Magnets have fascinated humanity for centuries, from the simple lodestone to the sophisticated neodymium magnets of today. This blog delves into the intriguing world of metal magnets, examining their properties, uses, and the science behind their magnetic force. Whether you are curious about how magnets help in everyday items like refrigerators and smartphones or interested in their industrial applications, this article will provide a comprehensive overview. Prepare to explore the different types of metal magnets, from the powerful neodymium magnets to the more traditional bar magnets, and understand their roles in modern technology and beyond.

What is a Metal Magnet and How Do They Work?

Understanding the Basics of Metal Magnets

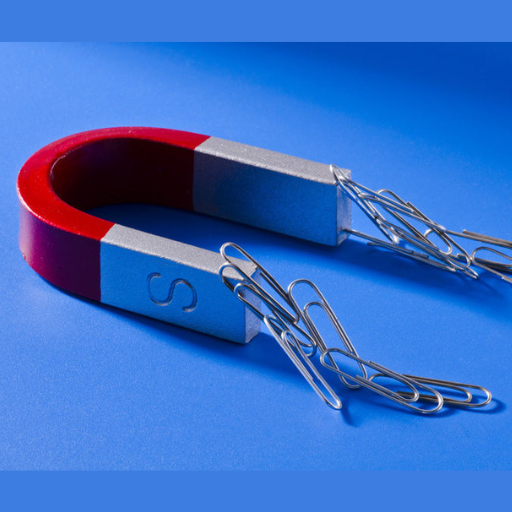

Metal magnets are designed to make a magnetic field, which is an unseen power that attracts or repels certain materials such as iron, nickel, and cobalt; this is the most important part of their design. The idea behind magnetism is very simple – everything has tiny regions called “magnetic domains” where groups of atoms align themselves with each other so their north and south poles point in opposite directions. When these regions line up all through something like a piece of metal then it becomes magnetic because its atoms become aligned too! Some magnets occur naturally like lodestones while others can be made by humans such as neodymium magnets or bar magnets produced by heating and cooling them within a magnetic field.

How Magnets are Made: From Ferrite to Neodymium Magnet

The method of making magnets differs depending on what they’re made out of i.e., whether ferrite or neodymium types are being created but both involve mixing powders together until they form solids. Ferrite ones which are often used since their cheapness mixes iron oxide powder with either strontium carbonate or barium carbonate powder; after being mixed thoroughly enough so that there’s no separation between particles any longer this mixture gets pressed into shape and then heated up until sintering takes place whereby everything fuses together tightly enough so nothing falls apart again when cooled down afterwards next exposed to some strong magnetism.

Neodymium magnets have an even more complicated process behind them because these types can produce stronger fields than any other kind known today but doing this requires much greater effort from us during manufacture. First, we must take three metals – neodymium (Nd), iron (Fe) and boron (B) – which need melting before casting into thin sheets for rolling into smaller grains later on during grinding still further into powders finally mixed well together before compressing tightly within dies followed by sintering at high temperatures ranging between 1000°C up towards 1300°C according specific composition used hereafter slicing off pieces according shape wanted after this coated against rusting before final magnetization done making sure that all directions align themselves properly thus giving maximum strength possible such magnets; it’s worth noting here though that even these won’t last forever unless cared for properly over time.

How Metal Magnets Are Used in Everyday Life

Metal magnets have many purposes in everyday life and they make up a part of many technologies and conveniences that are often overlooked. Here are a few examples:

- Home Appliances: Many household appliances like fridges, microwaves, washing machines and so on depend on metal magnets to function properly. For example, the motors in washing machines sometimes contain neodymium magnets because of their high energy product (up to 52 MGOe) that gives strong magnetic fields in compact forms.

- Electronics: In technology, speech systems, computer hard drives and earphones cannot do without iron magnets. Because neodymium magnets produce powerful magnetic fields that enhance sound quality, they are preferred for speakers as well as headphones. Also, these ones give rapid read/write speeds due to their strong and stable magnetism.

- Medical Equipment: Neodymium or superconducting wire is commonly used to make strong magnets found in different medical devices like MRI machines that rely on intense magnetic fields (usually between 1.5-3 Tesla) to provide body scan images with maximum detail. The strength of these magnets makes them ideal for medical diagnostics requiring precision and consistency.

- Transportation: Electric motors and various sensor-based systems in the automotive industry use magnets extensively. For example, electric or hybrid vehicles’ motors use neodymium being the best materials with high remanence and coercivity thus enhancing efficiency as well as performance.

- Renewable Energy: Wind turbines utilize powerful permanent magnets including those made from neodymium alloys which transform mechanical energy into electrical energy through generators placed inside them. By embedding them within rotor-stator arrangement within such a system this enables efficient conversion of energy at low losses thereby minimizing power losses.

- Industrial Automation: Industrial processes can be enhanced by using advanced robotic applications such as sensors or servo motors controlled by electromagnets. They increase accuracy as well as control features of any fully automated set-up.

These strong, versatile magnets are integrated into different applications across industries to improve performance, efficiency and bring about novel functionalities that would otherwise not be possible.

How to Choose the Right Magnet for Your Needs?

In The World of Magnets: From Rare Earth To Fridge Magnets

Choosing the right magnet for your individual needs depends heavily on its application and the properties required in a magnet.

- Rare Earth Magnets: These include neodymium and samarium-cobalt magnets that are characterized by their very strong magnetic characteristics. Neodymium magnets are the world’s strongest permanent magnets, used widely in applications that require high magnetic fields such as electric motors, MRI machines, and wind turbines. Samarium-cobalt magnets on the other hand are slightly less powerful than neodymium but they have better performance at high temperatures making them suitable for aerospace and military applications.

- Ceramic (Ferrite) Magnets: They consist of barium or strontium carbonate coupled with iron oxide. While they do not have as much strength as rare earth magnets, these types of magnets are cheap, do not corrode easily and remain magnetized for longer thus making them usable in loudspeakers, fridge seals and kid’s toys.

- Alnico Magnets: These ones contain nickel, aluminum, cobalt which makes it possible to withstand extremely high temperatures while retaining constant magnetic power. For example they could be used in electric guitar pickups, sensors or relays because their properties stabilize across a wide temperature range.

- Flexible Magnets: Rubber binders mixed with ferrite powders make them pliable enough to be shaped or cut out into rolls. Commonly found on refrigerator doors seals advertisements or magnetic signages as well; they offer flexibility both at home and office environments.

- Fridge Magnets: Generally made from flexible materials or ceramics but tend to be weak yet suitable for light weight purpose like holding notes on fridges

By understanding what makes each type of magnet unique you can choose the most appropriate one for your specific application criteria.

The Powerhouse Magnetics? What Makes Neodymium Strong?

Neodymium magnets are commercial strongest permanent magnets consisting of neodymium, iron and boron. Their high strength is due to a very large magnetic energy product, which is often ten times greater than that of ceramic magnets. As such, they are highly efficient in applications requiring strong compact magnetic fields. Moreover, neodymium magnets are known for their toughness as they retain their magnetism over time and can survive demagnetizing effects of other magnetic fields that it comes into contact with or due to temperature fluctuations. To enhance their performance in extreme conditions, some neodymium magnets receive coatings like nickel or epoxy on them that prevent corrosion and surface damage thereby ensuring long-lasting serviceability of such devices used in aerospace, military or advanced industries.

What Are the Uses of Magnets in Home and Office?

Uses of Magnetic Boards and Fridge Magnets

The roles magnetic boards and fridge magnets play both in homes and offices are critical. They act as handy tools for organization and communication.

- Magnetic Boards: Offices often use magnetic boards for project management, brainstorming sessions, scheduling among other uses. The magnetic surface allows for easy attachment and rearrangement of documents, notes, and visual aids facilitating collaboration among team members thereby improving productivity. Besides, they may be used at home to serve as family message centers, meal planners or homework stations so that every family member knows what is going on around them.

- Refrigerator Magnets: These deceptively simple things can do a lot. Most people usually put grocery lists, reminders and important notes on the fridge with the help of these magnets to make sure one has access to vital information at any time needed. And besides their practical purposes, magnets can also be decorative ones which reflect someone’s personality through showcasing their travel memories or hobbies as well as containing pictures of friends and relatives thus making it more personal rather than just a common household appliance.

If you want your office or house to function smoothly without any messes then consider using such items as magnetic boards along with fridge magnets for daily needs.

Organization And Decoration With Office Magnets

In a workplace where orderliness is key in saving time while working efficiently with quality results office magnets are essential tools for organization; however aesthetically they add beauty to an office setting. There are different types of office magnets that may be used such as those found on magnetic boards, file cabinets among other metallic surfaces to hold important documents like memos and schedules safely locked ensuring that essential information is within reach by the entire team. Additionally, some office magnets have an aesthetic value giving the workspace some color thereby adding some personality into otherwise dull walls of white paint. For instance, decorative magnets might reflect the company’s brand or culture whereas others could have motivational quotes while some could be visual arts that enhance general ambience in the office. By integrating functional and decorative magnets, offices can cultivate a more organized, efficient, and visually appealing workspace.

Convenient Kitchen Storage: Magnetic Knife Holder

A magnetic knife holder is a great solution for convenient kitchen storage. This device not only saves the counter space but also helps to organize knives better and make your kitchen safer. The use of a magnetic strip to hang knives ensures their accessibility as well as preventing them from being reached by children. Moreover, this type of holder will keep your knives sharp since they won’t be knocking up against each other in a drawer thus making them dull faster. Besides functionality, these holders make your kitchen décor look modern and sleek making it a practical yet stylish choice.

Everyday life in the kitchen, office or home is enhanced through the use of different types of magnets for organization purposes as well as personal touch. From magnetic knife holders to decorative refrigerator magnets, these small yet mighty devices go a long way in keeping spaces neat and attractive at the same time.

How to Handle and Store Metal Magnets Safely?

Safety Tips for Handling Strong Magnets

When moving powerful magnets, you must stick to specific safety rules and regulations to avoid getting injured or causing damage. First and foremost, always wear protective gloves and glasses to protect yourself from crushes or debris that may fly out. It is also necessary to keep the magnets as far away from electronic devices like mobile phones and computers because this can be dangerous for these devices. Furthermore, do not place strong magnets close to medical equipment such as pacemakers since they can interfere with their operations. Keep them in a secure non-metallic container that separates them so that they cannot snap together suddenly causing breakages and injuries. Finally, ensure that children are not near powerful magnets so as not to eat them accidentally or get injured when playing with them. By following these precautions, you will be able to safely use strong magnets.

Proper Storage to Maintain Magnet Strength and Longevity

Proper storage of magnets is essential to maintain their strength and prolong their lifespan.

- Avoid Heat Exposure: For instance too much heat could demagnetize your magnet therefore store it in a cool dry place. On the other hand, high temperatures lead into disordered magnetic domains which consequently cause weak magnetism.

- Keep Away from Magnetic Fields: In order to maintain magnetism at its maximal strength possible avoid storing the materials near electromagnetic devices and other materials of similar nature. This practice makes sure that their magnetic properties are retained.

- Use Spacers and Shields: To minimize impact or frictional damage through clumping of magnets together, one can apply spacers or magnetic shielding’s. This is supplemented by non-magnetic dividers or containers thus reducing an instant cracking sound if there is such an occurrence.

- Store Magnetically Aligned: Arrange the magnets in ways where there are no opposite magnetic fields among themselves. It helps sustain their stability in terms of magnetism hence avoiding any self-demagnetization.

These storage practices can help preserve the strength and functionality of your magnets over extended periods of time.

Understanding the Magnetic Properties in Various Environments

Magnets exhibit different properties depending on the environment in which they are placed. Here are some key factors and corresponding technical parameters that affect magnetic performance in diverse settings:

- Curie Temperature: The temperature limit above which a magnet loses it ability .For example neodymium has curie temperature of around 310-400 °C while samarium-cobalt has a high temperature of up to 700°C.

- Operating Temperature Range: The range within which different magnets may operate best is also another factor to consider. For example, the neodymium magnets can work suitably within temperatures of between 80-150 °C whereas alnico magnets can also be used at temperatures as high as 540 °C.

- Corrosion Resistance: Depending on the type, magnets like neodymium which is a rare earth magnet tend to corrode when exposed to highly humid environments. In order to prevent this problem nickel, zinc or even epoxy coating is often applied onto it.

- Coercivity: It is the resistance for being demagnetized by external magnetic fields. High-coercivity magnets such as rare-earth (neodymium, samarium-cobalt) materials have typical values of about 840-1200 kA/m.

- Demagnetizing Field: Greater size or specific morphologies like long and thin shapes produce internal demagnetization fields that cause overall weakening.

- Aspect Ratio: A higher proportion (length divided by diameter) makes the material more resistant towards self-demagnetization. This means that rods or cylinders are less likely than thin discs to achieve demagnetization.

- Tensile strength and brittleness: Neodymium magnets, for example, are intrinsically brittle and can break under mechanical strains; therefore they should not be placed in areas where they may be exposed to unforeseen shocks or impacts.

By taking into account these environmental factors and understanding their technical parameters, you can optimize the use and longevity of magnets across various applications.

How to Personalize Your Magnet Collection?

Creating Custom Metal Magnets for Home Decor

The first step in creating custom metal magnets for home decor is to pick a design that speaks to me or reflects the theme of the room where I want to use them. The next thing to do is choose high quality pictures or images and change their sizes so they can fit onto the magnets. Using adhesive paper, I put the design on it using a laser printer. This means cutting the piece of paper into shape based on which metal surfaces I go with (for example, small discs or larger sheets).

When all pieces are ready, apply adhesive design with precision and flatten all air bubbles and creases found on the metal. Sometimes though, these magnets; moreover; tend to be coated with a clear sealant or resin-like substance to make them stronger as well as shinier looking. Thus not only does this protect its appearance but also gives it an expert shine look after it has dried up fully. Finally, when everything is dry, placing my own custom metal magnets around different sections of my house such as fridge and that magnetic board will create my own unique taste.

Designing Photo Magnets and Souvenirs

Designing photo magnets and souvenirs requires a personal touch that makes each finished product special and worth remembering. First off, I have to find photos that bring back memories or else remind me of something important happening in life. Some examples include family gatherings, holidays as well as important functions among others things like these. After editing them so that they correspond with right pixels per inch (ppi)and dimensions required for magnet surface selected by me using this software program, later printing these pictures out onto photo stick papers is what follows through.

Then resize your photos accordingly so they can match your magnet’s dimensions.Scale down laminated paper prints before attaching them on your magnet bases such that you get rid of any air spaces remaining in between.The addled coverings ought to be substituted in the event of possible by laminating the magnets for protection. After the whole thing is completely dry, I am now ready to hang these customized photo magnets and give them as gifts for birthdays.

Choosing the Right Magnet Pack: Options and Versatility

In order to make a suitable choice, there are aspects like versatility and quality that I take into account while purchasing magnet packs. Packs that have a mixture of shapes such as squares, strips or discs which can be used for different projects are what I usually select. It is also important to consider how strong a magnet is; neodymium magnets have always been preferred because they hold better. Also, it would be nice if magnet packs come with an adhesive backing on their rear side to simplify their attachment process. Therefore, a diversified set of quality magnets comes in handy when attempting various DIYs and other creative works.

Frequently Asked Questions (FAQs)

Q: What are strong neodymium bar magnets?

A: Strong neodymium bar magnets are rare earth magnet types characterized by their powerful magnetic field and high magnetism levels, which makes them suitable for various applications including industrial and commercial purposes as well as hobby projects.

Q: Can stainless steel surfaces be withstood by a bar magnet?

A: Yes, though compatibility may vary considerably depending on the precise alloy composition, many stainless steel surfaces can be withstood by bar magnets. Check always if the specific stainless steel you have is ferromagnetic or not.

Q: What are some uses of iron magnetic materials?

A: These natural materials are applied in multiple fields including mounting equipments, tool holders, magnetic boards and even in some machineries given their durability and strength.

Q: How do super powerful neodymium disc magnets differ from ceramic magnets?

A: Super powerful neodymium disc magnets are constructed from rare earth (also called Neodymium) magnetic material having higher magnetism when compared to ceramics which tend to be less strong but more resilient to corrosion and cheaper to manufacture.

Q: Are there custom order metal magnetic solutions available?

A: Absolutely yes! There are numerous suppliers who avail a chance for anyone wishing to make an order based on exactly what they prefer such as sizes that haven’t been seen before or shapes that were never thought about before.

Q: What dimensions do typical bar magnets come in?

A: A common dimension of a bar magnet is 60 x 10 x 3 mm although they may come in different sizes according to demand. You need to choose the right size based on your application requirements.