Nickel, a silvery-white metal known for its strength and resistance to corrosion, plays a crucial role in various industries ranging from electronics to the production of stainless steel. However, one of the most intriguing questions about nickel is whether it possesses magnetic properties. In this blog, we will delve into the scientific principles behind magnetism, explore the magnetic characteristics of nickel, and uncover the conditions under which nickel may exhibit these properties. Join us as we separate fact from fiction and provide a comprehensive understanding of nickel’s magnetic nature, its practical implications, and its applications in the modern world.

What Makes Nickel Magnetic?

Understanding Ferromagnetic Materials

A ferromagnetic material refers to a substance whose atomic arrangement and electron configuration cause it to possess strong magnetic qualities. These materials contain regions known as magnetic domains in which the atoms belonging to atoms of this metal were arranged such that their magnetic moments are parallel. When these materials are subjected to an external field, the domains will move together generating a large-scale magnetism. Examples of such materials include iron, cobalt and nickel among others. In particular, Nickel is believed to have these tendencies because it has single unpaired electrons that play a part in lining up the atom’s magnetics moments within its structure making it fall under one category called magnetic metals.

The Role of Nickel’s Atomic Structure

Nickel’s highly unusual atomic structure is largely responsible for its magnetic character. At the atomic scale, nickel features an electron configuration [Ar] 3d^8 4s^2. The presence of unpaired electrons in the 3d orbital is key towards its ferromagnetism. If these unpaired electrons lie next to each other with parallel spins, a moment is created therein that can be described as magnetism. In nickel, under certain conditions, these 3d-electrons can align themselves by means of an external field leading to the manifestation of different properties.

Technical Parameters of Nickel’s Magnetism:

- Curie Temperature: The Curie temperature for nickel is around 358°C (676°F) after which it loses its ferromagnetic characteristics and becomes paramagnetic.

- Magnetic Susceptibility: It has a relative permeability (μ/μ_0) ranging from 100-600 showing how well it can be magnetized.

- Saturation Magnetization: The saturation magnetization value for nickel stands at about 0.61 teslas (T) suggesting maximum magnetization attained through cross influence by an outside field.

These parameters serve to highlight how under specific circumstances; nickel can show a magnetism that can be sustained and used in various technological and industrial fields.

Temperature Effects: Curie Point of Nickel

The temperature called Curie point, or Curie temperature is the limit at which ferromagnetic changes to paramagnetic state for nickel. Heating nickel above its Curie temperature (about 358°C or 676°F) means that there will be significant changes occurring to its atomic structure. At this phase, the magnetic moments within the 3d electron cease to line up due to thermal energy. This disturbance leads to randomization of the moment thus causing nickel to lose its ferromagnetic properties. Beyond the Curie temperature, nickel cannot retain a permanent magnetization and behaves as a paramagnetic material, weakly attracted by magnetic fields. In various applications such as magnetic storage technologies, some materials must be maintained below their respective curie temperatures (in this case nickel’s curie point) so as they don’t lose their magnetic properties.

How Does Nickel Compare to Other Magnetic Metals?

Comparing the Magnetic Properties of Nickel and Cobalt

Saturation Magnetization

- Nickel: The saturation magnetization is about 0.61 teslas (T) for nickel.

- Cobalt: On the other hand, cobalt has a higher saturation magnetization which is around 1.8 teslas (T).

Curie Temperature

- Nickel: The Curie temperature for nickel is usually 358°C (676°F).

- Cobalt: Conversely, cobalt has a higher Curie temperature which reaches up to approximately 1,115°C (2,039°F).

Coercivity

- Nickel: Generally having lower coercivity makes it easy to magnetize and demagnetize nickel.

- Cobalt: Its coercivity tends to be higher than that of nickel thus maintaining its magnetism and resisting demagnetization more easily.

Permeability

- Nickel: Nickel exhibits less magnetic permeability as compared to cobalt.

- Cobalt: As such, cobalt enjoys greater magnetic responsiveness because of its high magnetic permeability.

In brief, though both nickel and cobalt are ferromagnetic metals having various practical uses in different spheres, it can generally be observed that cobalt has better magnetic properties characterized by higher values of saturation magnetization, Curie temperature, coercivity and permeability. These differences imply that cobalt serves best where strong and stable magnetic properties are needed at elevated temperatures while low coercivity and saturation magnetization make nickel suitable for applications requiring softer magnets.

Similarities and Differences between Nickels And Irons?

Magnetic Properties

- Nickel and Iron: At this point let’s introduce two ferromagnetic metals namely; nickel and iron which means their nature allows them to either get attracted or get magnetized by magnets. For instance the value of saturation magnetisation in iron is usually higher than that in nickel hence making it an overall stronger material for magnets.

Curie Temperature

- Nickel: The Curie temperature of nickel is lower than that of iron, and it ranges around 358°C (676°F).

- Iron: Its Curie temperature which comes to about 770°C (1,418°F) is higher as compared to that for nickel hence allowing it to remain ferromagnetic at higher temperatures as opposed to its counterpart.

Coercivity

- Nickel: Nickel’s coercivity is relatively low indicating that it can be magnetized or demagnetized quite easily.

- Iron: When compared to nickel, iron has greater coercivity meaning its magnetization tends not to change much and it is harder to demagnetize.

Permeability

- Nickel: Nickel has a lower magnetic permeability so it does not respond readily to an external magnetic field.

- Iron: This implies that iron displays a higher magnetic permeability which makes it capable of detecting the presence of a magnetic field.

Therefore, while both nickel and iron are ferromagnetic metals, the former has a higher saturation magnetization, Curie temperature and magnetic permeability. On the other hand, due to its low coercivity level, nickel finds use in applications where magnetisation processes are simple and reversible. This sets apart these types of metals in terms of their suitability for different industrial applications with iron being more preferred for stronger magnets while softer uses favor nickel.

Can Nickel Alloys Be Magnetic?

The part that alloying elements play in magnetism

Magnetism of nickel and iron alloys can be significantly influenced by the presence of alloying elements. Different magnetic properties for many industrial applications can be achieved by carefully selecting and combining these elements. Below are some of the key alloying elements and their effects:

- Cobalt (Co): The addition of cobalt to nickel or iron alloys increases the Curie temperature and improves magnetic saturation. Cobalt based alloys such as Permendur are known for their excellent high-temperature magnetic performance.

- Chromium (Cr): Magnets become weak when chromium is added to them so that high-chromium stainless steels have magnet properties which are weak.

- Molybdenum (Mo): Molybdenum can also slightly affect the magnetic properties by reducing coercivity, while at the same time enhancing strength and toughness of an alloy.

- Silicon (Si): By raising electrical resistivity of an alloy, silicon minimizes losses due to eddy currents. For instance, silicon steel has been used widely in transformer cores nowadays because it exhibits improved magnetic qualities with reduced energy loss.

- Copper (Cu): Copper additions generally lead to a slight decrease in the material’s magnetic permeability but help to control mechanical properties of the alloy besides improving its ductility and thermal conductivity.

Major Technical Parameters

Curie Temperature:

- Cobalt: Cobalt raises Curie temperature (e.g., Permendur up to 940°C).

Saturation Magnetization:

- Cobalt: Saturation magnetization increased.

- Chromium: Saturation magnetization decreases.

Permeability:

- Silicon: Magnetic permeability improved(4,000 in pure iron ,10,000 ).

Coercivity:

- Molybdenum: Coercivity decreased.

- Copper: Marginally lower magnetic permeability.

To sum up, whatever contributes towards making a specific combination between different alloys as concerned is what defines the magnetic properties of nickel and iron alloys. This knowledge is beneficial for engineers who can control magnetic characteristics with high accuracy when designing materials for specific purposes.

Magnetic Properties of Some Common Nickel Alloys

Permalloy (78Ni-22Fe)

Permalloy, an alloy made of Ni and Fe, has a low coercive force and a good permeability making it suitable in numerous magnet applications. Its composition is approximately 78% nickel and 22% iron.

Technical Parameters:

- Permeability: High (>100,000)

- Coercivity: Very Low (about 0.05-0.3 Oe)

- Saturation Magnetization: Moderate (8,000-10,000 Gauss)

- Curie Temperature: Below pure iron (~400°C)

Mu-Metal (77Ni-16Fe-5Cu-2Cr)

Another common nickel–iron alloy called mu-metal contains copper and chromium in addition to significant amounts of iron and nickel in its structure at ratios of 2% and 5%, respectively. It has great capabilities as a material for making shields that prevent electromagnetic fields from spreading out.

Technical Parameters:

- Permeability: Extremely high (>300,000)

- Coercivity: Very low

- Saturation Magnetization: Lower than Permalloy (7,000-8,000 Gauss)

- Curie Temperature: Similar to Permalloy

Invar (64Fe-36Ni)

Invar is an alloy with moderate magnetic properties but very low coefficient of thermal expansion due to the fact that it comprises more than one-third by weight of nickel which forms around sixty percent of the constituents remaining being mainly iron.

Technical Parameters:

- Permeability: Moderate – High

- Coercivity: Medium

- Saturation Magnetization: High (15,000 Gauss)

- Curie Temperature: Relatively high (~280°C).

Supermalloy (79Ni-16Fe-5Mo)

Supermalloy, a high-performance nickel-iron alloy with 79% Ni, 16% Fe and 5% Mo content, is used when initial permeability must be maximized while power loss minimized.

Technical Parameters:

- Permeability: Very high (>200,000)

- Coercivity: Extremely low

- Saturation Magnetization: Moderate (7,000-9,000 Gauss)

- Curie Temperature: Below iron (~400°C)

With the understanding of these alloys and their accompanying technical parameters it becomes possible to effectively modify the magnetic properties of materials that will meet specific application requirements.

Are All Forms of Nickel Magnetic?

Pure Nickel versus Nickel Alloys

When comparing pure nickel to nickel alloys, it is necessary to take into account their magnetic properties and technical parameters.

Pure Nickel

Pure nickel is inherently magnetic; hence it has numerous uses in magnetic applications. Nevertheless, its magnetic properties are generally not as pronounced as those of many nickel alloys that have been specifically engineered for enhanced characteristics.

Technical Parameters:

- Permeability: Moderately high

- Coercivity: Low

- Saturation Magnetization: High (~ 15 kG)

- Curie Temperature: Relatively high (~ 358 ºC)

Nickel Alloys

On the other hand, nickel alloys have modified their magnetic properties to suit their composition. Here are some technical parameters for some commonly-used nickel alloys:

Mu-metal (77Ni-16Fe-5Cu-2Cr):

- Permeability: Extremely high (up to 300,000)

- Coercivity: Very low

- Saturation Magnetization: Lower than pure nickel (7 – 8 kG)

- Curie Temperature: Similar to pure nickel

Invar (64Fe-36Ni):

- Permeability: Moderate-high

- Coercivity: Moderate

- Saturation Magnetization: High (~ 15 kG)

- Curie Temperature: Relatively high (~ 280 ºC)

Supermalloy (79Ni-16Fe-5Mo):

- Permeability: Very high (>200,000)

- Coercivity: Extremely low

- Saturation Magnetization: Moderate (7 – 9 kG)

- Curie Temperature: Lower than pure nickel (~400 ºC)

Clearly, by analyzing these figures, one can tell that while pure nickel has good magnetic properties; there exist certain other desirable features which are achievable only through use of specially designed nickle alloys.

Effects of Nickel Plating on Magnetism

Nickel plating can change the magnetism in materials very much. One foremost effect is the presence of a thin, protective coat that tends to affect the total magnetism. Its main outcomes are:

- Decrease in Permeability: With nickel plating, magnetic permeability of the material can be reduced. This is because the surface layer acts as a barrier to magnetic field lines by effectively slowing their rate of travel through it.

- Increase in Coercivity: Nickel plating could increase the coercivity of any given material due to displacements and strains at atomic level during its process. Consequently, more external magnetic field would then need to be employed for demagnetizing it.

- Slight Drop in Saturation Magnetization: When there is an extra non-magnetic film such as nickel on top of a plated material, the overall saturation magnetization decreases slightly. The core material’s ability to reach its maximum magnetization under an external magnetic field is mildly hampered.

Nonetheless, these changes that come with nickel plating are insignificant and well tolerated within specific industrial applications where corrosion resistance or durability is paramount. Engineers tend to weigh between increased physical durability and slightly affected magnetic characteristics upon identifying these effects.

Applications of Nickel’s Magnetic Properties

Nickel in Permanent Magnets

Nickel is a metal that is widely used in manufacturing magnets. In first-person terms, I’d say this: Nickel increases the magnetic properties, when mixed with other ferromagnetic elements like iron and cobalt. This will create a magnet having strong magnetic performance as well as resistance to corrosion or rusting. Also, these magnets are more stable and reliable over longer periods, necessary for applications in various sectors from electronics to automobiles. By adding nickel we can have both the durability and strength of magnetism that enables them operate efficiently in various environments.

Nickel in Electrical and Electronics Industries

In electrical and electronics industries, nickel’s use becomes inevitable due to its unique features . First off, I would point out nickel’s good conductivity and toughness makes it ideal for batteries, connectors among others. As an example, nickel-based batteries last for long periods thereby making them dependable power sources currently used in mobile devices and electric cars. Furthermore, the electronic connectors made of this metal do not wear out easily hence they retain their good performance especially under intense conditions or based on the environment they are exposed to being resistant to environmental degradation via corrosion attacks. With modern consumers demanding efficient electronic devices at affordable prices coupled with greater product life expectancy figures; the importance of nickel has become much more important as it combines innovative functionality with long-term reliability. In this way using nickel in such instances creates sturdy high-performance systems that run smoothly.

Nickel in Metal Detectors

From what I understand about metal detectors nickel plays a significant role towards their effectiveness . Nickel is often employed when constructing coils used on detectors due to its magnetism properties as well as ability to conduct current through it. When you turn on a metal detector its coil generates magnet lines around it or rather field When any form of metallic material mainly made of nickel gets close enough it distorts this field causing an alert that indicates there is something metallic nearby it could be a coin or a key for instance. Nickel being in the coil increases sensitivity and overall performance of a metal detector, making it to detect metals more precisely and faster. As far as I’m concerned, nickel has unique properties that make it an important part of any reliable and high-performance metal detectors.

Reference sources

- National Center for Biotechnology Information (NCBI)

Magnetic Properties of Nickel

This scholarly article provides an in-depth analysis of nickel’s magnetic properties, supported by scientific research and studies. - Encyclopædia Britannica

Nickel (Ni) – Chemical Element

This entry offers a comprehensive overview of nickel, including detailed information on its magnetic properties and applications. - Materials Science and Engineering: An Introduction (Book)

Magnetic Properties of Materials

This widely-used textbook includes a section dedicated to the magnetic properties of various materials, including nickel, providing authoritative and educational content.

Frequently Asked Questions (FAQs)

Q: Is Nickel a Magnetic Metal?

A: Yes, nickel is a magnetic metal. This implies that when it comes close to a magnetic field, it will be able to generate magnetism.

Q: How does nickel interact with magnets?

A: Nickel can interact with magnets since it is listed as one of the transition metals, which are paramagnetic in nature. In fact, the strength of attraction experienced is dependent on the quantity of nickel.

Q: What are the magnetic properties of nickel?

A: The paramagnetic property of nickel makes it a paramagnetic metal. For instance, if such metal is exposed to strong magnetic fields, they get magnetized but do not retain those properties after removal from such fields.

Q: Can nickel be used in combination with iron to enhance magnetic strength?

A: Yes, mixing ferromagnetic iron with nickel boosts its magnetism due to their good interplay between each other.

Q: Are there types of stainless steel that contain nickel?

A: Yes, there are sorts of stainless steel containing nickels that affect total alloy’s magneticity. It depends on the amount of this element, whether steel qualifies to be called non-magnetic or magnetic.

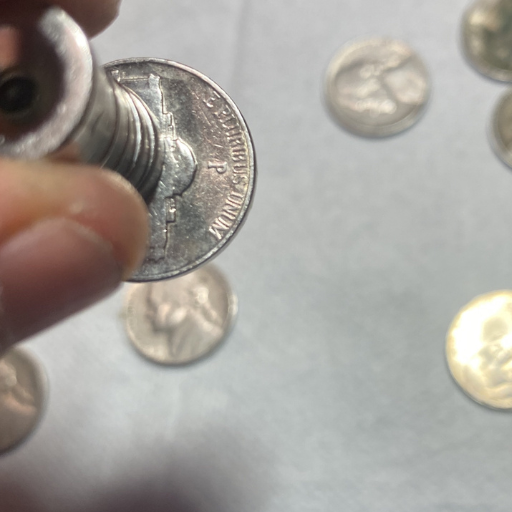

Q: Is a US nickel coin magnetic?

A: A U.S. coin made from 75% copper and 25% Nickel cannot stick on any metallic surface. It has no attraction for metals like copper hence being unmoving by external forces