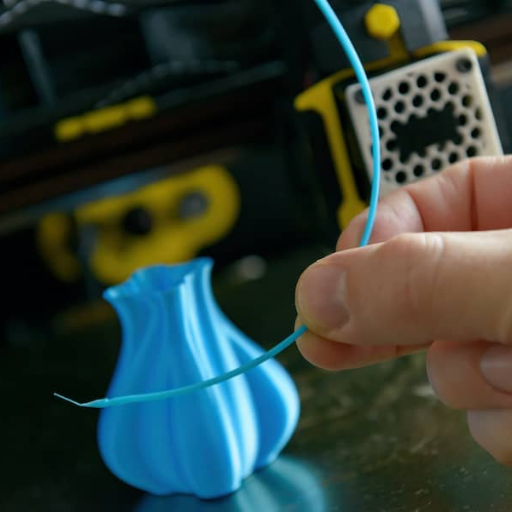

What is PETG and Why is it Popular in 3D Printing?

Image source: https://www.unionfab.com/

Understanding PETG: A Polyethylene Terephthalate Glycol Compound

The Physical and Chemical Properties of PETG

Another thing that makes PETG (Polyethylene Terephthalate Glycol) stand out is its unique blend of physical and chemical properties. Physically, PETG’s impact resistance and flexibility are noteworthy, which makes it an enduring option for a variety of applications. It has a glass transition temperature of about 80°C, meaning it can be exposed to relatively high temperatures before it becomes moldable. In actual fact, PETG is chemically resistant to various substances including water, acids and alkalis hence its applicability in diverse environments.

PETG also exhibits a low shrinkage rate that significantly reduces warping during the printing process. This property combined with excellent layer adhesion results in high quality consistent prints. Transparency remains one of its remarkable attributes that assures users clear visibility when required. On top of that, PETG can simply be used by most people who have basic knowledge on 3D printers because there is no requirement for heated beds or special extruders thus making it user-friendly to both beginners and experts as well.

Comparison: PETG vs. PLA Filaments

When you compare PETG with PLA filaments, there are several striking differences and advantages.

- Strength and Durability: Generally, PETG is stronger and more durable than PLA. It has high impact resistance and flexibility hence suitable for mechanical parts and objects requiring high durability. On the other hand, PLA is easier to print but is brittle; therefore it’s ideal for aesthetic models & prototypes.

- Ease of Printing: PLA is usually recommended for beginners because it has low printing temperature as well as little warping. Its printing temperature ranges from 180°C to 220°C without needing a heated bed. Conversely, PETG requires higher printing temperatures which lies between 220°C – 250°C, thus users require a heated bed to eliminate warping; however it remains comparatively easy to print with good layer adhesion.

- Environmental Impact: PLA is made using renewable resources like cornstarch hence biodegradable under industrial composting conditions making it be an environmentally friendly choice. On the other hand PETG comes from petroleum, which means that though not biodegradable, it can still be recycled thereby presenting a different approach to sustainability.

- Chemical Resistance: As compared with PLA filaments PETG exhibits better chemical resistance. It can stand up better in water, acids and alkalis used in various chemicals or outdoor environments.

- Applications: Because of its properties PETG is commonly used in functional parts such as food safe containers and medical equipment. Educational purposes prototypes as well as applications where delicate detailing and aesthetics hold greater importance than strength are suited by PLA the best.

What is the Melting Point of PETG and How Does it Affect 3D Printing?

The Science Behind PETG’s Melting Point

The kind of polymer PETG is determined by its temperature range that spans from 220°C to 250°C. PETG is basically a glycol-modified version of polyethylene terephthalate (PET). This polymer has glycol in it’s molecular structure which makes it less crystalline hence being clearer and tougher. That explains why PETG is highly resistant to chemicals and long lasting.

Key Technical Parameters:

- Melting Point: 220°C – 250°C

- Glass Transition Temperature (Tg): ~80°C

- Heating Temperature for Printing: 230°C – 250°C

- Bed Temperature Requirement: 70°C – 90°C

How to Achieve the Ideal Printing Temperature for PETG

Dealing with PETG’s Relatively High Melting Point During the Printing Process

What are the Ideal Print Settings for PETG to Avoid Issues like Warping?

Setting the Appropriate Nozzle Temperature and Bed Temperature

When you want to print with PETG, set the right nozzle temperature which starts at extruder temperature range of 230°C-250°C. In case one observes that filament is not flowing well, it is advisable to keep on increasing the temperature within this range until the best flow is attained. The bed temperature also plays a critical role in minimizing warping and fostering proper adhesion between printed layers. Adjust the bed temperature to between 70°C –90 °C depending on how stable the first layer looks.

Technical Parameters:

- Extruder Temperature: 230°C – 250°C

- Bed Temperature: 70°C – 90°C

Why Layer Adhesion and Bed Adhesion are Crucial for PETG

Common Problems and Solutions When Printing with PETG

Printing with PETG can sometimes be problematic. Here are some common problems and their remedies:

- Stringing and Oozing

- Problem: Too many strings or oozes between the print sections.

- Solution: Increase retraction settings and print speed. Lower the nozzle temperature if possible, and make sure filament is dry since moisture worsens this problem.

- Poor Layer Adhesion

- Problem: Weak prints caused by layers that don’t bond well together.

- Solution: Raise the print temperature a bit for better fusion between layers. Check on cooling fans to avoid too much cooling as it affects layer adhesion for PETG.

- Warping and Lifting

- Problem: Corners of the print lifting off bed or warping.

- Solution: Ensure bed temperature falls within recommended range (70°C – 90°C). Use glue stick or hairspray on bed to improve adhesion. Maintain proper bed leveling as it keeps first layer stable.

What Temperature Range is Best for Printing PETG?

Finding the Right Thermal Settings for Your 3D Printer

In order to determine the suitable thermal settings for your 3D printer, you must take into consideration the recommended temperature range for your filament. For PETG, this normally means setting the nozzle to a temperature within the range of 230°C to 250°C and the bed at a temperature between 70°C and 90°C. Here is a step-by-step process that is based on common suggestions:

- Consult Manufacturer Guidelines: Start with the recommended temperatures given by the makers of these filaments, which serves as a benchmark due to their unique format.

- Incremental Adjustments: Begin at lower end of recommended temperature range and increase in increments of five degrees Celsius. Be vigilant about changes in print quality when making adjustments.

- Test Prints: Test with small prints to find out which temperature gives good layer adhesion but does not lead to issues such as stringing or overheating.

- Bed Adhesion Tactics: If warping or lifting occurs, then use bed adhesives like glue stick or painter’s tape on it. First-layer stability can be enhanced through this method.

- Calibration: Regularly check if you have properly calibrated your 3D printer; this will ascertain whether its heating components are functioning well and its nozzle height and bed level are accurate.

The Impact of Glass Transition Temperature on Print Quality

Optimal Printing Temperatures for Various Projects

For distinct print jobs, which temperature to select as the optimum is a determining factor of final success. Below is a brief guide about temperatures from top Google sources:

- PLA (Polylactic Acid): PLA nozzle temperature usually ranges from 190°C to 220°C. Good adhesion without warping can be ensured by maintaining the bed temperature between 50°C and 60°C.

- ABS (Acrylonitrile Butadiene Styrene): As for ABS, it is generally recommended that you set the extruder’s temperature at around 220°C to 250°C. The build plate should be heated to higher temperatures, about 90 to 110 degrees Celsius, so as to prevent such issues like warping and layer separation.

- PETG (Polyethylene Terephthalate Glycol): PETG works best with nozzle temperatures ranging from about 230 to 250 degrees Celsius. The bed temperature should be kept in the range of between roughly seventy and ninety degrees Celsius in order that it could enhance adhesion while reducing deformation.

Why is PETG Understood to be a Durable and Impact Resistant 3D Printing Filament?

Mechanical Properties of PETG That Ensure Durability

PETG’s durability is attributed to several key mechanical properties.

- High Impact Resistance: PETG behaves excellently when subjected to an energy input from an impact load without fracturing. This means that it can withstand highly demanding conditions which could otherwise break or crack other filaments.

- Tensile Strength: PETG has a high tensile strength and can be stretched considerably without breakage. In this regard, the part can remain intact when under stress.

- Flexural Modulus: The flexural modulus attribute of PETG is well balanced in terms of both stiffness and flexibility. This implies that materials made out of it do not snap off abruptly but rather curve a bit when loaded.

Together with its chemical composition, these mechanical properties make it a versatile and resilient material for many 3D printing applications where durability matters most.

How PETG’s Water Resistance and Thermal Stability Boost Performance

One way in which printed parts can be made more durable is by keeping them from absorbing moisture through water-resistant properties of PETGs so as to avoid warping or degradation over time. It gives such components their lasting endurance despite exposure to humidity or fluids thus retaining their reliability and functionalism all through.

Another important characteristic of PETGs is thermal stability, which plays an important role in enhancing performance. With its high glass transition temperature, PETG retains its mechanical properties and structural integrity even at higher temperatures. Therefore, heat does not bend items made from this material hence they are said to be thermally stable unlike other products that get deformed easily due to warmth making them unsuitable for hot-temperature applications.

Because these combined attributes increase the longevity of prints made from PETGs while expanding their application across difficult environments ranging from outdoor environments to automotive components needing robust thermal capacity.

Using PETG for Prototypes and End-Use Parts

What Comparisons Can Be Made Between PETG and Other 3D Printing Filaments?

As well as this, PETG also provides very good chemical resistance almost comparable to or better than both PLA and ABS respectively thereby increasing consumer utility of its use in environments that might come into contact with chemicals. In general terms though, toughness of PETG material along with its ability to maintain its shape at high temperatures; ease of printing; excellent chemical resistance make it an outstanding filament for many applications: this enhances flexibility and expands applicability scope consequently.

How PETG Compares to PLA Filament

Several distinctions between PETG and PLA filament can be observed:

- Mechanical Properties: PETG is usually stronger and more durable than PLA. It has good impact resistance and flexibility, which makes it ideal for functional parts that are subjected to mechanical stresses. Conversely, this type of plastic is brittle, meaning it will work best for decorative products or those that do not require much strength.

- Thermal Properties: PETG’s glass transition temperature is generally higher (about 80°C) compared to PLA’s (around 60°C), enabling PETG components to resist higher temperatures before deforming. This makes it suitable in heat-related applications.

- Printing Ease: For instance, compared to its counterparts such as the ABS filaments; the material used in making the PLA filament has a low printable temperature range of about 200° Celsius. On the other hand, printing with PETG requires higher temperatures (approximately 240 °C) and may need special bed adhesion techniques although print warping is less common than with ABS.

- Environmental Impact: PLA is made from renewable sources such as corn starch and it can biodegrade in an industrial composting facility hence being more environmentally friendly option. On The Other Hand, PET-G cannot break down but can be recycled and exhibits superb chemical resistance making it an advantage in some applications.

Evaluating ABS Filaments Versus PETG

Several factors distinguish ABS (Acrylonitrile Butadiene Styrene) filaments from PETG when compared:

- Strength and Durability: PLA is less strong than both ABS and PETG. However, ABS is often chosen because of its toughness as well as the ease of machining it after printing. On the other hand, PETG is highly resilient.

- Thermal Properties: In terms of glass transition temperature, ABS’s is higher, at around 105°C, compared to that of PETG which has it at about 80°C making it more preferable for applications that will experience higher heat. This however also means that ABS requires higher printing temperatures and is more likely to warp.

- Printing Ease and Environmental Impact: Unlike ABS with a high instance of warping during printing due to fumes released into the air; without good ventilation this can be unpleasant for human beings. In terms of environmental friendliness, unlike PLA which cannot be composted but can be recycled while PETG brings in recyclability but no compostability.

Benefits of Using PETG Over Other Filaments

Reference sources

-

MatterHackers – Guide to PETG Filament

- MatterHackers offers an extensive guide on PETG filament, covering its properties, including melting point, printing parameters, and best practices for achieving optimal results in 3D printing projects.

- Source: MatterHackers

-

Prusa Research – How to Succeed with PETG

- Prusa Research provides a comprehensive article on working with PETG, detailing its material characteristics, recommended print settings, and melting temperature. The guide is designed to help users achieve high-quality prints using PETG filament.

- Source: Prusa Research

-

Simplify3D – PETG Print Quality Troubleshooting Guide

- Simplify3D’s troubleshooting guide covers the essential aspects of printing with PETG, including optimal printing temperatures and common issues related to the filament’s melting point. This resource is valuable for both novice and experienced 3D printing enthusiasts.

- Source: Simplify3D

Frequently Asked Questions (FAQs)

Q: What is the melting point of PETG filament used in 3D printing?

A: PETG filament, commonly used in 3D printing, has a melting point of about 230°C to 240°C. However, the exact temperature may vary depending on the manufacturer.

Q: How does the melting point of PETG compare to other 3D printing materials?

A: PETG has a higher melting point than materials like PLA, which typically melts at around 180°C to 220°C. Whereas PETG offers better thermal stability and strength, making it ideal for functional 3D printed parts.

Q: Why is nozzle temperature vital when printing with PETG?

A: The nozzle temperature is vital for PETG 3D printing because it ensures proper extrusion and layer adhesion. For PETG, the ideal nozzle temperature is usually around 230°C to 250°C.

Q: What are the properties of PETG filament that make it a popular choice?

A: The properties of PETG filament include high strength, flexibility, and good chemical resistance. PETG is considered a food-safe material and is less brittle compared to PLA, making it suitable for a variety of applications.

Q: Can PETG be used in place of other thermoplastic filaments like ABS or PLA?

A: Yes, PETG can be used in place of other thermoplastic filaments. It combines the ease of printing seen in PLA with the strength and durability of ABS, making it a versatile material.

Q: What print settings are recommended for PETG filament?

A: Recommended PETG print settings include a nozzle temperature of about 230°C to 250°C, a bed temperature of around 70°C to 80°C, and a slower print speed to enhance layer adhesion. It’s also beneficial to keep PETG filament in a dry environment to prevent moisture absorption.

Q: What issues might arise when 3D printing with PETG?

A: Common issues when 3D printing with PETG may include stringing due to its lower viscosity at high temperatures and warping if the bed temperature is too low. Proper PETG print settings can mitigate these issues.

Q: Is PETG considered a safe material for food-related 3D printing projects?

A: PETG is considered food-safe, making it suitable for creating 3D printed parts that come into contact with food. However, it’s important to use food-safe certified PETG and avoid contaminants during the printing process.

Q: Why might one choose PETG over other thermoplastics for 3D printing?

A: One might choose PETG over other thermoplastics because of its excellent mechanical properties, easy printability, and chemical resistance. PETG is better than PLA for making functional parts and offers more strength compared to other common 3D printing materials.

Q: What should be considered when storing PETG filament?

A: When storing PETG filament, it’s crucial to keep it in a dry environment to avoid moisture absorption, which can affect the print quality. Using a filament storage box or vacuum-sealed bags with desiccants can help maintain the integrity of the PETG filament.