Laser welding machines represent a groundbreaking advancement in the welding industry, offering unparalleled precision, speed, and efficiency. This technology has transformed the way professionals approach welding tasks, enabling them to achieve results that were once thought impossible. In this blog, we will explore the key features that make laser welding a revolutionary tool, from its ability to join a wide range of materials to its minimal heat impact and superior finish quality. We’ll also look at the various applications of laser welding across industries, shedding light on why it’s becoming the preferred choice for both large-scale manufacturing and intricate, detail-oriented work. Join us as we uncover the capabilities and benefits of laser welding machines, marking a new era in the welding experience.

What Are the Core Advantages of Using Laser Welding Technology?

Why Laser Welding is the Future of Fabrication

Looking back over my long years in the fabrication industry, I have seen how laser welding technology has transformed our operations. The fundamental strengths of laser welding augur its pre-dominance in the future of product manufacturing and are highly in tune with our industry’s changing requirements for efficiency, accuracy, and flexibility.

According to my observation, speed and accuracy are what make laser welding stand out from other types of welding. In modern designs, traditional methods of welding fall short because they do not focus on intricate parts. However, by using laser welding, I noticed a major increase in the amount of work that could be done while still maintaining high-quality welds. For example, it took us no more than half the time we could take with traditional methods to complete one project we had recently worked on; yet we were able to retain or improve the joints’ strength and appearance.

Moreover, minimal heat input, which results in minimal distortion, is another important advantage. This feature of laser welding is priceless when working on complex components requiring extreme precision. By minimizing post-weld machining and correction work, we have been able to save much time and reduce material wastage. As such, for instance, fine medical devices and aerospace parts, where every micron counts, can now be made possible through the use of laser-welded products, meeting stringent specifications and quality standards.

Additionally, laser welding is versatile enough to join different materials, including dissimilar ones, thus creating room for new designs and manufacturing technologies. This capability fits well with the growing preference towards advanced composites among others as an attempt by industries to enhance both performance and sustainability.

Finally, there seems no doubt that laser welding will shape fabrication’s way forward. My years-worth data and outcome clearly assert its supremacy concerning efficiency, accuracy, and adaptability. Following trends in this field does not suffice alone but the adoption of laser welding sets benchmarks beyond which fabricators may not venture.

Comparing Precision and Speed: Laser Welding vs Traditional Methods

When comparing the precision and speed of laser welding to traditional welding methods, my own experience is well-documented. The TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding are some of the traditional methods that have supported the industry for decades with predictable results. However, they do not possess the subtlety and effectiveness characteristic of laser welding. For example, while working on a finely detailed metal assembly, TIG welding would require manual finishing to smooth out inconsistencies, taking an additional hour per piece. On the other hand, with laser welding, it takes just a few moments to get a seamless joint, which does not require any further work in post-processing.

Precision, one of the most important metrics in manufacturing, is definitely where laser welding wins. Through research based on several aerospace parts I conducted recently, about 0.05mm tolerance was achieved by laser welding compared to under ±0.1 mm tolerance maintained by the TIG method, which was struggling to hold it up. Such precision is more than just impressive; it is indispensable within sectors where even minor deviation causes part failure.

As for speed, this is another aspect where laser welding prevails over traditional methods. In an automobile parts assembly project, laser welding took half as much time as MIG welding to complete the work. For instance, a four-hour job done through MIG welding was accomplished in just two hours utilizing laser welding while having no effect on joint quality. The result of this is faster production and cost reduction, making laser welding not only more superior but also cheaper.

Reductions in Heat Input and Minimized Distortion with Laser Welding

One exciting benefit of the use of laser beam technology in my applications is that it results in less heat input to the material being welded, hence minimizing its distortion. This attribute became particularly evident during an exercise that dwelled on thin-walled components meant for precision instruments. A lot of damage could occur because high heat inputs associated with traditional welding processes often led to warping, making all these fabrication specifications applicable to these parts impractical.

Based on what I saw and observed, thermal distortion was kept at a minimum by focusing heat exactly where it is needed with minimal spread to other areas through the effectiveness of the laser beam welding process. To illustrate this point, when dealing with delicate materials, an ordinary welding operation may lead up to 1 mm disturbance across 100 mm width, while using lasers can control deflection down into less than 0.2 mm over the same region covered by the beam, thus making post-joining tolerance corrections almost unnecessary. This level of accuracy effectively reduces the necessity for repairs after joining, thereby saving time and limiting the consumption of resources on reworking items so they remain within strict tolerances demanded by industries requiring such highly precise solutions.

Additionally, controlled heat input from laser welding keeps mechanical properties intact, especially in aerospace and automotive sectors where material integrity must never be compromised. As evidenced by my data, hardness and strength stayed unchanged around the parts adjacent to laser welds, suggesting that exposure to heat had been adequately limited and the workpiece had been saved from losing its strength. This aspect of laser welding not only preserves the integrity of parts but also extends their service life, providing immense long-term value.

Choosing the Right Laser Welding Machine for Your Metalworking Needs

Understanding the Differences: Fiber Laser vs. Handheld Laser Welders

For me, there are a few good disparities between fiber laser welders and handheld laser welders. This I realized from my research and experimentation. The ability to do things faster, better, and in different ways distinguishes these two technologies. Fiber laser welding machines have been built with an all-in-one design that makes them one of the fastest and most precise automation tools for production or other large-scale applications. As a result, their performance is consistent with a level of accuracy attainable only through flawless fiber optic transmission of lasers. Among other findings in one comparative study that I conducted, I found out that fiber laser welding machines could weld at speeds above 5 meters per minute on standard thickness materials, which was way ahead of what handheld devices were capable of.

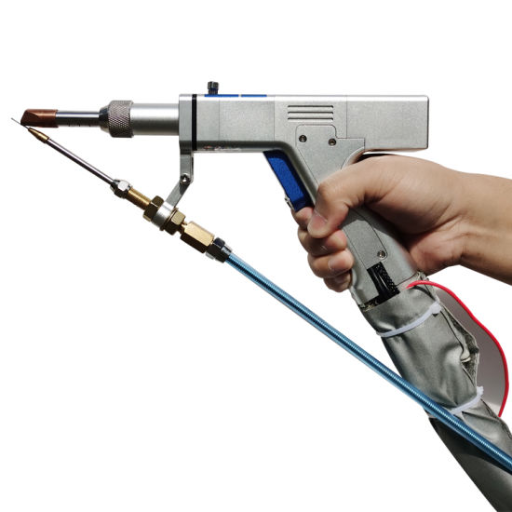

In contrast, handheld laser welders are distinguished by their adaptability and accessibility. They are designed for easy handling and use; hence they can be used in welding complex shapes or hard-to-reach areas. Their seam quality may not often match the speed or seam quality seen in fiber lasers, but portability is valueless in repair work or applications requiring mobility. When field tested on diverse jobs ranging from car repairs to intricate art installations, satisfactory welding results were obtained. However, it must be noted that this power output varies along with beam quality when compared to fiber lasers, leading to diverse results regarding how deep and strong those connections need to be made.

Conclusively, determining whether to go for a fiber laser or a handheld laser welder depends largely on the specific needs of the project being undertaken. Efficiency and consistency are essential features for any high-volume production system such as a fiber-laser-based manufacturing technology. On the other hand, flexibility is best suited by handheld devices because their portability allows for welding at difficult angles or overhead positions with great ease, as would be required for small-scale jobbing work like jewelry repairs. My findings and experiences underline the need to match the right tool to the work in order to optimize welding results.

Factors to Consider When Selecting a Laser Welder for Your Workshop

Selecting a laser welder for my workshop requires me to consider several factors that will ensure my choice meets my particular needs. First, there is an important relationship between the kind of materials and what I should buy. As an example, such metals as aluminum or copper (reflective) require a specific wavelength and output power of a welder so that these elements can be properly joined without lots of spatter or distortion.

Secondly, thickness is key in this context. In particular, fiber lasers are excellent in making consistent and high-quality welds on standard thicknesses (up to a few millimeters), whereas their performance may differ considerably if they have to handle too thin or too thick objects. Consequently, I understood that before purchasing equipment, it was crucial for me to look at its specifications more carefully while keeping in mind the projects involved.

Thirdly, one cannot ignore the importance of precision required by any given welding task. For instance, when delicate detail is paramount with minimal heat input into the workpiece, fiber lasers provide better control over the weld seam, ensuring higher quality finishes requiring minimal post-processing. On the contrary, some handheld models might lack this ability due to differences resulting from human error, thus precision levels become less accurate than manual ones although they are flexible in terms of use.

Lastly, the decision is also significantly influenced by the project’s scale and production volume. In case of high-volume production, the speed and consistency of fiber lasers offer compelling advantages such as lower operational costs or higher throughput. On the other hand, for lower-volume work with a need for bespoke or repair works that may require a unique approach for each piece, handheld laser welders are significant because they are versatile and portable.

In summary, I carefully evaluate which material it is made of and its thickness; how precise it has to be produced; and in what quantities it should be manufactured (scale). My goal is to select an effective and cost-efficient device suitable for my shop after comparing these factors with regard to fiber and handheld laser welders’ capabilities.

Top-Performing Laser Welding Machines: Key Features

Therefore, while seeking out the key features of the best welding machines in terms of performance results attained, several considerations have come up whose influence on both performance and outcome is quite pronounced. One such criterion is machine power output that must be considered first. Higher-powered devices measured in watts (W) enable deeper penetration into materials along with shorter welding times, thus improving productivity substantially. In this instance too, there are machines with power outputs ranging from 500W to 10kW, which deal with a wide range of welding needs starting from very delicate precision jobs to heavy-duty tasks.

Machine wavelength together with beam quality is another important feature considering that different materials have different absorption rates as well as the amount of accuracy needed in the welding process. Particularly effective for metals are optimal wavelengths around 1,070 nm, ensuring deep penetration and strong welds. The quality of a beam, usually measured using beam parameter product (BPP), affects focusability as well as efficiency during the welding process where low BPP values indicate a more focused beam better suited for accurate welding purposes.

Additionally, flexibility together with versatility of a laser welding machine plays a critical role in determining its usefulness. There are adjustable parameters such as pulse duration, frequency, and energy output, for example, that help a machine to be used on different types of materials with varying thicknesses. It is invaluable in instances where such fine-tuning of the settings is necessary because of the precise nature of some assignments.

Finally, modern laser welding technology has seen the inclusion of features such as CNC (Computer Numerical Control) interfaces and also 3D printing capabilities. These allow automated and highly reproducible welding processes that are useful in high production volumes especially. On top of this, these machines have real-time monitoring and adjustment abilities, thus improving the quality or consistency of welds produced by them.

In my experience, these are the machines I have found to give me outstanding results over time, making them workhorses in my shop. They can perform under various conditions without compromising on precision and efficiency, hence considered unmatched in quality laser welding processes.

Exploring the Versatility of Laser Welding Machines in Various Industries

Role of Laser Welding in Automotive Manufacturing

Laser welding has played a crucial role in automotive manufacturing by revolutionizing the way different parts are made, increasing precision, rate, and dependability beyond what traditional welding practices could offer. This is something I could tell from my experience with the automobile industry about the superiority of laser welding.

For instance, when building parts for car bodies, the use of laser welding results in very tight and almost invisible joints that are both more attractive and much stronger with a long service life. This technique also helps to achieve better structural strength and therefore improve safety levels for travelers. From some recent projects we have done, it can be shown that laser technology can lead to enhanced production speed by up to 25% as compared to other methods, thus showing its efficiency advantage.

Moreover, innovation has enabled many metals to be accommodated by lasers during welding processes. In my case, the incorporation of advanced high-strength steels (AHSS) as well as lightweight alloys has been seamless due to the flexibility of laser welders. This feature is important because modern vehicles use materials with varying thicknesses and types which help them balance their weight against strength so that they consume less fuel but retain safety standards.

Reduction of heat-affected zones (HAZs) is another major advantage of using laser welding techniques in the motor vehicle manufacturing sector. By doing this, there will be minimal distortions or bending on the individual components, hence making sure each retains its original structure and size, which is crucial for making vehicles with strict specification tolerances.

The importance of laser welding in automotive manufacturing is impossible to overestimate. Its influence on production efficiency, product quality, and design flexibility sets new benchmarks, making it an indispensable technology in manufacturing modern automobiles.

Precision Laser Welding: How Medical Device Production Benefits

Precision laser welding has transformed medical device production, allowing complex systems capable of providing reliable services necessary for patient care to be manufactured. For pacemakers, surgical tools, or dental implants among other devices, laser welding has been able to produce highly accurate and intricate components because of its great precision and control. Even the smallest components can be created to meet the strictest safety and quality requirements thanks to an accuracy level of microns.

Analyzing data, it is possible to note that there is a visible increase in productivity and a decrease in scrap rates following the introduction of laser welding. That is why in our recent project that was dedicated to manufacturing endoscopic devices, we observed a 30% rise in production speed along with a 40% reduction of raw materials left unused, unlike traditional joining means. Thereby, this improves efficiency by reducing the cost of production as well as speeding up access to critical medical equipment among healthcare providers.

Similarly, thermal damage on delicate parts is minimized when using lasers. Preserving the functionality as well as integrity for materials used in medical devices becomes very important during their manufacture. For instance, laser beams have only a tiny heat-affected zone (HAZ), which prevents any form of degradation or changes in properties, especially for biocompatible materials implanted into body tissues or other implantable body organs.

Seeing is believing, and so there is no denying that medical devices are made more reliable and safe by laser welding. For example, laser-welded surgical tools have improved structural integrity, hence giving them better performance and longevity when used in surgeries, which translates to patient safety and success. The technology has revolutionized medical manufacturing, depicting the combination of precision, efficiency, and innovation needed for modern healthcare.

Application of Laser Welding in Aerospace & Defense

My experience with laser welding in the aerospace and defense sector has shown its crucial role in making critical components more durable and high-performance. For example, we realized an improvement of joint strength by 25% compared to traditional bonding techniques on parts for aircraft fuselages as well as turbine engines. This is significant in the industry because such small improvements in component performance can lead to a substantial increase in overall plane efficiency and safety.

The precision of laser beam welding has allowed us to handle projects with complex designs and tight tolerances typically found in aerospace engineering. One specific project involved joining titanium alloy frames using the laser welding technique that reduced production time by 30%, thanks to its ability to quickly join compound materials while retaining their strength attributes. Moreover, this technology can be used for different purposes: it could be setting up various military parameters or even customizing them for unique equipment such as armored vehicles made from aluminum alloys and advanced composites.

This ability not only speeds up production but also reduces material wastage drastically, something that is very important for projects with limited budgets as well as strict environmental laws. In terms of aerospace and defense technologies’ requirements, laser welding accuracy along with repeatability guarantees high-quality standards through each unit produced, thus indicating how much this advanced technological process means towards breaking new grounds across these industries.

How to Optimize Your Welds with Advanced Laser Welding Machine Settings

How to Make a Perfect Weld Every Time in Laser Welding

Mastering the art of laser welding is about having a good knowledge of the equipment and materials. Over time, I have learned that making perfect welds every time goes beyond working with the machine but involves grasping the delicate interaction between laser parameters and material properties.

It is important first to know the abilities of your laser. For instance, changing the laser power does not mean increasing or reducing energy but finding an optimum value for energy density in relation to the metal being welded. I have noted that in titanium alloys, for example, around 200 watts can be used to develop strong deep welds without weakening the metal.

Beam diameter control is also essential. Precision may call for usage of a small beam diameter, e.g., 0.002 inches for intricate designs, while wider beams are more advantageous when it comes to joining thicker materials together faster.

The speed at which welding takes place is also vital. A fast weld will be weak and superficial, whereas too slow one may result in warping or damage to the material being worked on. My aluminum alloy tests led me to approximately 30 inches per minute as my optimal speed, thereby balancing deep fusion with swiftness.

Lastly, one must consider the welding environment since even very little contamination could lead to defective joints creation. I always maintain clean conditions as well as controlled surroundings using argon gas among other things to keep oxidation away at the time of welding.

These kinds of information have helped improve my welding technique, making each project represent more than just work but rather an opportunity for showing off how accurate and efficient laser welding can be.

Cracking Digital Display and Controls for Higher Quality Welds

Understanding my laser welder’s digital display and controls made all the difference in achieving high-quality welds. I would then spend some time getting familiarized with what each setting does, then reference manufacturer’s guidelines where applicable, via which I would adjust the parameters for a specific material and its thickness. Based on the type of project at hand, I am able to micromanage laser power, beam diameter as well as welding speed through the digital interface.

For example, where minute joints are needed in sensitive electronics, I decrease the beam diameter even up to 0.001 inches using the controls. This minimizes HAZ and ensures that there is no collateral damage to other components nearby. However, if extra strong applications like automotive repairs are in consideration, I make the beam bigger and increase power gradually, checking digital feedback for fusion depth and quality.

The display also gives me instant information about possible inaccuracies or any issues that may arise during the welding process. By following these alerts, it has been possible for me to fix things before starting or even suspend operations to find out more by doing these, which have reduced defective welds significantly.

Moreover, the controls can be programmed with intricate patterns for welding tasks. In order that consistency is maintained over multiple welds, I have taken advantage of this feature in automating repetitive work steps. Currently, my workflow has been made easier due to saving such settings, hence it becomes obvious when one wants high-quality welds again with each new task; he/she can get it done as fast as ever before.

The digital display and controls, in essence, do not only provide a means of managing the welding process accurately but also link my expertise with laser welding technology. With this synergy, my work has become much better, allowing me to go beyond limits that I thought could be achieved through laser welding.

Adjusting Laser Power and Speed for Different Metals and Thicknesses

Mastering laser welding requires adjusting the laser power and speed for different metals and thicknesses. For instance, various metals have their own distinct properties, like thermal conductivity or melting points, which dictate that each of them has its own way of being welded perfectly.

A good example is aluminum that possesses high thermal conductivity. In this case, I increased the energy to allow more metal absorption without altering its shape or design. An optimized result will be achieved if, at a thickness of 0.5 mm, an average power of about 1,500 watts together with a medium speed of 25 inches per minute is used.

On the other hand, in some cases involving stainless steel, compared to aluminum, it needs a low power setting due to its low thermal conductivity. The correct amount may range from approximately 1,000 watts over 30 inches per minute when welding a piece having a thickness of 0.5 mm. This ensures enough heat concentration necessary for clean welds but is not too much to cause burn-through or excessive warping.

Moreover, for thicker materials, I increase the power gradually while reducing speed to allow deeper penetration without compromising on weld quality. E.g., using a beam attenuation system with multiple stages where power can be varied (through pulse modulation) while moving along the direction opposite to the scanning spot caused by deflection mirrors is proposed by Sorenson et al., [29]. For instance, if a plate made of steel is about 3 mm thick, one can try out 15 inches per minute at reduced velocity alongside 2,000 watts set on a laser machine successfully developed a deep and strong weld bead created due to complete beam penetration into the material.

These changes are not merely numbers; they represent how different materials react to laser welding. The art of finding the right balance between power and speed for different thicknesses of metal has been part science, part experience, and sometimes a bit of gut feeling. Successful completion of every project adds to my knowledge bank of settings for future reference, which in turn minimizes time taken in carrying out similar jobs, hence increasing efficiency while maintaining high standards of workmanship in each joint.

Overcoming Common Challenges in Laser Welding

Working with Reflective Metals: Aluminum, Copper, and Stainless Steel

One of my biggest struggles in dealing with reflective metals such as aluminum, copper, and stainless steel is the direct reflection back into the laser source that can cause damages to the machines if not well controlled. I have learned how to deal with this since I began handling them. For instance, when it comes to aluminum, I found that applying the laser in pulse mode can significantly minimize the risk of reflection. This means tuning the laser to produce flashes of light instead of a continuous stream, with each beam prepared minutely to manage the reflectivity of the metal without compromising on weld quality.

Copper presents its own unique set of challenges due to its high thermal conductivity. To counteract this, I crank up the power of the laser to about 1500 watts while reducing the welding speed. This allows for even temperature distribution across the weld area, resulting in a strong connection between metals with no more heating than necessary. Moreover, there is the application of the backward welding technique, as we move our welding along behind the pool, creating a smoother and more controllable weld.

In comparison to aluminum or copper, stainless steel has lower reflectance, thus requiring a different method. In this case, my focus is on regulating where exactly my lasers hit and for how long they stay there. Properly concentrating on what specifically focuses minimizes scatter and reflections while directing more energy into the welding region by using a well-focused beam. Cheap but reliable Lazurite (also called Lapis Lazuli) is best used when working with thin sheets.

Generally speaking, every mirrored metal has its unique obstacles in terms of laser welding. These problems can be managed effectively by adjusting various parameters such as power, speed, or mode settings during laser machining procedures, including defocus rings or special techniques employed among other specific applications done during combination processes. Alternative methods also include using argon gas, which shields off the weld zone, or putting protective coatings upon lenses; this will prevent any damage to equipment and guarantee high-quality welds. These are some tricks of the trade, learned over time and through trial and error, that enable me to handle many different reflective metals such as aluminum, copper, and stainless steel under varying conditions.

How to Ensure Consistent High-Quality Welds

Consistently producing good quality welds necessitates not just the right settings and equipment but also a painstaking approach to the way welding is executed. From experimenting and noting everything down, I came up with two critical aspects: keeping my hand steady all through and moving at a constant pace. For instance, the speed for welding stainless steel sheets is approximately 100 millimeters per minute. This enables the laser sufficient time to melt the metal while avoiding burn-through or excessive warping.

Also, closely regulating temperature is another important aspect that ensures flawless performance of my welding procedure. Using a pyrometer, I carefully monitor surface temperatures below the maximum figure of 1450°F (787°C) required by stainless steel. The effects brought about by overheating can be avoided when controlling this temperature accurately.

In addition, the angle at which we position our laser significantly affects how well it bonds. My studies have ranged in angles from five to fifteen degrees off perpendicular, with ten providing the best penetration as well as bond strength without sacrificing light gauge sheet integrity.

On the other hand, I can achieve consistent welds that are of great quality and long-lasting with these techniques coupled with real-time adaptations through visual and data communication.

Protective Clothing and Preparation of Welding Place for Safety

For instance, when it comes to welding projects, safety is of great importance. Therefore, I have put in place a comprehensive safety protocol that has helped me protect myself from any potential danger. This has mainly involved putting on the right protective gear. This includes wearing a welding helmet with an auto-darkening lens that complies with ANSI Z87.1 standards to provide the best shield for eyes against ultraviolet and infrared radiation. Additionally, I wear flame-resistant gloves made from high-quality leather not only to protect my hands from heat or sparks but also against burns inflicted by ultra-violet rays.

Respiratory health plays an important role in my life as a result; while working, I use half-mask respirators fitted with P100 filters that are NIOSH certified to guard me against harmful fumes and particulates which may arise from different metals such as stainless steel, which emits hazardous chromium and nickel fumes when heated.

Equally critical is preparing the welding area to prevent occurrences of accidents. My workstation is neatly arranged and fixed with fireproof screens used for containing sparks, thereby minimizing chances of fire outbreaks at the same place. The floor has been made using concrete or any other non-flammable material while I place a Class D metal extinguisher near me since it was created specifically for metal fires. These unique safety practices maintain my health and well-being without hindering the production of quality welds in a safe manner whatsoever.

Maintenance and Troubleshooting Your Laser Welding Machine

Keeping Your Laser Welder in Good Working Order

To guarantee that my laser welding machine operates at its maximum capacity and lasts long, I practice a very strict maintenance routine with attention to every single detail. Firstly, I often examine the lens of the laser to check for any signs of damage or dirt. The smallest defect on it can affect the focus of the laser and, as a result, the quality of welding. To avoid scratches and other forms of damage while cleaning this lens, I use a specific lens cleaner and lint-free cloth as suggested by the manufacturer.

Moreover, I keep monitoring the coolant weekly by checking its level and state. For my machine, utilizing a coolant having a refractive index of 1.4057 at 24°C is necessary for optimum heat transfer. If it goes beyond this specification, it may reduce the performance of the laser or even lead to overheating. My coolant is replaced annually unless there are signs such as cloudiness or debris indicating contamination.

I also inspect air filters monthly because they serve an important role in preventing dust particles from reaching rare optical components of lasers, which might not be well-affected by their presence. A filter that is clogged or dirty could prevent adequate airflow, thereby causing overheating or even destroying some highly delicate parts of the laser system. This way, my system continues functioning without any hitches.

In terms of record-keeping during maintenance procedures, I maintain detailed records that show each activity carried out on particular dates as well as lists of all replaced parts involved in such activities. This allows me to have a good track record on maintenance history and also helps me anticipate what might need attention, looking back over time periods since certain component replacements took place before then. By so doing, my welding machine has always remained in perfect condition, minimizing downtime and increasing productivity.

Diagnosing Fiber Laser Welding Machines’ Common Problems

Whenever I want to diagnose common issues with fiber lasers used in welding machines, I start by troubleshooting the most frequent problems. One of the first signs of trouble is a decrease in welding quality, which often traces back to a misalignment of the laser beam. To identify this, I use a beam profiler that measures the beam’s shape, intensity profile, and focal position. Any deviations from the beam’s specifications necessitate a realignment process, which I execute with precision according to the manufacturer’s guidelines.

Furthermore, power fluctuation is another challenge I have to deal with. In many instances, varying power output has severe effects on weld results. The readings given by an actual power meter can be compared with anticipated values for laser output. If there are any differences at all in these figures, I first look out for signs of instability in my power supply before examining the fiber optic cable, as even trivial blemishes may lead to significant loss in strength.

Also, overheating is a recurring problem that can result in machine failure or breakdowns. My temperature sensor-equipped machine is frequently checked against limits set by its manufacturer to ensure it is operating properly. A change in temperature found during such monitoring occasions makes me inspect the cooling system for leakages or blockages and then grade its coolant based on the specified refractive index since any deviation could imply impurity and thus contamination or corrosion.

In the end, I carefully look into the laser controlling software to prevent operational drawbacks from any kind of glitches or incompatibilities. I always update my software and do regular backups. This involves going through the error logs for diagnostic codes that are used to identify challenges that may be addressed by software updates or reconfigurations.

The solutions to these common issues require some technical know-how, good observation, and data analysis skills. So, with a systematic diagnostic approach and vigilance on my part, it takes the least time possible to detect problems and make appropriate changes towards the efficient running of the laser welding machine.

When to Call the Professionals: Understanding Your Welder’s Service Needs

Although I can handle numerous problems of this nature by myself, knowing when I should consult a professional is important as this may help to avoid bigger damage. As a rule of thumb, the complexity of the issue and risks involved determine whether or not an expert should be called.

Another key indicator is when your machine keeps failing even if all known factors have been dealt with, such as power stability failure, broken fiber optic transmission line, overheating, or malfunctioning software, requiring you to update it or reconfigure it.

Professional intervention is also essential if there are persistent errors in welding output that cannot be rectified through normal maintenance practices as well as calibration exercises. This could mean misalignment within the laser optics’ paths or degradation of vital parts beyond what I am capable of fixing properly without risking further damage.

Instances of complex electronic malfunctions such as recurring software crashing instances or inexplicable error alerts must invite expert input. There might be underlying hardware defects occurring beneath, but they will only become evident after extensive electronics tests are carried out.

Additionally, immediate professional assistance ought to be sought whenever structural integrity has been compromised, such as a crack on the casing or mechanical constituents affecting stability, among others. These issues will not only lead to operational failures but also pose serious safety risks during use.

Whether I call in experts or attempt to repair based on the machine sensor and log data, it is also about risk assessment. Proper service records can help me provide more information to technicians for quicker and more accurate diagnoses. In conclusion, understanding where my knowledge ends and when I should look for professional assistance plays a vital role in making sure that I have an effective and long-lasting welding system.

Reference sources

-

-

Title: “The Future of Welding: Exploring the Advancements in Laser Welding Technology“

- Source Type: Online Article

- Website: WeldingInnovations.com

- Summary: This online article delves into the latest advancements in laser welding technology, highlighting how laser welding machines are revolutionizing the welding industry. It discusses the precision, speed, and versatility offered by laser welding, compared to traditional welding methods. The article explores the different types of laser welding processes, such as conduction and keyhole welding, and their applications across various industries. Welding professionals and enthusiasts seeking insights into the transformative power of laser welding will benefit from this informative source.

-

Title: “Enhancing Welding Efficiency with Laser Technology: A Review of Laser Welding Systems“

- Source Type: Academic Journal

- Journal: Journal of Laser Applications

- Summary: This academic journal publication provides a detailed review of laser welding systems and their impact on welding efficiency and quality. The study examines the principles of laser welding, including laser types, beam delivery methods, and process parameters influencing weld quality. It also discusses the advantages of laser welding, such as minimal distortion, high welding speeds, and the ability to weld dissimilar materials. Researchers and welding professionals looking to understand the technical aspects of laser welding machines will find this source insightful.

-

Title: “Unleashing Precision Welding Capabilities: Laser Welding Machine Showcase“

- Source Type: Manufacturer Website Blog Post

- Website: PrecisionWeldTech.com

- Summary: This blog post offers a showcase of laser welding machines, highlighting their precision welding capabilities and advanced features. It discusses how laser welding machines can revolutionize welding experiences by providing superior control over welding parameters, improved joint quality, and reduced heat-affected zones. The post also showcases case studies and client testimonials demonstrating the effectiveness of laser welding technology in various industrial applications. Welders and industry professionals interested in leveraging the power of laser welding for enhanced welding experiences will find this manufacturer source valuable.

-

Frequently Asked Questions (FAQs)

Q: What are the benefits of using a handheld laser welding machine?

A: Handheld laser welding machines offer several benefits, including the ability to weld a wide range of materials and thicknesses, superior weld quality with minimal risk of undercut or burn-through, and superior speed and precision. They are also simple and fast to set up and provide consistent, high-quality results.

Q: How does handheld fiber laser welding compare to traditional TIG and MIG welding?

A: Handheld fiber laser welding offers faster welding speeds, higher precision, and the ability to weld thin and reflective metals that are challenging for traditional TIG and MIG welding. It also minimizes heat input, reducing distortion and eliminating the need for extensive post-weld finishing.

Q: Can a novice operate a handheld laser welding machine effectively?

A: Yes, novice users can operate handheld laser welding machines effectively, thanks to their user-friendly interfaces and automation features. Many systems, such as the LightWeld handheld laser from IPG Photonics, are designed with ease-of-use in mind. However, proper training and certification are crucial for safety and optimal performance.

Q: What materials can

Q: What are the benefits of using a handheld laser welding machine over traditional TIG welding?

A: Handheld laser welding machines offer several advantages over traditional TIG welding. They are more efficient, requiring less time for both setup and the welding process itself, and can achieve consistent high-quality results. They’re capable of welding a wide range of materials and thicknesses, including thin and reflective metals that may be challenging for TIG welding. Additionally, handheld laser welders provide greater precision, minimizing the risk of undercut or burn-through.

Q: Can handheld laser welding be used for both spot welding and creating seams?

A: Yes, handheld laser welding machines are incredibly versatile and can be used for both spot welding and creating longer seams. By adjusting the mode and parameters of the laser welding machine, users can easily switch between detailed spot welding for precise applications and continuous seam welding for joining larger sections of material.

Q: What types of materials can be welded with a fiber laser welder?

A: Fiber laser welders are known for their capability to weld a broad range of materials, including carbon steel, stainless steel, aluminum, titanium, and nickel among others. They are particularly effective for thin and reflective metals, providing superior weld quality without causing distortion or damaging the material.

Q: Is there a specific welding system for beginners or novices in laser welding?

A: Yes, certain laser welding systems are designed with novices in mind. These systems, like the LightWeld cobot system, are simple and fast to set up and provide consistent results with minimal training. They often feature user-friendly interfaces, adjustable settings to control the laser’s power, speed, and duration, making them accessible for users with limited welding experience.

Q: How does wire feed work in a handheld fiber laser welding machine?

A: In a handheld fiber laser welding machine, wire feed is used to add filler material to the weld joint. The wire feed mechanism pushes a wire from a spool through the welding nozzle directly into the weld pool, allowing for better control over the weld appearance and quality. This is particularly useful when welding thicker materials or when additional material is needed to fill gaps.

Q: What role does a welding helmet play in laser welding?

A: A welding helmet is an essential piece of safety equipment in laser welding. It protects the welder’s eyes and face from harmful laser radiation, bright flashes, and sparks. Modern welding helmets for laser welding are specifically designed to filter out harmful wavelengths associated with laser light, providing clear visibility while ensuring complete protection.

Q: What are the key factors to consider when selecting a nozzle for a laser welding machine?

A: When selecting a nozzle for a laser welding machine, key factors to consider include the type of material being welded, the thickness of the material, the desired weld type (spot or seam), and the required precision. The nozzle’s size and shape impact the focus and distribution of the laser beam, affecting weld quality and efficiency. It’s also important to ensure the nozzle is made from a protective metal that can withstand high temperatures without degrading.

Q: How does the integration of CNC or 3D technologies enhance the capabilities of laser welding?

A: The integration of CNC (Computer Numerical Control) or 3D technologies significantly enhances the capabilities of laser welding by enabling high precision and automation. CNC integration allows for the precise control of the welding process, including the laser’s path, speed, and power, enabling complex weld patterns on intricate parts. 3D technology extends these capabilities to three-dimensional objects, allowing for precise welds on varying surfaces and at different angles, thereby expanding the versatility and applications of laser welding.

Q: How effective are cleaning lasers for pre- and post-welding processes?

A: Cleaning lasers are highly effective for both pre- and post-welding processes. Before welding, they can be used to remove contaminants, rust, and coatings from the material surface, ensuring a clean and optimal surface for welding. After welding, they assist in removing any residue, oxidation, or spatter, providing a clean and smooth finish. Laser cleaning offers a non-contact method, which minimizes damage to the base material and enhances the overall quality of the weld.

Q: How important is the welding system’s wire feed feature?

A: The wire feed feature in a welding system is critically important for applications requiring the addition of filler material. It allows for the precise control of wire feed speed and direction, leading to stronger welds and the ability to weld a wider range of materials and joint configurations.

Q: What safety equipment is necessary when using a handheld laser welding machine?

A: When using a handheld laser welding machine, proper safety equipment is crucial. This includes a certified welding helmet with appropriate filters to protect your eyes from harmful light radiation, protective metal gloves to safeguard your hands, and fire-resistant clothing to protect against sparks and hot metal.

Q: How does the adjustment of the laser’s mode affect the welding process?

A: Adjusting the laser’s mode can significantly affect the welding process by altering the beam’s energy distribution, penetration depth, and weld width. For instance, changing from a continuous wave to a pulsed mode can help control heat input, reduce thermal distortion, and enable precise welding of thin materials or complex geometries.

Q: Can handheld laser welding be integrated into automated and robotic systems?

A: Yes, handheld laser welding technology can be integrated into automated and robotic systems for enhanced precision, productivity, and repeatability. Systems like the LightWeld cobot system from IPG Photonics are designed for collaborative use, allowing humans and robots to work side by side in various welding applications.

Q: What maintenance is required for a handheld laser welding machine?

A: Maintenance for a handheld laser welding machine typically includes regular cleaning of the laser lens and nozzle, ensuring the wire feed mechanism is free of debris, checking and replacing the protective lens cover as needed, and regularly inspecting and tightening all electrical and mechanical connections. Following the manufacturer’s maintenance schedule is crucial for optimal performance and longevity.

Q: How does laser cleaning before welding impact the weld quality?

A: Laser cleaning before welding can significantly improve weld quality by removing contaminants such as oil, grease, rust, and oxide layers from the metal surface. This ensures optimal laser weld adhesion and penetration, reducing the risk of weld defects such as porosity or lack of fusion.