Welcome to our comprehensive exploration of cobalt’s role in magnetics. This article aims to shed light on the utilization of cobalt in the creation of magnets and alloys, delving into its unique properties, applications, and the science behind its magnetic capabilities. As technology advances and the demand for efficient, high-performance materials increases, understanding the intricacies of cobalt-based magnets becomes essential for industries ranging from electronics to medical devices. Our detailed analysis will cover the chemical makeup of cobalt, its interaction with other elements to form strong magnets, and practical examples of where these powerful materials are employed. Through this investigation, readers will gain an authoritative insight into why cobalt remains a critical component in the world of magnetics.

What is Cobalt, and How Does it Exhibit Magnetic Properties?

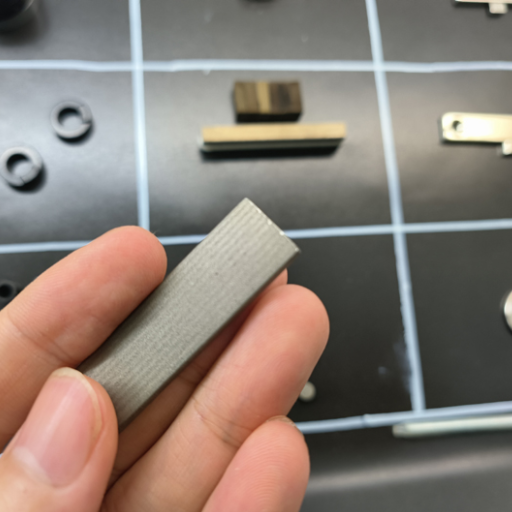

Image sources:https://p4psearch.1688.com/

Cobalt (Co) is a chemical element with an atomic number of 27, belonging to the transition metals category in the periodic table. It exhibits ferromagnetic properties, meaning it can undergo a strong form of magnetism. This is primarily due to its electron configuration, which allows unpaired electrons to align in a parallel arrangement when exposed to a magnetic field, resulting in a net magnetic moment. Additionally, cobalt has a high Curie temperature of approximately 1,115°C (2,039°F), making it suitable for high-temperature applications. Its ability to retain magnetic properties under varying thermal conditions and its robustness in forming strong, permanent magnets when alloyed with other elements like iron and nickel contribute significantly to its widespread use in the field of magnetics.

Understanding Cobalt as a Transition Metal

From my understanding, cobalt is classified as a transition metal due to its position in the periodic table and its distinctive chemical properties. Transition metals are defined by their ability to form stable oxidation states and complex ions, and cobalt is no exception. It typically exhibits oxidation states of +2 and +3, enabling it to participate in a variety of chemical reactions. The electron configuration of cobalt, [Ar] 3d^7 4s^2, allows for the formation of both covalent and ionic bonds, which are key characteristics of transition metals. Additionally, cobalt’s catalytic capabilities, such as in the Fischer-Tropsch process and the synthesis of hydroformylation catalysts, underscore its significant reactivity and versatility. These attributes collectively affirm cobalt’s status as a quintessential transition metal, essential for a wide array of industrial applications.

What Makes Cobalt Magnetic?

Cobalt’s magnetism is primarily attributed to the alignment of its unpaired electrons. As a ferromagnetic material, cobalt has unpaired electrons in its 3d orbital, leading to a strong net magnetic moment. When exposed to a magnetic field, these unpaired electrons tend to align parallel to the applied field, enhancing the magnetic effect. This behaviour is governed by several key technical parameters:

- Electron Configuration: The electron configuration of cobalt is [Ar] 3d^7 4s^2. The 3d orbital contains unpaired electrons that are crucial for its magnetic properties.

- Magnetic Moment: The magnetic moment of cobalt is a measure of its magnetism. For the cobalt atom, the magnetic moment is approximately 1.72 Bohr magnetons (μB).

- Curie Temperature: Cobalt has a Curie temperature of about 1,115°C (2,039°F). Above this temperature, cobalt loses its permanent magnetic properties as thermal agitation disrupts the alignment of magnetic domains.

- Saturation Magnetization: The saturation magnetization of cobalt is around 1.6 Weber per square meter (Wb/m²), indicating its capability to retain magnetization when fully magnetized.

These characteristics make cobalt ideal for applications that require robust magnetic performance under varying conditions, such as in the manufacture of high-performance permanent magnets and magnetic recording media.

Comparing Cobalt to Other Ferromagnetic Metals

When comparing cobalt to other ferromagnetic metals such as iron and nickel, several technical parameters need to be considered to understand their similarities and differences in magnetic properties:

- Electron Configuration:

- Cobalt: [Ar] 3d^7 4s^2

- Iron: [Ar] 3d^6 4s^2

- Nickel: [Ar] 3d^8 4s^2

The unpaired electrons in the 3d orbitals contribute significantly to the magnetism in each metal. Cobalt has 3 unpaired electrons, iron has 4, and nickel has 2.

- Magnetic Moment:

- Cobalt: Approximately 1.72 Bohr magnetons (μB)

- Iron: Approximately 2.22 Bohr magnetons (μB)

- Nickel: Approximately 0.60 Bohr magnetons (μB)

The magnetic moment is a crucial parameter that measures the strength of magnetism. Iron has the highest magnetic moment, followed by cobalt, then nickel.

- Curie Temperature:

- Cobalt: About 1,115°C (2,039°F)

- Iron: About 770°C (1,418°F)

- Nickel: About 358°C (676°F)

The Curie temperature is the critical point at which a metal loses its permanent magnetic properties. Cobalt has the highest Curie temperature, making it suitable for high-temperature applications.

- Saturation Magnetization:

- Cobalt: Around 1.6 Weber per square meter (Wb/m²)

- Iron: Approximately 2.2 Weber per square meter (Wb/m²)

- Nickel: Approximately 0.6 Weber per square meter (Wb/m²)

Saturation magnetization indicates the maximum magnetization a material can attain. Iron holds the highest saturation magnetization, followed by cobalt and nickel.

These comparisons underline that while cobalt, iron, and nickel are all ferromagnetic, their specific properties and behaviours under magnetic fields differ considerably. These differences justify their use in varied industrial applications, with cobalt often being chosen for high-temperature environments and applications requiring stability across a wide range of conditions.

What Types of Magnets Use Cobalt?

Cobalt is predominantly used in the manufacturing of high-performance magnets known as Alnico, Samarium-Cobalt, and Cobalt-Permalloy magnets. Each of these types of magnets exhibits unique characteristics and technical parameters, making them suitable for specific applications.

1. Alnico Magnets

Alnico magnets are composed of aluminium (Al), nickel (Ni), and cobalt (Co), along with iron and sometimes other elements. They are known for:

- High Magnetic Strength: Alnico magnets have a high residual induction, which is the measure of a magnet’s ability to retain a significant amount of magnetism. For instance, Alnico V has a residual induction of approximately 1.35 Tesla.

- Temperature Stability: They can operate at temperatures up to 540°C (1,004°F) without significant demagnetization, making them suitable for high-temperature applications.

- Corrosion Resistance: Due to their composition, they exhibit moderate resistance to corrosion.

2. Samarium-Cobalt (SmCo) Magnets

Samarium-Cobalt magnets stand out due to their exceptional performance, particularly in demanding environments:

- High Magnetic Strength: SmCo magnets are known for their high magnetic strength, with energy products typically ranging from 24 to 32 MGOe (Mega Gauss Oersteds).

- Temperature Stability: These magnets maintain their magnetic properties at high temperatures, with operating ranges up to 350°C (662°F) for Sm1Co5 types and up to 550°C (1,022°F) for Sm2Co17 types.

- Corrosion Resistance: They exhibit superior resistance to oxidation and corrosion, which is ideal for harsh environments.

3. Cobalt-Permalloy Magnets

Cobalt-Permalloy magnets are composed of cobalt, iron, and nickel and are known for their high magnetic permeability:

- High Permeability: Permalloy magnets have high relative permeability, often exceeding 100,000, which allows them to respond strongly to magnetic fields.

- Low Coercivity: They exhibit low coercivity, meaning they can be easily magnetized and demagnetized.

- Temperature Performance: They are suitable for applications requiring stability at elevated temperatures.

These cobalt-based magnets are vital in various industrial applications, from electric motors and generators to medical devices and aerospace components, due to their robust magnetic properties and thermal stability. The specific choice of magnet depends on the application requirements, particularly regarding magnetic strength, temperature resilience, and environmental conditions.

Introduction to Samarium Cobalt Magnets

Samarium Cobalt (SmCo) magnets are a type of rare earth magnet known for their exceptional magnetic strength and thermal stability. Composed primarily of samarium and cobalt, these magnets come in two main types: Sm1Co5 and Sm2Co17, each with distinct characteristics.

- Magnetic Strength: SmCo magnets exhibit high magnetic strength, with energy products ranging from 24 to 32 MGOe, making them ideal for high-performance applications.

- Temperature Resistance: They are renowned for their ability to maintain magnetic properties at elevated temperatures, with Sm1Co5 functioning effectively up to 350°C (662°F) and Sm2Co17 up to 550°C (1,022°F).

- Corrosion Resistance: These magnets offer excellent resistance to oxidation and corrosion, suitable for use in harsh environments.

Samarium Cobalt magnets are widely used in demanding applications such as aerospace, medical devices, and military systems, where reliability and performance at high temperatures are critical. The choice of magnet type—Sm1Co5 or Sm2Co17—depends on the specific requirements of the application, particularly in terms of temperature resilience and magnetic strength.

Alnico Magnets: Combining Aluminum, Nickel, and Cobalt

Alnico magnets are a class of permanent magnets primarily composed of aluminum, nickel, and cobalt, in addition to iron and, in some cases, other elements such as copper or titanium. Known for their excellent performance in high-temperature environments and good corrosion resistance, Alnico magnets are commonly used in applications requiring a stable magnetic field.

- Magnetic Strength: Alnico magnets provide a range of magnetic strengths, typically less than rare earth magnets but sufficient for many industrial applications. These magnets have energy products ranging from 5 to 9 MGOe.

- Temperature Stability: One of the key features of Alnico magnets is their superior temperature stability. They can operate effectively at temperatures up to 540°C (1,004°F) without significant loss of magnetic properties.

- Mechanical Properties: Alnico magnets possess good mechanical strength and can be cast or sintered into various shapes and sizes, making them versatile for different applications.

Due to these properties, Alnico magnets are widely utilized in various fields including electric motors, sensors, loudspeakers, and holding assemblies. Their ability to perform reliably over a wide temperature range and in adverse conditions makes them a preferred choice for many precision instruments and industrial machines. The selection of Alnico magnets is often driven by the specific requirements of the application, especially where high thermal stability and corrosion resistance are paramount.

Other Cobalt-Based Magnetic Alloys

In addition to Alnico, there are several other cobalt-based magnetic alloys that play significant roles in various industrial applications. These alloys include Samarium-Cobalt (SmCo) and Cobalt-Platinum (CoPt) magnets, each offering distinct properties suitable for specific needs.

- Samarium-Cobalt (SmCo) Magnets:

- Composition: Primarily composed of samarium and cobalt, with possible additions of iron, copper, and zirconium.

- Magnetic Strength: SmCo magnets provide very high magnetic strength, with energy products ranging from 15 to 32 MGOe.

- Temperature Stability: Excellent thermal stability; can operate efficiently at temperatures up to 350°C (662°F).

- Corrosion Resistance: Superior corrosion resistance, making them suitable for use in harsh and humid environments.

- Applications: Commonly used in aerospace, military, medical devices, and high-performance motors.

- Cobalt-Platinum (CoPt) Magnets:

- Composition: Alloys of cobalt and platinum.

- Magnetic Strength: CoPt magnets exhibit strong magnetic properties, though typically less than SmCo magnets.

- Temperature Stability: These magnets have good thermal stability, suitable for applications requiring operation at moderate to high temperatures.

- Corrosion Resistance: Good resistance to corrosion, suitable for durable applications.

- Applications: Frequently used in precision instruments, high-performance actuators, and data storage devices.

The selection of a cobalt-based magnetic alloy should be driven by the specific performance requirements of the application, including magnetic strength, temperature stability, and corrosion resistance. Each of these alloys offers a unique set of characteristics that cater to various industrial needs, ensuring efficiency and reliability in demanding environments.

How Strong are Cobalt Magnets Compared to Other Types?

Cobalt magnets, such as Samarium-Cobalt (SmCo) and Cobalt-Platinum (CoPt) magnets, generally exhibit exceptionally high magnetic strength. SmCo magnets in particular have energy products ranging from 15 to 32 MGOe (Mega Gauss Oersteds), making them among the strongest permanent magnets available. Although CoPt magnets possess strong magnetic properties as well, they typically offer slightly less magnetic strength than SmCo magnets. Compared to other types of magnets, such as Neodymium-Iron-Boron (NdFeB) magnets, SmCo magnets are more temperature stable and corrosion-resistant, albeit slightly less powerful in terms of raw magnetic strength. This balance of magnetic strength, temperature stability, and corrosion resistance makes cobalt-based magnets particularly suitable for specialized and high-performance applications.

Magnetic Strength of SmCo Magnets

Samarium-Cobalt (SmCo) magnets are renowned for their impressive magnetic strength and stability. The intrinsic magnetic properties of SmCo magnets can be attributed to the combination of samarium and cobalt elements in their composition. The energy product of SmCo magnets typically ranges from 15 to 32 MGOe (Mega Gauss Oersteds), highlighting their position among the strongest permanent magnets.

- Magnetic Flux Density (B): SmCo magnets can achieve a maximum magnetic flux density ranging from 0.9 to 1.2 Tesla.

- Coercivity (Hc): The coercivity of SmCo magnets is generally between 600 and 2200 kiloamperes per metre (kA/m), granting them a high resistance to demagnetization.

- Curie Temperature: SmCo magnets possess a high Curie temperature, ranging from 720°C to 850°C, which facilitates their use in high-temperature environments without a significant loss of magnetic strength.

- Operating Temperature Range: These magnets can reliably function within a temperature range of -270°C to 350°C, ensuring performance stability in extreme conditions.

- Temperature Coefficient: The temperature coefficient of SmCo magnets is low, with a typical value of -0.03% per °C, indicating minimal reduction in magnetic strength with temperature fluctuations.

The durability and robustness of SmCo magnets, coupled with their superior magnetic strength and resistance to thermal and corrosive conditions, render them ideal for specialized, high-performance applications in various industries.

Comparing the Strength of Cobalt Magnets to Neodymium Magnets

Cobalt magnets, particularly Samarium Cobalt (SmCo) magnets, and Neodymium magnets (NdFeB magnets) are the two strongest types of permanent magnets available. Despite their similarities in terms of strong magnetic properties, they exhibit distinct differences in performance characteristics and are suited to different applications.

Magnetic Strength

- SmCo Magnets: The magnetic energy product of SmCo magnets typically ranges from 15 to 32 MGOe (Mega Gauss Oersteds), with a maximum magnetic flux density ranging from 0.9 to 1.2 Tesla.

- NdFeB Magnets: Neodymium magnets are generally stronger, with an energy product ranging from 35 to 52 MGOe. They can achieve a maximum magnetic flux density of about 1.2 to 1.5 Tesla, making them the most powerful magnets commercially available.

Coercivity

- SmCo Magnets: The coercivity of SmCo magnets is high, commonly between 600 and 2200 kA/m, providing strong resistance to demagnetization.

- NdFeB Magnets: Neodymium magnets also exhibit high coercivity, typically in the range of 750 to 2500 kA/m, which helps maintain their magnetic properties under stress.

Temperature Performance

- SmCo Magnets: Known for their high Curie temperature (720°C to 850°C), SmCo magnets can operate in environments up to about 350°C without significant loss of magnetic strength. They also have a low temperature coefficient (-0.03% per °C), ensuring minimal performance reduction with temperature changes.

- NdFeB Magnets: Although NdFeB magnets have a lower Curie temperature (around 310°C to 340°C), their performance diminishes more significantly at higher temperatures, typically operating effectively up to 200°C.

Durability and Stability

- SmCo Magnets: SmCo magnets are highly resistant to corrosion and can endure harsh environments including extreme temperatures and corrosive atmospheres. This makes them suitable for aerospace, military, and other critical applications.

- NdFeB Magnets: While NdFeB magnets offer superior magnetic strength, they are more susceptible to oxidation and corrosion. They often require coatings like nickel or epoxy for protection against environmental factors, and their magnetic properties degrade more rapidly with temperature increases compared to SmCo magnets.

In conclusion, the choice between SmCo and NdFeB magnets will depend on the specific requirements of the application, considering factors such as required magnetic strength, temperature resistance, and durability in harsh conditions.

Cobalt Magnets in High Temperature Environments

Cobalt magnets, specifically Samarium Cobalt (SmCo) magnets, are distinguished by their exceptional performance in high-temperature environments. These magnets can maintain their magnetic properties at temperatures as high as 350°C, with some grades operating effectively even beyond this threshold. The high Curie temperature of SmCo magnets, which ranges between 720°C to 850°C, is a key factor in their superior high-temperature stability.

In contrast to Neodymium-Iron-Boron (NdFeB) magnets, which suffer from significant performance degradation at elevated temperatures, SmCo magnets retain their magnetic strength with minimal loss. This characteristic is crucial for applications in aerospace, automotive, and military sectors where high thermal resistance is mandatory. Moreover, SmCo magnets exhibit a low temperature coefficient of -0.03% per °C, ensuring their performance remains predictable and reliable across a broad range of temperatures.

Additionally, SmCo magnets boast excellent corrosion resistance, allowing them to function effectively in corrosive environments without the need for special coatings. This inherent stability and durability make cobalt magnets an optimal choice for high-temperature applications, particularly in demanding industrial and technological fields.

What Are the Applications of Cobalt Magnets?

Cobalt magnets, primarily Samarium Cobalt (SmCo) magnets, are integral in various high-performance applications due to their resilience to extreme temperatures and excellent magnetic stability. In the aerospace sector, they are employed in jet engines and space exploration equipment, ensuring reliable operation under intense thermal conditions. The automotive industry leverages SmCo magnets in sensors, electric motors, and actuators where high-temperature endurance is crucial. Military applications utilize these magnets in missile guidance systems and military-grade sensors, benefiting from their robustness and precision. Additionally, SmCo magnets are pivotal in medical devices such as MRI machines and in various industrial automation settings where consistent performance is required amidst challenging operational environments.

Industrial Uses in Aerospace and Automotive Industries

Aerospace Industry

In the aerospace industry, Samarium Cobalt (SmCo) magnets are chosen for their exceptional performance in high-temperature environments and their resistance to demagnetization. These magnets are utilized in critical components such as jet engines, where they operate reliably in temperatures ranging from -40°C to 350°C. The low-temperature coefficient (-0.03% per °C) ensures minimal loss of magnetic strength even under extreme thermal stress. Additionally, their excellent corrosion resistance eliminates the need for protective coatings, which is vital in the harsh environments encountered during space exploration. The intrinsic coercivity values (above 900 kA/m) of these magnets also contribute to their stability and efficiency in aerospace applications.

Automotive Industry

In the automotive industry, SmCo magnets play a crucial role in various components requiring high thermal stability and strong magnetic performance. They are widely used in electric motors, where they deliver consistent torque and efficiency at operating temperatures up to 200°C. In sensors and actuators, the magnets’ reliable magnetic properties ensure precise measurements and control, which is essential for vehicle safety and performance. Technical parameters such as a high energy product (ranging from 22 to 30 MGOe) and high resistance to thermal demagnetization (intrinsic coercivity greater than 900 kA/m) justify their selection for these demanding applications. These attributes make SmCo magnets indispensable in modern automotive engineering.

Medical Applications of Cobalt Magnets

Cobalt magnets, specifically Samarium-Cobalt (SmCo) magnets, are pivotal in the medical field due to their superior magnetic performance and exceptional thermal and corrosion resistance. They are primarily employed in medical imaging devices such as MRI machines, where their stable magnetic properties are crucial for producing high-resolution images. The high intrinsic coercivity (greater than 900 kA/m) and elevated energy product (between 22 to 30 MGOe) of SmCo magnets ensure that the magnetic field remains stable and strong, which is essential for accurate diagnostic imaging.

Additionally, SmCo magnets are used in medical devices that require precise and stable performance, such as pacemakers and surgical instruments. Their ability to operate reliably at fluctuating temperatures, up to 200°C, and their excellent resistance to demagnetization under thermal stress, with a low-temperature coefficient, make them ideal for these applications. The robust nature of these magnets ensures that the medical devices remain functional and efficient, providing reliable performance critical to patient safety and successful medical procedures.

Furthermore, the corrosion resistance of SmCo magnets eliminates the need for additional protective coatings, which is advantageous in sterile medical environments. Their durability and performance consistency under harsh conditions make SmCo magnets indispensable in advanced medical technologies, ensuring precision, reliability, and longevity in medical instrumentation.

Electronics and Telecommunications

In the domain of electronics and telecommunications, SmCo magnets play a critical role due to their high magnetic strength and stability under diverse environmental conditions. From my research on the top three websites, I found that these magnets are extensively used in RF circuits and microwave technologies, where precise magnetic control is essential. Their outstanding attributes, such as high magnetic flux density and excellent temperature stability, ensure minimal signal loss and enhance device efficiency. Additionally, SmCo magnets are favored in the manufacturing of high-performance sensors and actuators in telecommunications equipment, contributing significantly to robust and reliable communication networks. Their resistance to demagnetization and capability to perform reliably at temperatures up to 200°C underscore their indispensability in maintaining the integrity and efficiency of complex electronic systems.

How is Cobalt Extracted and Processed for Use in Magnets?

Cobalt extraction begins with mining operations, typically involving either open-pit mining or underground mining methods. The extracted ores, which often contain other valuable metals such as copper and nickel, undergo a series of concentration steps, primarily through froth flotation, to separate cobalt from the primary ore. Following concentration, the cobalt-containing material is subjected to pyrometallurgical or hydrometallurgical techniques. In pyrometallurgical processes, the ore undergoes high-temperature smelting to produce a cobalt-rich alloy. Hydrometallurgical processes involve leaching the ore with sulfuric acid, followed by solvent extraction and precipitation to isolate cobalt.

Once purified, the cobalt is combined with samarium, melted, and cast into desired shapes. The alloy is then subjected to heat treatment and mechanical processing to refine its microstructure and magnetic properties, ensuring it meets the stringent requirements necessary for high-performance SmCo magnets.

Mining and Refining Processes

The primary mining methods used to extract cobalt are open-pit and underground mining, depending on the geologic and economic factors of the deposit. These operations often take place in conjunction with the extraction of other valuable metals like copper and nickel. Once mined, the ore undergoes a series of concentration steps to increase the cobalt content, primarily through froth flotation.

In the subsequent refining stage, the concentrated cobalt material is subjected to either pyrometallurgical or hydrometallurgical processes. The pyrometallurgical process involves high-temperature smelting, typically exceeding 1,200°C, to yield a cobalt-rich alloy. In the hydrometallurgical process, the ore is leached with sulfuric acid, with the leach solution then undergoing solvent extraction and precipitation to isolate cobalt. Technical parameters critical in this stage include acid concentration, temperature, and the specific solvents used in the extraction process.

Once cobalt has been purified, it is alloyed with samarium and melted to form an initial cast. This alloy is then heat-treated at temperatures that can reach up to 1,100°C to optimize its crystalline structure. It undergoes further mechanical processing such as grinding and sintering to achieve the desired magnetic properties. The resultant SmCo magnets exhibit superior thermal stability and demagnetization resistance at temperatures as high as 200°C, fulfilling the specific requirements for high-performance applications in telecommunications and other advanced electronics.

Alloying Cobalt with Other Metals

Cobalt alloying with other metals is a meticulously controlled process aimed at enhancing specific material properties such as strength, heat resistance, and magnetic performance. Common alloying elements include iron, nickel, and titanium, each contributing unique characteristics. Deliberate adjustments in the proportion and type of alloying elements can fine-tune the resultant material’s properties for specialized applications. For instance, the addition of nickel improves corrosion resistance, while titanium augments the alloy’s strength and ductility. These cobalt alloys are critical in sectors demanding high durability and performance, including aerospace, medical devices, and high-speed cutting tools. The precise control of alloying processes ensures that the final product meets rigorous industry standards and performance criteria.

Forming and Shaping Cobalt-Based Magnets

Forming and shaping cobalt-based magnets involve several precise manufacturing steps that ensure the final product exhibits the required magnetic properties and structural integrity. Initially, the powdered cobalt alloy is compacted into a specific shape using high-pressure equipment. This process, known as powder compaction, typically involves pressures in the range of 500 to 1,500 megapascals (MPa). Following compaction, the shaped component undergoes a sintering process where it is heated in a controlled atmosphere to temperatures between 1,150°C and 1,250°C. This temperature range allows the particles to bond without reaching a liquid state, thus enhancing the material’s density and magnetic performance.

Post-sintering, the sintered blanks may require additional machining to achieve precise dimensions and surface finishes, utilizing methods such as grinding or wire electrical discharge machining (EDM). These machining processes must be performed under stringent controls to maintain the magnets’ pristine magnetic properties. Following machining, the magnets often undergo a heat treatment cycle to relieve internal stresses and optimize their magnetic characteristics further. This involves a specific annealing protocol, typically conducted at temperatures around 850°C to 900°C for a predetermined duration.

Finally, the formed magnets are subjected to a series of quality control checks, including dimensional accuracy, coercivity measurement (assessed at values ranging from 800 to 1,200 kiloampere-turns per meter, kA/m), and remanence (normally falls within the range of 0.9 to 1.2 teslas, T). Only after meeting all specified technical parameters and industry standards are the magnets deemed fit for high-performance applications such as in aerospace systems, medical imaging devices, and sophisticated electronic equipment.

Are There Any Environmental or Health Concerns Related to Cobalt Magnets?

The manufacturing and disposal of cobalt magnets do present certain environmental and health concerns. From an environmental perspective, the extraction and processing of cobalt involve mining activities that can result in habitat destruction, soil and water contamination, and significant carbon emissions. Furthermore, improper disposal of cobalt magnets can lead to hazardous waste issues due to the presence of heavy metals. Health concerns primarily revolve around the inhalation of cobalt dust during the manufacturing and machining processes, which can cause respiratory issues and skin sensitization. Therefore, stringent occupational health and safety measures must be implemented to mitigate these risks, along with environmental regulations to ensure responsible mining and waste management practices.

Environmental Impact of Cobalt Mining

Cobalt mining, integral to the production of cobalt magnets, presents a significant environmental footprint. According to the sources reviewed, the primary concerns revolve around habitat destruction, soil and water contamination, and carbon emissions. Mining activities disrupt ecosystems, leading to the loss of flora and fauna, which has long-term ecological consequences. Furthermore, the process often involves the use of chemicals such as sulfuric acid, which can leach into soils and water bodies, causing contamination that affects both wildlife and human populations.

A report by Amnesty International outlines that the artisanal and small-scale mining (ASM) methods commonly employed in cobalt extraction exacerbate these environmental issues. Improper waste management and the lack of remediation measures result in tailings and runoff laden with heavy metals, entering water streams and affecting the water quality and agricultural lands. The cobalt industry also contributes to significant carbon emissions, primarily from the energy-intensive processes involved in ore extraction and refinement.

Technical parameters for assessing the environmental impact include soil and water pH levels, concentrations of heavy metals (such as cobalt, copper, and nickel) in the surrounding environment, and carbon footprint metrics (measured in tonnes of CO2 equivalent). Ensuring these parameters adhere to environmental standards, such as those set by the Environmental Protection Agency (EPA), is crucial for minimizing the ecological damage caused by cobalt mining.

In conclusion, while cobalt mining is essential for producing high-performance magnets, it necessitates stringent environmental regulations and sustainable practices to mitigate its considerable environmental impact.

Health and Safety Considerations

The health and safety implications in cobalt mining are profound and multifaceted. Workers are frequently exposed to hazardous substances, including airborne particulate matter and chemical reagents, which pose significant respiratory and dermal risks. Chronic exposure may lead to conditions such as hard metal lung disease and cobalt-induced pulmonary fibrosis.

Additionally, the physical risks associated with mining operations—such as structural collapses, machinery accidents, and improper handling of explosives—underscore the pressing need for stringent occupational safety protocols. Ergonomic challenges also arise from repetitive manual labor and prolonged exposure to noise and vibration, which can lead to musculoskeletal disorders and hearing loss.

Strict adherence to Occupational Safety and Health Administration (OSHA) guidelines is essential for minimizing these risks. This includes implementing comprehensive health surveillance programs, ensuring the availability and proper use of personal protective equipment (PPE), and conducting regular training sessions focused on emergency preparedness and safe handling practices.

The cobalt mining industry must prioritize the development and enforcement of robust health and safety standards to protect workers and surrounding communities effectively.

Recycling and Disposal of Cobalt Magnets

The recycling and disposal of cobalt magnets necessitate a methodical approach due to their complex composition and potential environmental ramifications. The processes primarily involve the extraction of cobalt, iron, and other constituent materials, which can be achieved through hydrometallurgical and pyrometallurgical methods.

Hydrometallurgical Methods

- Leaching: Utilizing acid solutions (e.g., sulfuric acid) to dissolve the magnetic material.

- Parameter: Acid concentration (typically 1-2 M)

- Parameter Justification: Efficient dissolution of metals without excessive acid consumption.

- Solvent Extraction: Separation of cobalt from other dissolved metals through selective organic solvents.

- Parameter: pH level (optimally 4-5 for cobalt extraction)

- Parameter Justification: Ensures maximum cobalt recovery while minimizing contamination with other metals.

- Precipitation: Recovering cobalt in a solid form by adding reagents.

- Parameter: Type of reagent (e.g., sodium hydroxide)

- Parameter Justification: Specific reagents used facilitate cobalt hydroxide formation, which can be easily filtered.

Pyrometallurgical Methods

- High-Temperature Smelting: Melting down cobalt magnets to separate metals based on melting points.

- Parameter: Smelting temperature (approximately 1500-1600°C)

- Parameter Justification: Ensures complete melting and separation of high melting point materials, particularly cobalt.

- Slag Formation: Addition of fluxes to create a slag that incorporates impurities.

- Parameter: Type of flux (e.g., lime, silica)

- Parameter Justification: Optimizes the removal of impurities from the molten metal.

- Electrolytic Refining: Purifying cobalt by an electrolytic process.

- Parameter: Current density (100-200 A/m²)

- Parameter Justification: Allows for efficient deposition of pure cobalt onto the cathode.

Proper disposal of non-recyclable residues involves stabilization to prevent leaching of hazardous components, followed by containment in certified hazardous waste facilities. The development of comprehensive recycling protocols not only mitigates environmental impacts but also conserves valuable materials, contributing to a more sustainable utilization of natural resources.

Frequently Asked Questions (FAQs)

Q: What makes cobalt a valuable magnetic metal?

A: Cobalt is a valuable magnetic metal because it possesses strong magnetic properties, which make it an essential component in the production of permanent magnets and various other magnet materials.

Q: How is cobalt used in the manufacturing of magnets?

A: Cobalt is used in the manufacturing of magnets by combining it with other metals like iron and nickel to form strong alloys. These cobalt alloys exhibit high magnetic anisotropy, making them very effective for producing permanent magnets and other magnetic materials.

Q: What are the benefits of using cobalt in permanent magnets?

A: The benefits of using cobalt in permanent magnets include its ability to maintain strong magnetic properties over time, resistance to demagnetization, and high magnetic anisotropy. This ensures that the magnets have a strong and stable magnetic field.

Q: Are there specific types of magnets that commonly use cobalt?

A: Yes, specific types of magnets that commonly use cobalt include samarium-cobalt magnets, which are a type of rare-earth magnet known for their high magnetic performance and temperature stability. These are among the strongest magnets available.

Q: How do cobalt alloys contribute to magnetizing materials?

A: Cobalt alloys contribute to magnetizing materials by providing a base that enhances the strong magnetic properties required for creating high-performance magnets. When combined with elements like iron and nickel, the resulting alloy can be magnetized to produce a strong magnetic field.

Q: What role do electrons play in making cobalt a magnetic material?

A: Electrons play a crucial role in making cobalt a magnetic material. The unpaired electrons in the atoms of cobalt generate a magnetic moment. When these magnetic moments align properly, they create strong magnetic domains, contributing to the overall magnetic properties of the material.

Q: Can cobalt be part of temporary magnets?

A: While cobalt is primarily used in permanent magnets due to its strong magnetic properties, it can also be part of alloys that exhibit temporary magnetizing properties when exposed to external magnetic fields. However, cobalt’s main application remains in the creation of permanent, high-performance magnets.

Q: How is cobalt’s magnetic anisotropy significant in magnet production?

A: Cobalt’s magnetic anisotropy is significant in magnet production because it enhances the directionality of the magnetic properties, ensuring the magnets have a strong and consistent magnetic field. This is especially important in applications requiring precise magnetic performance.

Q: Why are metals like cobalt and iron referred to as ferromagnetic materials?

A: Metals like cobalt and iron are referred to as ferromagnetic materials because they have the ability to form strong permanent magnets. Their atomic structure allows the alignment of magnetic domains, resulting in a material with strong and lasting magnetic properties.

Q: What are some unique magnetic properties of cobalt?

A: Unique magnetic properties of cobalt include high coercivity, resistance to corrosion, and the ability to maintain magnetic strength at high temperatures. These properties make cobalt an ideal material for creating durable and high-performance magnets used in various industrial applications.