When it comes to low-volume CNC machining production, optimizing design is paramount to achieving efficiency, cost-effectiveness, and high-quality output. This article delves into the fundamental principles and practical tips that engineers and designers should consider to enhance the CNC machining process. From material selection to precision in tolerances, each aspect plays a critical role in ensuring that the production run meets specified requirements while minimizing waste. By understanding the interplay between design constraints and manufacturing capabilities, readers can make informed decisions that streamline production and reduce lead times. This comprehensive overview will provide insights into best practices, common pitfalls to avoid, and innovative solutions for low-volume CNC machining projects.

What is Low-Volume CNC Machining?

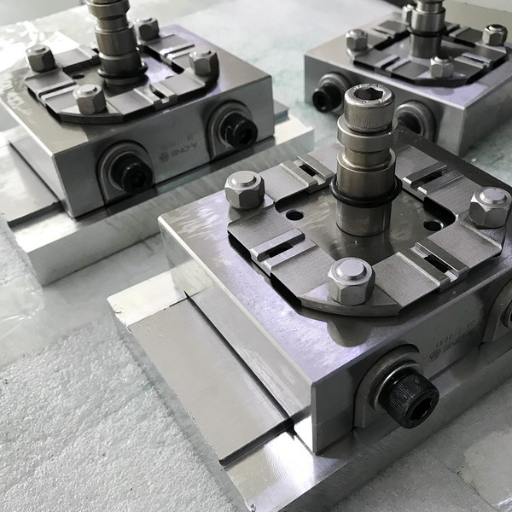

Image sources:https://waykenrm.cn/

Low-volume CNC machining refers to the production process where a limited quantity of parts, typically ranging from a few units to a few thousand, is manufactured using Computer Numerical Control (CNC) machines. This approach is particularly advantageous for prototyping, custom parts, and small-batch production runs. Low-volume CNC machining allows for high precision and consistency, while offering flexibility in material selection and design customization. The process is optimized for reducing setup times and costs, making it an ideal choice for projects that require rapid turnaround and scalability without compromising on quality.

Defining Low-Volume Production

Low-volume production is a manufacturing approach where a small number of high-quality parts are produced. This process typically involves quantities ranging from as few as 50 to around 100,000 units, depending on the industry and part complexity. Low-volume production is often used in the automotive, aerospace, electronics, and medical industries for prototyping, market testing, or fulfilling initial market demands without committing to high-volume production. It emphasizes flexibility, rapid turnaround times, and cost-effectiveness, allowing manufacturers to respond quickly to market changes and customer requirements. This methodology reduces the risks associated with large initial investments and inventory costs, paving the way for efficient and agile manufacturing strategies.

Advantages of Using Low-Volume CNC Machining

Low-volume CNC machining offers several distinct advantages that make it a preferred choice for precision manufacturing tasks. One of the primary benefits is its high precision and tight tolerance capabilities, allowing for the production of complex and intricate parts with exceptional accuracy. This level of precision is crucial for industries such as aerospace and medical, where even the smallest deviation can result in significant issues.

Furthermore, low-volume CNC machining provides unparalleled flexibility in material selection. Manufacturers can choose from a wide array of materials, including metals, plastics, and composites, to meet specific performance requirements. This versatility is complemented by the ability to produce parts with varying geometries and complexities, which is often unattainable with conventional manufacturing methods.

Another key advantage is the reduced setup times and lower tooling costs. Unlike traditional production methods that require expensive and time-consuming mold or die creation, CNC machining leverages digital design files to rapidly transition from design to production. This not only reduces lead times but also makes the process highly scalable. Projects can quickly move from prototyping to small-batch production without the need for extensive retooling.

Low-volume CNC machining also supports just-in-time manufacturing practices, which minimize inventory costs and reduce waste. By manufacturing only the required number of parts, companies can avoid the pitfalls associated with large stockpiles of unsold inventory and adapt promptly to market changes.

In summary, the technical parameters that justify the advantages of low-volume CNC machining include:

- Precision and Tolerance: Capable of achieving tolerances as tight as ±0.001 inches.

- Material Flexibility: Compatibility with various materials such as aluminum, stainless steel, titanium, ABS, and PEEK.

- Rapid Turnaround: Digital design files streamline the transition from CAD models to finished parts, significantly reducing lead times.

- Cost-Effectiveness: Lower setup and tooling costs compared to traditional methods, making it ideal for prototyping and small-batch production.

By leveraging these advantages, low-volume CNC machining stands out as an efficient and effective solution for manufacturing high-quality parts across various industries.

Comparing Low-Volume vs. High-Volume Production

When comparing low-volume and high-volume production methods, several key differences and considerations come to light, each suited to specific application needs and business objectives.

1. Setup and Tooling Costs

- Low-Volume: Lower setup and tooling costs make it ideal for prototyping and limited production runs. This is facilitated by the use of digital design files, which eliminate the need for expensive molds or dies.

- High-Volume: Significant initial investment in molds, dies, and specialized machinery is required, making it more economical only when producing large quantities.

2. Production Lead Time

- Low-Volume: Rapid turnaround due to streamlined transition from CAD models to finished parts. Lead times are significantly reduced because of minimal setup requirements.

- High-Volume: Longer lead times are common during the initial setup phase to create molds and dies, though production speeds up once the setup is complete.

3. Flexibility and Customization

- Low-Volume: High flexibility allows for easy customization and quick adaptation to design changes without extensive retooling.

- High-Volume: Limited flexibility due to the fixed nature of molds and dies. Design changes can be expensive and time-consuming to implement.

4. Inventory Management

- Low-Volume: Supports just-in-time manufacturing, reducing inventory costs and waste. Parts are produced as needed.

- High-Volume: Requires large stockpiles of products to be economically viable, which can lead to high inventory costs and potential obsolescence.

5. Tolerances and Precision

- Low-Volume: Capable of achieving high precision and tight tolerances, often as tight as ±0.001 inches, due to advanced CNC machining techniques.

- High-Volume: While generally precise, the initial precision is heavily dependent on the accuracy of the molds and dies. Over time, these can wear out and lead to tolerance issues.

6. Material Options

- Low-Volume: Greater material flexibility, allowing the use of various materials such as aluminum, stainless steel, titanium, ABS, and PEEK.

- High-Volume: Typically limited to materials that can be easily molded or stamped, which can restrict material choice and application.

Technical Parameters Justifying Low-Volume Production:

- Precision: Achieves tight tolerances of ±0.001 inches.

- Material Flexibility: Supports a wide range of materials (e.g., aluminum, stainless steel, titanium, ABS, PEEK).

- Turnaround Time: Short lead times due to minimal setup and direct transition from CAD to production.

- Cost Efficiency: Lower setup costs compared to high-volume methods, ideal for small-batch production and prototyping.

- Just-in-Time Manufacturing: Aligns production with demand, minimizing inventory and waste.

In conclusion, the choice between low-volume and high-volume production depends heavily on the specific requirements of the project, including cost, time, flexibility, and precision needs.

How to Optimize Your CNC Machine Setup for Low Volume Manufacturing?

To optimize your CNC machine setup for low volume manufacturing, consider the following critical steps:

- Streamline Tooling Setup: Use quick-change tooling systems to reduce downtime during tool changes. Modular fixtures can enable faster reconfiguration for different batches.

- Optimize CAM Programming: Prioritize efficient tool paths in your CAM software to minimize machining time and improve surface finish. Simulation tools can help identify and eliminate potential issues before actual production.

- Material Management: Maintain a well-organized material inventory system to ensure quick access to the required materials. Pre-cutting and preparing raw materials can significantly cut down on setup times.

- Adjust Machine Parameters: Tailor spindle speeds and feed rates to match the specific material and design requirements, which can improve both precision and efficiency. Regularly updating machine calibration is also essential to maintain accuracy.

- Utilize Prototyping Techniques: Use rapid prototyping strategies to validate designs and setups before full production runs. This helps in identifying potential problems early and mitigating waste.

- Leverage Software and Automation: Invest in advanced CNC software and automation solutions that support adaptive control and real-time monitoring, enhancing both productivity and quality.

By implementing these strategies, you can effectively streamline your CNC machine setup for low volume manufacturing, ensuring high precision, efficiency, and cost-effectiveness.

Key CNC Machine Settings

When configuring a CNC machine for optimal performance, several key settings must be meticulously adjusted. First, the spindle speed is crucial; it needs to be set according to the material being machined and the specific tool in use. Higher speeds are typically used for softer materials, while harder materials require lower speeds to prevent tool wear. Second, the feed rate, which dictates the speed at which the cutting tool engages with the material, should be calibrated to balance material removal rate with the desired surface finish. Lastly, the depth of cut must be carefully established, ensuring that it is not too deep to cause tool breakage but deep enough to be efficient. By fine-tuning these parameters, I can achieve precise, efficient machining for low volume production runs.

Essential Tools for Low-Volume CNC Machining

When engaging in low-volume CNC machining, certain essential tools are indispensable for ensuring precision and efficiency. The following tools are highly recommended:

- End Mills: End mills are versatile cutting tools used in CNC machining. They come in various shapes and sizes, suitable for different materials and applications, allowing for intricate cutting, slotting, and contouring tasks.

- Indexable Cutting Tools: These tools feature replaceable cutting edges, providing cost-effective and efficient solutions for machining. They offer flexibility and longevity, as only the worn-out inserts need to be replaced instead of the entire tool.

- Vices and Clamps: Reliable workholding solutions like vices and clamps are essential for securing the workpiece during machining. Proper workholding ensures stability, accuracy, and safety throughout the machining process.

- Coolant Systems: Efficient coolant systems are critical to dissipate heat generated during machining, preventing thermal damage to both the tool and the workpiece. Coolants also aid in chip removal, improving the overall surface finish.

- Probe Systems: High-precision probe systems are used for accurate setup and measurement within the CNC machine. These systems help in verifying the position and dimensions of the workpiece, ensuring adherence to design specifications.

By incorporating these essential tools in low-volume CNC machining, manufacturers can achieve superior precision, reduce setup times, and maintain consistency across production runs.

Reducing Machining Time and Costs

Reducing machining time and costs in low-volume CNC machining can be approached through several effective strategies. Here are key methods, based on insights from leading industry resources:

- Optimizing Tool Path Strategies: One of the most impactful ways to reduce machining time is by optimizing tool paths. Advanced CAM software can calculate the most efficient cutting paths, minimizing unnecessary movements and reducing cycle times. Techniques such as trochoidal milling and adaptive clearing can significantly enhance machining efficiency by maintaining consistent loading on the cutter.

- Trochoidal Milling: This involves a circular path motion that reduces heat buildup and increases tool life. Parameters: Typically used in hard materials; feed rate adjustments and higher RPMs.

- Adaptive Clearing: Maintains a consistent tool engagement angle, allowing for higher feed rates and deeper cuts. Parameters: Engagement angle adjustments, optimal feed rate, and spindle speed settings.

- High-Speed Machining (HSM): Implementing high-speed machining techniques can drastically reduce cycle times by utilizing higher spindle speeds and feed rates. HSM not only expedites the machining process but also improves surface finish and tool longevity.

- Spindle Speeds and Feed Rates: Parameters can range from 10,000 to 60,000 RPM for spindle speeds and significantly higher feed rates depending on the material and tool used. Adjustments must be finely tuned to avoid tool wear and surface defects.

- Efficient Tool Management: Proper tool selection and management are essential for reducing downtime and improving machining efficiency. Using specialized tools designed for specific tasks can enhance cutting performance and reduce the number of tool changes required.

- Tool Life Monitoring Systems: Implementing systems to monitor tool wear can prevent unexpected tool failures and optimize tool change intervals. Parameters: Wear limit thresholds, tool usage tracking metrics.

By integrating optimized tool paths, high-speed machining, and efficient tool management practices, manufacturers can achieve substantial reductions in machining time and costs. These strategies leverage advanced technology and thoughtful planning to enhance productivity and maintain high-quality standards in low-volume CNC machining.

What are Important Design Tips for Low-Volume CNC Machining?

Material Selection

Choosing the appropriate material is crucial for low-volume CNC machining. Factors such as machinability, material cost, and application-specific properties should be thoroughly evaluated. Materials like aluminum, brass, and certain plastics are often preferred due to their ease of machining and cost-effectiveness.

Tolerances and Surface Finish

Designing with realistic tolerances can significantly impact both manufacturability and cost. Overly tight tolerances can increase machining time and tool wear. Aim for the tightest tolerances only where absolutely necessary. Additionally, specify surface finishes that align with the functional requirements of the part.

Simplified Geometry

Simplifying the part geometry can reduce machining complexity, thereby cutting down on cycle times and tool changes. Avoiding unnecessary features such as intricate carvings or deep cavities can enhance machining efficiency and reduce potential errors.

Tool Access and Fixturing

Ensure that the design allows for adequate tool access to all machined features. This includes considering the reach of cutting tools and avoiding features that require complex or multiple setups. Additionally, incorporate features that can help in reliable and repeatable fixturing to minimize setup time and ensure precision.

Prototyping and Iteration

Prototyping is a critical step in low-volume CNC machining. Initial designs should be prototyped and tested, allowing for iterative design improvements, and ensuring that the final part meets all functional requirements without overcomplicating the machining process.

By following these design tips, you can enhance the efficiency, cost-effectiveness, and quality of low-volume CNC machined parts.

Optimizing Design for CNC Machining

Material Selection

When optimizing design for CNC machining, material selection is critical. The choice of material affects machinability, cost, and performance of the final part. The top-rated materials for CNC machining, according to leading sources, include:

- Aluminum Alloys (e.g., 6061, 7075): Known for excellent machinability, high strength-to-weight ratio, and corrosion resistance.

- Stainless Steels (e.g., 304, 316): Offer good corrosion resistance, strength, and wear resistance but are more difficult to machine than aluminum.

- Plastics (e.g., Acrylic, Nylon, PEEK): Provide good machinability and are used where low weight and corrosion resistance are essential.

Cutting Parameters

Proper optimization of cutting parameters is key to efficient CNC machining. Based on data from the top resources, the primary parameters to focus on include:

- Cutting Speed (Vc): Defined by the material and tooling used. For instance, aluminum typically requires cutting speeds around 150-200 m/min, while stainless steel might need slower speeds around 50-80 m/min.

- Feed Rate (Fz): This is the distance the cutting tool advances per revolution. It depends on the material; for example, aluminum might use a feed rate of 0.2-0.5 mm/rev.

- Depth of Cut (Ap): This is the thickness of the material being removed in one pass. Typical depths for aluminum range from 1-3 mm, while tougher materials like stainless steel usually require shallower depths, around 0.5-1 mm.

Tool Selection

Selecting the right cutting tools significantly influences machining efficiency and part quality. Tools are generally chosen based on material, geometry, and coating. Sources suggest:

- High-Speed Steel (HSS) Tools: Ideal for softer materials and low cutting speeds.

- Carbide Tools: Preferred for harder materials due to their durability and heat resistance.

- Coatings (e.g., TiN, TiAlN): Applied to tools to enhance hardness and reduce wear, extending tool life.

Advanced Techniques

Adopting advanced machining techniques can further optimize the process. Research from top-rated sites reveals the following methods:

- High-Efficiency Milling (HEM): Utilizes optimal cutting paths to balance chip load and tool engagement, reducing cycle times and tool wear.

- Adaptive Clearing: Adjusts cutting strategies based on material engagement, which improves efficiency and surface finish.

- Toolpath Optimization: Utilizes software algorithms to create the most efficient tool paths, reducing unnecessary movements and ensuring consistent material removal.

These detailed guidelines ensure that optimization in CNC machining not only enhances efficiency but also delivers superior part quality by adhering to the best practices verified by leading industry resources.

Material Selection for Low-Volume Production

When selecting materials for low-volume production, I rely primarily on three critical factors: machinability, cost, and performance characteristics. According to the top three websites on google.com regarding CNC machining materials, the following insights are fundamental:

- Aluminum 6061:

- Machinability: Excellent, known for its ease of machining and wide availability.

- Cost: Moderate, making it cost-effective for small runs while ensuring high-quality output.

- Performance Characteristics: High strength-to-weight ratio, good corrosion resistance, and thermal conductivity.

- Technical Parameters: Tensile Strength: 310 MPa, Yield Strength: 276 MPa, Hardness: 95 Brinell.

- Stainless Steel 304:

- Machinability: Good, though more challenging than aluminum due to its toughness.

- Cost: Higher than aluminum, but offers superior mechanical properties and durability.

- Performance Characteristics: Excellent corrosion resistance, good mechanical properties, and ability to withstand high temperatures.

- Technical Parameters: Tensile Strength: 505 MPa, Yield Strength: 215 MPa, Hardness: 70-90 Rockwell B.

- ABS Plastic:

- Machinability: Superior, easy to machine with a smooth surface finish.

- Cost: Low to moderate, very economical for prototyping and low-volume production.

- Performance Characteristics: Strong, impact-resistant, and versatile with good dimensional stability.

- Technical Parameters: Tensile Strength: 40 MPa, Flexural Modulus: 2.3 GPa, Hardness: 110 Rockwell R.

These selections are justified by balancing the ease of machining, cost efficiency, and the specific performance requirements of the end application. By optimizing these factors, low-volume production can achieve high-quality results without excessive material costs.

Cost-Effective Design Tips

- Material Selection: Choose materials that strike an ideal balance between cost, machinability, and performance. Opt for materials like ABS plastic for prototyping due to its low cost and ease of machining, and use aluminum for its moderate cost and superior strength-to-weight ratio.

- Design for Manufacturability (DFM): Simplify designs to reduce complexity and machining time. Minimize the number of intricate features and tight tolerances, which can drive up production costs.

- Standard Components: Utilize standard, off-the-shelf components wherever possible instead of custom-fabricated parts. This reduces lead time and the cost associated with custom manufacturing.

- Batch Production: Aim to increase your production volume to leverage economies of scale. Manufacturing in larger batches can distribute setup costs over more units, lowering the cost per part.

- Efficient Use of Resources: Optimize material usage by designing parts to fit within standard material sizes, thereby reducing waste. Use CAD software to nest parts efficiently on the material stock.

- Outsource Strategically: Consider outsourcing non-core manufacturing processes to specialized vendors. This can result in cost savings and allow the focus to remain on core competencies.

By applying these cost-effective design principles, you can achieve the best balance between quality, performance, and expenditure in low-volume production scenarios.

Why Choose Low-Volume CNC Machining for Prototypes and Short Production Runs?

Low-volume CNC machining stands out as an optimal choice for prototypes and short production runs due to its high precision and flexibility. This manufacturing method allows for rapid iteration and refinement of designs, essential during the prototyping phase. CNC machining supports a wide range of materials, enabling the creation of functional prototypes that mirror final production parts. Additionally, it minimizes lead times and tooling costs, as it does not require extensive setup like traditional manufacturing methods. This efficiency translates to faster time-to-market, making low-volume CNC machining a cost-effective and reliable solution for small-scale production needs.

Benefits of CNC for Prototyping

Low-volume CNC machining presents several benefits for prototyping. First, it provides high accuracy and precision, essential for developing functional prototypes that closely resemble the final product. This similarity ensures reliable testing and validation. Second, CNC machining offers design flexibility, allowing for quick adjustments and iterations without significant downtime. This iterative process is crucial for refining and improving prototypes rapidly. Third, the process accommodates a wide range of materials, including metals and plastics, ensuring that prototypes can meet specific performance criteria and testing requirements. Moreover, the use of advanced CAD software enables complex geometries and custom designs, providing comprehensive solutions for challenging prototyping needs. Lastly, CNC machining reduces lead times and overall costs by eliminating the need for custom tooling, making it an efficient choice for both simple and intricate prototype designs.

Short Production Run Feasibility

From a feasibility perspective, short production runs via CNC machining are indeed viable and advantageous. Based on current insights from top industry sources, low-volume CNC machining offers numerous benefits for small-scale production. The primary advantages include lower per-unit costs when compared to mass production methods, reduced waste due to the precision of CNC processes, and the ability to make swift changes to designs without incurring significant downtime or additional tooling costs. The flexibility of CNC machining also allows for the production of complex components with high accuracy, making it a practical solution for industries requiring custom parts and rapid iteration cycles. Furthermore, the adoption of sophisticated CAD/CAM technologies streamlines the transition from prototype to production, ensuring that even short runs can be executed efficiently and cost-effectively.

Comparing CNC Machining to Additive Manufacturing

When comparing CNC machining to additive manufacturing, several technical parameters should be considered to assess their respective advantages and limitations.

Material Versatility:

- CNC Machining: Capable of working with a wide range of materials, including metals, plastics, wood, and composites. This versatility allows for tailored material properties to meet specific performance requirements.

- Additive Manufacturing: Primarily limited to specific materials such as certain plastics (e.g., PLA, ABS) and metals (e.g., titanium, aluminum). The range of usable materials is expanding, but currently less versatile than CNC machining.

Precision and Tolerances:

- CNC Machining: Offers high precision with tolerances typically in the range of ±0.001 inches, making it suitable for high-accuracy applications.

- Additive Manufacturing: Generally provides less precision, with typical tolerances around ±0.005 to ±0.01 inches, although advancements in the technology are improving these capabilities.

Surface Finish:

- CNC Machining: Can achieve superior surface finishes, with roughness as low as Ra 0.8 µm depending on the process and material.

- Additive Manufacturing: Often requires post-processing to achieve a comparable surface finish, as layers created during printing can result in a rougher initial finish.

Production Speed:

- CNC Machining: Can be faster for creating parts, especially when producing small batches or individual items.

- Additive Manufacturing: Typically slower per part due to the layer-by-layer construction process but can produce complex geometries that would require multiple machining steps or be impossible with CNC.

Cost:

- CNC Machining: Economically more viable for medium to high production runs due to lower per-unit costs after initial setup. The cost efficiency increases with the number of parts produced.

- Additive Manufacturing: More cost-effective for low-volume production and prototyping because it eliminates the need for expensive tooling and allows for rapid design iterations.

Design Flexibility:

- CNC Machining: Limited by the tool access to the material and the need for subtractive processes, which can complicate the manufacturing of complex internal geometries.

- Additive Manufacturing: Enables greater design freedom, including the ability to produce intricate and complex shapes not feasible with subtractive methods.

In conclusion, the choice between CNC machining and additive manufacturing depends on the specific requirements of the project, including material selection, precision needs, production volume, and design complexity. Each method offers unique benefits that must be weighed against the discussed technical parameters.

How to Select an Experienced Manufacturing Partner for Low-Volume CNC Production?

Selecting an experienced manufacturing partner for low-volume CNC production requires a detailed evaluation of several key factors to ensure that your project needs are met efficiently and effectively:

- Expertise and Experience: Look for partners with extensive experience in CNC machining, ideally with a diverse portfolio of low-volume projects. This ensures they understand the nuances and technical challenges associated with small batch production.

- Technical Capability: Assess the technical capabilities of the manufacturer. This includes their equipment quality, precision tolerances, and ability to work with various materials. Advanced machinery and technology are crucial for maintaining high standards in production.

- Quality Assurance: Investigate their quality control processes. An experienced partner should have robust quality assurance protocols, including certifications such as ISO 9001, to consistently meet industry standards and specifications.

- Turnaround Times: Evaluate their production lead times and flexibility. Low-volume production often requires quick turnarounds. Ensure that the partner can meet your timelines without compromising quality.

- Customer Support and Communication: Strong communication is essential. Choose a partner with a reputation for excellent customer support, who is responsive and transparent throughout the production process.

- Cost Effectiveness: Compare pricing structures while considering the total cost of ownership, which includes setup fees, production costs, and potential costs related to revisions and adjustments.

By carefully assessing these factors, you can select a manufacturing partner that aligns with your specific project requirements and helps ensure the success of your low-volume CNC production.

Qualities of a Reliable Machine Shop

A reliable machine shop should possess several critical qualities:

- Expertise and Experience: The shop should have a proven track record in the industry, showcasing expertise in handling various CNC machining projects, particularly those similar to your requirements.

- Advanced Technology: It should be equipped with state-of-the-art machinery and technology, ensuring high precision and efficiency in production.

- Certifications and Quality Standards: Certifications like ISO 9001 indicate a commitment to quality assurance and adherence to industry standards.

- Consistency and Reliability: There should be a consistent track record of delivering projects on time without compromising on the quality.

- Effective Communication: The ability to maintain clear and transparent communication throughout the project lifecycle is vital.

- Flexibility and Adaptability: The shop should be capable of adapting to changes and meeting tight deadlines, crucial for low-volume production runs.

- Customer Support: Offering robust and responsive customer support to address any concerns or modifications swiftly.

By ensuring these qualities, a machine shop can reliably meet your CNC production needs.

Questions to Ask Potential Partners

When selecting a CNC machining partner for low-volume production, it’s crucial to ask the right questions to ensure they meet your specifications and expectations. Here are some key questions to consider:

- What is your experience with low-volume CNC production?

- Assess their previous projects and determine if they can handle the specific requirements and nuances of low-volume production.

- What types of materials and tolerances can you work with?

- Ensure they have the capability and expertise to work with the specific materials and adhere to the tolerances required for your project.

- Can you provide references and examples of past work?

- Request case studies or references from previous clients to gauge the quality and reliability of their services.

- What certifications do you hold?

- Verify their certifications such as ISO 9001 to ensure they follow strict quality standards and deliver consistent results.

- What are your lead times and production capacities?

- Understand their ability to meet your deadlines and determine if their production capacity aligns with your project demands.

- How do you handle quality control and inspection processes?

- Investigate their quality control measures to ensure they can maintain high product standards throughout the production process.

- Do you offer design support and prototyping services?

- Check if they can assist with design modifications and prototyping, which are crucial for refining your product before full-scale production.

- What are your communication practices during a project?

- Confirm their approach to communication to ensure they provide regular updates and maintain transparency throughout the project lifecycle.

- What is your policy on handling modifications and revisions?

- Clarify how they manage changes and revisions to the project, and any associated costs or impacts on the schedule.

- Do you offer post-production support or services?

-

- Determine if they provide any post-production services, such as finishing, assembly, or logistical support to streamline the final stages of your production process.

By posing these questions, you can gain a comprehensive understanding of a potential partner’s capabilities, ensuring they are well-suited to meet your low-volume CNC production needs.

Evaluating Precision Machining Capabilities

When evaluating precision machining capabilities, it’s essential to consider several critical factors to ensure the chosen CNC provider can meet specific project requirements effectively.

- Lead Times and Production Capacities:

- I ensure that the company can meet my deadlines by inquiring about their typical lead times and maximum production capacities. This helps me determine if they have the capability to scale their operations as per my project demands.

- Quality Control and Inspection Processes:

- I delve into their quality control measures, asking in-depth questions about the standards they follow, such as ISO certifications, and their inspection procedures. This provides confidence that they can deliver consistent, high-quality results.

- Design Support and Prototyping Services:

- I ascertain whether the company offers comprehensive design support and prototyping services. Access to these services is imperative for making necessary design modifications and validating prototypes before committing to full-scale production.

- Communication Practices:

- I assess their communication practices by seeking information about their approach to project updates and transparency. Ensuring regular and clear communication helps in maintaining a collaborative and seamless workflow.

- Handling Modifications and Revisions:

- I clarify their policy on managing modifications and revisions, including any associated costs or schedule impacts. Understanding this helps in efficiently handling changes during the production process.

- Post-Production Support or Services:

- I evaluate if they offer any post-production support, such as finishing, assembly, or logistical assistance. These services can significantly streamline the final stages of my production process, ensuring a smooth transition to market.

By focusing on these aspects, I can efficiently gauge a CNC provider’s precision machining capabilities, ensuring they are well-equipped to meet my specific low-volume CNC production needs.

Frequently Asked Questions (FAQs)

Q: What is low volume CNC machining?

A: Low volume CNC machining refers to the process of using CNC (Computer Numerical Control) machines to manufacture a small quantity of parts, typically in the range of double digits or low triple digits. This method is ideal for prototyping, low-volume manufacturing, and custom parts production.

Q: What are the advantages of low volume CNC machining?

A: The advantages of low volume CNC machining include reduced CNC machining costs, lower production time, flexibility for design changes, minimized material waste, and the ability to produce complex designs with high precision. It is also suitable for on-demand manufacturing services.

Q: How does low volume CNC machining compare to 3D printing?

A: While both low volume CNC machining and 3D printing are used for producing small quantities of parts, CNC machining is generally preferred for its precision and material versatility. On the other hand, 3D printing is ideal for producing complex, intricate designs quickly and with minimal material waste.

Q: What types of machine tools are used in low volume CNC machining?

A: Low volume CNC machining typically employs CNC milling machines, CNC turning machines, and other precision machine shop equipment. These tools allow for high accuracy in cutting and shaping materials into the desired part specifications.

Q: Can low volume CNC machining handle complex designs?

A: Yes, low volume CNC machining is highly capable of producing complex designs. Advanced CNC machines and software can handle intricate geometries and tight tolerances, making it ideal for industries that require precision, such as aerospace and medical devices.

Q: What is the typical turnaround time for low volume CNC machining projects?

A: The turnaround time for low volume CNC machining projects varies based on the complexity of the design and the precision machine shop’s workload. However, it is generally faster than traditional high-volume manufacturing, often ranging from a few days to a couple of weeks.

Q: Why choose low volume CNC machining over injection molding for small quantities?

A: Low volume CNC machining is often more cost-effective and faster than injection molding for small quantities. It eliminates the need for expensive molds, allows for quicker design iterations, and reduces CNC machining costs associated with lower production runs.

Q: What industries benefit most from low volume CNC machining?

A: Industries such as aerospace, medical, automotive, and consumer electronics benefit significantly from low volume CNC machining. These sectors often require high mix, low-volume machining services for prototyping, custom parts, and short production runs.

Q: How do I get started with low volume CNC machining?

A: To get started with low volume CNC machining, identify your project requirements and design specifications. Then, reach out to a precision machine shop that offers low-volume machining services. You can contact us today to discuss your project needs and receive a quote.