To ensure the safety, reliability and performance of materials used in different applications, engineering and manufacturing depend heavily on material testing. This blog post seeks to offer a complete overview of material testing covering principles down from the grassroots to advanced methods used in industries. We all look into various methodologies employed in materials testing, their practical application areas, and how the future is shaping as far as this field is concerned. In the technology-driven world today; be it you’ve been around for long or are just fresh faced into this area, looking at what matters in material testing will be necessary for you. Join us on this journey as we unravel the intricacies and advancements that have made material testing quality and innovation’s backbone.

What is Material Testing and Why is it Important?

Comprehending the Fundamentals of Material Testing

Material testing is a way or method used to appraise materials in order to understand their physical, chemical, thermal and mechanical properties. This kind of analysis is important for confirming that materials are up to the mark as per the required specifications and standards for their intended purpose. The reason why material testing is necessary can be summarized as being responsible for ensuring the safety, reliability and durability of materials employed in diverse sectors like construction, aerospace, automotive and healthcare. Through identification of probable weaknesses or flaws, material testing prevents accidents while supporting product development hence protecting users and investments.

Use of Tests in Quality Control & R&D

Material testing is essential in both quality control and research and development (R&D). Testing ensures materials meet specific standards set by authorities thereby maintaining uniformity during production as well avoiding defects with quality control. This process entails regular controls and validations at different stages of manufacturing so that the final product can be safe and dependable too. For R&D, material testing helps invention by providing insights on various properties an item has. This data is then used by researchers to come up with new products while bettering on what they already have thus pushing technology forward for competitive edges among industries around.

The Role of Material Testing in Ensuring Product Safety and Reliability

In various industries, product review testing is a vital component for ensuring materials are safe and of good quality. Tests help verify that the product can be used in real world conditions by confirming that it is capable of resisting stress, strain and other environmental forces. Some common parameters assessed:

- Tensile strength: It measures the highest tensile stress which material can withstand before failure by being stretched.

- Hardness: It is measured using tests such as Brinell, Rockwell and Vickers to determine the resistance of materials to deformation.

- Fatigue limit: This shows how well a material can resist repeated loading without breaking.

- Impact resistance: Charpy or Izod tests are usually performed on this type of property to check the ability of a material not to crack under sudden forces

- Corrosion resistance: This determines whether a material will degrade due to its reactions with corrosive chemicals or due to electrochemical processes

- Thermal conductivity: The heat conducting ability that makes a difference when temperature swings are involved.

For each case, these technical characteristics play an important role in estimating both their performance and durability within respective applications wherein meticulous testing identifies any potential flaws at the earliest possible stage so that necessary corrections may be made before final product integration has been done depending upon the same perspective toward reducing failures along with accidents thereby protecting users while ensuring trustworthiness about investments made into them.

Exploring Different Types of Material Testing

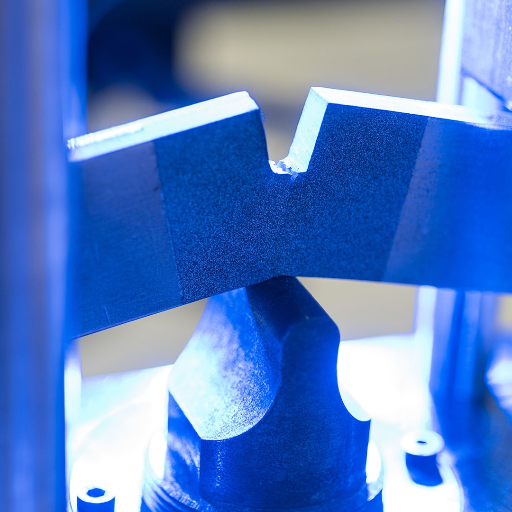

Tensile Testing and Its Importance in Assessing Material Strength

It is a basic way of assessing the power of materials and their resistance to different types of forces. I found out from my research that tensile testing entails stretching a sample material until it breaks for measurement of its tensile strength, elongation and modulus of elasticity. It has been established that this kind of test gives information on how materials will behave in diverse forms of stress hence determining their suitability in particular applications. Consequently, knowing the tensile characteristics of a material helps you to identify its behavior under real working conditions necessary for ensuring safety and reliability in engineering and manufacturing processes.

Compression Testing: Methods and Applications

Compression testing is a very important method that is used in determining how materials respond to compressive forces, thus giving insights into their mechanical properties. It entails loading a specimen uniaxially until it fails or deforms. The results provide valuable data on:

- Compressive Strength: This reveals the ultimate stress at which the material fails under compression. Therefore, this property is crucial in understanding how a material behaves when subjected to crushing forces.

- Modulus of Elasticity: The stiffness of the material during elastic deformation also known as Young’s modulus. This makes it possible for one to determine how much a given load will cause any deformation of the tested material.

- Yield Strength: The point at which plastic deformation sets in for particular materials. Knowledge of this helps design materials that can take up certain loads without undergoing permanent distortion.

- Ultimate strength: This describes the highest stress level where the object undergoes before breaking apart completely. It is critical in ensuring that construction, automotive and aerospace industry components with long lifespan and safety are used.

Different methods exist for conducting compression testing depending on the material being considered and its intended application; however, common types include using an Universal Testing Machine (UTM) to apply this weight and measure subsequent changes in shape as well as dimensionality. Such technical parameters aid engineers when selecting appropriate materials and designs so that they may end up with safe, yet efficient structures and products.

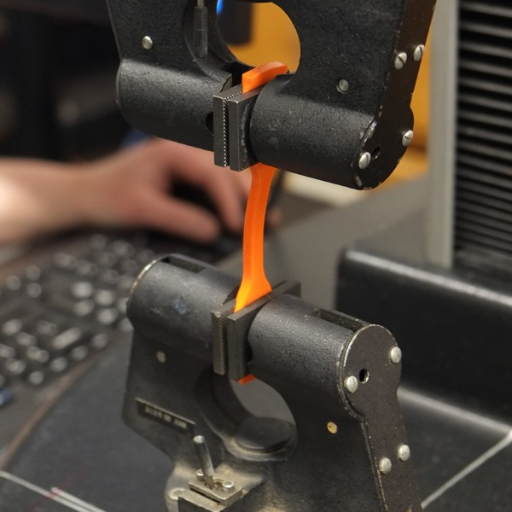

Understanding Bend and Flexure Testing in Materials

The tests for bend and flexure are critical in evaluating the ability of materials to bear bending forces without breaking. In general, these tests involve loading specimens until they deform or break, thus giving an indication of their flexural strength and stiffness. Normally, methods such as three-point bending test are used whereby a sample is placed between two supports with the load applied at the middle.

Key Parameters in Bend and Flexure Testing:

- Flexural Strength: This is the stress experienced by a material when it breaks. It helps to evaluate how well a material can carry loads.

- Flexural Modulus: Shows how rigid a material is when bent; which plays an important role in applications requiring rigidity.

- Flexural Yield Strength: The stress that results in elastic-plastic transition during bending suggests to engineers about parts that will not yield under operating loads.

By these tests, reliability and longevity of materials are ensured as far as their use is concerned in different fields like construction and aviation for example.

The Significance of Shear and Peel Strength Tests

I know how important it is to carry out shear and peel strength tests because it determines the performance of materials and adhesives under stressed conditions. The internal structure of a material or adhesive that allows the material to slide against itself defines this property. Materials used for structural components and assembly joints are subjected to stress parallel to their surfaces, and as such need to have high shear resistance.

On the other hand, peel strength tests determine how well an adhesive bond can withstand separation when peeled off. This is crucial in packaging, automotive, aerospace among others where the quality of the adhesive bonds has significant impacts on product safety and performance. Material engineers use these tests to verify if materials they have used will function reliably in their applications thus enhancing the life expectancy of products made from them thereby reducing accidents.

How to Choose the Right Test Machine for Your Material Testing Needs

Comparing Different Types of Material Testing Machines

When contrasting various types of material testing machines, one must reflect on your testing applications. Here are the main types of machines to consider based on information from the best resources:

Universal Testing Machines (UTMs):

Versatile and multi-purpose, UTMs can perform tests such as tensile, compressive and bending. They are suitable for wide range of test methods required by different applications that involve different materials thus making them widely used in many industries.

Hardness Testers:

These machines measure how hard a material is using various techniques like Rockwell, Vickers or Brinell testing methods. They are necessary where knowledge about resistance to deformation and wearability of the substance being tested for hardness is important.

Impact Testers:

Toughness or ability to absorb energy without breaking under sudden loads imposed on it can be determined by impact tests which evaluate this property called toughness in materials; this category includes automotive industry among others which require materials that can withstand shock loads during accidents or sudden stops caused by other vehicles hitting them while moving at high speeds through air space.

Knowing what each kind does best will enable you select wisely so that accurate outcomes may be achieved in relation to one’s material testing requirements.

Universal Testing Machines: A Complete Solution to Material Testing

In our material testing arsenal, there is no way we can overlook the usage of Universal Testing Machines (UTMs). From my extensive research using reliable sources, I’ve come to know that UTMs are outstanding because of their versatility and all-encompassing tests. They allow me to do various types of tests such as tensile, compression, and bending which is particularly useful while working with different materials. As a result of this adaptability, I am capable of determining material properties accurately and dependably across various applications. In summary UTMs provide a powerful tool which is flexible enough to satisfy the wide ranging demands for material testing before it is used in many industries.

Key Considerations When Choosing a Test Machine

There are several critical factors that I have found necessary to consider when choosing a test machine so that it can be suitable for my specific needs. The first factor includes the nature of the material under investigation which plays a key role; some materials may necessitate different test methods. For example metals could require tensile and hardness tests while plastics might need flexibility and impact tests more than anything else. Secondly, it’s important to have a machine that can perform multiple operations with regard to the intended uses. A Universal Testing Machine (UTM) that caters for different types of materials has great importance since it will give results about various properties exhibited by these materials in general terms. Finally accuracy and precision become critical elements in the selection process. It’s important to get accurate measurements from your machine at all times if you are going to trust your data output at any point in time. Lastly,the ease of use and software compatibility can significantly affect my testing processes’ efficiency making it simple integrate the machine into existing workflows.I use these criteria when selecting an ideal test machine which provides accurate& trustworthy results for my material testing requirements..

Understanding the Science Behind Compression and Elongation Tests

The Process and Principles of Compressive Testing

Determine how a material behaves under a compressive load through compression testing. In this test, the specimen of the material is subjected to controlled compression until it deforms or fails. It simply involves putting the material between two plates then applying force on it which reduces its height. Some of the important parameters that are recorded include compressive strength, deformation and modulus of elasticity. To ensure that I prepare a uniform sample, as well as conform to testing standards for sample dimensions. The force applied during the test is closely monitored by me using very sensitive sensors and software that also track corresponding deformation. This gathered data helps me understand how much load the material can bear without breaking down thus essential in areas like construction industries that require materials to withstand high amounts of compressive stress.

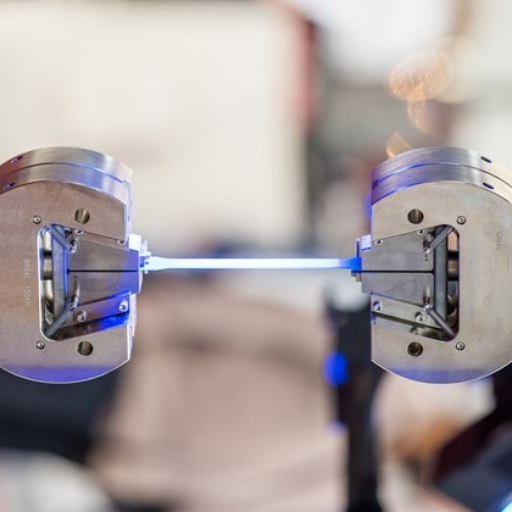

Measuring Elongation: Techniques and Significance in Material Testing

Elongation measurement is an important aspect of materials testing because it provides information regarding ductility and tensile characteristics of materials. My elongation tests involve subjecting samples to tensile forces until they elongate before breaking apart naturally. Extensometers are some of my highly accurate tools used to determine such deformations precisely. There are two main measurements taken into consideration; these are elongation at breakage and percentage elongation. Determining how far material can stretch before failure is crucial for manufacturing cables, fabrics or structural elements that demand flexibility coupled with tensile strengths for their quality products’ sake only but not limited thereon. Such data not only verifies if certain underspecifies meet industrial norms but also anticipates real world stresses performance.

Deformation Testing: How Materials Respond to Load and Stress

In deformation tests, I will investigate how various materials behave when different loads and stresses are applied on them. I then observe what happens when a controlled load is imposed on it which could be stretching, compression, bending or torque amongst others depending on response by the material. Yield strength of materials, which marks the beginning of permanent deformation and ultimate tensile strength, the maximum stress it can endure before it ruptures are established through this process. These properties are essential in estimating materials performance and ensure that they meet specific application requirements outlined by relevant standards. The knowledge gained from deformation tests is important for designing reliable products that can be employed in a range of industries such as construction and aerospace as well that require high level safety measures to be observed so as to avoid any possible accidents.

Applying Material Testing in Diverse Industries: Case Studies

Material Testing in Construction: Ensuring Safety and Compliance

Within construction, material testing is a necessary step to ensure both safety and regulatory compliance. In order for me to verify that construction materials such as concrete, steel, composites conform to the specified industrial standards and have ability to survive under anticipated loads as well as environmental conditions through rigorous testing methods. These include tests like compressive strength tests for concrete and tensile strength tests for steel. For any potential weakness which could undermine structural integrity, I can evaluate these features by observing these properties of tested materials. The significance of this aspect is demonstrated in its usage to strengthen safety codes and regulations while at the same time providing data that helps in certifying that materials used in construction comply with required standards thereby resulting into long lasting structures.

Advancements in Polymer and Composite Material Testing

The development of polymer and composite material testing has completely changed how we study them hence leading to their use in various industries. Through the adoption of new techniques such as dynamic mechanical analysis (DMA) and differential scanning calorimetry (DSC), I am able to get more precise information about the mechanical properties of polymers as well as composites thermal characteristics Studies using DMA can allow me assess a material’s stiffness across temperatures ranging from low frequencies while also giving insights on how it behaves during damping, thus provide a complete picture regarding its real-world performance.Due to advancements made in this field like scanning electron microscopy (SEM) or atomic force microscopy (AFM), modern imaging technologies enable me determine accurately what makes up the microstructural composition of these compounds.The aim here is ensuring that polymer content does not fall short of meeting industry specifications if they are optimized so that they can perform better than before especially when applied on automobiles or space crafts.

Innovative Testing Methods in Geotechnical Engineering and Ceramics

Such innovative approaches in geotechnical engineering have improved soil characterization techniques by leaps and bounds including cone penetration testing (CPT) and pressuremeter testing. The process of CPT, for example, yields soil resistance profile plots that help me infer soil stratigraphy as well as changes in soil composition with minimal disturbance. Similarly, the information obtained from pressuremeter testing by measuring the stress-strain relationship helps to estimate the ground deformability and stability.

In ceramics, non-destructive testing (NDT) methods have been transformed by new technologies such as X-ray tomography and ultrasonic testing. Use of X-ray tomography enables me to obtain internal structure’s three-dimensional image without damaging sample so that I can detect defects and track microstructural changes taking place inside it. At the same time, ultrasonic tests utilize high frequency sound waves to search for such defects and measure thickness accurately ensuring tightness and safety of ceramic components used in critical applications. These latest techniques assure higher-quality construction materials whether they be geotechnical or ceramic based.

Reference sources

1. Online Article: “Basics of Material Testing” – AZoM (Azom Materials)

- Source: AZoM

- Summary/Annotation: This article from AZoM provides a thorough introduction to material testing, covering fundamental concepts and common testing methods such as tensile, compression, hardness, and impact tests. It explains the purpose of each test, how they are performed, and their relevance in various industries such as construction, automotive, and aerospace. AZoM is a reputable online resource for materials science and engineering information, ensuring the content is accurate and credible. This source is beneficial for readers seeking foundational knowledge about different material testing techniques and their practical applications.

2. Academic Journal: “Recent Advances in Non-Destructive Testing Methods for Material Characterization” – NDT & E International

- Source: NDT & E International

- Summary/Annotation: This peer-reviewed paper published in NDT & E International reviews the latest advancements in non-destructive testing (NDT) methods for material characterization. The study covers ultrasonic testing, radiography, magnetic particle testing, and eddy current testing. It includes experimental data, case studies, and comparisons of traditional and advanced NDT techniques. As an academic journal, this source offers high credibility and technical depth, making it essential for readers interested in a rigorous scientific understanding of cutting-edge material testing technologies and their applications.

3. Manufacturer Website: “Material Testing Equipment and Solutions” – MTS Systems Corporation

- Source: MTS

- Summary/Annotation: MTS Systems Corporation’s website provides detailed information about their material testing equipment and solutions, including mechanical test systems, fatigue testers, and environmental simulation systems. The site features technical specifications, application notes, and industry-specific guidelines for conducting various types of material tests. It also includes practical tips for ensuring accurate and reliable test results, along with customer success stories showcasing real-world applications. MTS is a leading manufacturer of testing systems, providing authoritative and practical insights relevant to professionals and researchers seeking to implement and understand both basic and advanced material testing techniques.

Frequently Asked Questions (FAQs)

Q: What is material testing and why is it important?

A: Determining physical and mechanical properties of a given material is an essential aspect in the process of material testing. It also assists in the identification of whether some materials are fit for various applications amongst other things. These are useful to control the quality of finished products or as criteria for design or research work.

Q: What is a bend test in material testing?

A: A bend test refers to measuring the flexibility and ductility of materials like metals and plastics through mechanical testing. The process involves applying forces that bend or break a specimen within a fixture. In this case, angles at which plastic deformation begins without cracking are denoted bending points. This test requires special equipment that apply bending stress, used to measure deformability without fractures.

Q: How is crush resistance tested and why is it necessary?

A: Crushing resistance tests determine how much force can be applied on a sample before it collapses under compression. Such tests are crucial when assessing the load-bearing capacity of materials employed in construction industry, packaging industry as well as different industrial applications. For instance, after placing a sample between two plates, its crushing strength can be measured using load cells among others. Identifying whether a product will carry out a particular bearing function depends highly on its crush resistance.

Q: Can you explain what mechanical testing covers and how it’s conducted?

A: Mechanical testing constitutes diverse determinations regarding mechanical attributes such as tensile strength, modulus of elasticity, shear strength and compressive strength in materials subjected to loads . For example , these trials are done with specimens that include components like bending bars , dogs bone shape , or hollow cylinders etc . In this respect , extensometers or strain gauges connected to load cells often help measure force , elongation or deformation respectively during the experiments .

Q: How ASTM and ISO are relevant in material testing?

A: Material testing standards that are internationally recognized, provided by ASTM (American Society for Testing and Materials) as well as ISO. These standards state the conditions and methods under which the tests should be carried out, thus they ensure consistency, accuracy and reliability of test results. For physical as well as mechanical laboratories, it is quite common to observe compliance with ASTM and ISO standards when certifying materials for use in industry; this facilitates research and development activities as well as quality control procedures. Hence data from different sources become comparable, reliable when these code of practice are adhered to.

Q: How do testing laboratories determine the modulus of a material?

A: The modulus of a material or stiffness or young’s modulus is the measure of its resistance to elastic deformation due to loads applied. The tensile stress test method measures it whereby a sample is pulled until it undergoes strain on a test machine. The length change with respect to force applied can be measured using tools such like extensometer on specimen. The ratio of stress to strain portion of graph depicts elasticity moduli Reliable measurements require accurate measurement devices used by certified labs that employ standard techniques such as those outlined in ASTM D638.

Q: What considerations are there when needing to modify the testing machine setup for brittle materials?

A: Special considerations may have been made while conducting tests on brittle materials so as not to have premature failure or inaccurate results will happen. These modifications may include changing support fixtures that help spread forces more evenly throughout samples thus reducing localized stress leading to initiation of cracks Testing machines may contain better load cells or even grips designed in favor applying forces without introduction additional stress points Moreover how quickly load is being added becomes important because quick application could lead into shock failure or extremely slow rates might fail at representing actual environment conditions Standards dictate most adjustment steps but adjusting them appropriately needs skills necessary for proper setup modification during brittle material experiments.

Q: How is shear strength tested in materials, and what does it indicate about the material’s properties?

A: Shear strength tests measure how well a material can keep its layers from sliding against each other through force applied in a way that causes the material to move along a plane internal to it. In order for this to happen, mechanical testing machines have shear fixtures that applies loads either perpendicular or parallel to the surface area of the specimen. When the applied pressure per unit area reaches the value at which the material starts to slide across itself, it is called shear strength. i.e., shearing test results are used to judge whether given materials have capability of preventing their structural failure due to slipping under effects of forces like torsional twist or lateral push.