Using OBJ files to turn them into STL format is vital for people who want to get their 3D designs printed. This article has been written to help readers understand how this transformation takes place and explain the importance of different file types in the 3D printing realm. Usually, OBJ files with rich functionality that can store complex geometry and materials must be converted into a more printable STL format, simplifying the model by providing only a geometric surface. With this guide, you will master your own ways of making your 3D models ready for printing, whether you are an experienced designer or a beginner trying to find your way around. It will give you confidence with your creative projects and widen their scope when moving from novice level to expert one, during which one can seamlessly prepare their models for eventual reproduction via 3D printers.

What is an OBJ File?

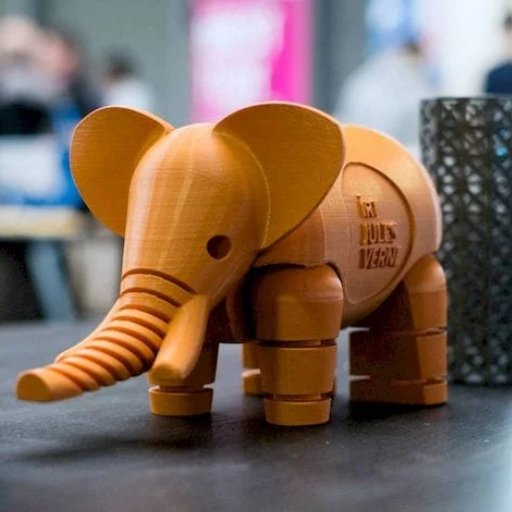

Image source: https://www.fabbaloo.com/

This format is widely used in computer graphics and 3D printing as it supports geometry and appearance for a 3D model. Wavefront Technologies developed OBJ files to carry information regarding vertices, texture coordinates, normals, and polygonal faces of 3D models. This has made them very popular among different industries because they can faithfully represent complicated models or surfaces like those required by engineers or architects in animation projects, video game design, or industrial manufacturing. So before they can be converted into simpler formats such as STL for rapid prototyping applications, they are often used to make accurate three-dimensional representations of objects.

Understanding the OBJ File Format

Dealing with 3D geometry has become much easier with the emergence of a globally recognized OBJ file format, a simple and inclusive way of representing it. The OBJ file consists of vertices and data points defined in three dimensions: texture and color. It supports both polyhedral and free-form geometries, thereby accommodating complex designs. A critical aspect of it is that it employs separate material files (MTL) to define all surface appearances for any specific object, including textures and shading properties that could be attached to an OBJ file. This human-readable form factor makes it easy for individuals to edit or share among different software applications; hence, it is preferred by many graphic artists, filmmakers, and developers who use special effects on games or films. OBJ is an open format that can be used for 3D modeling, encouraging creativity and technical innovation.

Common Uses of OBJ Files in 3D Printing

OBJ files have found their way into different stages of the 3D printing process, in my own experience. They serve as a base format for creating complex models because they can capture intricate geometric details. For instance, I typically export my prototypes as OBJ files to ensure that all the necessary characteristics, such as textures and surface finishes, are accurately represented. Moreover, many other slicing software programs work with OBJ formats, vital in turning 3D models into printable formats like STL. Consequently, I can quickly prepare my designs for 3D printing, ensuring they maintain their original vision. Finally, these files remain high quality and easy to edit, making them an ideal choice for iterative design processes, thus enabling me to handle any corrections before final printing.

Advantages of Using OBJ Files

- Broad Compatibility: OBJ files are widely compatible because they can be used by many 3D modeling software and applications, such as the famous Blender, AutoCAD, and Maya. This means developers and artists can work across different platforms without compromising model accuracy.

- High Detail Representation: OBJ files are good at representing complex geometrical attributes, including not only 3D shapes but also intricate texture details. These details are essential for generating high-quality visual outputs in animations and games, so professionals prefer using them.

- Ease of Editing: OBJ format is much easier to edit than binary formats due to its human-readable nature. Users can manually adjust parameters and/or properties within the file, enabling quick alterations without specific tools and making the design process more efficient.

What is an STL File?

STL (Stereolithography) files are a popular 3D printing format that represents the surface geometry of a three-dimensional object without any color, texture, or other attributes. Introduced in the 1980s by 3D Systems, STL files present an object’s shape using a set of triangular facets that define every vertex and are typical of each section’s surfaces. Given the simplicity of STL design, it is most compatible with more types of 3D printers and slicing software, which makes it ideal for prototyping and manufacturing in the additive fabrication process.

Overview of the STL File Format

An essential feature of the STL file format is that it is simple and effective for 3D printing, as it mainly comprises triangular facets that collectively define the surface of an object. It acts as media via which geometric data can be transferred from computer-aided designs to three-dimensional printers. ASCII or binary form can save STL files, whereas binary format is smaller and more common in professional circles. Its simplicity allows it to be supported by different CAD programs and slicing software, making it a vital asset in additive manufacturing. Nevertheless, shape is the only information that can be gleaned from STL files since they do not contain details on coloration, texture, or other advanced specifications relevant to non-tangible applications such as physical representation and prototyping. This means that when designers are dealing with more intricate visual elements of their models, they usually go with other file types like OBJ or AMF instead.

Benefits of Using STL Files for 3D Printing

For my 3D printing projects, STL files are a better option. Initially, they can be easily integrated into my workflow without format worries because of their widespread compatibility with most 3D printers and slicing software. Additionally, the simplicity of the STL format enables quick processing and efficient handling, thus saving me time during preparation. Furthermore, as the standard format for 3D printing, STL files have many resources and community support, making it easier for me to find troubleshooting tips and design inspirations. Finally, geometry is represented clearly in STL files that enable precision in prototyping and manufacturing; hence, I can concentrate on the shape and structure of my designs.

How STL Files Compare to Other Formats

Various considerations come up when comparing STL files with other 3D file formats. Unlike STL, file types such as OBJ or AMF can handle more detailed visual aspects, including texture and color, making it suitable for projects requiring intricate visual representations. For example, the OBJ format supports the inclusion of polygon meshes along with different materials and textures, thus helping to make complex designs appear realistic. Furthermore, AMF (Additive Manufacturing File format) improves upon STL by providing more descriptive model definitions, including the ability to define multiple materials and color gradients.

Nevertheless, despite these positives, STL files remain the industry standard due to their simplicity, ease of use, and comprehensive support within various slicing and printing software. This makes them the most preferred option for standard 3D prints and prototypes.

How to Convert OBJ Files to STL

OBJ files can be converted into STL using software tools or online converters. Here is a short guide on how it is done:

- Software: Many 3D modeling programs, such as Blender, MeshLab, or Tinkercad, allow importing OBJ files and exporting them in the STL format. Users simply open the OBJ file in this software and then export it as an STL file.

- Online conversion tools: Some websites offer free online conversion services. For example, sites like AnyConv and Online-Convert enable users to upload their OBJ files and download them in STL format without requiring software installation.

- Command-line tools: Advanced users can also use OpenSCAD or Autodesk’s Fusion 360 with specific commands or scripts.

By following these methods, one can successfully convert OBJ files to STL, which allows smooth integration into your 3D printing process.

Step-by-Step Guide to OBJ to STL Conversion

- Get your Converter: Start by choosing a dependable conversion tool. If you prefer, you can use online converters like AnyConv or Online-Convert or 3D modeling software such as Blender.

- Import Your OBJ File: Go to the upload/import feature of your preferred software or online service.

- Adjust settings (if necessary): Some software may allow you to adjust parameters like scale and material properties to make them compatible with the desired output type, especially if it is for 3D printing.

- Choose STL as Output Format: After locating the export/convert button, ensure that STL is the format you choose from the list of alternatives presented.

- Convert and Download: Begin the conversion process. Once you’ve finished, download the STL files to your gadget.

- Verify the STL File: This involves opening an STL file using a slicer or 3D printing software to confirm that everything has been appropriately converted into a printable format.

In this way, step by step, one will be guaranteed a successful and smooth changeover from OBJ data into STL, which makes perfect sense for your three-dimensional design models.

Best OBJ to STL Converters Available

When converting OBJ files to STL, I know several dependable tools that have always given me satisfactory results. These are the top three I would recommend:

- Blender: This open-source 3D modeling software will convert your OBJ into STL format and provide high-powered modeling tools. This is a great advantage, especially if you want to adjust your model before printing.

- MeshLab: It’s another powerful open-source tool that’s best at editing and converting 3-D models. It can work with multiple formats and offers extensive features for optimizing a model for printing and cleaning up.

- Web Apps Such As Online-Convert: This online conversion utility is easy to use but efficient for those who favor quick and stress-free solutions. This service is ready to go if you want to change your OBJ file into an STL file on the fly without installing any software.

These tools have effectively ensured that original models remain intact during conversions.

Using Online Tools for Conversion

One can use several of the best tools for the online conversion of OBJ to STL.

- Tinkercad: This web-based 3D design software tool has been designed to allow users to upload their OBJ files and simply convert them into STL format. It’s got a user-friendly interface, making it the right choice for beginners who quickly want to prepare their models for 3D printing.

- AnyConv: A simple, straightforward online conversion tool specializing in many file formats. This platform allows users to upload their OBJ files, convert them into STL, and later download the converted files without necessarily having to install software, thereby making the process quick and efficient.

- Online 3D Converter: Here’s another website offering an easy way to convert 3D models. Users can upload their OBJ files or choose from multiple formats when receiving STL ones. This comes particularly handy if you don’t need too many features but require fast conversion.

Therefore, these converters on the Internet make transitioning from OBJ to STL easy, saving time and effort while preserving the quality of a 3D model.

What Software Do You Need for 3D Printing?

To effectively prepare and execute 3D printing, there are several essential software tools to have in place:

- 3D Modeling Software: This is used to create or amend 3D models. Popular options include Blender, Tinkercad, and Autodesk Fusion 360. They enable users to fashion their own models or make some changes to existing models.

- Slicing Software: The slicing software converts the model into instructions that the 3D printer can read. Examples of this kind of software include Cura, PrusaSlicer, or Simplify3D. Using them, you can adjust parameters like layer height, print speed, and support structures.

- Printer Control Software: For more advanced models, printer control software, such as OctoPrint, may be needed to handle the printer directly. This allows one to monitor and manage the printing process remotely.

Thus, such software can immensely help streamline the design-to-print process.

3D Modeling Software: Creating Your OBJ Files

There are several options for 3D modeling software that can be used in the creation of OBJ files, each of them having their own unique features and capabilities:

- Blender: Blender is free and open-source software known for its strong community support and rich functionality in designing complex 3D models and animations. Its tools are powerful enough to create OBJ files, and numerous tutorials can guide beginners through the application.

- Tinkercad: Tinkercad provides an intuitive interface for creating simple 3D models, mainly targeted at beginners. It can export designs as OBJ files, making it ideal for educational purposes and quick projects.

- Autodesk Fusion 360: Autodesk Fusion 360 is a professional-grade software that combines parametric modeling with freeform modeling, enabling the design and engineering of intricate objects with precision. To facilitate thorough preparation for a 3D printout, Fusion 360 allows users to export all these model files into OBJ format.

Therefore, these tools will allow users to efficiently create high-quality OBJ files targeted to their individual requirements when printing in 3D.

Slicing Software: Preparing Your STL Files for Printing

I generally use slicing computer software to have my 3D models converted into instructions that I can feed to my printer. Ultimaker Cura, PrusaSlicer, and Simplify3D are famous for their user-friendly interfaces and settings suitable for diverse 3D printing requirements. Of all the available choices, I prefer Ultimaker Cura due to its continuous development and support from many community members. This program has a simple design that helps me quickly tweak many aspects like print speed, layer height, and support to get better results. A G-code file is made as the software slices it, and I then transmit it onto my 3D printer for printing.

Best CAD Software for 3D Printing

Based on current industry standards and user feedback, three popular choices are the top CAD software for 3D printing.

- TinkerCAD: This is a free online application that is ideal for newcomers or teachers. It simplifies the 3D design process further with a straightforward user interface. It comes with drag-and-drop functionality, making it easier to create models efficiently and export them as STL or OBJ files seamlessly.

- Fusion 360: Fusion 360 is designed for both professionals and hobbyists. It integrates CAD, CAM, and CAE in one single platform. Its powerful parametric modeling capabilities make it suitable for complex designs. Additionally, users benefit from its collaborative features and can create detailed technical drawings.

- SolidWorks: SolidWorks is a well-known CAD software offering advanced functionalities and parametric design options. It supports complex modeling and simulations, making it more preferred in engineering applications. Moreover, SolidWorks supports different formats while exporting files, including STL for 3D printing.

These options range across skill levels and project needs so anyone can locate a solution that fits their 3D printing needs.

How to Optimize Your 3D Models for Printing?

Some optimization techniques should be taken to ensure successful 3D prints. Firstly, checking the model for manifoldness regarding non-manifold edges, intersecting geometries, or holes is always essential, as they may result in printing errors. Second, simplify your geometry to reduce the polygon count, which can increase slicing speed and improve print quality. Furthermore, supports could be added if necessary, like in cases of overhangs, thus helping to avoid breakages by having sufficient wall thicknesses. Besides this, when you use slicer software, it is good to arrange some models in a certain way to stabilize them during the printing process. Finally, there are repair tools such as Netfabb and Meshmixer, which can also be used to correct any faults before slicing the model. These guidelines will significantly improve the printability of your 3D models.

Reducing File Size for Faster Printing

It’s essential to make your 3D models smaller so they can be processed more quickly and printed efficiently.

- Mesh Simplification: Blender or MeshLab software tools simplify the polygons without losing details. This step makes the model less complex but emphasizes its most crucial parts.

- Check for Unused Components: Many models have redundant features, such as hidden elements or duplicates, that should be removed. Removing these unnecessary components will substantially reduce the file size and enhance overall performance.

- Use Appropriate File Formats: STL or OBJ formats are better for managing file sizes. These formats often strike a balance between quality and size that is suited for 3D printing.

- Model Compression: Netfabb or Simplify3D tools can compress files while retaining their integrity. This is especially useful for transferring files over the Internet or to other platforms.

- Decimate Modifier: In Blender software, for instance, you can use the Decimate modifier to lower your mesh complexity at a distance yet maintain its unique appearance, making it small-file-size friendly for faster printing.

These strategies will help you optimize your 3D models effectively, reducing processing time and improving print quality.

Ensuring Compatibility with 3D Printers

To be compatible with printers, I have a few things that I look out for in my 3D models. This includes ensuring that the maximum size and material it can handle are checked on the specifications of my printer. In the next step, I tailor the scales and dimensions of my model to optimize their fitting within these boundaries. In addition, non-manifold edges may cause printing issues; therefore, I ensure my models are “watertight” by manifoldness analysis. Besides, I use file types like STL or OBJ, which have broad software support for most printing applications. Finally, if possible, I make a test printout for smaller sections to enable me to catch any complications before embarking on full printouts. The following tips will help me achieve higher chances of getting an acceptable printout from my printer.

Tips for Preparing Your Model File for Printing

- Mesh Cleaning: Before exporting, ensure your mesh is clean by deleting unwanted geometries, overlapped vertices, or faces. This will prevent printing errors and increase precision.

- Check for Normals: Ensure that all normals are pointing outward. In software like Blender, you can recalculate normals to fix any inconsistencies. If the normals are wrong, there may be a problem when slicing.

- Wall Thickness Should Be Correct: Confirm if your model’s wall thickness meets the minimum required thickness by your printer manufacturer. Concentrate on models with fragile walls, as they tend to become structurally weak, while those with excessively thick walls may result in material wastage.

- Think about Support Structures: When there are overhangs in your model, design it with possibilities of support structures or rotate it so that the need for supports reduces. This can save time and material during printing.

- Try Slicing Settings: Try various slicing settings in your 3D printing software to determine what works best for your specific modeling and printer type, such as layer height, infill density, and print speed.

By adhering to these tips, you will considerably improve the quality and effectiveness of your 3D printed projects.

Where to Find Free Online Converters?

There are a lot of free online converters for various file types and formats. Zamzar, Online-Convert, and Convertio allow you to change documents, images, and videos into different formats with the help of a user-friendly interface without any software installation required. For particular conversions of files, such as exporting 3D models for printing purposes, it might be helpful to use applications like MeshLab or Blender. Before these services are used for this purpose, always review the user reviews and check their privacy policies for your own benefit to secure your data.

Top Free Tools for OBJ to STL Conversion

- Convertio: It is a valuable tool for video conversion that can easily convert between various file formats, including OBJ and STL. Moreover, the developers of this software made it as user-friendly as possible. They allowed users to upload files from different sources such as computers, Google Drive or Dropbox. That is why many people prefer it because converting with it is easy.

- AnyConv: I have always considered this serving system one of the most effective in converting files such as OBJ to STL. It is free to use and does not require downloading any software program. You can simply upload your OBJ files and, within seconds, get your STL file converted for you, already giving you a link to download.

- Online-Convert: If I need a free 3D converter that supports a wide range of formats, including 3D model conversions, then I should definitely visit this website called Online-Convert. How to convert OBJ into STL? In other words, the interface provides flexibility before conversion by allowing one to modify settings related to models, which increases its efficiency when dealing with specific requirements.

How to Download Your STL File

I usually follow a simple process that differs slightly depending on the tool I use to download my STL files after conversion. For Convertio, I only have to click on the download link on the result page once the conversion is done. AnyConv has a download button that pops up as soon as my OBJ file finishes converting, and by clicking on it, I can get my STL file just like that. Finally, when I use Online-Convert, I only need to go to the result page after converting and simply click the download link. In general, these three websites ease users’ downloading process.

Reviews of Popular Online Converters

- Zamzar: Zamzar is very popular for its online conversion services. Customers love the software’s interface and how fast it converts. This program stands out because of the many formats it can convert—over 1,200. Some users have found the free service convenient, but it has limitations such as file size and the number of conversions per day.

- CloudConvert: CloudConvert’s strength is its powerful conversion functionality and wide range of supported formats. It allows users to adjust conversion settings, thus improving general usability. Users often testify to the reliability of this platform’s operations and its ability to safeguard privacy through deleted files upon conversion. Nevertheless, there are size limits for files in the free tier and change frequency.

-

FileZigZag: FileZigZag is yet another good option that has a simple conversion process outlined. The variety of file types that users can easily convert distinguishes this facility from others; moreover, this service offers an email-receiving option where users can receive their changed items via email. While it may not be fit for urgent tasks due to slow performance during peak hours, according to some reviewers, FileZigzag remains dependable regarding basic conversions.

Frequently Asked Questions (FAQs)

Q: What is the difference between OBJ and STL file formats?

A: The OBJ format is a 3D file format that supports geometry and color information, making it suitable for multi-color 3D printing. In contrast, the STL format is more focused on geometry and does not support color information, which can result in smaller file sizes but limits the detail of the 3D object.

Q: Why must I convert OBJ files to STL for 3D printing?

A: Many 3D printing software and slicing tools primarily support the STL format because it is a widely accepted 3D printing file format. Therefore, if you have a 3D model in OBJ format, you must convert your OBJ to STL to ensure compatibility with your 3D printer.

Q: What are some standard methods of converting OBJ to STL?

A: Several methods of converting OBJ to STL include dedicated file converters, 3D modeling software, and online conversion tools. Many 3D file converters can handle this file conversion easily and quickly.

Q: Can I use free 3D file converters to convert OBJ to STL?

A: Many free 3D file converters are available online that allow you to convert OBJ files to STL format without any cost. These tools can help you convert your OBJ files quickly and efficiently.

Q: What software do I need to convert OBJ files to STL?

A: You can use various 3D modeling and slicing software to convert OBJ files to STL format. Popular options include Blender, MeshLab, and Tinkercad, which provide straightforward tools for file conversion.

Q: Are there any limitations when converting OBJ to STL?

A: When converting OBJ to STL, you may lose specific details such as color and texture, as STL files do not support these features. Additionally, ensure that the geometry of the 3D object is manifold to avoid issues during 3D printing.

Q: What should I do if my OBJ files do not support conversion?

A: If your OBJ files do not support conversion, you may need to check the integrity of the files or use a different 3D file converter that can handle more complex OBJ files. Sometimes, simplifying the 3D model can help achieve a successful file conversion.

Q: How do I ensure my STL files are suitable for 3D printing?

A: To ensure your STL files are suitable for 3D printing, use 3D slicing software to check for errors in the model, such as non-manifold edges or holes. This software can help you prepare the 3D printable file and optimize it for your specific printer.

Q: Can I convert OBJ files to formats other than STL?

A: Yes, you can convert OBJ files to various other formats, including 3MF and PLY, depending on your needs. Many 3D file converters support multiple formats to accommodate different 3D graphics and printing applications.

Q: What is the best practice for converting 3D files for printing?

A: The best practice for converting 3D files for printing is to first check the model’s compatibility with the desired file format, ensure it is manifold, and use reliable 3D file converters or slicing software to perform the conversion. Always preview the model after conversion to confirm its integrity.