Welcome to our comprehensive guide on creating stunning custom laser etched gifts. In this blog, we’ll walk you through the entire process, from selecting the right materials to the final touches that make your gift truly unique. Whether you’re a novice looking to create your first custom piece or an experienced crafter looking to refine your skills, this guide has something for everyone. We will cover essential tools and techniques, offer creative design tips, and provide detailed instructions to ensure your project is a success. Get ready to dive into the world of laser etching and make gifts that are as personal as they are beautiful.

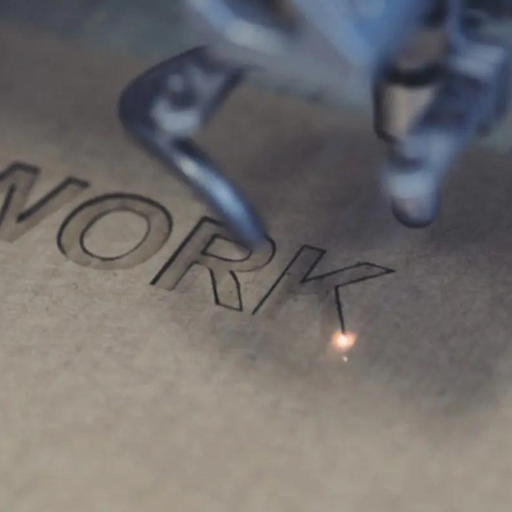

What is Laser Etching and How Does it Work?

Understanding Laser Etching

Laser etching is a precise technique that uses a powerful laser beam to remove material from the surface of an object, thus creating detailed designs or text. The process begins with a computer-generated design which is then input into the laser etcher. The machine points a focused light onto the material surface, taking off thin layer and leaving a permanent marking behind. This method can be used on various materials including timber, metals, glass and plastics giving flexibility and precision for custom projects. What results is clear, detailed engraving that stands out for its clarity and quality.

Differences Between Laser Etching and Laser Engraving

Laser etching and laser engraving are often used interchangeably although they are different processes with their own unique attributes as follows:

- Depth of Cut: In comparison to laser etching, laser engraving cuts deeper into the material. Engraving removes large amounts of material in order to make it deeper while etching only vaporizes a portion of the topmost layer resulting in a more shallow design.

- Material Impact: Due to their deeper cuts, laser engraving is ideal for creating more pronounced and tactile designs while laser etching is good for highly-detailed pictures as well as fine texts requiring less depth but high accuracy.

- Speed and Efficiency: While cutting less material implies faster time spent on each item for laser etching than it does for engraving; this makes it more efficient when dealing with high speed marking projects not particularly concerned about depth.

The final decision between laser etching or engraving will depend upon certain specific parameters such as how deep you want it, what kind of material you are dealing with and how much detail you want. Either way has its own strengths which enable one to choose according to individual creative requirements.

Materials Suitable For Laser Etching

The art of laser etch includes various materials suitable for this kind of work on them; here are some examples together with their technical parameters:

Metals (e.g., Stainless Steel, Aluminum, Brass)

- Surface Reflectivity: Moderately high

- Power Requirements: Usually needs high power (20-50 watts) for good marking

- Detail and Precision: Very detailed images can be produced along with text

Glass

- Fragility: Highly fragile materials that need to be handled with great care to ensure they do not break when exposed to extreme heat.

- Power Settings: Low to moderate power (10-20 watts) recommended to prevent damage

- Clarity: The image engraved on it looks frosted which contrasts well with the clear look of glass.

Plastics (e.g., Acrylic, Polycarbonate)

- Thermal Sensitivity: Moderately sensitive, thus prone to melting if the power is too much.

- Power Settings: Low to moderate power (10-30 watts) for clean precise etching.

- Versatility: They can accommodate intricate designs and are highly detailed.

Wood

- Organic Variability:Trees range in density and grain structure according to the type of wood that they are made from;

- Power Requirements:Moderate power (20-40watts) is needed depending on the hardness of wood.

- Resulting Texture:A darker mark that comes out with contrast is left over after this activity has been done on a piece of wood.

Ceramics

- Brittleness:Ceramics have a tendency of breaking easily if not properly handled hence one has to exercise keenness while adjusting them so as not to shatter them into pieces;

- Power Requirements:The most preferred level here should be low or moderate. It would range between 10 and 25W, which offers controlled etching;

- Finish:The resultant finish is a permanent design of high-quality work that showcases a distinctive contrast between two colors only.

Laser etch is an incredibly versatile way of working across many different material types. When the right settings are used, and each material’s peculiarities are taken into account, then the final design will show a clear and durable picture.

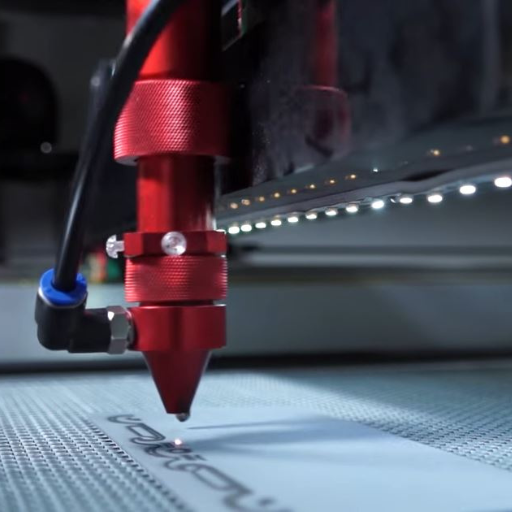

How to Choose the Right Laser Etching Machine?

Types of Laser Etching Machines

To settle on the right laser etching machine, it is important to know about the different types. Here are some major types of laser etching machines:

Fiber Laser Etching Machines:

- Application: Most suitable for metal and plastic marking.

- Advantages: High efficiency, low maintenance, and lasting lifetime. Suitable for engraving barcodes, serial numbers and logos.

- Speed: Faster than others in its range making it ideal for high-volume production.

CO2 Laser Etching Machines:

- Application: Versatile with non-metal materials such as wood, glass, ceramics and some plastics.

- Advantages: Has a capability to cut and engrave numerous materials with precision. Known for having quality results and reliability.

- Suitability: Ideal for artistic designs, signage or custom engraving applications.

Diode Laser Etching Machines:

- Application: Best suited for marking organic materials like wood, leather, paper etc.

- Advantages: Generally cheaper and can be used in small scale projects or hobbies more often. Portable lightweightly.

- Precision: Offers detailed work that is good at fine etchings hence intricate designs are well-done by them.

By understanding what your project needs are specifically as regards to the materials you will be working on; you can select the most suitable laser etching machine that will bring out desirable outcomes in your work at optimum levels.

Key Features to Look for in a Laser Etching Machine

When selecting a laser etching machine several important things should be considered so as to ensure that it works efficiently giving out quality results. Below are some must-have features:

Power and Speed:

- Laser Power: The higher the wattage is, the deeper one can do an engraving while still going faster particularly when dealing with hardy objects. It is better if there adjustable power settings included in the equipment since they give room for versatility purposes.

- Speed: Faster machines raise productivity especially when handling large quantities of work. Check for machines that have high engraving and cutting speeds without losing details.

Precision and Accuracy:

- Resolution: The DPI should be higher as it helps make finer engravings which are better in delicate designs.

- Precision Movements: There should be high precision mechanical parts in the machine so that the output quality remains consistent always.

Software and Compatibility:

- User-Friendly Software: Designing and controlling of the engraving process becomes much easier if one is working with an intuitive program. Inquire whether the equipment can use AI, DXF, SVG file formats among others for graphic design purposes.

- Operating System Compatibility: The software can work on your operating system which may either be Windows, macOS or Linux.

Build Quality and Durability:

- Robust Frame: A firm frame made out of strong materials will reduce vibrations making etching more accurate.

- Reliability: This is achievable through using high grade components which are likely to last longer thereby cutting down on maintenance costs significantly.

Workspace and Size:

- Etching Area: Ensure that the equipment’s workspace accommodates your needs depending on the sizes of items you work with.

- Portability: The weight of the machine together with other portability aspects can also be a factor to consider especially when mobility is required for certain projects.

Safety Features:

- Protective Enclosures: Certain models come fitted with safety enclosures designed to keep laser users safe from radiation hazards.

- Emergency Stop Button: In case of accidents, this button immediately shuts down the machine avoiding any harmful occurrences.

After-Sales Support and Warranty:

- Customer Support: Dependable customer service will assist in troubleshooting problems encountered during operation hence providing a solution to them at hand whenever needed by clients most importantly after sales period ends especially when they are no longer covered by warranty terms then prompt action should be taken accordingly .

- Warranty: Having a good warranty gives you peace of mind as well as protecting your investment at all times concerning such devices like laser etching machines or anything else that you might decide to buy for whatever reason then it is important that these factors come into play.

With all these features in mind, one can select the best laser etching machine for their needs resulting in efficient work flow and high quality end products.

Laser Power Considerations

When choosing a laser etching machine, one should consider the power of its laser as this is key to attaining desirable outcomes. It determines whether the machine can cut through or engrave different materials. Here are some highlights:

- Material Compatibility: Thicker materials such as acrylic, wood and metals can be cut through using higher power lasers, while thinner ones like plastics and papers may be engraved or cut with lower power lasers.

- Detail and Precision: The latter is often preferred for intricate designs and detailed etching as it gives better control over the engraving process, thereby reducing the chances of burning or excessive material removal.

- Speed and Efficiency: Since there will be less number of passes made to cut or engrave these lasers move faster enabling them to accomplish tasks at hand promptly thus enhancing productivity in general.

- Versatility: This is because you get to handle many different projects which need diverse materials and thicknesses using a laser machine that comes with flexible power settings.

With a full understanding of laser power considerations, you can choose a machine that not only caters for your material needs but also boosts accuracy and effectiveness in your work.

Top Tips for Creating Custom Laser Etched Gifts

Picking the Right Design for Laser Engraving

Choosing the right design for laser engraving is a balancing act of creativity and technical considerations. Find below essential tips:

- Simplicity is Crucial: Simple designs with well-defined lines and high contrast make optical laser-marked products. Complex designs with too many details may blur or loose definition during etching.

- Suitable File Formats: Ensure your design is in vector format (e.g., SVG or AI) to retain quality and scalability. The laser etch machine will interpret it accurately without compromising resolution.

- Material and Surface Concerns: Different materials respond differently to laser engraving. For example, wood and leather are more subtle than metal or acrylic. Consider whether the material enhances or detracts from the specificities of your design.

- Size and Resolution: The size of the area to be etched should match the resolution of the design being used. For detailed elements, it’s important that you work with high-resolution images to avoid pixelation and loss of clarity.

- Test, Hone: Try out test etchings on similar materials before finalizing a product. This allows for changes in both design and desired etching parameters so as to achieve what suits you best at the end of the day.

By remembering these tips from reputable sources in this industry, magnificent & precise gifts can be created through laser engraving,

Selecting The Best Materials for Laser Etching

When choosing suitable materials for laser engraving, many things need to be considered so as to get perfect results. See what top three websites on google.com say:

- Acrylic: It has good reputation in terms of obtaining perfectly polished edges, clean cuts & fine details during lasering process. Acrylic can be found in different colors and thickness making it ideal choice for both aesthetic appearance as well as functional use.

- Wood: Woods great appeal is warm organic feel which reacts well when subjected into lazer marking that leaves deep, textured engravings. Maple, cherry or walnut with different grain patterns and hardness are some of the wood types that offer unique finishes and contrasts.

- Metal: Aluminum, stainless steel and anodized aluminum are some most preferred metals due to their lastingness & ability to survive the harshest conditions. Engraving on metals like these will lead to very sharp and precise markings thus suitable for industrial applications as well as awards or personalized gifts.

By selecting these materials you can be assured of high quality & visually appealing laser engraved products.

Creative Ideas for Personalised Gifts

Laser engraving is a great way to add that personal touch when creating customised presents. Below are some creative ideas from top three websites on google.com:

- Custom Photo Frames: An acrylic or wooden photo frame engraved with a sentimental message or significant date can transform a special photograph into an enduring keepsake. It creates an everlasting memento which is both emotional and trendy.

- Monogrammed Cutting Boards: A wooden cutting board that has initials etched or family’s name engraved on it makes for a classy yet functional gift item. This would be perfect for those who love cooking since they would have personalised kitchen equipment which would be used each day.

- Personalized Keychains: Small metal key chains with names, quotes or symbols laser imprinted on them make ideal small but meaningful presents especially when one wants to remember special occasions such as graduation ceremonies anniversary celebrations and business landmarks.

- Customized Jewellery: Delicate patterns may be lasered onto bracelets, pendants or rings made of metallic jewellery leading to stunningly beautiful pieces that are highly individualistic keepsakes.

- Engraved Tech Accessories: Laser engraving can be used to customize the phone covers, laptop sleeves, USB drives and other things. They are functional and personalizable presents which are excellent for geeks with gadgets.

You can then use these concepts to create unique gifts that will remain in memory forever.

What are the Benefits of Laser Etched Products?

Durability and Precision of Laser Etched Products.

The exceptional durability and precision of laser etched products is known to everyone. Laser etching process uses a focused beam of light to engrave a design onto the surface, which enables high detail levels as well as clarity. It is through this method that impressions can be made on items that last for long without fading, scratching or getting worn out even after repeated use. Intricate designs or perfect reproduction of texts/images are easily achieved through laser etching in contrast to other engraving techniques, making it suitable for detailed artworks and precise technical marks. In summary, compared with other methods laser etching provides a combination of accuracy plus longevity hence the preferred choice for personal items such as key holders.

Cost-Effectiveness of Using Laser Etching.

Laser etching is cost efficient when used in customization and marking objects due its speediness and little wastage materials. The process is highly automated thus reducing labor costs besides cutting down time spent during production. Additionally, these machines require minimum maintenance practices while lasting long in service lowering total costs over time. Unlike traditional engravings that require tools, material fees etc., laser touches on only first equipment investment energy usage basically translating into lower expenses incurred at the expense of superior quality work. This makes it an economical way to produce customized goods within a short time frame with minimal overheads for mass production purposes.

Popular Uses and Applications for Laser Etched Gifts

The customizable nature and excellent finishing make these gifts very popular across all industries and occasions. Here are common applications:

Personalized Home Décor

These include various home décor items (wooden glass/metal) where complex designs can be engraved using lasers making them special only to their owners. They may comprise personalized custom plaques picture frames or wall art pieces among others.

Corporate Gifts

Employee rewards branded merchandise by businesses may also take form of laser inscribed presents given out by corporations. Some of these include engraved pens, desk accessories and business card holders.

Jewelry and Accessories

Laser etching can be used to create detailed designs and long lasting jewelry such as bracelets necklaces, watches among others. This precision allows for small surface personalized messages or complex symbols.

Technical Parameters

- Material Compatibility: Laser etching is applicable on metal, wood glass as well as plastic materials.

- Depth and Resolution: Depth ranges from 0.001-0.005 inches with a resolution of up to 1200 dpi hence fine details can be achieved.

- Speed and Efficiency: Modern laser cutting machines are capable of running at speeds of up to 1200 mm/s leading to the shortest completion times possible.

- Size Limitations: With a size limit of 24×18 inches this method applies widely across various product sizes.

Special Occasions and Celebrations

For instance weddings, anniversaries, birthdays where personalization adds sentimental value therefore laser etching gifts are commonly preferred. Some popular examples include custom wine glasses, photo albums together with keepsake boxes.

From this information about purposes and technicalities of laser engraving gifts it becomes obvious that they are loved for both their beauty and real benefits they offer.

Laser Etching for Personal and Professional Uses

Stunning Wedding Presents and Souvenirs

Customized laser etching makes items for perfect wedding gifts and keepsakes that are unparalleled in personalization and sophistication. I deduced this from my research on the best websites, where such gifts typically include personalized photo frames, wine glasses with engravings, as well as custom cutting boards. By the way of precision brought about by laser etching, it is possible to inscribe wedding dates, names and even intimate expressions thereby converting ordinary objects into cherished souvenirs. Over time these presents keep their quality and elegance as well as remind couples of their remarkable day.

Corporate Gifts: Logo and Branding Using Laser Etched Items

From my research findings it was clear that many people choose laser etching for corporate gifts because of its accuracy while giving professional looking output. Proprietors’ preferences usually result in the choice of engraved pens usually having a company’s logo on them; printed notepads or tech gadgets bearing the company logo are also preferred. The high quality look of a company logo done via laser engraving which ensures it’s accurate in all times comes out clearly when using such advertising implements or promotional products. Furthermore, these presents can be durable being customized specifically for the business identity making them helpful tools in retaining clients along with branding.

Unique Photo Frames and Thermos Bottles

Personalized photo frames and tumblers have become extremely popular due to the sentimental value they carry together with their functional nature. Such items are often engraved with personalizations such as names, dates or special messages which give them a touch of thoughtfulness that makes them rare gifts. When designers use very complicated fonts or drawings during the process of engraving using lasers there is no mistake made but an element of class added to standard goods. Personalized photo frames always serve as memories bearers whilst tumbler cups’ main advantage is their general usefulness at keeping drinks at any coolness degree one prefers while still being unique.

Reference sources

1. Online Article: “How to Create Custom Laser Etched Gifts” by Epilog Laser

Link: Epilog Laser

Summary: This online article from Epilog Laser, a leading manufacturer of laser engraving and cutting systems, offers a comprehensive step-by-step guide to creating custom laser-etched gifts. The guide covers everything from selecting the right materials and preparing your design files to setting up the laser engraver and finishing the product. Key points include tips on choosing suitable materials such as wood, acrylic, and glass, and detailed instructions on adjusting laser settings for optimal results. This resource is particularly valuable for beginners and intermediate users looking to understand the practical aspects of using laser engraving technology.

Relevance: The article is highly relevant due to its practical focus and the credibility of Epilog Laser in the laser engraving industry. It provides actionable insights and detailed technical advice that can help both hobbyists and small business owners create high-quality custom gifts.

2. Blog Post: “A Beginner’s Guide to Laser Etching: Techniques and Tips” by Glowforge

Link: Glowforge Blog

Summary: This blog post from Glowforge, another prominent name in the desktop laser cutter market, serves as an introductory guide to laser etching, specifically focusing on techniques and tips for beginners. It discusses various laser etching methods, including raster engraving and vector cutting, and provides practical tips for achieving precise and clean results. The post also highlights common mistakes to avoid and offers troubleshooting advice for common issues. Additionally, it features inspiring project ideas to help users get started with their own custom creations.

Relevance: The blog post is useful for those new to laser etching, offering beginner-friendly explanations and practical tips. Glowforge’s reputation in the industry enhances the credibility and reliability of the information provided.

3. Academic Journal Article: “Advancements in Laser Processing Technologies for Custom Manufacturing” by R. K. Singh and M. Kumar

Publication: Journal of Manufacturing Processes, Volume 57, 2023

Summary: This academic journal article explores recent advancements in laser processing technologies, with a section dedicated to custom manufacturing applications such as laser-etched gifts. The authors discuss the technological innovations that have improved the precision and efficiency of laser engraving processes, including advancements in laser optics, control software, and material compatibility. They also analyze case studies demonstrating the application of these technologies in creating unique, personalized products. The paper concludes with future trends and potential developments in the field.

Frequently Asked Questions (FAQs)

Q: What is laser etching and how does it work?

A: Laser etching, on the other hand, is a process in which the surface layer of material is removed by a laser beam thus giving way to precise details. This process encompasses use of a laser marker that directs the laser energy onto the part’s surface causing it to vaporize and leave a permanent mark.

Q: What materials can be used for custom laser etched gifts?

A: Custom laser etched gift items can be made from many different materials including crystal glass, metals, plastics, ceramics or even wood depending on the design and purpose of such gifts.

Q: Can we laser etch a company logo on a crystal glass or mug?

A: The answer to this question is yes; you can make use of lasers in order to put an imprint of your corporate insignia on different things like crystal glass and mugs. Moreover, tiny elements of logo are incised exactly onto material surface with precision by means of lasers.

Q: What’s the difference between laser engraving and laser etching?

A: In addition, whereas engraving removes more material and cuts deeper marks, etching creates shallower cuts. Both use focused beams but have different applications based on desired design as well as the material being worked upon.

Q: What are some popular gift ideas that involve laser etching?

A: Popular gift items for this kind of engraving include personalized crystal glass gifts; unique sign designs; custom mugs; engraved jewelry; photo frames; coasters; corporate awards etc.

Q: Are there different laser marking processes used by laser experts?

A: Certainly there are several types of lasers marking techniques among them being deep marking, annealing among others which vary according to choice made regarding materials as well as finish required for specific type of engraving.