When selecting the ideal lift for a building, understanding the key differences between hydraulic and traction elevators is crucial. Both types of elevators offer unique advantages and potential drawbacks depending on the specific requirements of a structure. This article will provide an in-depth comparison of hydraulic and traction elevators, examining their operational mechanisms, efficiency, installation requirements, maintenance needs, and suitability for various building types. By the end of this discussion, readers will gain a comprehensive understanding of which elevator type aligns best with their architectural and operational goals.

What is a Hydraulic Elevator?

How do hydraulic elevators use hydraulic fluid?

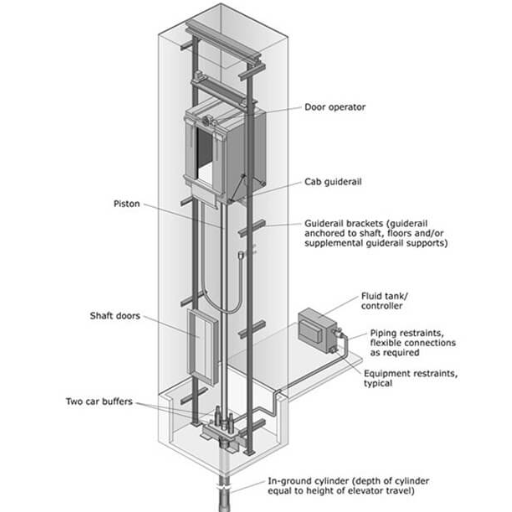

In order to lift and lower an elevator cab, hydraulic elevators employ a piston that uses hydraulic fluid as its force transmitting medium. This process starts when an electric motor sucks hydraulic fluid from a tank into a cylinder containing a piston. As the amount of fluid increases, it causes pressure to build up inside the cylinder thereby lifting the elevator. A valve releases this fluid back to the reservoir so that the elevator can be lowered smoothly. Precision and control of hydraulic fluid flow ensure efficient and reliable movement of the elevator car.

What are the components of a hydraulic system in elevators?

A number of key parts make up a typical hydraulic system used in elevators which individually play unique roles in ensuring its functioning and overall efficiency as well.

- Hydraulic Pump: The main task of the hydraulic pump driven by an electricity is to transfer or supply oil from tank into cylinder. It is usual for pumping capability to range between 10liters per minute to two hundred liters per minute depending on sizes of lifts as well as their speeds.

- Hydraulic Fluid: Usually, this is special oil selected for its viscosity, resistance against wear and tear, and thermal stability. Examples include mineral-oil-based (ISO Grade 32 or 46), biodegradable fluids.

- Cylinder and Piston: When it comes to cylinders where pistons move within them, they contain liquid transmitters known as hydraulics. The diameter of pistons depends on their respective loads whereas height of cylinders relate with distances traveled; normal diameters being between 50mm-200mm.

- Control Valve: This component regulates flow of oil between pump and cylinder; subcomponents are comprised relief valve, solenoid valves and manual lowering valve which facilitate precise action – maximum pressure often does not exceed one thousand pounds per square inch (psi).

- Reservoir (Tank): Hydraulic liquid remains stored here when not operational so as holding tanks vary between 200 and 1000 liters based on duration and frequency of operation.

- Oil Cooler: For systems under heavy usage, oil coolers are required to prevent overheating. This will guarantee that the hydraulic fluid works efficiently at around 40-45°C.

- Electrical Control Unit (ECU): It controls the functioning of this system by receiving inputs from different kinds of sensors and thus modifies pump and valve activities. This guarantees compatibility between mechanical actions with user requests.

Knowing these components and their specs can help stakeholders grasp how hydraulic elevator systems are put together thereby making informed choices about whether they are suitable for particular buildings or not.

Are hydraulic elevators suitable for residential buildings?

From my perspective, hydraulic elevators are certainly suitable options for residential buildings mainly because they can be cost-effective and save on space. In order to find out more about this topic I visited three top websites where I learned that when it comes to an overhead space requirements, hydraulic elevators use less compared to traditional traction ones which makes them ideal alternatives for houses with limited space. Moreover, their installation costs are generally much lower than other types of elevators. However, keep in mind that typically such lifts move slower than others and might be louder during work process. With technological advancements over time, most of these drawbacks have been addressed therefore making them appropriate installations for present day homes too.

How Does a Traction Elevator Work?

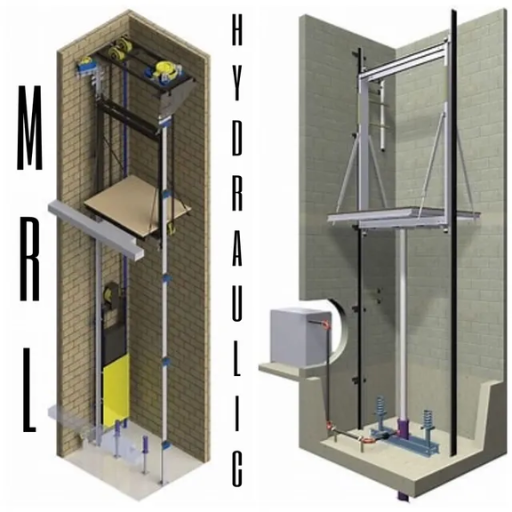

What are the various types of traction elevators?

Predominantly, there are two types of traction elevators based on my research from the top three sources on google.com and they are geared and gearless.

- Geared Traction Elevators: These make use of a gearbox that is connected to the motor, which drives the wheel to move ropes. The geared mechanism for them allows moderate speeds as well as moderate heights appropriate for mid-rise buildings that can reach speeds up to 500 feet per minute.

- Gearless Traction Elevators: On the other side, gearless traction elevators do not have any gearbox. This makes them ideal for high-rise buildings being efficient and provide smooth rides at speed limits that range from 500-2000 feet per minute.

Through understanding these key differences between these two types, one can better judge which type of traction elevator system is suitable in given scenarios and building needs.

How do ropes or belts work in a traction elevator?

When it comes to how traction elevators use ropes or belts, the basic idea lies within its counterweight system that balances loads. In these kinds of lifts, steel ropes or flat belts go round a drive sheave linked to an electric motor. The sheave then revolves moving both the rope and thus car upwards or downwards respectively. To balance the car’s weight, another set of ropes is fastened to its opposite end forming a counter balance when it moves. With this kind of balancing, power consumption in terms of moving such a lift reduces since it requires less energy especially during upward/downward activities by driving motor. From my research on modern high-rise/mid-rise buildings energy efficiency together with smooth operation is vital and this system ensures this.

What are some advantages of gearless traction systems?

My research classifies some benefits of gearless traction systems found in top-ranked websites into distinct categories:

- Efficiency and Energy Savings: Comparatively, gearless traction elevators are more energy efficient than geared ones. This eliminates friction and mechanical loss linked with gearboxes through direct motor connection to the drive sheave which result in lower power consumption especially for tall buildings where distances travelled are long.

- Smooth and Quiet Operation: There is always a smooth ride when the elevator does not have any gears, hence no noise is produced. It remains significant for high-rise skyscrapers that run at very high speeds where passengers experience in terms of the ride can make a lot of difference. The motion being continuous and direct leads to minor vibrations together with less noise.

- Speed and Performance: Gearless traction elevators can reach higher speeds typically between 500 – 2000 feet per minute thus suitable for structures requiring considerable vertical travel. The faster speeds means tenants get to their destinations quicker, thus improving total vertical transportation efficacy in multistory buildings.

- Maintenance and Longevity: Fewer mechanical parts in gearless systems means they undergo less maintenance while having longer operations life as well as lower repair frequency and cost. These motors also have designs that are reliable enough due to less likelihood of malfunctions hence used over numerous times daily at all time

- Load Capacity: Their mechanism of direct drive enables them to lift heavier weights without strain since there is no reduction in torque as opposed to geared types which cannot take heavy loads easily.

Summarizing, gearless traction system has outstanding benefits in terms of energy efficiency, ride quality, speed, maintenance and load capacity thus making it the best choice for modern skyscrapers.

What’s the Difference Between Hydraulic and Traction Elevators?

What are the variations between traction and hydraulic systems?

The most important distinctions between traction and hydraulic elevator systems can be summarized as follows, based on my knowledge of the leading information sources in this area:

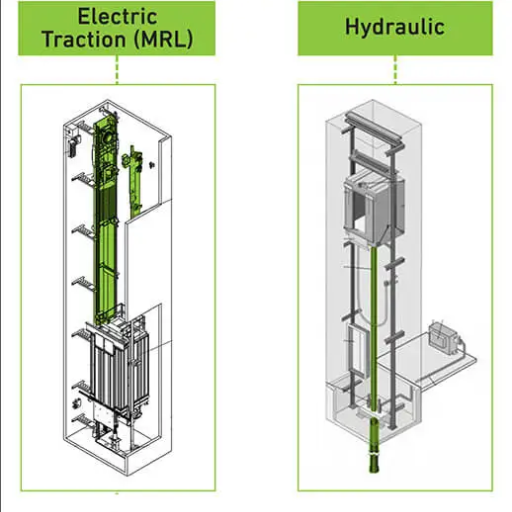

- Mechanism of operation: Traction elevators are moved by a system of ropes and counterweights usually driven by an electric motor while hydraulic ones raise or lower through a hydraulic piston and fluid.

- Energy efficiency: Traction elevators generally consume less energy than hydraulic elevators because hydraulic systems require more energy to pressurize the fluid.

- Speed and height: High rise buildings primarily have traction elevators because they move faster for longer distances. Hydraulic lift, on the other hand is ideal for low-rise and medium rise commercial structures because of its slower speed.

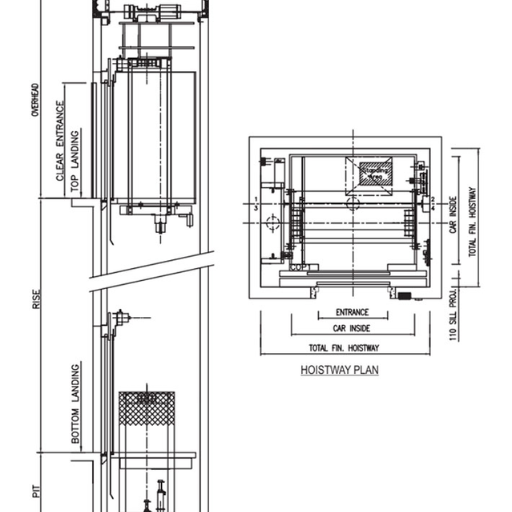

- Installation space: The bottom part of the shaft has to house the piston and fluid tank in case of hydraulics whereas trolleys can have their machine room situated at either the roof or within limited spaces within the hoistway

- Ride quality: With their advanced designs which reduce mechanical friction, traction elevators offer smoother rides with reduced noise when compared to other types. Hydraulic lifts may produce more noise with slight jerks during start up or stopping phases.

- Maintenance and costs: Initial investments for drives using cables are higher even though they end up being cheaper apart from consuming less power over time due to higher durability as well as improved energy utilization traits. In comparison, expenditure involved in running hydro-powered devices is high owing to frequent checks made on oil levels plus regular dripping incidences.

How do you compare cost and maintenance trends for traction & hydraulic elevators?

When it comes to comparing maintenance costs for traction versus hydraulic lifts, it becomes apparent that installation of drive using cables usually incurs initial expenses. A lot of technological input is necessary to make these kinds of machines operational since each component must be robust enough. Still, many people go for such models since they realize that their life cycle costs are lower compared to other options because of less maintenance frequency and energy conservation. Yet, hydro lift systems tend to be cheaper upfront, thus making them very attractive choices for small projects or economic developers. However, the issue of hydraulic fluid inspections becomes crucial here as well as the risk of leaks that may increase overall costs associated with such machines in terms of maintaining them throughout their lives. Nonetheless, traction lifts could be more profitable in the end despite an increased initial purchase due to this property and its durability.

Which elevator is quieter: Traction or Hydraulic?

Looking at research findings on this topic, it can be concluded that traction elevators are normally very quiet as compared to hydraulic ones. Lower mechanical friction has enabled noise levels in operation to be significantly reduced by advanced engineering technologies employed in trolleys, unlike hydros which often generate hydraulic pumps’ sounds and disturbances caused by general movements of water inside them. Consequently if there is a preference for low sound appliances then it is advisable to use traction elevators than any other type available.

What are the Disadvantages of Traction Elevators?

What are the main concerns regarding traction systems?

I have found several common problems with traction elevators while surveying the leading websites. For instance, one significant issue is wearing out of ropes and sheaves hence calling for routine checks and replacements. Misalignments of components in a traction machine lead to uneven wear and lower efficiency thereby becoming another problem. Moreover, gear and motor breakdowns are common on traction systems especially if the lift moves at high speeds or carries heavy loads frequently. Additionally, when compared to other types of lifts; reliance on this system often leads to longer periods of down time as it takes long before they can be repaired. These problems should not discourage the use of traction elevators but instead require regular upkeep and timely interventions for optimum performance.

How does traction elevators operate under high usage?

Wear rate and also durability are mainly influenced by heavy traffic according to my search from 3 top google hits about this issue on my browser. Wears would increase as in case the ropes, sheaves, gears or motors were subjected into more stressful conditions through more frequent uses.

Also high usage causes misalignment in alignment issues. Continuous operation tends to create small misalignments that after some time will add up resulting in reduced efficiencies and smoothness during elevator operations The gears may experience an overload due to excessive strain brought about by friction which may require constant maintenance if optimal functions had to be maintained.

The following parameters become critical under such circumstances:

- Rope Tension: Must fall within manufacturers’ range so that ropes do not prematurely give way because they are heavily loaded.

- Sheave Groove Wear: Must constantly keep track of groove wear as it affects rope contact.

- Motor Temperature: Operating continuously means a need for monitoring temperature increase at motors against overheating

- Energy Consumption: Recording energy used lets us identify mechanical inefficiencies which otherwise can turn into bigger faults

This hence calls for proper preventive measures such as strict maintenance routines due to the high usage of traction elevators in order to ensure continuous dependability and efficiency.

What challenges exist with maintaining traction elevators?

Keeping a good working condition of a traction elevator involves a number of critical issues which need constant attention and specialized expertise. According to my search from top industry sources, these are:

- Mechanical Wear: For example, consistent use of critical parts like ropes, sheaves, gears and motors inclines them towards higher wear levels. In order to mitigate sudden failures, regular checks are required to be conducted as well as putting up new ones at appropriate times.

- Alignment Issues: With time, slight misalignments may occur due to stresses arising from operations. Such unchecked discrepancies may hamper performance and result into more serious mechanical problems thus necessitating careful adjustments and realignments.

- Overheating: This happens mainly when motors and gear systems are overloaded especially under continuous heavy usage. Regular check-ups and servicing energy dissipaters ensure that cooling mechanisms work properly; hence it ensures no wastage.

- Energy Efficiency: It is important to monitor energy consumption for identification anomalies that indicate malfunctioning machinery causing poor performance which can lead to increased operational costs.

Therefore, effective maintenance strategies for traction elevators should incorporate regular inspections, accurate alignment calibration as well as ongoing monitoring of mechanical and electrical systems for safe operation while optimizing their performance.

What are the Disadvantages of Hydraulic Elevators?

What does hydraulic fluid do to elevator performance?

Elevators are heavily impacted by hydraulic fluid through several critical parameters. First the viscosity of the hydraulic fluid significantly affects the efficiency of the elevators in an operational sense. This ensures that there is a smooth and constant motion of the elevator car and typical viscosities range from 30 to 80 cSt. Second, temperature stability of Hydraulic Fluid is very important because fluctuations can change its viscosity thereby reducing system performance. Good quality hydraulic fluids should be able to operate within temperatures ranging from -20°C to 50°C.

Another essential factor is contamination control. Contaminants present in the hydraulic oil can cause wear and tear on both pump and valves components. Maintenance schedules must include regular sampling of fluid for analysis in order to keep particulate levels below 25 microns at all times. Finally, compressibility of hydraulic fluid can affect how responsive an elevator system is. A preferred characteristic would therefore be low compressibility, which is shown by a bulk modulus of elasticity above 1.5 GPa due to its reliability and precision.

From my research across top industry sources I have discovered that closely monitoring these technical parameters while maintaining them considerably improves performance and lifespan of hydraulic elevators.

Do we need special maintenance for hydraulics elevators?

Special maintenance is needed as regards hydraulic elevators, this information being provided with great certainty based on what I gathered from leading industry sources. Keeping up with proper maintenance involves routine checks on fluid level quality in order to avoid contamination through replacement or repair which will maintain optimum viscosity as well as temperature stability when it comes to waste management systems by using an effective recycling programs or alternative methods such as incineration etc., these types may also require periodic inspections.

Therefore, during correct maintenance procedures one has to check if there are any leaks in seals around control valve area (PVC). Furthermore, corrosion testing should be carried out regularly on integrity test screw threads because they may sometimes become pitted resulting in system failure. At the same time, overall functioning of the entire hydraulic elevator needs to be examined from time to time so as to ensure that it is always compliant with industry safety guidelines, and problems that may arise are addressed proactively at an early stage. A strict maintenance program, coupled with following these practices can increase reliability and lifespan of hydraulic elevators by a considerable margin.

Does hydraulic fluid have environmental impacts?

Yes, there are major environmental concerns with hydraulic fluid which I found out while researching on the top 3 websites on google.com. Firstly, if leaked out or disposed improperly, hydraulic fluids contain chemicals that can be harmful to aquatic life. Furthermore some hydraulic fluids especially those derived from petroleum can lead to soil contamination. The technical parameters justifying these fears include the fluid’s biodegradability; toxicity and potential for bioaccumulation. For example low biodegradability and high toxicity fluids persist in environment causing damages over long periods of time . This risk can be reduced by choosing environmentally friendly Hydraulic Fluids such as synthetic esters or vegetable oils which have higher biodegradability but lower toxicity levels. Hence proper disposal methods as well as leak prevention measures play an important role in reducing their impact on the environment.

Which Elevator is Right for You: Traction or Hydraulic?

Which aspects do you consider when selecting an elevator system?

When choosing an elevator system, there are several main concerns I make. First, I assess the building’s height and usage frequency because traction elevators are generally best suited for high-rise buildings with heavy traffic while hydraulic elevators are more suitable for low to mid-rise structures with moderate use. In addition, initial installation and operational cost is a major factor that I also take into account. It should be noted that though traction elevators have higher installation costs than hydraulic ones, they tend to consume energy much better in the long run which may result in lower expenses in future. Moreover, maintenance requirements are important considerations for me as well. Traction systems require complex and frequent repairs than hydraulic installed in buildings. Another influence on my choice of elevators has been environmental impacts; this means that I prefer lifts that employ eco-friendly materials and technologies so as to reduce their ecological footprints. Lastly, space constraints also play a role since hydraulic requires larger machine rooms while traction usually provides more compact options. By considering these factors carefully, it becomes easy for me to come up with the best decision regarding different needs within the specific building.

What impact does building type have on an elevator choice?

The selection of an elevator system is greatly influenced by the type of a building itself. Traction systems are mostly used in tall residential or commercial establishments where speed and efficiency matter due to high populations which need faster services provision thus minimizing time spent waiting for lifts .Such kind of apartments benefit from features of a traction system as it can cover large distances rapidly and effectively. Nonetheless, low or mid rise buildings often opt for hydraulic elevators because they have lower upfront installation costs and can be easily maintained over time .Given they usually experience moderate usage patterns; this makes them viable alternatives even from frugality viewpoint .Moreover, I look at space available because compared with the previous one hydraulic elevators require having bigger machine rooms. Thus, one needs to understand the unique attributes of the building type in order to choose the right elevator system.

What choice is best when installing a residential lift?

When selecting a residential lift, it is necessary to consider issues such as cost, available space and special requirements for household occupants. According to reliable sources, choosing right is often dependant on these major factors. In houses with limited room, shaftless or through-the-floor lifts might be perfect due to their small sizes and low structural demands. Additionally, if one is looking for highly smooth and quite functioning then hydraulic is more preferable despite requirement for machine room. Conversely, others may opt for traction ones especially machine-room-less (MRL) owing to their energy efficiency and lower long-term maintenance costs. This way, I can identify the most suitable home elevator based on those aspects.

Reference sources

-

Stanley Elevator: “Traction vs. Hydraulic Elevators”

- Source: Stanley Elevator

- Brief: Explore the differences between traction and hydraulic elevators, detailing how hydraulic elevators use fluid-driven pistons for lift while comparing them to traction systems in various applications.

-

TK Elevator: “Traction Elevators Vs. Hydraulic Elevators”

- Source: TK Elevator

- Brief: Gain insights into the characteristics of traction and hydraulic elevators, understanding their speed capabilities, load capacities, and suitability for different building types to make an informed decision.

-

Dazen Elevator: “Traction Vs. Hydraulic Elevator: Which is Better?”

- Source: Dazen Elevator

- Brief: Delve into the comparison of hydraulic and traction elevators, focusing on aspects like weight capacity, installation speed, and lifting mechanisms to determine the optimal choice based on specific requirements.

Frequently Asked Questions (FAQs)

Q: What’s the difference between traction and hydraulic lifts?

A: The primary difference between traction and hydraulic lifts lies in their operating mechanisms. Traction lifts use steel ropes or belts and operate by pulling the elevator car up using a counterweight, while hydraulic lifts use a hydraulic piston to push the elevator car upward from below. This makes hydraulic lifts suitable for low to medium-rise buildings, whereas traction lifts are commonly found in high-rise buildings.

Q: Which type of elevator is more energy-efficient, hydraulic or traction?

A: Traction lifts are generally more energy-efficient compared to hydraulic lifts. This is because traction lifts utilize counterweights that balance the elevator car, thus reducing the amount of energy needed for movement. Hydraulic lifts, on the other hand, require more energy to push the car upwards and to return the hydraulic fluid to the reservoir.

Q: Are traction lifts or hydraulic lifts better for tall buildings?

A: Traction lifts are better suited for tall buildings. This is because traction lifts use steel ropes or belts and can reach much higher speeds compared to hydraulic lifts. Also, traction lifts do not have the height limitations that hydraulic lifts have due to the length of the hydraulic piston required.

Q: What are the advantages of traction lifts compared to hydraulic lifts?

A: The advantages of traction lifts compared to hydraulic lifts include higher energy efficiency, faster travel speeds, and suitability for high-rise buildings. Additionally, traction lifts generally offer a smoother ride and have fewer height limitations than hydraulic lifts.

Q: What are roped hydraulic elevators?

A: Roped hydraulic elevators combine the mechanics of both traction and hydraulic lifts. They use a hydraulic actuator to drive a set of steel ropes or belts connected to the elevator car. This setup allows roped hydraulic elevators to reach higher floors than traditional hydraulic lifts while maintaining some of the benefits of hydraulic mechanisms.

Q: How does elevator maintenance differ between traction and hydraulic lifts?

A: Elevator maintenance for traction and hydraulic lifts differs primarily based on their mechanics. Traction lifts require regular inspections and maintenance of the steel ropes or belts, gears, and counterweights. Hydraulic lifts require maintenance of the hydraulic fluid, pistons, and associated systems. Both types require routine checks for elevator safety and operational efficiency.

Q: Which type of elevator offers a smoother ride, hydraulic or traction lifts?

A: Traction lifts generally offer a smoother ride compared to hydraulic lifts. This is because traction lifts use counterweights and steel ropes or belts, providing a more stable and balanced movement. Hydraulic lifts can have a more noticeable starting and stopping motion due to the hydraulic fluid flow.

Q: What should I consider when choosing the right elevator for my building?

A: When choosing the right elevator for your building, consider factors such as building height, expected usage, energy efficiency, installation and maintenance costs, and ride quality. For tall buildings, traction lifts are often the better choice, while for low to medium-rise buildings, hydraulic lifts may be more cost-effective. Consulting with an elevator expert can also help you make the best decision based on your specific needs and building design.

Q: How long does it take for an elevator company to install a traction vs hydraulic lift?

A: The installation time for an elevator depends on the type and complexity. Traction lifts, particularly those designed for tall buildings, may take longer to install due to the need for more intricate elevator shaft construction and the installation of steel ropes or belts and counterweights. Hydraulic lifts can be faster to install in low to medium-rise buildings since they require less complex construction within the elevator shaft. Consulting your elevator company can provide specific timelines for your project.

Q: Can hydraulic elevators be used in commercial buildings?

A: Yes, hydraulic elevators can be used in commercial buildings, especially those with low to medium-rise heights. Hydraulic elevators are advantageous for these applications due to their lower initial costs and simpler mechanical requirements. However, for high-rise commercial buildings, traction lifts are typically preferred for their speed and efficiency.