Understanding Laser Wavelength Basics

Image source: https://alkatheebme.com/

What is laser wavelength and its significance?

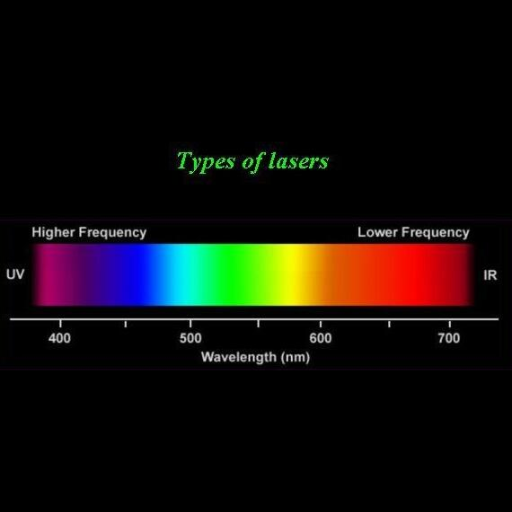

A laser wavelength is a definite distance separating the successive wave crests that are emitted by lasers. This measure is usually given in nanometres (nm) or micrometres (µm). The direct effect on the characteristics and usability of laser results from its wavelength range. Following are some major technical terms related to laser wavelength.

- Wavelength Range: Lasers emit light across a broad spectrum of wavelengths, ranging from ultraviolet (UV) to infrared (IR):

- UV Lasers: Typically 100-400 nm

- Visible Lasers: Approximately 400-700 nm

- IR Lasers: Generally 700 nm to 1 mm

- Energy Levels: The energy of laser light is inversely proportional to its wavelength:

- Higher Energy: Higher energy wavelengths such as Ultraviolet have short-wavelengths hence they can be used for precise applications such as micro fabrication processes and medical diagnostic.

- Lower Energy: Lower energy wavelengths like Infrared have longer wavelengths thus making them suitable for communication systems and thermal imaging.

- Material Interaction: The interaction of the laser with different materials depends on its wavelength:

- Absorption and Penetration: Different wavelengths are absorbed more efficiently by certain materials which dictate how well a laser can cut, engrave or weld various substrates.

How is the wavelength of a laser measured in nm?

Typically, a spectrometer or wavelength meter device is used to measure the wavelength of a laser. These devices use diffraction gratings to split the light into its various wavelengths. Here is a brief summary:

- Spectrometer: This instrument resolves the laser light through a diffraction grating that splits it up into its individual wavelengths. The light then falls on a detector which records the intensity of each wavelength thus allowing precise determination of the laser’s wavelength in nanometers (nm).

- Wavelength Meter: A device for measuring the wavelength of light by means of interference patterns made by beams split from a single source, one being reflected and the other transmitted before being recombined. So, such pattern gives an extremely accurate measurement of wavelength in nanometer.

- Calibration: In order to ensure accuracy, both spectrometers and wave length meters usually need calibration with a known reference laser source. Once calibrated, these instruments can provide highly precise wavelength measurements, crucial for applications demanding exact specifications.

Differentiating between laser types based on wavelength range

Lasers operate in different wavelength ranges and this is important when determining their applications. This concise overview is based on the latest information from the top sources:

- Ultraviolet (UV) Lasers: TThese are lasers that function with wavelengths between 100 nm to 400 nm approximately. For example, they find applications in dermatology, sterilization, micromachining and other areas where precision as well as minimal thermal effect is required.

- Visible Lasers: Visible light lasers which are common have a range of wavelengths between 400 nm and 700 nm. These are extensively used in display technologies, laser show and surveying.

- Infrared (IR) Lasers: Infrared lasers cover the range from about 700 nm to 1 mm. As such, they are useful for telecommunications, medical laser treatments like laser surgery as well as industrial processes such as cutting and welding because they penetrate objects more deeply.

The Role of Semiconductor Diodes in Determining Laser Wavelength

How semiconductor diodes emit light at specific wavelengths

Through the process of electroluminescence, semiconductor diodes generate light at definite wavelengths. When a given voltage is applied to the semiconductors, electrons in the conduction band join with holes in valence band. Energy is released as photons during recombination with wavelength (λ) and energy (E) governed by semiconductor material’s band gap energy(Eg). The photon energy-wavelength relation can be given by the equation:

\[ E = \frac{h \cdot c}{\lambda} \]

where:

- \( E \) is the energy of the photon,

- \( h \) is Planck’s constant (\( 6.626 \times 10^{-34} \) Js),

- \( c \) is the speed of light in a vacuum (\( 3 \times 10^8 \) m/s),

- \( \lambda \) is the wavelength of the emitted light.

The band gap energy (Eg) in electron volts (eV) can also be related to the wavelength in nanometers (nm) as:

\[ Eg (eV) = \frac{1240}{\lambda (nm)} \]

The impact of diode material on the output wavelength

Comparing laser diode types and their wavelength capacities

They are made of a wide range of materials for semiconductors, so the different types have different wavelength ranges.

- Gallium Arsenide (GaAs) Laser Diodes: Infrared applications, typically 850-900 nm. These are needed for optical fibers communication, night vision devices and remote control systems. Longer wavelengths make GaAs lasers very suitable for long distance communications because they exhibit lower fiber optic cable losses at those wavelengths.

- Gallium Nitride (GaN) Laser Diodes: Blue to ultraviolet spectrum, approximately 400-450 nm. GaN diodes are used in Blu-ray players, high-density data storage and some medical imaging systems having shorter wavelengths that allow more information to be stored in a given area and high resolution.

- Indium Gallium Arsenide Phosphide (InGaAsP) Laser Diodes: Near-infrared region with specific emission wavelength between 1000-1700nm. Applications include the telecommunications industry, medical diagnostics and optical coherence tomography where accurate measurements and reliability are critical.

Exploring the Applications of Various Laser Wavelengths

This means that lasers can be modified to suit certain purposes by working at various wavelengths. Optical losses are low, so they are best used for fiber optic communications and remote sensing. Also, there is a wide range of applications for blue ultraviolet lasers produced by GaN diodes including higher resolution medical imaging, Blu-ray technology and others such as high-density data storage. These InGaAsP laser diodes run in the near-infrared and are used in telecommunication and medicine since they give precision and reliability. So every special field like advanced medical systems or consumer electronics has its own class of wavelengths.

Laser applications in the medical field: differences in wavelengths

The suitability of lasers for diverse medical applications is determined by their specific wavelengths which may influence the interaction with biological tissues. The following are types of lasers based on their associated medical uses and wavelengths.

- Ultraviolet (UV) Lasers (180 – 400 nm)

- Applications: Phototherapy, vision correction (LASIK), and sterilization.

- Technical Parameters: High energy photons that can break molecular bonds; useful for cutting at the surface but not deep into the tissue.

- Visible Light Lasers (400 – 700 nm)

- Applications: Ophthalmology (retinal surgeries), dermatology (skin treatments), and diagnostics.

- Technical Parameters: Moderately penetrating, ideal for pigmented tissue targeting. These include argon lasers used in laser photocoagulation emitting at 488nm and 514nm.

- Near-Infrared (NIR) Lasers (700 – 1400 nm)

- Applications: Soft tissue surgery, laser coagulation, dental treatments, and low-level laser therapy (LLLT).

- Technical Parameters: Deeper penetration depths. GaAs diode NIR lasers operating around 800-900nm provide high precision with low thermal damage.

- Mid-Infrared Lasers (1400 – 3000 nm)

- Applications: Ablative laser surgery, such as laser lipolysis and resurfacing.

- Technical Parameters: Such lasers are very good tissue vaporizers due to high water absorption e.g. Erbium YAG(2940nm) that have minimal thermal spread during ablation.

- Far-Infrared Lasers (3000 – 10000 nm)

- Applications: CO2 lasers (10600 nm) used in soft tissue surgeries, dermatology, and gynecological procedures.

- Technical Parameters: Because they are best absorbed by water to cut or coagulate tissues properly; high power outputs makes them suitable for a wide range of surgical procedures.

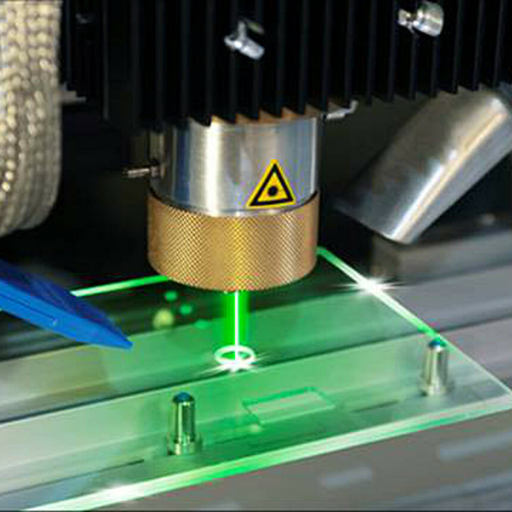

The use of different wavelengths in laser cutting and welding machines

Optimizing material processing is essential for the use of different wavelengths in laser cutting and welding machines. When it comes to materials, various wavelengths act differently; affecting factors such as absorption, precision, and thermal impact.

- Fiber Lasers (typically around 1064 nm)

- Applications: Widely used for cutting and welding metals such as stainless steel and aluminum.

- Advantages: High beam quality and efficiency, deeper penetration, minimal maintenance. Its wavelength ensures good absorption by metals so that they can be cut with great precision and cleanliness.

- CO2 Lasers (10600 nm)

- Applications: Ideal for cutting non-metallic materials like wood, plastics or textiles.

- Advantages: High power output at low cost and versatility in thickness of materials handled. This is due to the longer wavelength which makes it possible to have a high-quality edge on non-metallics since gas utilization is efficient.

- Diode Lasers (800 – 980 nm)

- Applications: Often used for welding thins sheets of metal and plastics.

- Advantages: High electrical efficiency coupled with compact size. The range of wavelengths ensures excellent absorption behaviour in a variety of materials making them appropriate tools for fine welding work

Each type of laser wavelength has its own benefits depending on the material being worked upon in order to achieve an objective best suited for both cutting operations and weldings performance purposes.

Optical communications and the importance of selecting the right laser wavelength

Laser wavelength choice is important for effective data transmission in optical communications. Typically, the main wavelengths used in optical communication systems are approximately 1310 nm and 1550 nm. These wavelengths lie within low-attenuation windows for optic fibers meaning that they do not suffer significant losses over long distances and thus can be used for efficient data transfer.

- 1310 nm Wavelength

- Applications: Often used in metro, access networks, or any other short to medium distance communications.

- Technical Parameters: Its dispersion is low making it outstanding in applications requiring high signal integrity over shorter spans.

- 1550 nm Wavelength

- Applications: Preferred for long distances and large capacities such as undersea cables and long haul telecommunications.

- Technical Parameters: The 1550 nm wavelength experiences even lower attenuation than the 1310 nm wavelength does, which means it has better loss characteristics at this wavelength and may use Erbium-Doped Fiber Amplifiers (EDFAs) without converting its signal into electrical forms resulting in a lot of amplification.

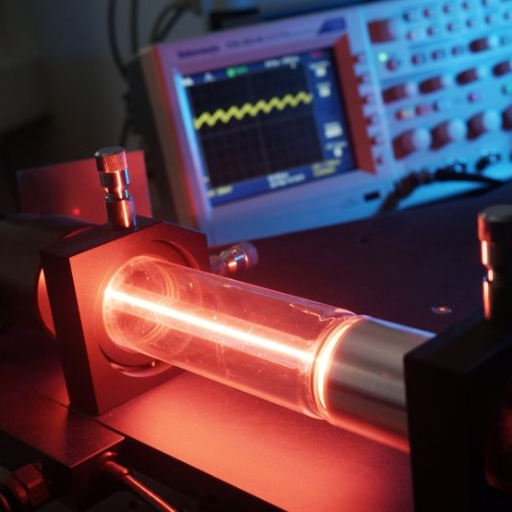

Gas Lasers and Their Unique Wavelength Properties

Carbon dioxide (CO2) lasers on the other hand work with a wavelength of 10.6 µm and are widely used for industrial cutting and engraving due to their high power output capacity and efficiency levels. Argon-ion lasers can emit light in the blue and green regions, particularly at 488 nm and 514 nm, respectively, making them appropriate for use in medical applications such as retinal phototherapy or scientific research purposes. The peculiar wavelength characteristics of gas lasers make them universal tools that have been chosen individually according to specific tasks’ requirements related to optimal wavelengths designs towards achieving intended objectives in different fields.

How gas types influence the wavelength of gas lasers

The wavelength of light emitted by a gas laser is directly determined by the type of gas used because different gases have peculiar energy levels on atomic or molecular level which give rise to specific wavelengths when excited. Here are some examples of how different gases affect the wavelength of gas lasers along with their corresponding technical parameters:

- Helium-Neon (HeNe) Lasers:

- Wavelength: 632.8 nm (red light)

- Technical Parameters: hese are low power devices, usually <20 mW with HeNe lasers known for their excellent beam quality and wavelength stability, which makes them suitable for applications requiring high precision such as alignment and interferometry.

- Carbon Dioxide (CO2) Lasers:

- Wavelength: 10.6 µm (far-infrared)

- Technical Parameters: These can be seen as being extremely efficient in cutting, welding and engraving materials due to their high power output that often goes up to several kilowatts as well as the capacity they have of generating continuous beams useful in manufacturing.

- Argon-Ion Lasers:

- Wavelengths: 488 nm (blue) and 514 nm (green)

- Technical Parameters: Such class of lasers has an output power range of milliwatt to several wattage capacities. They are frequently employed in medical and scientific fields where multiple wavelengths with high spectral purity can be generated.

- Nitrogen Lasers:

- Wavelength: 337.1 nm (ultraviolet)

- Technical Parameters: Nitrogen lasers exhibit high peak powers, short pulse durations in nanoseconds, and moderate average powers making them suitable for applications like laser-induced fluorescence or atmospheric remote sensing.

Excimer laser: Understanding its unique UV wavelength output

The role of gas lasers in industrial and scientific applications

Advanced Concepts in Laser Wavelength

Tunable lasers: Adjusting the wavelength for specific applications

In order to suit certain applications, tunable lasers have an added advantage of being capable of changing their wavelength. This is particularly beneficial in fields like spectroscopy, medical diagnostics, and telecommunications. One can adjust the laser by use of different methods such as changing the gain medium, employing external gratings or employing acousto-optic or electro-optic modulators. Key technical parameters for tunable lasers are:

- Wavelength Range: The range across which the wavelength may be altered e.g., Optical Parametric Oscillator (OPO) that may offer tunability from 400 nm to 700 nm.

- Linewidth: It is measured in nanometres (nm) or gigahertz (GHz). In this case a narrow linewidth for high resolution spectra.

- Tuning Speed: The speed at which the laser’s wavelength can be adjusted normally given in nm/s

- Output Power: The power level of the laser output ranges from milliwatts (mW) to watts (W), depending on the application need.

- Mode-Hopping Range: A distance over which a laser can shift between different longitudinal modes maintaining coherence and hence sustaining stability.

The process of wavelength amplification in lasers

Stimulated emission: Achieving precise wavelengths

Choosing the Right Laser: Wavelength Considerations

The importance of wavelength in selecting a laser for optical applications

For optical application in lasers, the right wavelength is important for best performance and efficiency. To choose the wavelength needed for a laser, consider the following:

- Application Specificity:

- Medical: YAG lasers (1064 nm) are perfect for reaching deep tissues without harming surface ones, while CO2 lasers (10.6 μm) are great on superficial treatments.

- Industrial: Fiberlasers have been known to cut through metals with precision at a 1070nmwavelength and also weld them. Marking, etching and micro-machining can be done better by UV lasers (355 nm).

- Interaction with Materials:

- Some materials absorb some wavelengths of light more than others do. Green lasers(532 nm), therefore are appropriate for metalworking tasks where metals and other reflective objects are involved since they get absorbed more by it hence faster process.

- Absorption rates through wavelength testing- Metals such as copper (e.g., 532 nm), etc., plastics such as polymers(e.g., 10.6 μm).

- Environmental Factors:

- Ambient Light Interference: Look for wavelengths that suffer minimum interference from surrounding lights.Near-infrared lasers (808 nm) usually witness little disturbance from the surrounding light.

- Temperature Stability: Make sure the laser system has efficient thermal management to reduce wavelength drift.Temperature control mechanisms should be used in the designs together with active cooling systems to keep these factors stable.

- Technical Parameters:

- Wavelength Accuracy: Precision applications demand high accuracy levels; hence, ensure that your laser has this feature within ±0.1 nm as its limit.

- Beam Quality (M^2 factor): A beam quality close to one with a low M^2 factor is required when dealing with focused and precision applications only.

- Power Density: Ensure that power density matches well against material specifications hence there will be no destruction within the surroundings of materials being processed if this occurs effectively.

Comparing ultraviolet (UV), visible, and infrared (IR) lasers

UV, Visible and IR lasers are compared in this text, emphasizing the uniqueness of each one.

- Ultraviolet (UV) Lasers:

- Wavelength Range: UV lasers operate in the range of 100-400 nm.

- Absorption and Precision: It causes a lot of materials to absorb UV light leading to precise, clean cuts with minimal thermal impacts. They are best suited for medical applications, semiconductor manufacturing and micro-machining.

- Common Applications: Photolithography is the main use of these devices although they can also be found in medical equipment as well as other sensitive material processing tools.

- Visible Lasers:

- Wavelength Range: They operate between about 400-700 nm which falls within the visible spectrum.

- Versatility and Visibility: As these lasers fall under a range where they are visible easily by human beings hence mainly used in alignment tasks, laser pointers or entertainment. Consequently, such lasers have moderate absorption into materials making them suitable for general purposes.

- Common Applications: Alignment exercises by industrialists; display technologies; laser shows as well as educational tools.

- Infrared (IR) Lasers:

- Wavelength Range: The wavelength range that infrared (IR) lasers cover starts from 700 nm to 1 mm.

- Depth of Penetration: In some respects IR lasers reach more deeply into several substances than UV and visible ones making them useful for cutting, welding or medical therapies. They work particularly well when heat treatment or material processing is involved.

- Common Applications: Industrial cutting and welding; laser surgery amongst others; telecommunications industry and military uses also apply here.

Through knowing these distinctions users would be capable of choosing appropriately their very specific needs regarding the type of laser they want maximizing efficiency in their applications.

Key considerations when selecting a laser diode’s nm range for specific tasks

The determination of the nm range appropriate for a laser diode is dependent on many factors such as the material to be processed, the desired application, and efficiency requirements. Below are key points to consider:

- Material Properties: Different materials have various degrees of absorbance for different wavelengths. For instance, there are UV lasers (200-400 nm) that are suitable for fine material processing and semiconductor manufacturing because many materials have high absorption at those Wavelengths. Conversely, IR lasers (700 nm – 1 mm) are used for cutting and welding where deep penetration into the material is essential.

- Application Requirements: The exact job at hand will largely dictate which nm range to select. Medical lasers, for example, often use IR wavelengths because they can penetrate deeper into tissues than other types do whereas visible lasers (400-700 nm) are commonly employed in applications requiring precision visibility such as alignment or education tools.

- Efficiency and Performance: It is important to consider how efficient a laser is in converting electrical power into coherent light. Longer wavelength lasers such as near-infrared tend to be more efficient and hence preferred in industrial applications where performance and cost-effectiveness are critical.

- Safety and Regulatory Compliance: Different wavelengths carry different risks. The invisibility of some UV or IR wavelengths implies that they may be more dangerous requiring more stringent safety precautions with respect to them being invisible to human eyes thus forcing compliance with certain standards set by authorities.

Reference sources

-

Lab9 – Understanding CO2 Laser Wavelength

- Lab9 provides an in-depth guide on CO2 laser wavelengths, detailing their functioning and various applications. This resource is essential for grasping the fundamental aspects of laser wavelengths and their practical uses.

- Source: Lab9

-

Handbook of Laser Wavelengths (Laser & Optical Science)

- This comprehensive volume compiles an extensive list of laser wavelengths across different media, offering detailed technical insights. The handbook is a valuable reference for professionals seeking precise and up-to-date information on laser wavelengths.

- Source: Handbook of Laser Wavelengths

-

Laser-Crylink – Unlocking the Mysteries of Laser Crystals

- Laser-Crylink presents a thorough guide on laser crystals, the core components affecting laser wavelengths. This source explains the principles, types, and applications of laser crystals, making it a significant reference for understanding wavelength properties.

- Source: Laser-Crylink

Frequently Asked Questions (FAQs)

Q: What type of laser is used in medical applications?

A: In medical applications, different lasers are used, such as the diode laser for skin treatments and the CO2 laser for surgical procedures. The choice depends on the wavelength of the laser, as specific wavelengths are absorbed differently by tissues, affecting how the laser energy interacts with the cells. For example, a 532nm laser is commonly used for dermatological conditions due to its high absorption in hemoglobin and melanin, making it effective for targeting specific skin concerns.

Q: How does laser light differ from regular light?

A: Laser light is unique because it is coherent, monochromatic, and highly directional. Unlike regular light, which consists of many wavelengths and spreads out in all directions, laser light has one wavelength within a very narrow spectrum, which allows it to be focused into a tight beam. This coherence and directionality make laser light intensely powerful and precise, essential for applications ranging from optical communications to surgery.

Q: Can you explain the basics of how a laser works using optics principles?

A: Lasers operate on the principle of light amplification by stimulated emission of radiation. It involves energizing or “pumping” a medium (which could be a gas, liquid, or solid) to create a population inversion, where more atoms are in an excited state than in a lower energy state. When light passes through this medium, it triggers a cascade of stimulated emission, releasing photons that are in phase and have the same wavelength of the light originally used to excite the atoms. Optics are used within the laser to focus and direct this light into a coherent beam.

Q: What is the significance of the wavelength of the laser in fiber optic communications?

A: The wavelength of the laser in fiber optic communications is crucial because it determines the capacity and efficiency of data transmission. Lasers producing light in the near-infrared part of the electromagnetic spectrum, typically around 1550nm, are favored because this wavelength experiences lower absorption and scattering in the silica-based optical fibers, allowing for longer distance communication without significant loss of signal. The choice of wavelength within the system can also affect the bandwidth, with certain wavelengths allowing for denser wave division multiplexing (WDM), thus increasing the data transmission rate.

Q: What is the role of a pump source in generating laser pulses?

A: A pump source in a laser system provides the initial energy required to create a population inversion, which is the first step in generating laser pulses. This can be achieved by various means, including electrical discharge in gas lasers, intense light from flashlamps or other lasers in dye lasers, or electrical current in diode lasers. The pump energy excites the atoms or molecules of the gain medium to higher energy states. When these atoms or molecules return to their ground state, they emit photons, contributing to the stimulated emission process that produces the coherent, monochromatic laser pulse.

Q: How does one achieve frequency doubling or tripling in lasers, and what are its implications for the wavelength of the laser?

A: Frequency doubling or tripling involves passing laser light through a non-linear crystal that alters the light’s frequency, thereby changing its wavelength. In frequency doubling, also known as second harmonic generation, the crystal effectively halves the wavelength of the laser, producing light at a frequency twice that of the original. Similarly, frequency tripling triples the original light’s frequency, reducing the wavelength by a third. This process is used to produce laser radiation at wavelengths that are not easily achievable directly from lasers, such as in the visible or UV range from infrared lasers. It allows for the versatility of laser outputs, enabling applications that require specific wavelengths not readily produced by the laser’s active medium.

Q: Why is the narrow spectrum of a laser beam advantageous in precise material processing?

A: The narrow spectrum of a laser beam is highly advantageous in precise material processing because it allows for a very focused application of energy. The monochromatic nature means all the laser energy is concentrated at one wavelength, enabling it to interact uniformly with the material. This precise energy application can be tailored to the absorption characteristics of different materials, allowing for controlled cutting, drilling, or engraving with minimal damage to surrounding areas. The predictability and repeatability of these interactions make lasers invaluable tools in intricate manufacturing processes, including semiconductor fabrication and micromachining.

Q: How do the wavelengths between 400 nanometers and 700 nanometers correspond to the visible light spectrum?

A: The wavelengths between 400 nanometers (nm) and 700 nm correspond exactly to the range of the visible light spectrum perceived by the human eye. This range starts with violet light at around 400 nm, moving through the spectrum to blue, green, yellow, orange, and finally red light at around 700 nm. Each color has a specific wavelength range within this overall spectrum, with the variation in wavelength determining the color observed. Lasers operating within this visible range can produce beams of light in various colors, depending on the specific wavelength produced by the laser.