lighthouse construction for their flexibility and ability to absorb shock from strong winds and waves. This can help in maintaining the structural integrity of the lighthouse.