This blog aims to delve into the fascinating world of magnetic metals, shedding light on the magnetic properties of various metals and alloys. Magnetism is a crucial characteristic in many technological applications, from electric motors to data storage devices. Understanding which metals are magnetic, and the reasons behind their magnetic behavior, provides valuable insights for both scientific inquiry and practical uses. In this comprehensive guide, we’ll explore the fundamental principles of magnetism, identify the metals that exhibit magnetic properties, and discuss their significance in industrial and everyday contexts.

What is Magnetism and How Does it Affect Metals?

Magnetism Defined: Going Back to Basics

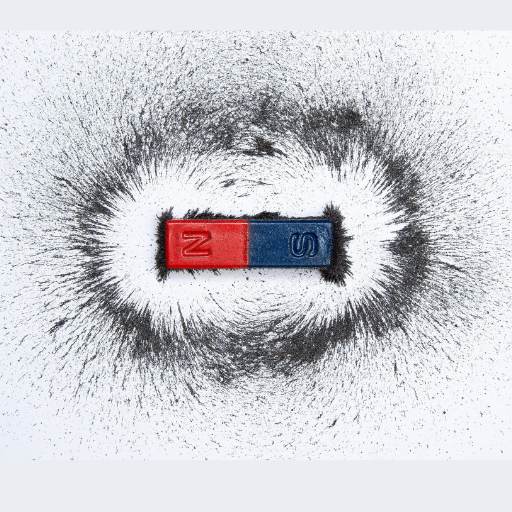

Moving electric charges result in attraction and repulsion among objects hence causing a physical phenomenon known as magnetism. Put simply, it is the force which makes certain things, usually metals, attract or repel each other. Magnetism at atomic level comes from either electron orbital motion or spins. The magnetic field of a material exists when the magnetic moments of many atoms align along one direction. These properties may be inherent or determined by external factors such as an applied magnetic field.

The Effects of Magnetism on Metal Physical Properties

Magnetism affects metal physical properties in several ways. Notably, this property changes the electrical conductivity of metals. When subjected to a magnetic field, electrons’ movement can be influenced thus changing their electrical resistivity referred to as magnetoresistance effect. Additionally, these metallic materials undergo mechanical stress under influence of magnetic fields that impact their structure stability and durability. This happens especially in ferromagnetic metals such as iron (Fe), cobalt (Co), and nickel (Ni) where alignment of magnetic domains lead to changes in dimensions- magnetostriction effect. Moreover, thermal properties of metals can be affected by their magnetism regarding heat conduction characteristics they exhibit across them. During the transfer of thermal energy through metallic lattices with the presence of a magnetic field, industrial cooling and heating processes are altered accordingly using this as grounds for modification to suit specific devices and materials having enhanced performance due to those features.

Different Kinds of Magnetisms Exposed

Many forms share magnetism characterized by different features and operating principles beneath them all; let us discuss some types along with technical aspects:

- Diamagnetism: Diamagnetic behavior is shown by all substances resulting from induced opposing magnetic moments when subjected into external fields however weakly it may be against strong magnets for example. diamagnetic materials

- Paramagnetism: Paramagnetic is the phenomenon exhibited by materials having unpaired electrons. The magnetic moments of such electrons will align with an applied magnetic field and therefore show positive magnetic susceptibility. However, if the magnetic field is removed, this alignment disappears.

- Ferromagnetism: Ferromagnetism appears in substances like nickel, iron and cobalt where atoms’ magnetic moments immediately arrange themselves into permanent magnets even without any external magnetization. These metals have a large magnetization and hysteresis properties.

- Antiferromagnetism: In antiferromagnetic materials, adjacent atomic magnetic moments align in opposite directions, cancelling each other out and resulting in no net macroscopic magnetization. This happens at temperatures below a certain point called Néel temperature.

- Ferrimagnetism: Ferrimagnetic substances also possess opposing magnetizations but unlike antiferromagnets; these are not equal in magnitude resulting in a net value. For instance, this property is common in some oxides like Fe₃O₄ or magnetite.

To develop and apply magnetic materials in different fields of technology, it is necessary to understand various forms of magnetism with their relevant technical parameters.

Which Metals are Magnetic?

List of Common Magnetic Metals

- Iron (Fe): Iron is the best known magnetic metal. Because of its ferromagnetic properties, it is used in many applications including electric motors, transformers and magnetic recording media.

- Cobalt (Co): Cobalt is another common magnetic metal with a high Curie temperature and capable of retaining magnetism at higher temperatures. This makes cobalt suitable for high-performance alloys as well as magnetic recording materials.

- Nickel (Ni): Nickel has significant ferromagnetic properties and often used in alloys or as a plating material to improve the magnetic properties of other metals. Batteries, electronic devices also use nickel

These metals are very important in different technological applications due to their strong magnetic properties that make them useful for making magnets, electronics components among others.

Characteristics of Ferromagnetic Metals

Ferromagnetic metals have special features that make them important in numerous technological applications. Below is a concise summary of these characteristics and the corresponding technical parameters:

- Spontaneous Magnetization: Ferromagnetic substances exhibit spontaneous magnetization implying they can be magnetized even without an external field being present. This occurs because their atomic moments align along the same axis.

- Curie Temperature: Each FM metal has a specific Curie temperature above which it loses its FM nature and becomes PM. For example, iron has approximatly 770°C curie temperature while that of cobalt are around 1,115°C and nickel about 358°C.

- Magnetic Saturation: This refers to a maximum magnetization amount attainable by any material when subjected to an external magnetic field. For instance iron’s saturation point is approximately 1.6 Tesla, while for cobalt it can be up to 1.8 Tesla, for nickel it can be upto 0.6 Tesla.

- Coercivity: Coercivity measures how resistant a ferromagnetic substance will resist demagnetization. High coercivity materials, such as cobalt, are used in permanent magnets while low coercivity materials like iron are used in electromagnets and transformer cores.

- Remanence: Ferromagnetic material retain some magnetization called remanence even after the external magnetic field is removed. For example, this property is very important for magnetic storage. Iron, for instance has a high remanent magnetization which makes it useful in data storage technologies.

This kind of information about these properties and technical parameters is required to use effectively ferro-magnetic metals across various industries starting from the electronics till advanced material science.

Examples of Non-Magnetic Metals

There are non-magnetic metals that do not react to magnets due to their inability to be magnetized and this group comprises both common metals and rare elements specifically. Here are several examples:

- Aluminum: It weighs less than other metals hence it is widely used in industries such as aerospace, construction, packaging etc. The fact that aluminum is not attracted to magnets makes it suitable where there could be magnetic interferences.

- Copper: Electrical wiring, plumbing or electronics due to its excellent electrical and thermal conductivity characteristics are some of the areas where copper is largely employed. Its lack of magnetism also enhances its usability as it does not affect magnetic systems at all.

- Gold: Gold highly conducts electricity besides being nonmagnetic and tarnish resistant hence it is applied in electronics industry dentistry and precision connectors. It can also be used on sensitive electronic applications since gold does not react with any substance including oxygen since it stands out best for such purposes.

These metals have a vital role to play when there should be no magnetism involved thus ensuring effectiveness in many technological industrial processes.

What is a Ferromagnetic Metal?

Understanding Ferromagnetism

Ferromagnetism is defined as the tendency of certain materials to demonstrate long-range magnetic order below a particular temperature known as the Curie point. The existence of this magnetic order is due to atoms or ions within the material aligning their magnetic moments in the same direction, hence resulting in a strong permanent magnetization. One notable characteristic possessed by ferromagnetic metals is that they can retain their magnetization even when the applied field has been removed.

Key Points:

- Magnetic Domains: Small areas within ferromagnetic substances are referred to as magnetic domains. Within these domains, magnetic moments are oriented in such a way that makes them produce strong local fields.

- Curie Temperature: The Curie temperature marks the point at which a ferromagnetic material loses its ability to be permanently magnetized and begins exhibiting paramagnetism properties. It means that below this temperature, it will have very strong permanent magnetism.

- Examples of Ferromagnetic Metals: Iron, cobalt and nickel are common examples known for their high magnetisation and are widely used in various applications including manufacturing magnets, transformers and data storage devices.

Understanding these principles is crucial for developing and applying different varieties of ferro-magnets in technology and industry fields.

Examples and Applications of Ferromagnetic Materials

Magnetic materials with unique features play an important role in many technical spheres as well as industries. Below are some leading examples together with their applications:

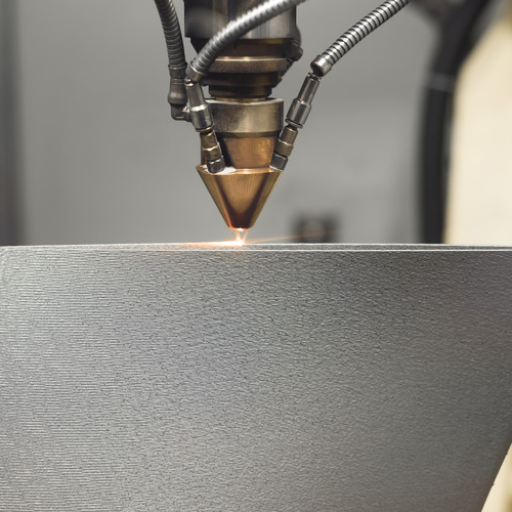

- Iron (Fe): Due to its high abundance on earth coupled with its pronounced magnetic properties iron stands out as most commonly used among all other FMGs. It finds extensive use in manufacturing electromagnets, transformers, electric motors, generators etc. Iron also constitutes the main component of magnetic recording media such hard disk drives and tapes.

- Cobalt (Co): Cobalt provides great magnetic strength and heat-resistance capabilities making it ideal for high-performance magnets called Alnico (aluminum, nickel, and cobalt) in advanced alloys. Such materials are used in permanent magnets for aerospace applications including jet engines.

- Nickel (Ni): Nickel is known for its ferromagnetic characteristics and resistance to corrosion. Hence, it is often used in electroplating to give steel articles a protective as well as nice looking finish. Other than that, electronic equipment and telecommunication gadgets like permalloys would not have been successful if not for their high permeability with low coercivity nature.

Applications:

- Electronics and Data Storage: Ferromagnetic materials are indispensable components of data storage devices, magnetic sensors that form part of circuits’ inductive components.

- Medical Devices: Magnetic resonance imaging (MRI) machines rely on strong permanent magnets made from ferromagnetic materials.

- Household Appliances: Many everyday appliances such as speakers use ferromagnetic components to operate.

- Power Generation and Transmission: Transformers and inductors within power grids employ ferromagnetic substances so as to efficiently transfer or convert electrical energy

Technological advances continue to enhance both practical functionalities and technological capabilities across various fields by exploiting inherent properties of FMGs.

Why Some Metals are Strongly Attracted to Magnets

Ferromagnetic metals like cobalt, nickel and iron are highly attracted to magnets because of the arrangement of their magnetic domains. This region in these metals is called domain, where atomic magnetizations fall into groups that are aligned parallel one another. These domains all turn towards one direction when subjected to an outside magnetic field causing a great attraction. The reason for this lies in their atomic structure which has unpaired electrons whose spins combine to give a net strong magnetic moment. Technological uses demand metal having such qualities inherent in them thus enabling them to retain substantial magnetization even after withdrawal of external magnetic fields.

How to Detect Magnetic and Non-Magnetic Metals?

Metals Identification through Magnetic Properties

To determine if a metal is magnetic or not using its magnetic properties, some simple tests can be done. To begin with, you can use a basic handheld magnet to check if the metal gets attracted to it. If the metal sticks to the magnet then it is likely that it is made out of ferromagnetic materials such as iron, cobalt, and nickel. One can also accurately identify a metal through measuring its magnetic susceptibility using a magnetometer. Non-magnetic metals like copper, gold and silver will not stick onto magnets and show insignificant magnetic susceptibility. This method helps in establishing quickly the magnetic properties of metals employed in various applications.

Metal Detection Tools and Techniques

Some tools and techniques that may be used when detecting both nonmagnetic and magnetic metals are as follows:

- Hand-held Magnets: A simple tool which quickly reveals the nature of metals with regards to their magnetism; any metal which adheres to this kind of magnet is probably ferromagnetic.

- Magnetometers: These are instruments for determining highly accurate values of metals’ magnetic susceptibilities. They give detailed information about both strength as well as directionality of magnetic fields produced by these metallic substances.

- Metal Detectors: Metal detectors generate electromagnetic induction where they create a magnetic field that identifies the presence of metals; therefore, these detectors discriminate between different types based on their conductive qualities and magnetism.

- X-ray Fluorescence (XRF) Analyzers: XRF analyzers allow non-destructive chemical analysis hence making them useful in identifying different kinds of materials in waste streams including plant samples. They are particularly helpful in classifying various elemental compositions found in different types of metallics.

- Eddy Current Testing: Eddy currents are induced within a conducting specimen by alternating current applied around any unit area accompanying an electric field perpendicular to itself. This behavior encountered by these eddies brings forth an efficient method used for distinguishing among dissimilar types of metals, particularly in finding out imperfections and cracks in metallic structure.

Practical Examples/Applications

In industries manufacturing goods, metal detection is significant in making sure that manufactured products meet the right standard for consumption. Magnetometers and eddy current testing are commonly used to examine machine parts for defects and confirm compliance with strict quality requirements. For instance, these methods are applied to determine flaws on engine components and other crucial parts within the automotive industry which prevent mechanical breakdowns.

Detection involved in metal is key during recycling and waste management process. Metal detectors as well as x-ray fluorescence analyzers can be employed to separate different types of metals from waste streams so as to boost recycling rate through recovery of valuable metals. This not only helps save natural resources but also reduces environmental impacts associated with mining and processing of metals.

In security systems, especially defense mechanisms that ensure public safety; metal detectors play a vital role during their operations. They are usually set up at various public places including airports, schools or court halls among others where they help identify hidden weapons or forbidden stuffs. Furthermore, magnetometers along with hand-held magnets are used by armies to detect mines together with unexploded ordnance for purposes of safeguarding individuals both soldiers and civilians alike from any harm that may occur.

These actual situations show varied roles played by or using the tools for detecting metal across different sectors promoting safety, efficiency as well as environmental friendliness.

Can Stainless Steel Be Magnetic?

The Types of Stainless Steel and Their Magnetic Properties

When talking about the magnetic properties of stainless steel, it is important to note that not all types are created equal. There are three main classes of stainless steel, namely austenitic, ferritic and martensitic. My study findings indicate that austenitic stainless steels like those in the 300 series have high chromium and nickel contents thus being non-magnetic when annealed. Ferritic stainless steels belonging to the 400 series are magnetic due to high iron content and low nickel content. Martensitic stainless steels which also fall under the category of 400 series exhibit magnetism and are commonly used for cutlery and tools because of their higher hardness levels. Understanding these distinctions can help choose the right kind of stainless steel for a given application, especially where its magnetic attributes come into play.

Why Some Stainless Steels Are Magnetic And Others Not?

The magnetic properties of stainless steel depend primarily on its microstructure which is determined by its composition. For example, austenitic stainless steels such as those in the 300 series possess high amounts of nickel and chromium which stabilize face-centered cubic (FCC) crystal structure thus preventing magnetism from occurring. On the other hand, ferritic and martensitic grades mostly found in group 4xx are generally magnetic as they have BCT or BCC structures characterized by strong magnetism features. The absence of nickel implies that such alloys retain iron’s magnetic characteristics. In essence, it is the specific arrangement of atoms, along with certain alloying elements being present or absent that determines whether a particular type of stainless steel is magnetic or not.

Applications for Magnetic versus Non-Magnetic Stainless Steels

To understand what types may be best suited to different applications it’s necessary to appreciate the individual properties inherent in each one. Magnetic types such as ferritic (4xx) or martensitic (4xx) are used where hardness, wear resistance and moderate corrosion resistance is needed.

For instance, this kind is often preferred for making automotive parts, industrial equipment and appliances. It has magnetic properties as well as high resistivity for stress cracking. Most cutting tools, knives, and turbine blades have been fabricated from martensitic stainless steels which also possess high hardness and toughness.

By contrast, non-magnetic austenitic stainless steels (300 series) boast both excellent corrosion resistance and high ductility. It is these attributes that render them suitable for use in chemical and food processing industries as well as architectural components where both appearance and functionality matter. These are also applied in electronic devices or any other medical apparatus that would not be interfered by any form of magnetic field.

Key Technical Parameters

Ferritic Stainless Steels (400 series)

- Chromium Content: 10.5-27%

- Nickel Content: 0-1.5%

- Crystal Structure: Body-Centered Cubic (BCC)

- Applications: Automotive parts, appliances, industrial equipment

Martensitic Stainless Steels (400 series)

- Chromium Content: 11.5-18%

- Nickel Content: 0-0.75%

- Crystal Structure: Body-Centered Tetragonal (BCT)

- Applications: Cutlery, surgical instruments, turbine blades

Austenitic Stainless Steels (300 series)

- Chromium Content: 16-26%

- Nickel Content: 6-22%

- Crystal Structure: Face-Centered Cubic (FCC)

- Applications: Chemical processing equipment, food processing, architectural components

Understanding these technical parameters and applying them towards a given performance requirement and environment will help in selecting the appropriate type of stainless steel.

Reference sources

- Metal Supermarkets:

- This source provides a comprehensive overview of which metals are magnetic. It explains the common metals used for permanent magnets and discusses the types of magnetism.

- Source: Metal Supermarkets

- Mead Metals:

- This guide details the elemental metals that are magnetic, such as iron, cobalt, and nickel, and also discusses compounds and alloys that exhibit magnetic properties when they contain iron.

- Source: Mead Metals

- Cut My Plastic:

- This site provides an in-depth explanation of ferromagnetic metals, like iron, nickel, and cobalt, and explains why these metals have strong magnetic properties due to their electron structure.

- Source: Cut My Plastic

Frequently Asked Questions (FAQs)

Q: Which ordinary metals are magnetic?

A: Commonly, most magnetic metals contain iron, cobalt, or nickel. These also include certain steel alloys and iron, nickel, and cobalt. They are considered as ferromagnetic materials and they experience a strong attraction to a magnet.

Q: What types of magnets can be created from these metals?

A: Magnets made of magnetic metals can either be temporary or permanent. Permanent magnets retain their magnetism over long periods while temporary ones like annealed iron can only exhibit magnetism when in the presence of a magnet.

Q: How does the magnetic field affect different metals?

A: A magnetic field creates dipoles that are magnetic in a metal. In instance where it is ferromagnetic material these dipoles tend to align themselves in the same direction thus creating very strong attracting forces. In paramagnetic metals, the dipoles are weakly attracted to the field. Diamagnetic materials repel a magnet.

Q: What is the significance of the periodic table in identifying magnetic metals?

A: The periodic table reveals what elements within each metal have the potential for exhibiting magnetism. Transition metals especially possess magnetic properties on account of their electron configuration as well as crystalline structure.

Q: Can non-magnetic metals become magnetic under certain conditions?

A: Yes some nonmagnetic metals may reveal weak magnetism at low temperatures or high fields. For example some nonmagnetic metallic substances can become weakly polarized by applying powerful external fields.

Q: How can you detect non-magnetic metals?

A: Specialty tools that gauge electrical conductivity, density or other characteristics will detect these metallic objects without any induced response to a pulling force through them which typically arise due to amagnetisem.