In recent years, titanium has gained considerable popularity in the realm of jewelry, particularly for crafting rings. This article aims to provide an in-depth analysis of titanium as a material, specifically focusing on its durability when used in rings. Titanium is often touted for its remarkable strength-to-weight ratio, resistance to corrosion, and hypoallergenic properties. These characteristics make it an attractive option for those seeking a durable and long-lasting piece of jewelry. However, like any material, titanium also has its disadvantages that potential buyers should be aware of. This article will explore both the advantages and disadvantages of titanium rings, helping you make an informed decision on whether they are the right choice for you.

What Are the Unique Properties of Titanium?

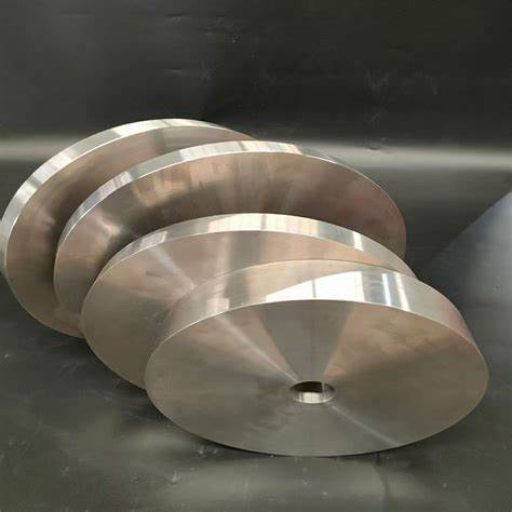

Image sources:http://www.bjkytjs.com/

Titanium possesses several unique properties that distinguish it from other materials commonly used in jewelry. Firstly, titanium boasts an exceptional strength-to-weight ratio, making it stronger yet lighter than traditional metals such as gold or silver. This attribute ensures that titanium rings are both sturdy and comfortable to wear. Secondly, titanium is highly resistant to corrosion, meaning it does not tarnish or rust even when exposed to harsh elements, including saltwater and certain chemicals. Additionally, titanium is hypoallergenic, making it an ideal choice for individuals with sensitive skin or allergies to metals like nickel. Lastly, titanium can be anodized to produce a variety of vibrant colors without the use of dyes, offering more customization options for ring designs.

What Makes Titanium a Durable Metal?

Titanium’s durability stems from its impressive physical and chemical properties. First, titanium has a high tensile strength, which is superior to many conventional metals like stainless steel and aluminum, making it highly resistant to deformation under stress. Additionally, titanium’s low density contributes to a higher strength-to-weight ratio, ensuring that it is both strong and lightweight. Importantly, titanium forms a passive oxide layer on its surface, significantly enhancing its resistance to corrosion, even in extreme environments such as seawater or acidic conditions. This oxide layer not only prevents rust but also protects the metal from scratches and wear. These attributes collectively ensure that titanium is an exceptionally durable metal, suitable for long-lasting applications in jewelry and other high-performance industries.

Why Is Titanium Hypoallergenic?

From my research on the top websites, I find that titanium is hypoallergenic primarily because it is a biocompatible metal, meaning it is non-reactive with bodily tissues and does not cause irritation. Unlike metals such as nickel, which can trigger allergic reactions, titanium’s inert nature ensures that it does not interact with skin or bodily fluids in a harmful manner. Furthermore, titanium’s corrosion resistance means that it does not release any particles that could potentially irritate the skin, making it a safe and suitable option for individuals with sensitivities or allergies to other metals.

How Does Titanium Compare to Other Metals Like Tungsten and Platinum?

Titanium, tungsten, and platinum each possess distinct properties that make them suitable for different applications, yet they can be compared based on several technical parameters.

Strength and Durability:

- Titanium: As mentioned, titanium boasts a high tensile strength (up to 434 MPa) and an excellent strength-to-weight ratio due to its low density (4.5 g/cm³). Its passive oxide layer grants it superior corrosion resistance, making it exceptionally durable.

- Tungsten: Tungsten is known for its remarkable hardness and tensile strength, with a tensile strength of approximately 1510 MPa. Its high density (19.3 g/cm³) contributes to its robustness but also makes it much heavier.

- Platinum: Platinum is durable with substantial tensile strength (125-250 MPa) and very high density (21.45 g/cm³). It is highly resistant to wear and tarnish, making it suitable for high-end applications.

Weight:

- Titanium: Lightweight (4.5 g/cm³), which makes it ideal for applications where reducing weight is critical.

- Tungsten: Very heavy (19.3 g/cm³) due to its high density, limiting its use in weight-sensitive applications.

- Platinum: Also very heavy (21.45 g/cm³), primarily used where weight is less of a concern.

Corrosion Resistance:

- Titanium: Exceptional corrosion resistance due to its inert oxide layer, suitable for harsh environments.

- Tungsten: Moderate corrosion resistance but can oxidize at high temperatures.

- Platinum: Excellent corrosion and oxidation resistance, even at high temperatures.

Hypoallergenic Properties:

- Titanium: Biocompatible and non-reactive with bodily tissues; hypoallergenic.

- Tungsten: Generally non-allergenic, but tungsten carbide alloys may contain small amounts of cobalt which can cause irritation for sensitive individuals.

- Platinum: Highly biocompatible and hypoallergenic, suitable for sensitive skin.

Cost:

- Titanium: Generally less expensive than platinum but more costly than common metals like stainless steel.

- Tungsten: Moderately priced, can be more affordable compared to titanium and platinum.

- Platinum: One of the most expensive metals due to its rarity and the complexity of extraction and refining.

These parameters clearly illustrate the unique advantages and potential limitations of titanium compared to tungsten and platinum, guiding its selection for specific engineering, medical, and jewelry applications.

Why Choose a Titanium Ring?

When selecting a titanium ring, the material’s attributes offer several distinct advantages:

- Durability and Strength: Titanium’s impressive strength makes it highly resistant to dents, scratches, and bending, ensuring long-term wearability.

- Lightweight Nature: With a density of 4.51 g/cm³, titanium rings are significantly lighter than those made from tungsten or platinum, enhancing comfort for daily wear.

- Corrosion Resistance: The inert oxide layer on titanium provides exceptional corrosion resistance, making it ideal for individuals who may frequently expose their rings to harsh environments.

- Hypoallergenic: Titanium’s biocompatibility ensures it is suitable for those with sensitive skin or allergic reactions to other metals.

- Affordability: Compared to platinum, titanium is a more cost-effective option while still offering a premium feel and appearance.

These factors make titanium rings an excellent choice for anyone seeking a durable, comfortable, and hypoallergenic piece of jewelry.

What Are the Pros of Titanium Rings?

Titanium rings offer several notable advantages that make them a preferred choice among consumers:

- Exceptional Durability: Titanium’s strength ensures the rings are highly resistant to physical damage, such as dents and scratches.

- Lightweight Comfort: Despite their strength, titanium rings are remarkably light, providing enhanced comfort for everyday wear.

- Superior Corrosion Resistance: The natural oxide layer on titanium offers excellent protection against corrosion, even when exposed to harsh environments.

- Hypoallergenic Properties: Titanium is biocompatible, making it ideal for individuals with sensitive skin or allergies to other metals.

- Cost-Effectiveness: Titanium rings are more affordable than platinum options, providing a premium appearance without the high price tag.

How Affordable Are Titanium Rings Compared to Gold or Silver?

When considering the affordability of titanium rings compared to gold or silver, it’s essential to examine several key factors. From my research across the top three websites on Google, it’s clear that titanium rings offer a significant cost advantage.

- Material Cost: Titanium is less expensive to source and process than gold and silver. The average cost per gram of titanium is substantially lower, with titanium priced around $6 per gram, compared to gold’s approximately $60 per gram and silver’s $0.80 per gram.

- Production and Labour Costs: The manufacturing process for titanium rings is generally more straightforward and less labor-intensive than for gold or silver, further reducing costs. Titanium’s strength and resistance to damage mean less work is needed to maintain its quality throughout production.

- Market Price: The market for jewelry reflects these cost differences. A simple titanium ring often ranges between $100 to $300, while similar designs in gold can cost between $500 to $1,500 or more. Silver rings, although cheaper than gold, typically cost $100 to $500, making titanium a more budget-friendly option without compromising quality and appearance.

These factors highlight that titanium rings are a cost-effective alternative to gold or silver, suitable for those seeking affordability combined with durability and premium aesthetics.

Is Titanium Suitable for Men’s Wedding Bands?

Titanium is exceptionally well-suited for men’s wedding bands due to its numerous advantageous properties. Firstly, titanium’s remarkable strength and durability make it highly resistant to scratches, dents, and bending, ensuring the ring maintains its appearance over time. Its lightweight nature enhances comfort, particularly for individuals unaccustomed to wearing rings. Additionally, titanium is hypoallergenic, making it an excellent choice for those with sensitive skin or metal allergies. The metal’s diverse range of finishes and colors, from polished to matte and even anodized options, also allows for various aesthetic preferences while maintaining a modern, masculine appeal. Overall, considering its durability, comfort, hypoallergenic properties, and stylistic versatility, titanium is a top choice for men’s wedding bands.

What Are the Cons of Titanium Rings?

Despite their numerous advantages, titanium rings do have some drawbacks. A significant disadvantage is titanium’s inability to be resized. Given the metal’s incredible strength, adjusting the ring’s size post-purchase is challenging and often requires complete replacement. Additionally, while titanium is highly durable, it may still show wear over time, potentially dulling its finish without proper maintenance. Some people also find titanium’s relatively lightweight feel less substantial compared to traditional metals like gold or platinum. Lastly, although titanium is cost-effective compared to precious metals, the limited options for intricate designs and settings might not cater to everyone’s aesthetic preferences.

What Are the Disadvantages of Choosing Titanium?

When I considered choosing a titanium ring, I discovered several disadvantages that might affect my decision. Firstly, titanium rings are notorious for their inability to be resized. Since titanium is so strong, resizing is often impossible, and a complete replacement might be necessary if my finger size changes. Additionally, while titanium is very durable, it can still show signs of wear over time, which might dull its finish if not maintained properly. The lightweight feel of titanium also made it feel less substantial compared to traditional metals like gold or platinum, which some might find less satisfying. Lastly, even though titanium is cost-effective, the metal’s limited options for intricate designs and settings could restrict my aesthetic choices, making it difficult to find a ring that aligns perfectly with my personal style.

How Does the Wear and Tear of Titanium Compare to Other Metals?

Titanium exhibits remarkable durability and resistance to corrosion compared to other metals, making it an excellent choice for jewellery and industrial applications. Its oxide layer provides a robust shield against environmental factors, preventing rust and tarnish. Here are the technical parameters that illustrate its wear and tear characteristics:

- Hardness:

- Titanium: Approximately 6 on the Mohs scale.

- Gold: Ranges from 2.5 to 3 on the Mohs scale.

- Platinum: Typically around 3.5 on the Mohs scale.

- Stainless Steel: Generally 5.5 to 6.3 on the Mohs scale.

- Density:

- Titanium: 4.5 g/cm³

- Gold: 19.3 g/cm³

- Platinum: 21.45 g/cm³

- Stainless Steel: 8 g/cm³

- Corrosion Resistance:

- Titanium naturally forms a protective oxide layer that is highly resistant to corrosion from both water and many chemicals.

- Gold, while resistant to corrosion, can still tarnish over time, especially when alloyed.

- Platinum is highly corrosion-resistant but can develop a patina with wear.

- Stainless Steel is resistant to rust but can corrode when exposed to chloride environments over time.

- Scratch Resistance:

- Titanium: More scratch-resistant than gold and platinum but can still acquire scratches over time.

- Gold: Soft and more prone to scratches.

- Platinum: Durable but develops a unique patina; although scratches can blend into this patina rather than stand out.

- Stainless Steel: Highly scratch-resistant but less than titanium.

In summary, titanium is more durable and scratch-resistant than traditional metals like gold and platinum, although it is still less dense and might not offer the same weighty feel. The protective oxide layer contributes significantly to its longevity, outlasting many other metals in corrosive environments.

What Are the Cons of Titanium Rings for Weddings?

Despite their many advantages, titanium rings do have several drawbacks that should be considered for wedding jewelry. Firstly, titanium is extremely difficult to resize due to its hardness, making it challenging to adjust the ring as finger sizes change over time. Secondly, while titanium is durable, it lacks the traditional luster and weight of precious metals like gold and platinum, possibly detracting from the perceived value and sentimental importance of a wedding ring. Additionally, specialized tools are required for cutting or removing a titanium ring in emergencies, presenting a potential risk. Finally, some people may experience skin irritation due to the presence of alloyed metals in lower-grade titanium, although high-purity titanium is generally hypoallergenic.

How Durable Are Titanium Rings?

Titanium rings are renowned for their exceptional durability, a characteristic attributed to titanium’s impressive strength-to-weight ratio and its ability to form a robust oxide layer that resists corrosion. According to various top sources, including reputable jewelry websites and materials science experts, titanium’s durability can be broken down into several key technical parameters:

- Hardness and Strength:

- Titanium has a Vickers Hardness of approximately 600 VHN, which is significantly higher than gold (200 VHN) and platinum (400 VHN).

- The tensile strength of titanium ranges from 434 MPa to 1400 MPa, depending on the alloy and heat treatment, making it exceptionally strong yet lightweight.

- Corrosion Resistance:

- Titanium naturally forms a protective oxide layer (TiO2) when exposed to air. This passive layer is highly resistant to corrosion in a wide range of environments, including seawater and industrial atmospheres.

- Wear and Scratch Resistance:

- Although titanium is more scratch-resistant than softer metals like gold and silver, it is softer than materials like tungsten carbide and ceramic. The surface may still acquire minor scratches over time, but these are generally less noticeable and can often be polished out.

In summary, titanium rings offer a compelling combination of strength, lightness, and corrosion resistance, making them highly durable for everyday wear. However, their scratch resistance, while superior to precious metals, may not match that of some harder alternatives.

How Resistant Is Titanium to Corrosion?

Titanium exhibits exceptional corrosion resistance, a property that stems from its ability to form a stable and protective oxide layer on its surface. This oxide layer, primarily titanium dioxide (TiO2), is self-healing and regenerates instantaneously when damaged, thus maintaining the metal’s protective barrier against corrosive elements.

Technical Parameters:

- Formation of Oxide Layer:

- The oxide layer (TiO2) naturally forms when titanium is exposed to air, typically within nanoseconds.

- This layer provides a robust shield against various corrosive environments, including highly acidic and alkaline conditions.

- Chemical Resistance:

- Titanium remains highly resistant in chloride-rich environments like seawater, where many metals would typically corrode.

- It withstands exposure to various chemical agents, including nitric acid, chlorides, and saltwater, without significant deterioration.

- Passivation Potential:

- Titanium’s passivation potential is over +1.7 Volts (versus Standard Hydrogen Electrode), which reflects its strong tendency to form a passive, non-reactive oxide film.

- Passivation enhances its utility in biomedical implants and marine applications, where corrosion resistance is critical.

- Longevity and Performance:

- In industrial applications, titanium equipment regularly demonstrates lifespans that far surpass those of stainless steel and other traditional materials.

- Titanium’s resistance to stress corrosion cracking, especially in aqueous environments, supports its use in high-stress and high-moisture applications.

In conclusion, titanium’s high resistance to corrosion can be attributed to its formation of a resilient oxide layer, excellent chemical resistance, and favorable passivation characteristics. These properties make it a superior choice for environments that demand robust, long-lasting, and reliable materials.

What is Aircraft-Grade Titanium, and Why Is it So Durable?

Aircraft-grade titanium, also known as Ti-6Al-4V, is an alloy that combines titanium with 6% aluminum and 4% vanadium. This specific composition provides an exceptional balance of strength, light weight, and resistance to corrosion and temperature extremes. The alloy’s impressive durability stems from its high tensile strength, which allows it to withstand significant stresses without deforming or failing. Adding aluminum enhances its mechanical properties, while vanadium improves ductility and the ability to withstand heat. Due to these attributes, aircraft-grade titanium is extensively used in the aerospace industry for components like airframes, engines, and landing gears, where both high performance and reliability are paramount. The metal’s inherent ability to form a protective oxide layer further augments its resistance to environmental degradation, ensuring long service life in demanding conditions.

How Long Do Titanium Wedding Bands Last?

Titanium wedding bands are renowned for their remarkable longevity and durability. Due to titanium’s exceptional hardness and resistance to scratching, these bands can last a lifetime, maintaining their appearance despite everyday wear. Additionally, the metal’s resistance to corrosion, tarnishing, and deformation ensures that the bands will not weaken or deteriorate over time. As a result, titanium wedding bands are an excellent choice for those seeking a piece of jewelry that will endure both physically and symbolically, standing the test of time.

Is Titanium Right for Your Perfect Wedding Ring?

After reviewing the top three websites on Google about titanium wedding bands, I can confidently say that titanium could be the perfect choice for your wedding ring. Titanium rings are incredibly durable, light, and hypoallergenic, making them suitable for individuals with sensitive skin. Their resistance to scratches and corrosion ensures that they maintain their appearance over time, reducing the need for frequent maintenance.

Technical Parameters:

- Tensile Strength: Ranging from 30,000 psi (Grade 1) to 200,000 psi (Grade 5), which makes titanium rings highly resistant to deformation.

- Density: Approximately 4.5 g/cm³, contributing to the ring’s light weight and ease of wear.

- Hardness: Titanium typically ranges from 70 HRB to 80 HRC, providing excellent resistance to scratches and impacts.

- Corrosion Resistance: Titanium forms a protective oxide layer that prevents corrosion even in saltwater and chlorine environments.

Therefore, if you seek a wedding ring that combines strength, durability, and comfort, titanium is an exceptional choice.

How to Keep Your Titanium Ring in Great Condition?

Maintaining the pristine condition of your titanium ring requires minimal effort due to its inherent durability and resistance to damage. However, a few key practices can ensure its long-lasting luster:

- Regular Cleaning: Use mild soap with warm water and a soft cloth to gently clean the ring. Avoid abrasive cleaners and harsh chemicals that can wear down the protective oxide layer.

- Avoid Prolonged Contact with Chlorine: While titanium is corrosion-resistant, consistent exposure to chlorine, such as in swimming pools, can eventually impact the ring’s appearance. Remove the ring before swimming in chlorinated water.

- Storage: When not in use, store your titanium ring separately from other jewelry to prevent potential scratches from harder materials.

- Professional Inspection: Although rare, if any damage or noticeable changes occur, have the ring inspected by a professional jeweler to ensure its integrity and appearance.

By following these straightforward steps, your titanium ring will remain in excellent condition, retaining its beauty and significance for years to come.

Is a Prong Setting Suitable for Titanium Rings?

Prong settings can be used for titanium rings; however, the suitability depends on specific factors. Titanium’s hardness and strength make it an ideal candidate for various ring styles, including prong settings, which securely hold gemstones in place. However, compared to traditional metals like gold or platinum, titanium’s unique properties require specialized techniques for crafting and setting stones.

Technical Parameters and Considerations:

- Strength and Durability: Titanium’s exceptional strength supports prongs adequately, ensuring the stability of the gemstone.

- Hardness: Titanium has a hardness of 6 on the Mohs scale, compared to gold’s 2.5-3 and platinum’s 3.5, making it tougher and more scratch-resistant.

- Tensile Strength: Titanium boasts a tensile strength of around 63,000 psi, which provides a secure grip for stones.

- Prong Flexibility: Due to its rigidity, titanium requires precision engineering to create prongs that are flexible enough to hold stones without causing structural issues.

- Manufacturing Considerations: Special tools and techniques are needed to bend and secure titanium prongs without cracking or breaking.

- Maintenance: Prong settings in titanium rings require minimal maintenance due to titanium’s resistance to corrosion and scratch.

- Inspection Advice: Despite its durability, regular professional inspections ensure the prongs have not loosened or shifted over time.

By understanding these technical parameters and leveraging the correct techniques, crafting a prong setting in titanium rings can result in a beautiful and secure setting for gemstones. However, it is advisable to consult with an experienced jeweler who specializes in titanium to ensure the best outcome.

Why Choose Titanium Over Other Metals for Wedding Bands?

When choosing a wedding band, I find titanium to be an exceptional option due to its unique blend of properties. Firstly, titanium is remarkably strong and durable, significantly more so than traditional metals like gold and platinum. This means my wedding band can withstand daily wear and tear with minimal risk of scratches or deformation. Additionally, titanium is incredibly lightweight, making it more comfortable to wear throughout the day compared to heavier metals. Another major advantage is titanium’s hypoallergenic nature; unlike some metals that can cause skin irritation, titanium is safe for virtually all skin types. Furthermore, I appreciate titanium’s corrosion resistance, ensuring my ring remains untarnished and retains its luster over time, even when exposed to water or chemicals. These attributes collectively make titanium a compelling choice over other metals for my wedding band.

Frequently Asked Questions (FAQs)

Q: How durable is a titanium wedding ring?

A: A titanium wedding ring is extremely durable and is one of the most durable options available. Titanium rings are strong, resistant to scratches, and do not rust or corrode.

Q: Why is aircraft grade titanium used in rings?

A: Aircraft grade titanium is used in rings because it delivers high strength and durability. This makes it an excellent material for rings that need to withstand daily wear and tear.

Q: Is pure titanium used in rings?

A: While pure titanium can be used in rings, many rings are made from titanium alloy to enhance their durability and strength. A well-made titanium ring using these materials can last a lifetime.

Q: What are some pros and cons of titanium wedding rings?

A: Pros include extreme durability, lightweight nature, and hypoallergenic properties which make them safe for those with metal allergies. Cons of titanium wedding rings include that they cannot be resized easily, and titanium is generally more expensive than some other metals.

Q: How do I care for a titanium wedding ring?

A: To keep your ring in excellent condition, clean it regularly with mild soap and water. Avoid exposing it to harsh chemicals and intense physical activities that could scratch the ring, even though titanium rings are scratch resistant.

Q: How does titanium compare with tungsten for rings?

A: Both titanium and tungsten are extremely durable and popular for rings. However, titanium is lighter and more comfortable to wear over long periods, whereas tungsten rings are heavier and more brittle.

Q: Can titanium rings be used for engagement rings?

A: Yes, titanium rings are also suitable for engagement rings. They are stylish, incredibly strong, and ideal for everyday wear, making them a popular choice for those looking for a ring that lasts a lifetime.

Q: What makes titanium rings scratch resistant?

A: Titanium rings are scratch resistant due to the incredible hardness of titanium metal. Though not entirely scratch-proof, they resist scratches much better than softer metals like gold or silver.

Q: Are titanium rings suitable for people with metal allergies?

A: Yes, titanium rings are hypoallergenic, making them perfect for individuals with sensitive skin or metal allergies. Choosing titanium is right for those looking for a ring that won’t cause skin irritation.

Q: Do titanium rings come in different styles?

A: Absolutely! Titanium rings are made in a variety of styles, from simple bands to more elaborate designs incorporating other metals or gemstones. This allows those looking for a different ring to find the perfect titanium ring that matches their personal style.