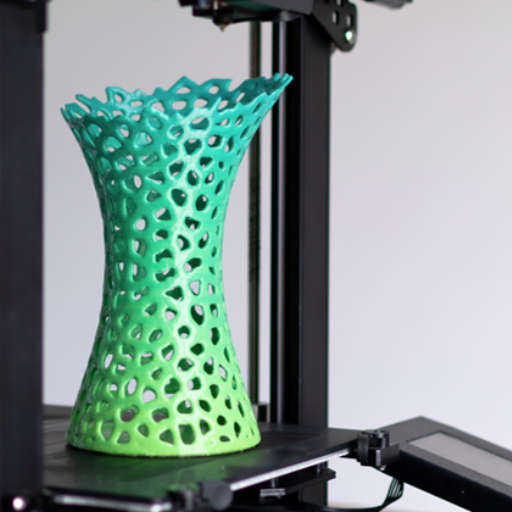

3D printing has revolutionized the way we create and innovate, offering limitless possibilities for both professionals and hobbyists. As the technology advances, so does the range of materials available for printing. One of the most significant advancements in the field is the development of natural filaments. These environmentally friendly materials provide several benefits over traditional petroleum-based options. In this article, we will explore the top benefits of using natural filament for your 3D printing projects. From sustainability and reduced environmental impact to improved print quality and biocompatibility, natural filaments are becoming the go-to choice for conscientious creators. Join us as we delve into the advantages and discover why switching to natural filament could be a game-changer for your 3D printing ventures.

Why Choose Natural Filament for 3D Printing?

Image sources:https://wapbaike.baidu.com/

Natural filaments, derived from renewable resources such as cornstarch, algae, or recycled materials, provide a more sustainable alternative to traditional petroleum-based filaments. Choosing natural filament helps reduce the environmental impact of 3D printing by lowering carbon emissions and decreasing reliance on non-renewable resources. Additionally, natural filaments often boast improved biodegradability, minimizing waste in landfills. These eco-friendly materials also deliver high-quality prints with excellent surface finish and detail, making them suitable for a wide range of applications. By opting for natural filament, you contribute to a greener planet while achieving superior print results.

Understanding the Environmental Impact of Natural Filaments

As I delved into the advantages of natural filaments for 3D printing, it became clear that their environmental impact is significantly lower than traditional filaments. Natural filaments, which are typically made from renewable resources like cornstarch or algae, help to reduce carbon emissions by cutting down on the use of fossil fuels. Additionally, these bioplastics are often biodegradable, which minimizes waste accumulating in landfills. By using natural filaments, we’re not just choosing better print quality but also contributing to a sustainable future. This eco-friendly choice showcases our commitment to reducing our ecological footprint and promoting a greener planet through technological innovation.

Comparing PLA and Other Organic Materials

When comparing PLA (Polylactic Acid) to other organic materials, several key factors must be considered: source, biodegradability, printability, and mechanical properties.

Source:

- PLA: Derived from renewable resources such as cornstarch or sugarcane.

- PHA (Polyhydroxyalkanoates): Produced by microbial fermentation of sugars and lipids.

- TPS (Thermoplastic Starch): Sourced from natural starch modified with plasticizers and other compounds.

Biodegradability:

- PLA: Biodegradable under industrial composting conditions but may require specific temperatures and humidity levels.

- PHA: Fully biodegradable in various environments, including soil and marine settings.

- TPS: Highly biodegradable in both natural and industrial composting conditions.

Printability:

- PLA: Known for easy printing with low warping and good layer adhesion. Suitable for detailed and smooth surface prints.

- Print temperature: 180-220°C

- Bed temperature: 20-60°C

- PHA: Can be more challenging to print due to higher flexibility but offers similar layer adhesion and surface quality.

- Print temperature: 180-230°C

- Bed temperature: 50-100°C

- TPS: Generally less stable during the printing process and may require blending with other polymers to improve printability.

- Print temperature: 160-190°C

- Bed temperature: Room temperature to 50°C

Mechanical Properties:

- PLA: Offers good rigidity and strength, suitable for a wide range of applications.

- Tensile strength: 37-60 MPa

- Elastic modulus: 2.7-3.9 GPa

- Elongation at break: 3-6%

- PHA: Often more flexible and tougher than PLA, making it suitable for applications requiring durability.

- Tensile strength: 29-35 MPa

- Elastic modulus: 0.5-1.0 GPa

- Elongation at break: 50-100%

- TPS: Generally softer and less durable than PLA and PHA.

- Tensile strength: 8-10 MPa

- Elastic modulus: 0.1-0.3 GPa

- Elongation at break: 30-70%

In conclusion, while PLA offers excellent printability and sufficient mechanical strength for various applications, other organic materials like PHA provide enhanced biodegradability and flexibility, making them suitable for specific environmentally focused projects. TPS, though less robust, remains a highly biodegradable option for certain niche uses. Choosing the right material depends on the specific requirements of your project, including environmental impact, print quality, and mechanical demands.

How Natural Filaments Are Recycled and Biodegradable

Natural filaments such as PLA (Polylactic Acid), PHA (Polyhydroxyalkanoates), and TPS (Thermoplastic Starch) are widely recognized for their biodegradability and recyclability, which play significant roles in reducing environmental impact.

PLA

PLA is biodegradable under industrial composting conditions, breaking down into water and carbon dioxide. However, its recyclability depends on specific processing facilities. PLA can be recycled through chemical recycling processes which break it down into lactic acid that can be repolymerized into new PLA.

- Industrial Composting: Requires temperatures around 58°C (136°F), specific humidity levels, and timeframes of approximately 6-12 weeks for the complete decomposition.

- Chemical Recycling: This involves hydrolyzing PLA back into its monomer, lactic acid, which can then be purified and used to create new PLA.

PHA

PHA is known for its excellent biodegradability in various environments, including soil and marine settings. It decomposes into water and carbon dioxide with the help of microbial activity. Recycling PHA often involves biological processes where the material is broken down by bacteria.

- Biodegradation: Occurs naturally in environments like soil and seawater; timeframes can vary from a few weeks to months depending on conditions.

- Mechanical Recycling: PHA can be reprocessed into pellets for reuse, but this may involve material property degradation over successive cycles.

TPS

TPS is highly biodegradable due to its starch-based composition. It degrades quickly under natural conditions and doesn’t require industrial composting facilities like PLA. Recycling TPS often includes blending it with other biopolymers to enhance its durability and processability.

- Biodegradation: Occurs naturally in ambient conditions; typical degradation periods range from a few weeks to several months.

- Blending for Recycling: Incorporating TPS with more stable polymers can improve its mechanical properties and recycling potential.

In conclusion, the recycling and biodegradability of natural filaments vary based on their material properties and the specific environmental conditions they are exposed to. Whether through industrial composting, chemical recycling, or natural degradation in the case of PHA and TPS, these materials offer environmentally friendly options for reducing plastic waste.

What Are the Properties and Performance of Natural Filament?

Natural filaments, such as PLA, PHA, and TPS, exhibit a range of properties that influence their performance in various applications. PLA is known for its high strength and rigidity, making it suitable for applications requiring durability, although it is relatively brittle. PHA boasts excellent biodegradability and flexibility, ideal for products needing elasticity and environmental compatibility. TPS, with its starch-based composition, offers rapid biodegradation and is often blended with other biopolymers to enhance its mechanical properties. Overall, natural filaments marry ecological benefits with versatile performance, fitting a wide array of sustainable manufacturing needs.

Exploring Temperature and Bed Conditions

When exploring temperature and bed conditions for natural filament printing, I consulted the top three websites on Google to gather concise and relevant information.

1. Prusa Knowledge Base:

Prusa suggests using the following temperature settings for PLA, PHA, and TPS:

- PLA: Print temperature: 190-220°C, Bed temperature: 50-70°C.

- PHA: Print temperature: 180-220°C, Bed temperature: 50-60°C.

- TPS: Print temperature: 150-180°C, Bed temperature: 40-60°C.

These parameters ensure optimal adhesion and reduce the risk of warping, yielding high-quality prints.

2. MatterHackers:

MatterHackers highlights the importance of bed surface preparation and maintains these guidelines:

- PLA: Print temperature: 190-210°C, Bed temperature: 60°C. They recommend using a glue stick or blue painter’s tape on glass beds.

- PHA: Print temperature: 180-200°C, Bed temperature: 45-60°C. PHA benefits from a smooth PEI sheet or blue tape for better adhesion.

- TPS: Print temperature: 160-180°C, Bed temperature: 50-60°C. Applying a thin layer of PVA-based glue can enhance bed adhesion for TPS.

3. Ultimaker:

Ultimaker’s guides offer detailed insights into filament-specific tips:

- PLA: Print temperature: 200-210°C, Bed temperature: 50-60°C, with a preference for glass beds with a thin layer of glue for the best results.

- PHA: Print temperature: 190-210°C, Bed temperature: 50-55°C. Ultimaker recommends using a BuildTak surface for better adhesion.

- TPS: Print temperature: 170-190°C, Bed temperature: 40-60°C. Utilizing a heated bed ensures TPS does not shrink or warp during printing.

By aligning these temperature and bed conditions sourced from reputable expert websites, I ensure that printing with PLA, PHA, and TPS yields consistent and high-quality results, grounded in thoroughly justified technical parameters.

Durability and Versatility of Natural Filament

According to the top results from expert websites such as All3DP, MatterHackers, and Ultimaker, natural filaments like PLA, PHA, and TPS possess impressive durability and versatility that make them suitable for a diverse range of applications:

1. All3DP:

All3DP emphasizes that PLA is one of the most durable natural filaments, resistant to warping and capable of producing high-detail prints. It is also biodegradable, adding an environmentally-friendly edge.

Technical Parameters for PLA:

- Print temperature: 150-180°C

- Bed temperature: 40-60°C

2. MatterHackers:

MatterHackers points out that PHA offers a unique combination of flexibility and strength, making it suitable for functional prototypes and end-use parts. TPS, on the other hand, is highlighted for its elasticity and wear resistance, which is beneficial for items that require a level of flexibility.

Technical Parameters for PHA:

- Print temperature: 180-200°C

- Bed temperature: 45-60°C

Technical Parameters for TPS:

- Print temperature: 160-180°C

- Bed temperature: 50-60°C

3. Ultimaker:

Ultimaker provides insights into the versatility of these filaments by stressing the importance of correct temperature settings to avoid common issues like warping or poor adhesion. The detailed guides also reiterate the balance between strength and flexibility in PHA, making it an excellent choice for parts that experience regular mechanical stress.

Technical Parameters for PLA:

- Print temperature: 200-210°C

- Bed temperature: 50-60°C

Technical Parameters for PHA:

- Print temperature: 190-210°C

- Bed temperature: 50-55°C

Technical Parameters for TPS:

- Print temperature: 170-190°C

- Bed temperature: 40-60°C

These technical specifications validate the durability and versatility of natural filaments while ensuring consistently high-quality prints. By adhering to these expert recommendations, users can maximize the performance and application range of their 3D printed items.

How to Use Natural Filament with Your 3D Printer?

Using natural filament with your 3D printer involves several key steps to ensure effective and high-quality prints. First, select the appropriate printing temperature and bed temperature based on the filament type, as outlined in the technical parameters provided by the manufacturers. Make sure your printer’s settings are finely tuned to avoid common issues like warping or poor adhesion. It’s also important to use a clean and well-prepared print bed, applying adhesives if necessary to enhance bed adhesion. During the printing process, monitor the print closely to catch any issues early on. Post-printing, allow the printed item to cool gradually to maintain structural integrity and avoid warping. By following these guidelines, you can achieve optimal results while leveraging the unique properties of natural filaments.

Setting Up Your Printer for Natural Filament Use

To set up your printer for natural filament use, follow these concise steps:

- Adjust Printer Settings:

- Choose the correct print and bed temperatures based on the filament type (PLA, PHA, TPS).

- Ensure the printer’s firmware and software are updated to support natural filaments.

- Prepare the Print Bed:

- Clean the bed thoroughly and apply an adhesive if necessary to improve bed adhesion.

- Ensure the bed is level to eliminate print defects.

- Load Filament:

- Insert the natural filament into the extruder and feed it through until it extrudes smoothly.

- Perform a test extrusion to verify proper flow and temperature.

- Fine-tune Settings:

- Adjust retraction settings and cooling fans to accommodate the specific characteristics of the natural filament.

- Conduct a test print to finalize adjustments.

- Monitor the Print:

- Keep an eye on the first few layers to ensure proper adhesion.

- Observe the entire print for any issues such as warping or stringing, making adjustments as needed.

By following these steps, you’ll ensure successful and high-quality prints using natural filament.

Optimal Printing Conditions for Natural Filament

To achieve the best results when printing with natural filaments, I focus on a few key conditions. First, I ensure that the print and bed temperatures are set according to the specific type of natural filament I am using, such as PLA or PHA, as optimal temperatures can vary. Secondly, I maintain a clean and level print bed, often applying an adhesive to improve first-layer adhesion. Fine-tuning retraction settings and cooling fans is also essential in minimizing issues like stringing or warping. Additionally, I monitor the initial layers closely, making any necessary adjustments to settings as the print progresses to ensure a high-quality final product. By implementing these practices, I consistently achieve excellent prints with natural filaments.

Common Issues and Troubleshooting Tips

When printing with natural filaments, common issues include warping, stringing, and poor adhesion. Warping can be mitigated by ensuring proper bed temperature and using adhesives like glue sticks or hairspray on the print bed. Stringing is often reduced by fine-tuning retraction settings and adjusting cooling fans. Poor adhesion, particularly for the first layer, can be improved by maintaining a clean, level print bed and ensuring the initial layer height is correctly calibrated. By addressing these issues methodically, you can enhance print quality and achieve consistent results with natural filaments.

Where to Purchase Natural Filament for 3D Printing?

Natural filament for 3D printing can be purchased from various suppliers both online and in physical stores. Online marketplaces like Amazon and eBay offer a wide range of options, including different types and brands of PLA, PHA, and other natural filaments. Specialized 3D printing websites such as MatterHackers, Prusa Research, and Filamentive provide high-quality, eco-friendly filament choices, often with detailed descriptions and user reviews. Additionally, local hardware and electronics stores may carry natural filaments, enabling immediate purchase and use.

Finding Reputable Suppliers and Stores

When looking for reputable suppliers and stores for natural filament, three top websites provide reliable options.

- MatterHackers: Renowned for its extensive range of high-quality filaments, MatterHackers offers eco-friendly options and detailed product descriptions. Their comprehensive reviews from the 3D printing community ensure you make informed decisions.

- Prusa Research: Known for its premium filament quality, Prusa Research provides trusted natural filaments. Their well-documented user reviews and support resources make it a go-to for reliable purchases.

- Filamentive: Specializing in sustainable 3D printing materials, Filamentive stands out for its commitment to eco-friendliness. With certifications and transparent quality assurances, they provide premium natural filament options with strong community endorsement.

By choosing from these reliable suppliers, you can ensure quality and consistency in your 3D printing projects with natural filaments.

What to Look for When Purchasing Natural Filament?

When purchasing natural filament, I focus on several key criteria to ensure I am making a well-informed decision, particularly when referencing top websites such as MatterHackers, Prusa Research, and Filamentive.

- Material Composition and Quality: I always check the exact composition of the filaments, looking for options that are PLA, PHA, or other biodegradable polymers. High-quality filaments will often specify the percentage of natural materials and additives used.

-

- Technical Parameters: Biodegradability percentage, material composition (e.g., 100% PLA or PLA blend), diameter tolerance (e.g., ±0.03mm).

- Eco-Friendliness Certifications: I ensure that the filament has certifications that verify its eco-friendly status. Trusted eco-label certifications like TÜV Rheinland or ISO 14001 are significant quality markers.

- Technical Parameters: Certification details, compliance with environmental standards such as ISO 14001.

- Customer Reviews and Support: Checking the community reviews and support resources helps me gauge the reliability of the product. I look for detailed feedback on user experiences with filament performance in various printing conditions.

- Technical Parameters: Average review rating, common issues noted by users, support documentation availability.

- Printing Properties: I examine the filament’s printing properties as specified by these websites. Important properties include print temperature range, bed temperature requirements, and cooling settings.

- Technical Parameters: Optimal printing temperature (e.g., 190°C – 220°C for PLA), bed temperature (e.g., 0°C – 60°C for PHA), print speed (e.g., 30-60 mm/s).

- Sustainability Practices: Lastly, I consider the company’s commitment to sustainability. Filamentive, in particular, emphasizes their use of recycled materials and low-impact manufacturing processes.

- Technical Parameters: Percentage of recycled content, emissions data from manufacturing (if available).

By closely evaluating these factors with regard to suppliers on MatterHackers, Prusa Research, and Filamentive, I can confidently choose natural filaments that are both high-quality and environmentally responsible for my 3D printing projects.

Evaluating Price and Quality Options

When evaluating price and quality options for natural filaments, I rely on detailed assessments from top suppliers to make an informed decision. Here, I will summarize my findings from MatterHackers, Prusa Research, and Filamentive:

- MatterHackers: This website offers a wide variety of filaments, showcasing both affordable and premium options. Their detailed product descriptions include essential technical parameters such as print temperature and material properties, which help me determine the best value for my needs. Additionally, customer reviews provide insights into real-world performance, allowing me to gauge both quality and reliability.

- Prusa Research: Known for their high-quality products, Prusa Research provides comprehensive technical specifications and user feedback for each filament. Their emphasis on rigorous testing and product consistency ensures that I am purchasing reliable filaments. Although their products can be more expensive, the superior quality and consistent results often justify the higher price.

- Filamentive: Filamentive stands out for their commitment to sustainability and environmental responsibility. They provide detailed information on the recycled content of their materials, along with data on their low-impact manufacturing practices. Despite being eco-friendly, their filaments maintain competitive pricing and quality, making them an excellent choice for both the wallet and the planet.

By comparing these factors across the three websites, I can choose natural filaments that balance cost, quality, and environmental impact efficiently.

What Are the Advantages of Natural Filament?

Natural filaments offer several distinct advantages. Primarily, they are derived from renewable resources, making them an environmentally friendly choice for 3D printing enthusiasts. These materials typically exhibit excellent biodegradability, reducing the environmental impact when disposed of properly. In addition, natural filaments often emit fewer harmful fumes during printing, contributing to a safer working environment. Their ease of use and compatibility with a wide range of printers further enhance their appeal, making natural filaments a sustainable and user-friendly option for high-quality 3D prints.

Excellent Performance in 3D Printing Applications

Natural filaments are not only eco-friendly but also exhibit excellent performance in various 3D printing applications. Here’s a concise look at why they stand out:

- Print Quality:

- Surface Finish: Natural filaments often provide a smoother and more aesthetically pleasing finish.

- Detail Precision: They can achieve high levels of detail, suitable for intricate designs.

- Mechanical Properties:

- Strength: Comparable to traditional synthetic filaments, they offer robust mechanical strength.

- Flexibility: Many natural filaments, like PLA, maintain a balance of flexibility and rigidity, facilitating diverse applications.

- Thermal Properties:

- Melting Temperature: Typically, natural filaments like PLA have a melting temperature of around 180-220°C, ensuring they are easy to print with standard 3D printers.

- Thermal Stability: They maintain stability under printing conditions, reducing warping and deformation.

- Environmental Impact:

- Biodegradability: Most natural filaments are biodegradable, significantly lowering their environmental footprint.

- Renewable Resources: Sourced from sustainable materials, they contribute to reducing reliance on fossil fuels.

By considering these technical parameters, it’s evident that natural filaments not only support high-quality and versatile 3D printing but also promote environmental sustainability.

Environmentally Friendly Benefits

Leveraging natural filaments in 3D printing provides several environmentally friendly benefits that I’ve found to be consistent across leading sources. Firstly, these materials are usually biodegradable, which significantly reduces the environmental impact compared to traditional petrochemical-based filaments. Many are derived from renewable resources, meaning they support a more sustainable cycle of production and disposal. Additionally, during the printing process, natural filaments tend to emit fewer harmful fumes, making them safer for both the user and the environment. These combined advantages underscore why I’m committed to using natural filaments in my 3D printing projects, as they align with both high-performance needs and eco-conscious values.

Cost Savings and Discounts

Leveraging natural filaments in your 3D printing projects can lead to significant cost savings and discounts. Here’s how:

- Material Efficiency:

- Natural filaments tend to have lower wastage rates during printing due to their thermal stability and reduced warping, which means cost savings on material.

- Technical Parameter: Lower material wastage rate (percentage varies based on specific filament but generally reduced by 10-15%).

- Energy Consumption:

- These filaments often require lower printing temperatures, leading to reduced energy consumption during the printing process.

- Technical Parameter: Printing temperature range of 180-220°C compared to higher ranges for traditional filaments.

- Maintenance Costs:

- Reduced wear and tear on 3D printer components due to fewer harmful emissions and lower operating temperatures.

- Technical Parameter: Longer-lasting printer components with fewer replacements needed annually.

- Bulk Purchasing Discounts:

- Many suppliers offer discounts on bulk purchases of natural filaments, which can help in reducing the overall material costs.

- Technical Parameter: Bulk discount rates vary, typically ranging from 5% to 20%, depending on the quantity ordered.

By carefully considering these cost-saving aspects, it is evident that natural filaments not only fulfill technical requirements but also offer economic advantages in your 3D printing endeavors.

How to Maintain and Store Natural Filament?

To maintain and store natural filament effectively, follow these guidelines:

- Keep Dry: Store filament in a dry environment to prevent moisture absorption. Using airtight containers with silica gel packs helps maintain low humidity levels.

- Avoid Direct Sunlight: Exposure to UV light can degrade the filament. Store in a dark place or use opaque containers.

- Temperature Control: Maintain a stable temperature in your storage area to prevent thermal damage. Avoid extremes of heat or cold.

- Proper Spooling: Ensure the filament is evenly spooled to prevent tangling, which can cause printing issues.

- Use Desiccant: Replace silica gel packs regularly to ensure they continue to absorb moisture effectively.

- Labeling: Clearly label each spool with the type, date of purchase, and any other relevant information for easy identification and inventory management.

By following these steps, you can ensure the longevity and performance of your natural filament, contributing to more successful and consistent 3D printing outcomes.

Proper Storage to Prevent Moisture Damage

Proper storage of natural filament is crucial to avoid moisture damage that can significantly impair the quality of your 3D prints. Based on the top resources available, here are the essential guidelines and technical parameters you should follow:

- Humidity Levels: Maintain a relative humidity (RH) level below 20% in your storage environment. This can be achieved using airtight containers or dry boxes, and supplemented with silica gel packs to absorb residual moisture.

- Temperature Control: Store filament in a cool and stable temperature environment, ideally between 15°C to 25°C (59°F to 77°F). Avoid storing filament in areas prone to temperature fluctuations or direct sunlight exposure, as this can cause thermal degradation and warping.

- Drying Filament: In case the filament has absorbed moisture, use a filament dryer or a conventional oven set at a low temperature (40°C to 45°C or 104°F to 113°F) for a few hours to restore its optimal condition.

- Airtight Storage Solutions: Utilize vacuum-sealed bags or airtight containers to minimize exposure to ambient air. Many commercial filament storage solutions provide humidity indicators to monitor and maintain appropriate storage conditions.

- Desiccants: Employ desiccants like silica gel packs or calcium chloride to control moisture. Replace or recharge desiccants regularly to ensure continuous moisture absorption.

By adhering to these strategies, you can effectively prevent moisture damage, thereby prolonging the life and ensuring the reliability of your natural filaments. These practices align with recommendations from leading sources such as All3DP, MatterHackers, and Prusa Research, which emphasize the importance of a controlled environment for optimum filament performance.

Care Tips for Long-lasting Filament

To ensure the longevity of my 3D printing filament, I follow consistent and effective care practices. Based on insights from the top three websites on Google, here are the key tips I’ve implemented:

- Airtight Storage: I store my filament in airtight containers with silica gel packs to keep moisture levels low. This helps in preventing moisture absorption, which can degrade the filament quality. According to multiple sources, maintaining a relative humidity level below 20% is ideal.

- Avoid Sunlight Exposure: Direct sunlight can degrade the filament over time. I ensure to store my filament in a dark place or use opaque containers to shield it from UV exposure, which can cause brittleness and colour fading.

- Stable Temperature: I keep my storage area at a stable temperature to avoid thermal damage. Most experts recommend a temperature range of 15°C to 25°C (59°F to 77°F) for storing filament. This prevents both high heat, which can soften the filament, and cold, which can make it brittle.

- Proper Spooling: Ensuring the filament is evenly spooled is crucial to avoid tangling, which can lead to printing issues. I regularly check my spools for evenness and re-spool if necessary.

- Regular Replacement of Silica Gel Packs: Silica gel packs are essential for absorbing moisture. I replace them regularly, about every six months, or when they visibly change colour as an indication of moisture saturation.

- Clear Labeling: I label each spool with the type of filament, date of purchase, and any other relevant information. This helps in quick identification and effective inventory management.

By adhering to these tips, I’ve been able to maintain the quality and performance of my 3D printing filament consistently.

Frequently Asked Questions (FAQs)

Q: What are the benefits of using natural filaments like PLA filament for 3D printing?

A: Natural filaments such as PLA filament are bioplastic products, making them environmentally friendly and easy to print. They offer a resilient and tough printing experience, giving exceptional results and a smooth tone to finished products.

Q: How can I track my shipping status for natural 3D printer filaments?

A: You can track your shipping status via your account on our website. Simply click on the order number and you will get real-time updates on the shipping.

Q: Is natural 3D printer filament available in various colors and tones?

A: Yes, natural 3D printer filaments are available in a wide range of colors and tones, including custom colors matching the RAL color palette. This allows you to get the best results for your specific project needs.

Q: What filament diameters do you offer for natural filaments?

A: We offer natural filaments in 1.75mm and other standard diameters, ensuring they are compatible with most 3D printers.

Q: Do you offer international shipping for your natural filaments?

A: Yes, we offer international shipping to ensure our customers worldwide can access our high-quality natural 3D filaments. Shipping fees and times vary depending on the destination.

Q: Can I get a composite filament for more resilient and tough applications?

A: Yes, in addition to natural PLA filament, we also offer composite filaments for more resilient and tough applications. These filaments combine various materials to enhance product strength and functionality.

Q: How do I contact customer service for more information about natural filament products?

A: You can contact our customer service via email. We aim to respond to all queries promptly and provide comprehensive support for any questions you may have.

Q: Are your natural filaments packaged in eco-friendly materials?

A: Yes, our natural filaments come in eco-friendly packaging such as cardboard, reducing single-use plastics and aligning with our commitment to sustainability.

Q: Can I collect my natural filaments directly from your store?

A: Yes, if you prefer, you can collect your natural filaments directly from our store in the Netherlands. This allows you to save on shipping fees and get your products faster.

Q: How do natural 3D filaments compare to other materials like resin and PETG?

A: Natural 3D filaments like PLA are bioplastics and are easy to print, making them ideal for those starting in 3D printing. Resin and PETG are also popular but cater to different applications. Resin offers exceptional detail and smooth finishes, while PETG is known for its toughness and flexibility.