Utilizing a laser to engrave on aluminum brings with it endless possibilities for artists, enthusiasts and professionals alike. This flexible method permits exacting, complex drawings to be incised into this tough material, making it ideal for numerous purposes from bespoke adornments and customized presents to commercial marking and decorative pieces of art. In this blog post we will attempt to expound on basic techniques in relation to aluminum laser engraving and give you practical ideas that can help you achieve the best results possible. Whether you are a beginner who wants to get an idea about the rudiments or an advanced engraver seeking to enhance his craft, this manual will assist you in unleashing the full power of laser engraving aluminum.

Choosing the Right Laser Engraver for Aluminum

Fiber Laser vs CO2 Laser: What’s Best for Engraving Aluminum?

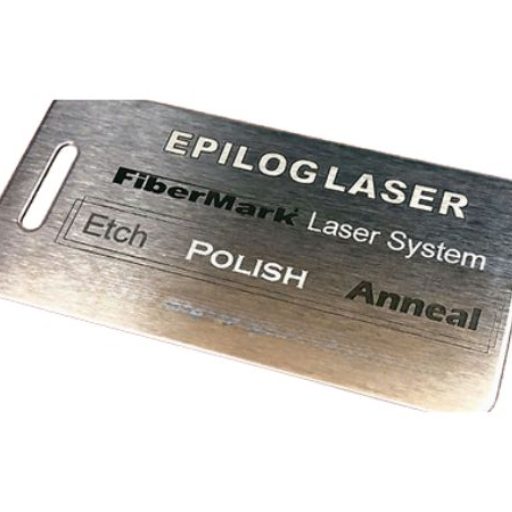

Talking about engraving of aluminum, from the viewpoint of an industry expert, a fiber laser is often better. The most important advantage attributed to fiber lasers is their potential to produce highly concentrated and intense beams which interact better with metals including aluminium hence producing cleaner, more precise engravings with minimal heat distortion. Conversely, CO2 lasers are versatile and effective for different materials such as wood or acrylic but do not work well on metals without using coatings or treatments. To this end purchasing a fiber laser would be the best investment if one is looking forward to quality results in aluminum engraving.

Understanding the Laser Power Requirements for Aluminum

There are several things that must be considered because they all contribute to deciding the right laser power for engraving aluminum. Thickness and type of aluminum being engraved are some key factors based on my experience. In most instances, 20-50 watt ratings are acceptable for typical thin gauge metal marking applications using a fibre laser. In this range, enough energy is available to achieve clear engraving without creating substantial thermal distortion or damaging the material. However, with thicker aluminium or more complex designs, you may need a higher power laser operating at between 50 and 100 watts in order to penetrate it deeply with enough clarity. It’s also advisable to have the frequency and speed settings of your laser as these can significantly affect its productivity when contemplating which one fits you best in terms of quality final output during engraving process.

All in all, depending on your specific project requirements for aluminium engraving, appropriate matching between specific applications will lead you into acquiring optimum results.

The Significance of Laser Type For Different Aluminium Materials

During my years spent working here I learnt something: Choosing the correct type of laser is extremely important when it comes to various aluminium materials since it ensures excellent engraving outcomes at all times! An example involves pure aluminium which easily responds even when subjected to lower power settings on a fibre laser. Precision engravings that use less power are therefore possible. On the other hand, aluminium alloys usually contain elements like copper or magnesium and they tend to be harder and as such for a clean as well as efficient engraving high power would be necessary and frequency settings may need adjustment.

Another consideration is anodized aluminum which has an oxide coating that is difficult to work with. In this case, using a fiber laser with carefully calibrated power and speed settings will etch through the anodized layer without compromising the integrity of the substrate. This can be critical for nameplates, barcodes, or decoration items that must have fine detail but still be long lasting. Overall, what should not be forgotten is that in order to achieve quality in engraving projects there is need to understand different aluminium materials including them with right laser type and settings.

Preparing Aluminum for Laser Engraving

Cleaning and Prepping Aluminum Surfaces

Cleaning and preparing aluminum surfaces properly is an important step in achieving excellent laser engraving results. As a professional in the industry, I suggest starting by cleaning them thoroughly using mild soaps and water to eliminate any dust particles, grease stains or other objects that may obstruct the engraving process. It is vital to dry the metal fully after you have cleaned it to avoid moisture from interfering with the engraving. When dealing with aluminum surfaces that are anodized, extra care must be observed during preparation so that the anodized layer remains intact. By following these preparatory steps, one will ensure smooth engraving process that will give clear and accurate designs.

Anodized vs Bare Aluminum: Engraving Techniques

In my opinion as a professional in this field, there are various ways of engraving on anodized and bare aluminum materials for best results. In this case of hard outer surface covering which is tough enough on anodized aluminum makes laser marking easy since removing the upper coat reveals bare metal with contrasting appearance underneath. For such cases involving anodized aluminum; however, it would be advisable to use fiber lasers with higher accuracy settings that will maintain clean-cut and sharp engravings to preserve its coating at large.

Nevertheless designing on pure aluminum can be a challenging task due to absence of this coated protection layer hence it’s very crucial for one to maintain low power levels during such artistic exercises otherwise they may lead into disfigured surfaces upon overburning. If one wants engraved marks on uncoated metals which are of high quality then he should also consider appropriate laser settings without overburning because when done excessively might result in distortion of surfaces.While undertaking any such exercise in relation to particular type of alloy exactly opposite can be said about choosing optimal approach for obtaining detailed lasting carvings.

Adjusting Laser Settings for Optimal Engraving on Aluminum

When adjusting laser settings for optimum engraving on aluminum, these parameters should be given careful attention. The first parameter is the laser power which can be adjusted in order to avoid causing harm to the bare metal while etching through this anodized layer of aluminum. Best results are usually obtained with a setting of between 20 and 30 watts. However, a greater wattage could be necessary when working with non-coated aluminum in order to go deep enough.

Secondly, the engraving speed should be adjusted to match the material’s characteristics. The slower the rate, the deeper and more noticeable engravings especially when it concerns plain aluminum. A moderate pace is okay for anodized aluminium items since they ought not to leave any residues of coating behind.

Thirdly, engraving quality may depend on frequency of laser pulses where higher numbers give better details but may require close temperature control so as not to heat up the aluminium too much.By experimenting with these settings and making small changes one can identify a combination that ensures accurate and long-lasting markings on aluminum.

Advanced Techniques in Aluminum Laser Engraving

Engraving QR Codes and Serial Numbers on Aluminum

This is necessary to achieve readability and durability while engraving QR codes and serial numbers on aluminum metal. In the case of QR code, therefore, high contrast and sharp edges that are clear become quite important because even a slight deviation will render it impossible to read the code. Thus, anodized aluminium is often favored due to its dark surface that enhances contrast when engraved.

For this reason, reduce power settings between 20-25 watts and slow down speed in order to avoid damaging the base metal whilst accurately engraving the anodized layer.

On the other hand, serial numbers need to be visible yet undying legible. More laser power (30-40 watts) with low speed is required if you are working on bare aluminum so as to achieve depth and clarity. Fine details should be produced by adjusting frequency without excessive heat which would distort material.

Both applications require regular calibration and testing in order to maintain ideal settings at all times. The purpose of this is illustrated by creating long-lasting legible marks whose print remains intact with time while still validating why careful attention must be given engraving parameters.

How To Achieve Deep Engraving On Aluminum Parts

To attain depth required without affecting the integrity of the material one should remember about such matters as power adjustment, focus setting as well as velocity rate when performing deep engravings on aluminum parts. For instance, starting with high laser powers usually ranging between 50 – 80watts when an expert in this field becomes critical since it should go through several surfaces effectively during its operation. In addition one can have a slower speed just to make sure that enough material has been taken away from the workpiece by the printer over a certain time frame thus preventing burning out or any other damages caused by excess energy during processing stages. Furthermore using higher frequencies (about 50kHz) makes results more uniform thereby giving smoother outputs.

Deep engravings require proper focusing; therefore, the laser beam has to be focused on just one layer of material. To achieve the desired depth in several steps, it’s good to focus the laser beam on multiple passes. After each pass, clean the surface so that residual dirt does not interfere with subsequent engraving.

Moreover, materials such as air or water should be used for cooling to prevent overheating and distortion. By adjusting these parameters systematically and performing regular tests one can make accurate deep engravings of aluminum parts that may be both functional and decorative.

Using Powder-Coated Aluminum for Vibrant Laser Markings

One question I get asked a lot is how to achieve vibrant laser markings on powder-coated aluminum, as an expert in this industry. For the reason of its glossy and long lasting finish, powder coated aluminium is a good option for high contrast marks which look very attractive. The following are the parameters that should be taken into account in order to get desired results:

- Laser Power: Powder coated aluminum would require moderate laser power ranging from 30 to 50 watts. This range prevents marking while damaging neither the coating nor underlying material.

- Speed: Using high speed will avoid the problem of lingering at one point for too long by avoiding burning or discoloring due to laser rays. A setting of about 300 – 500 mm/s works best.

- Frequency: A higher frequency, such as 20-30 kHz, is better for producing clean and crisp lines. Hence, this ensures that the laser pulses are well packed leading to smooth and uniform marks.

- Focus: For sharp and clear marks it’s important to have proper focus. So do not forget about focusing the laser beam accurately onto the surface of the powder-coated aluminum. Auto-focus system may be helpful in terms of accuracy preservation.

- Passes: More than one pass may be necessary depending on how deep you want them or their level of contrast. Normally one or two passes produce vivid marks but it all depends on coat thickness or color used.

- Cooling: Cooling approaches like air cooling can be used during marking process so as to prevent overheating which could potentially cause damage. In particular, when dealing with thick or dark colored powders that absorb more heat.

These parameters need careful tuning while comprehensive testing can lead to bright and durable powder-coated aluminum with high quality laser markers.The trick here is to find a compromise between esthetics (beauty) and longevity (how long they last).

Finishing Touches and Post-Engraving Processes

Cleaning After Laser Engraving: Best Practices

I understand from my experience that after laser engraving, proper cleaning is essential for professional results as well as longevity of the engraved material. These are a few things I think you should know.

- Prompt removal of debris: it is important to clear all dirt and residues which may be on the surface immediately after engraving. For such particles, I normally use a smooth cloth without fibers, thus wiping them off softly. In case there is some resolute garbage that might have remained then I brush the debris with a very small brush containing soft bristles

- Avoid strong chemicals: if used they can either damage the surface or blur out its marks. Personally, I tend to like using mild detergents mixed with water applied by a clean piece of cloth and sometimes sponge. It does not tamper with anything hence keeping it in good condition.

- Compressed air: Compressed air does magic to those difficult areas to access. For instance, very fine dust particles and little particles which get trapped in cracks can be blown away easily without having to touch them physically through compressed air. This is extremely handy for intricate engravings where a piece of cloth or brush cannot reach.

- Inspecting for Residues: After my first round of cleaning, I go over everything again just to make sure no residue remains behind because any leftover debris could hamper the look and durability of an engraving. If required, I repeat this process until it seems free from any materials.

- Protective coating: There are times when application of light protective coats helps preserve engravings especially on metals. A clear lacquer or some form of specialized sealant whether one chooses will provide long-term protection against exposure conditions

These steps ensure that not only do these pieces look great right after being done but also maintain our high standards on quality even in future periods when they are still supposed to boast about our work among peers in other companies. The act itself of bringing an object to completion is just as important to a professional finish as the engraving process.

Preservation Coatings for Keeping Aluminum Engravings Alive

The way to make them last is to coat these engravings. In this regard, I usually suggest the use of a transparent varnish or anodizing, which is not only beautiful but also forms a strong shield against corrosion, oxidation and other environmental factors. It’s possible to apply special sealants designed specifically for aluminum besides the usual clear lacquer or anodizing process. Continuous reapplication of these coatings helps in maintaining their efficiency hence it is important for me to suggest regular checks that could help identify any signs of abrasion or faults before they develop into bigger issues. These methods ensure that my aluminum engravings keep looking as good as new while at the same time displaying the craftsmanship quality of my business.

Rotary Engraving Enhances Intricate Finishes on Aluminum

As someone who knows what he/she is talking about when it comes to metal artistry,I can tell you without batting an eyelid that nothing beats engraving with rotary tools if you want complex finishes on your metallic surfaces.Rotary engraving works by using a rotating cutting tool to carefully cut out elaborate patterns;it provides accuracy and depth that cannot be realized through other methods.The speed and feed rates can always be adjusted by this tool enabling the best finishes with much precision thus creating intricate designs even on areas with limited space.Moreover,the technique works well with different types of alloys making it suitable across all spectrums from personalized gifts through industrial labels.From personal experience, rotary engraving has proven unparalleled in terms of sharpness and endurance in details engraved.Thus,it remains as one of the core techniques in the region’s metalwork industry after many decades.

Laser Engraving Machine Maintenance and Safety

Regular Maintenance Tips for Your Laser Engraver

Maintenance must be done meticulously to enhance durability and effectiveness of your laser engraver. Firstly, I usually start by cleaning the laser lens and mirrors consistently. Accumulation of dust and debris on these vital parts detrimentally affects the quality and efficiency of engraving. These surfaces are then gently wiped using a soft, non-abrasive cloth and appropriate lens cleaner to maintain their clarity.

Moreover, it is crucial to inspect as well as clean air assist systems. This ensures that there is proper flow of air preventing burning and providing cleaner cuts by blowing away cutting area waste materials. The air filters I check regularly for any obstructions together with tubing in order to replace them periodically.

Additionally, one needs to assess belt tension and alignment in order to maintain accuracy of engraving. When belts are installed loosely or wrongly aligned, they lead to design inaccuracies. Regular calibration and tightening of belts serve as a guarantee that movement of laser head stays precise for me.

Consequently, moving parts must be lubricated among other things hence reducing friction between rails and bearings through use of an appropriate amount of lube facilitating their smooth operation.

Therefore, I always make sure that once software updates become available I complete them immediately. These updates often come with enhancements as well as bug fixes that improve the machine’s performance significantly. Through observing these maintenance suggestions my laser engraver remains in its best shape thereby guaranteeing both safety measures aimed at preserving exceptional output quality at all times

Understanding Laser Safety When Working with Aluminum

Safety is the main concern for me when I’m dealing with laser engraving of aluminium surface. The first thing I usually do entails making sure that I have chosen the correct laser settings. Aluminum reflects light very well hence incorrect settings could destroy it and also be a tremendous danger to the machine itself. In response, I alter the laser’s power, speed as well as frequency configuration taking into account how thick or what sort of aluminum is being engraved.

Personal protective equipment also plays a critical role in working with lasers safely. These include safety glasses specifically designed for the wavelength of the laser. With this measure, my eyes can be protected from stray reflections and direct exposure to laser beam which may hurt them. Additionally, to avoid any possible harm due to fumes emitted when engraving aluminum, one has to ensure that there is enough air circulation or install an appropriate fume extraction system.

In conclusion, my regular examination on whether there are any signs of tear and wear on the laser engraver especially focusing on its protective casing as well as lens filters enables me maintain a safe and effective means of engraving. By doing this I make sure that it is not only safe but also efficient at work. Consequently, these cautious measures protect me from personal injuries while making my equipment last longer.

Choosing an Appropriate Ventilation System for Laser Engraving Aluminium

To ensure a safe and productive workplace environment it is vital that you choose an appropriate ventilation system for your aluminum laser engraving process. As an expert in this field, I would advise considering several important factors before selecting your ventilation solution. First consider size and capacity of your workspace in relation to airflow requirements needed; thus opt for high-efficiency fume extractor fitted with multi-staged filtering technology capable of getting rid of harmful particles as well as neutralizing potentially hazardous gases emitted during marking process.

Furthermore one should look out for those systems having HEPA filters since they trap even minute sized particles thus ensuring best air quality. Moreover, the use of activated carbon filters enhances the system’s ability to adsorb volatile organic compounds.

Another important factor to be considered is ease of maintenance; this means that a system which has easily replaceable filters and that gives clear indications when it is time for replacement can assist in saving time as well as prevent any form of disruption in workflow.

Lastly, one needs to consider the level of noise produced by this ventilation system. Quieter machines would make for a comfortable working environment by reducing stress and fatigue among operators.

By paying attention to these details, you will choose a ventilation system that protects your health while maintaining longevity and dependability of your laser engraving equipment.

Exploring Creative Projects with Aluminum Laser Engraving

Innovative Ideas for Engraving Aluminum with a Laser

Engraving aluminum with a laser can be looked at from many angles as per my experience in the industry. The first among these is personalized architectural features which include door, wall and ceiling custom engraved panels. You can add value to residential or business premises by having elaborate decorations or designs.

Making unique artwork pieces is an exciting project for example portraits, abstract designs or landscapes using laser engraving technique on aluminum. This aspect could be enhanced with anodized aluminum when combined with laser engraving to create stunning visual effects.

Furthermore, one can think of making custom awards and plaques. The use of laser-engraved aluminium instead of the conventional wooden or acrylic materials gives a sleek appearance that is both contemporary and sophisticated. It makes it suitable for company rewards, notice plates or even individual gifts.

Alternatively, you may consider venturing into high-end jewelry and accessories production. Laser engraving process enables precision and fine detailing hence facilitating fabrication of beautiful customized items such as bangle bracelets necklaces as well as key chains.

These are just some ideas for innovative projects that will make your work superb while attracting more customers who are interested in aluminum laser marking business

Combining Laser Engraving with Other Fabrication Techniques

To make your projects more complicated and versatile, it is possible to combine laser engraving with other manufacturing techniques. Based on my experience, combining CNC machining and laser engraving enables one to have complex shapes and structures before introducing intricate engraved details. This blend is especially useful in the production of highly accurate aerospace and automotive components.

Additionally, by merging anodizing techniques with laser engraving, aluminum products can be made more appealing visually and long-lasting. Anodizing the aluminum first makes the surface harder hence able to withstand wear from environmental impacts for a long time. Laser engraving that has been done on this anodized surface shows up the naturally colored aluminum beneath giving a strong contrast that is both tough as well as visually striking.

Laser Engraving & 3D Printing are also best combined which exhibit another example of fruitful synergy. Combining 3D printing for prototyping or component making with laser engraving in order to include fine text or designs can lead to a streamlined fabrication process which enjoys speediness as well as accuracy. This has great significance specifically in custom production and fast prototyping where timing and individualization are crucial considerations.

Finally, do not forget about how integrating traditional hand craftsmanship with laser engraving works wonders. The combination of exactness as got from lasers and hand finishing produces unique products that are one-of-a-kind high quality items which outshine others found in a very competitive market; this may appeal particularly within luxury goods sector where hand-made aspect boosts perceived worth & exclusivity.

Hence, these methods should be blended effectively so that you not only get unique high-quality products but also go beyond what’s achievable within aluminium fabrications for your customers.

Advice for Starting an Aluminum Laser Engraving Business

The idea of starting an aluminium laser business could be thrilling yet intimidating at the same time. My personal experience as a seasoned player in the industry has yielded several important pointers that can help you pull through this journey.

To begin with, you must invest in quality machinery. The performance of your laser engraver will determine the quality of your output as well. Do not compromise on this; good equipment is worth investing in.

Secondly, learn the techniques. Spend enough time trying various settings, materials and designs. This practical experience is invaluable and will help you comprehend the particularities of laser engraving.

Thirdly, develop a varied portfolio. Showing different styles and methods such as blending laser engraving with anodizing or 3D printing can open up new avenues for clients’ projects.

Still customer service also matters most. In such a competitive field, establishing strong bonds with your customers by offering them great services and ensuring they are well informed could be all you need to dominate the market.

Moreover, marketing your business effectively counts a lot. Leverage social media platforms and attend trade shows or join industry circles to increase your visibility. A professional website featuring examples from your past works may serve as a robust marketing tool too.

Finally, keep yourself updated with changing trends in technology and industry-wide patterns as whole. As far as laser engraving is concerned it keeps on evolving; therefore, being aware will make sure that your business remains cutting edge in competition zone

These are the ground works that if properly implemented will make sure that an Aluminum Laser Engraving Company thrives beyond expectations.

Reference sources

1. Industrial Laser Solutions – Online Technical Magazine

- Summary: An article titled “Mastering Aluminum Laser Engraving: Best Practices and Innovations” provides a comprehensive guide on the latest techniques in laser engraving on aluminum. It discusses the properties of aluminum that affect its engraving quality, such as reflectivity and thermal conductivity, and how to adjust laser parameters for optimal results. Additionally, it explores innovative approaches to overcome common challenges, like material deformation and residue management.

- Relevance: This source is highly relevant for anyone interested in the technical aspects of aluminum laser engraving. Industrial Laser Solutions is known for its focus on laser technology applications, making its content credible and authoritative. The article’s emphasis on best practices and innovations can help both beginners and experienced professionals improve their engraving techniques.

2. Journal of Applied Material Science & Engineering – Peer-Reviewed Journal

- Summary: The journal features a research paper, “Optimizing Laser Engraving Parameters for Enhanced Detail and Efficiency in Aluminum Alloys.” This study presents an empirical analysis of various laser settings, including power, speed, frequency, and focus, on the quality of engravings on different aluminum alloys. It aims to identify the optimal configurations for achieving high-precision engravings with minimal material waste and processing time.

- Relevance: For those seeking a deep scientific understanding of the interaction between laser beams and aluminum surfaces, this peer-reviewed journal article offers valuable insights. The empirical data and conclusions can assist engineers and designers in selecting the most efficient engraving parameters tailored to specific aluminum alloys.

3. LaserTech – Manufacturer’s Blog

- Summary: LaserTech, a leading manufacturer of laser engraving machines, has a detailed blog post titled “Tips and Tricks for Aluminum Laser Engraving Success.” The post covers practical advice on preparing aluminum surfaces before engraving, choosing the right laser engraver for aluminum projects, maintenance tips to prolong machine life, and creative ideas for projects. It includes case studies demonstrating successful engraving projects on aluminum, highlighting the diverse possibilities of laser engraving.

- Relevance: Coming directly from a manufacturer, this blog post offers a blend of technical advice and creative inspiration. It’s particularly useful for practitioners looking for actionable tips on the entire process of aluminum laser engraving, from preparation to completion. The inclusion of case studies adds a layer of credibility and showcases the real-world application of the techniques discussed.

Frequently Asked Questions (FAQs)

Q: What sort of aluminum should I use for laser engraving?

A: Anodized aluminum is the most fitting choice for laser engraving because it gives high-contrast markings. The anodized layer on the other hand, reacts to the laser beam and creates a white, frosty look against the colored background. Alternatively, bare aluminum can also be engraved with a specific type of laser and settings that are ideal.

Q: Can anodized aluminum be marked by fiber lasers?

A: Yes, marking anodized aluminium can be done through the use of fibre lasers. Their capability to emit beams of high intensity and precision makes them very effective in engraving and marking metal surfaces. The fiber laser gently etches away at the anodised layer to give sharp, crisp looking marks.

Q: Is it possible to engrave aluminum using a diode laser?

A: It is difficult to have such engravings since diode lasers have lower power output compared to fiber and CO2 lasers. Marking spray may sometimes work with diode lasers but not so much with either bare or non-anodized aluminium which might require special marki

Q:. How does marking spray improve laser engraving on aluminum?

A; Marking spray also known as laser marking spray is applied on materials like aluminium to enhance the quality of their engravings by absorbing some light energy from a laser beam resulting in permanent high contrasting marks on plain or difficult-to-engrave surfaces. This would mean especially where direct response to this kind of reaction with diode lasers is not observed.

Q: Can a laser cutter also etch or engrave on aluminum?

A: Absolutely, a laser cutter can go over the top in engraving or slightly marking an aluminium surface mainly of anodized and painted aluminium sheets. However, the depth and quality of the etching might not be as high as with a dedicated laser engraver. For deep engraving, CO2 laser cutters work well for marking anodized aluminum while fiber lasers are more suitable.

Q: What are the advantages of using a laser marking machine on anodized aluminum?

A: Precision, speed, non-destructive nature to underlying material; these are some benefits that you will get when you use a laser marking machine for anodized aluminum. They have also proven to be highly effective for detailed designs, text and logos making them popular choices among various industrial and personalized marking applications.

Q: Can xtool d1 pro be used for engraving aluminum?

A: Xtool D1 Pro has gained repute from its versatility and accuracy in handling different materials including engraving anodized aluminium. Nevertheless, this depends on the specific type of aluminium being engraved and the settings used in manufacturing it. Also, using marking sprays can improve bare aluminium surfaces so that they are clearly identified by D1 PRO.

Q: What is the best laser power for engraving aluminum sheets?

A: Often recommended for clear, sharp and fast markings would be at least 20W lasers for etching anodised aluminumsheet. The actual power required may depend upon specific technology fiber/diode/CO2 of the laser as well as what kind effects need to be produced. Lasers with higher powers create deeper engravings within shorter time limits, increasing their processing speeds.