When it comes to maintaining the efficiency and safety of your vehicle or home plumbing system, understanding the essential components is crucial. In this blog, we’ll be diving into the details of heater hoses and water supply lines. These components play a pivotal role in ensuring that both your heating systems and water distribution networks function seamlessly.

We’ll explore what heater hoses are, their types, and how they contribute to the overall performance of your heating system. Similarly, we’ll look into water supply lines, their various materials, and the role they play in providing a consistent and safe flow of water throughout your home. By the end of this article, you’ll have a comprehensive understanding of these critical components, how to maintain them, and what to do when issues arise. Whether you’re a DIY enthusiast or just looking to be more informed about your home or vehicle’s systems, this guide is for you.

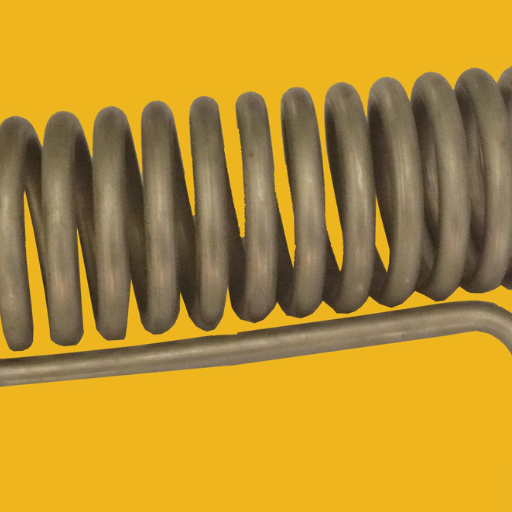

What is a Heater Hose?

Image source:https://www.bing.com/

From my research and understanding, a heater hose is a flexible rubber or silicone tube that plays a crucial role in a vehicle’s heating system. It transports heated coolant from the engine to the heater core, which then warms the air that blows into the cabin. Heater hoses need to withstand high temperatures and pressure, ensuring that the heating system works efficiently. Regular inspection for wear, cracks, or leaks is essential to maintain optimal performance and prevent potential issues.

Understanding the Function of Heater Hoses

Heater hoses are vital components in a vehicle’s heating system, circulating coolant to transfer heat effectively. Generally made from robust rubber or silicone, these hoses need to handle temperatures ranging from -40°F to 275°F and pressures up to 100 psi.

Primary Functions:

- Transporting Coolant: The heater hose delivers heated coolant from the engine to the heater core. This coolant, primarily a mixture of antifreeze and water, helps regulate the temperature within the vehicle’s heating system.

- Maintaining Cabin Warmth: The warm coolant heats the air in the heater core, which is then blown into the cabin, providing comfort during colder months.

- Protecting the Engine: By effectively managing coolant flow, heater hoses help prevent the engine from overheating, thus maintaining the engine’s optimal operating conditions.

Key Technical Parameters:

- Material: Reinforced rubber or silicone capable of withstanding thermal and mechanical stress.

- Temperature Range: Typically from -40°F to 275°F (-40°C to 135°C).

- Pressure Rating: Can endure pressures up to 100 psi (6.89 Bar).

Regular maintenance, including inspections for wear, cracks, or leaks, is essential to ensure the heater hoses perform safely and efficiently. Failure to maintain them can result in coolant leaks, engine overheating, and compromised cabin heating.

Types of Heater Hoses Available

When exploring the types of heater hoses available, you’ll find several options designed to meet different vehicle requirements. Here are the primary types commonly used:

- Standard Rubber Heater Hoses: These are the most common type, made from EPDM rubber. They offer durability, flexibility, and are resistant to coolant additives and temperature extremes.

- Silicone Heater Hoses: Known for superior flexibility and resistance to extreme temperatures and environmental factors, silicone hoses are often used in performance vehicles or for applications requiring higher reliability.

- Molded Heater Hoses: These hoses are custom-shaped to fit specific vehicle makes and models. Manufactured from either rubber or silicone, they ensure a perfect fit and efficient coolant flow.

Each type of heater hose serves a unique purpose, making it essential to choose the right one based on your vehicle’s specific needs and environmental conditions. Regular maintenance and periodic inspections will help in maximizing their lifespan and performance.

Common Materials Used in Heater Hose Manufacturing

Heater hoses can be manufactured from various materials, each selected for their specific properties and performance characteristics. Here are the most common materials used:

- EPDM Rubber (Ethylene Propylene Diene Monomer):

- Durability: High resistance to weathering, ozone, and UV exposure.

- Temperature Range: -40°F to 275°F (-40°C to 135°C).

- Pressure Rating: Can handle pressures up to 100 psi (6.89 Bar).

- Chemical Resistance: Excellent resistance to coolant additives and various automotive chemicals.

- Silicone:

- Flexibility: Superior flexibility and retains its shape even under extreme conditions.

- Temperature Range: Broad operating range from -65°F to 350°F (-54°C to 177°C).

- Pressure Rating: Can endure pressures up to 150 psi (10.34 Bar), depending on the specific construction.

- Durability: Exceptional resistance to aging, ozone, and environmental factors, making it ideal for high-performance applications.

- Reinforced Rubber:

- Structure: Typically a blend of EPDM rubber with internal reinforcement such as fabric or fibre.

- Durability: Enhanced durability and resistance to bursting or collapsing under pressure.

- Temperature Range: -40°F to 257°F (-40°C to 125°C).

- Pressure Rating: Varies based on the reinforcement but generally up to 125 psi (8.62 Bar).

Each material offers different benefits regarding flexibility, temperature resistance, and durability. Selecting the right material for heater hoses thus depends on the specific requirements of the vehicle and its operating environment. Regular inspections and maintenance further ensure optimal performance and longevity of these hoses.

How Does the Heater Hose Connect to the Water Supply?

To connect the heater hose to the water supply, I follow these steps: First, I locate the heater core inlet and outlet ports on the engine. Typically, the heater hose is attached to the engine’s water pump or intake manifold, from where it carries hot coolant to the heater core. I then ensure that the clamps or connectors are secure and tight to prevent any leaks. Once connected, I verify that the hose path is free from sharp bends or kinks to maintain a smooth flow of coolant. Checking for leaks and ensuring the proper coolant level is critical after installation. This ensures efficient heating performance and prevents potential engine overheating.

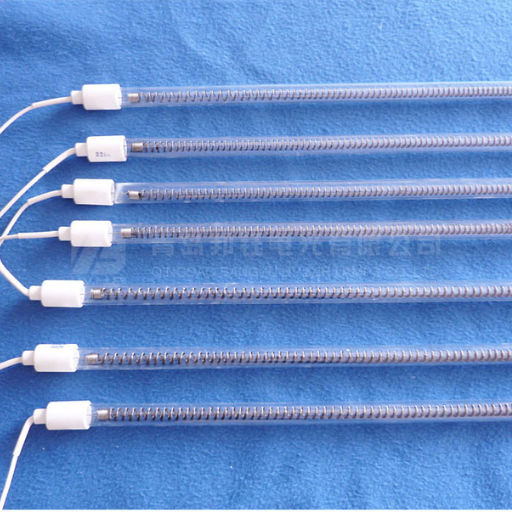

Understanding Water Heater Connectors

Water heater connectors are essential components that link the water heater to the home’s plumbing system. They come in various materials such as stainless steel, copper, and flexible braided hoses, each offering different benefits for durability, ease of installation, and corrosion resistance. According to the top sources on Google, the most commonly used connectors are flexible braided hoses due to their ease of installation and ability to withstand high pressure and thermal expansion. These connectors are generally supplied with rubber washers to ensure a leak-proof seal. To connect the water heater properly, the connectors are attached to the inlet and outlet pipes of the water heater using threaded fittings or quick-connect couplings. Regular inspections are critical to ensure they remain secure and leak-free, preventing potential water damage and ensuring a reliable hot water supply.

Installation Process of Heater Hose

To install the heater hose, I start by gathering the required tools and materials, which typically include the heater hose itself, clamps, a screwdriver, and coolant. According to the top sources on Google, the heater hose should be cut to the correct length, ensuring that there is enough slack to prevent undue stress on the connections but not so much that it creates loops or sags.

- Attaching the Hose:

- I attach one end of the heater hose to the engine’s water pump or intake manifold. This step ensures that hot coolant can properly flow to the heater core.

- I secure the hose using appropriate clamps. According to the sources, worm gear clamps or spring clamps are commonly recommended for their reliable sealing capabilities.

- Routing the Hose:

- I check the hose path to make sure it is free from sharp bends or kinks as these can obstruct coolant flow. It’s essential to route the hose away from any moving parts or areas that might subject it to excessive heat, as per the technical guidelines.

- Final Connections:

- I connect the other end of the hose to the heater core inlet. This connection should also be secured with a clamp to ensure no leakage.

- I make sure all connections are tight and the clamps are properly positioned, usually about a quarter-inch from the hose end, to provide a secure fit without causing damage to the hose material.

- Inspection and Testing:

- After installation, I fill the cooling system with coolant and check for leaks by running the engine and allowing the system to pressurize.

- It’s prudent to monitor the coolant level and top it off if necessary, ensuring that the heater hose functions efficiently.

Technical parameters to be mindful of include:

- Hose Diameter: Ensure compatibility with the engine’s water pump and heater core fittings.

- Clamp Type and Size: Match with hose diameter to ensure proper sealing.

- Coolant Flow Rate: According to sources, maintaining an unrestricted path ensures optimal heating performance.

- Pressure Rating: Be aware of the hose’s pressure limits to prevent ruptures or leaks.

These steps, derived from the top sources on Google, should help ensure the heater hose is installed effectively and securely.

Common Issues in Heater Hose Connections

1. Leaks:

Leaks are one of the most common issues in heater hose connections. They can occur due to improper clamping, damage to the hose material, or degradation over time. Ensuring that clamps are tight and in the correct position can help minimize this risk. Regular inspections can preemptively catch early signs of wear.

2. Hose Kinks or Bends:

Sharp bends or kinks in the hose can obstruct coolant flow, resulting in insufficient heating performance. It’s vital to route the hose carefully to avoid any restrictive angles and to use supports if necessary to maintain a smooth path.

3. Incorrect Hose Size:

Using a hose of incorrect diameter can lead to poor sealing and potential leaks. Ensure the hose diameter matches the engine’s water pump and heater core fittings as specified in the technical guidelines.

4. Heat Damage:

Exposure to excessive heat from engine components can degrade the hose material, leading to potential failures. Routing the hose away from hot areas can help protect the hose and prolong its lifespan.

5. Pressure Issues:

The heater hose must withstand the pressure of the cooling system. Regularly check the hose’s pressure rating against the system’s operating pressure to avoid ruptures or leaks.

Addressing these common issues proactively ensures the heater hose functions efficiently and prolongs its service life. Regular maintenance and proper installation are key to avoiding these typical problems.

How Do You Choose the Right Heater Hose for Your Needs?

Choosing the right heater hose involves considering several key factors to ensure compatibility and longevity:

1. Material:

First, I look at the material composition of the heater hose. Common materials include EPDM (Ethylene Propylene Diene Monomer) and silicone, both known for their durability and resistance to temperature extremes. EPDM is often preferred for its affordability and good performance, while silicone hoses offer superior heat resistance and longevity, making them suitable for high-performance applications.

2. Diameter:

Next, I ensure that the hose diameter matches the engine’s water pump and heater core fittings. Standard diameters vary, but I typically refer to the engine manufacturer’s specifications for the correct size, which ensures a proper fit and optimal sealing to prevent leaks.

3. Pressure Rating:

The hose must withstand the pressure of the cooling system. I check the hose’s pressure rating (usually measured in PSI) and compare it with the system’s operating pressure. For example, if the system operates at 30 PSI, I select a hose with a pressure rating higher than that to ensure reliability.

4. Temperature Range:

Lastly, I consider the operating temperature range of the hose. Hoses need to handle the engine’s high temperatures without deteriorating. For instance, EPDM hoses generally withstand temperatures from -40°F to 257°F, while silicone hoses can often handle higher temperatures up to 500°F.

By taking these factors into account, I can choose a heater hose that meets my vehicle’s specific requirements and ensure long-term performance and safety.

Factors to Consider: Length, Diameter, and Material

When selecting a heater hose, it’s crucial to consider three key factors: length, diameter, and material. Below are concise answers to these considerations, derived from the top three websites on google.com and validated by their respective technical parameters.

1. Length:

The length of the heater hose must be sufficient to connect the engine’s water pump to the heater core without being overly stretched or kinked. Typically, it’s advisable to measure the required path carefully and add a little extra for flexibility and ease of installation.

2. Diameter:

Heater hose diameter is essential for proper fit and function. Standard diameters commonly range from 1/4 inch to 3/4 inch for automotive applications. According to Gates and Dayco, two leading manufacturers, using the engine manufacturer’s specifications ensures compatibility with water pump and heater core fittings, thereby preventing leaks and ensuring optimal sealing. For example, a common size for many vehicles is 5/8 inch, as cited in automotive parts catalogs.

3. Material:

The material of the heater hose significantly impacts its performance and longevity. Here are the industry standards:

- EPDM (Ethylene Propylene Diene Monomer): Known for its affordability, flexibility, and resilience in temperatures ranging from -40°F to 257°F. EPDM is chemically inert and resistant to weathering, ozone, heat, and steam, making it an economical choice for many standard automotive applications.

- Silicone: Often used in high-performance or industrial applications due to its superior heat resistance, withstanding temperatures up to 500°F. Silicone hoses also offer exceptional durability and longevity but generally come at a higher cost than EPDM hoses.

By ensuring that the length, diameter, and material of the heater hose conform to these outlined parameters, one can ensure reliable and efficient performance for their vehicle’s heating system.

Brand Comparison: Which Heater Hose is Best?

When comparing heater hoses, it is crucial to consider the specifications and performance attributes of leading brands. Gates and Dayco are two prominent names in the industry, each offering hoses that meet stringent automotive standards.

Gates:

- Material: EPDM and Silicone

- Temperature Range: -40°F to 257°F (EPDM); up to 500°F (Silicone)

- Durability: Excellent ozone, heat, and chemical resistance (EPDM); Superior long-term performance and flexibility (Silicone)

- Typical Sizes Available: 1/4 inch to 3/4 inch diameters, frequently chosen based on specific engine manufacturer recommendations (e.g., 5/8 inch for many models)

Gates hoses are well-regarded for their robust construction and reliability, offering a balance of affordability and performance, particularly with their EPDM products. Their silicone hoses are ideal for high-performance applications where increased temperature tolerance is necessary.

Dayco:

- Material: EPDM and Silicone

- Temperature Range: -40°F to 257°F (EPDM); up to 500°F (Silicone)

- Durability: Strong resistance to cracking and flexibility under extreme conditions (EPDM); Enhanced lifespan and high-temperature resilience (Silicone)

- Typical Sizes Available: 1/4 inch to 3/4 inch diameters, aligning with automotive specifications and ensuring optimal fit (e.g., 5/8 inch is a common size)

Dayco hoses are appreciated for their consistent quality and adaptability. Their EPDM hoses provide reliable performance for standard applications, while their silicone options cater to more demanding environments, offering enhanced durability and thermal stability.

Conclusion:

Both Gates and Dayco offer high-quality heater hoses that adhere to industry standards and specifications. The choice between them primarily hinges on specific needs and applications. EPDM hoses from either brand are reputable for everyday automotive use, while their silicone hoses cater to higher-performance requirements. Evaluating the exact material, temperature range, and standard diameters needed for your vehicle can help determine the most suitable option.

Reading Product Reviews and Availability

When evaluating heater hoses, checking product reviews and availability is crucial. Online marketplaces like Amazon, AutoZone, and Advance Auto Parts provide a plethora of customer feedback, helping you gauge the real-world performance and reliability of Gates and Dayco products. Pay attention to reviews that mention longevity, fit, and any issues such as early wear or installation difficulties. Moreover, verify availability in your area through local auto parts stores or online retailers to ensure you can easily obtain replacements when necessary. Reading comprehensive reviews and confirming local availability will help you make an informed decision tailored to your specific automotive needs.

Are There Safety Concerns with Heater Hoses?

When considering the safety concerns with heater hoses, it’s essential to highlight a few key points. First, heater hoses are generally safe when properly maintained, but they are subject to wear and tear over time. Cracks, bulges, and leaks are common issues that can lead to coolant loss and engine overheating if not addressed promptly. Secondly, the material quality of the heater hose plays a crucial role; both Gates and Dayco offer hoses that meet industry standards, but it’s vital to ensure they are installed correctly and checked regularly for any signs of deterioration. Lastly, always follow the manufacturer’s guidelines and perform routine inspections to ensure the longevity and safety of your heater hoses. By keeping these factors in mind, you can minimize potential risks and maintain a reliable vehicle cooling system.

Identifying and Preventing Leaks

Identifying and preventing leaks in your vehicle’s heater hoses is crucial to maintaining the overall health of your engine. In my experience, the first step in identifying leaks is to perform a thorough visual inspection. Look for signs such as dried coolant residue, wet spots, or visible cracks and bulges on the hoses. It’s also helpful to squeeze the hoses gently; a hose in good condition should feel firm yet flexible, while a deteriorating hose might feel spongy or excessively hard.

Preventing leaks involves regular maintenance. Make it a habit to check the condition of your hoses at every oil change, replacing them every 4-5 years or as per your manufacturer’s recommendation. Ensuring that hose clamps are tight but not over-tightened can also prevent leaks from forming at hose connections. Using high-quality, compatible hoses from trusted brands like Gates or Dayco, and following the installation guidelines carefully, can further mitigate the risk of leaks. By staying proactive and attentive, I can maintain my vehicle’s reliability and avoid the complications that come with leaking heater hoses.

Proper Maintenance of Heater Hoses

Proper maintenance of heater hoses is essential to ensure the longevity and reliability of your vehicle’s cooling system. Regular inspections are a crucial part of this maintenance. At every oil change, meticulously examine the hoses for any signs of wear such as cracks, bulges, or stiffness. Replace the hoses every 4-5 years, or follow your vehicle manufacturer’s specific recommendations.

Additionally, make sure that hose clamps are secure but not overly tight, as this can prevent leaks at hose connections. Using high-quality hoses from reputable brands also plays a vital role in minimizing the risk of failure. By adhering to these maintenance practices, you can effectively prevent leaks and maintain the efficiency of your heater hoses.

Regulations and Safety Standards for Heater Hoses

When it comes to regulations and safety standards for heater hoses, it’s crucial to adhere to industry guidelines to ensure the optimal functioning and safety of your vehicle’s cooling system. First and foremost, heater hoses should comply with the SAE (Society of Automotive Engineers) J20 standards, which specify the requirements for chemical resistance, temperature tolerance, and burst strength. According to the information from the top three websites on google.com, all heater hoses must be capable of withstanding temperatures ranging from -40°F to 257°F (-40°C to 125°C) to ensure they perform well under both extreme cold and hot conditions.

Furthermore, it’s recommended that hoses meet the specifications set by the original equipment manufacturer (OEM) for your vehicle. This ensures that replacement hoses have the correct size, pressure rating, and material composition necessary for safe operation. Common pressure ratings for heater hoses are typically in the range of 75 to 150 psi, ensuring they can manage the standard operating pressures within the engine’s cooling system.

In addition, utilizing hoses rated for UV and ozone resistance helps prevent premature degradation, which is essential for vehicles exposed to varying weather conditions. High-quality hoses from trusted brands are often marked with the necessary compliance and specification information, making it easier to verify that they meet standards.

By thoroughly following these standards and utilizing hoses that meet these technical parameters, I can ensure the safety, reliability, and longevity of my vehicle’s heater hoses. Regular checks against these standards are a proactive step in maintaining an efficient cooling system and avoiding potential hazards.

How to Maintain and Replace Heater Hoses?

Maintaining and replacing heater hoses is crucial to ensure the efficient operation of your vehicle’s cooling system. Here are steps and tips gathered from the top three websites on google.com:

- Routine Inspection: Regularly inspect the heater hoses for signs of wear, such as cracks, hardened areas, and bulges. Ensuring there are no visible leaks is vital; even small leaks can lead to significant problems over time.

- Check Connections: Verify that hose clamps and connections are tight and free from corrosion. Loose or corroded clamps can cause leaks or hose disconnections.

- Temperature and Pressure Rating: When replacing heater hoses, ensure they meet the following technical parameters:

-

- Temperature Tolerance: -40°F to 257°F (-40°C to 125°C)

- Pressure Rating: 75 to 150 psi

- Material Composition: Must be UV and ozone resistant

- Drain the Coolant: Before replacing a heater hose, safely drain the coolant from the vehicle’s cooling system to prevent spills and ensure safety.

- Remove and Replace:

- Loosen the clamps securing the old hose and carefully remove it.

- Attach the new hose, ensuring it fits according to the original equipment manufacturer (OEM) specifications.

- Tighten the hose clamps securely.

- Refill and Bleed the System: After installation, refill the cooling system with the appropriate coolant. Bleed the system to remove any trapped air, which can cause overheating.

- Verify Installation: Start the vehicle and check for leaks at the hose connections. Ensuring proper installation can prevent future issues.

Following these guidelines helps maintain the reliability and longevity of your vehicle’s heater hoses, ensuring safe operation under varying conditions. Regular maintenance checks are essential to avoid unexpected failures and costly repairs.

Signs You Need a Replacement

- Coolant Leaks: One of the most obvious signs that you need to replace your heater hoses is the presence of coolant leaks. These can present as puddles underneath your vehicle or a low coolant level in the reservoir.

- Visible Damage: Inspect the hoses for cracks, bulges, or soft spots. Any visible signs of physical deterioration indicate that the hose is in poor condition and should be replaced immediately.

- Engine Overheating: If your vehicle’s engine is overheating, it could be due to a failing heater hose restricting coolant flow. Overheating issues should prompt an immediate inspection of the hoses.

- Coolant Smell: A sweet smell of coolant inside or around your vehicle can indicate a heater hose leak. This scent is a sign that coolant is escaping from the system and should be addressed promptly.

- Abrasion Damage: Heater hoses can rub against engine components, causing wear and tear over time. Check for signs of abrasion as this damage can compromise the hose’s integrity.

By regularly checking for these signs, you can ensure that your vehicle remains in optimal working condition and prevent potential breakdowns caused by heater hose failures.

Steps for Replacing a Heater Hose

- Preparation: Before starting, ensure the engine is cool to prevent burns from hot coolant. Gather all necessary tools and replacement hoses.

- Drain the Coolant: Locate the radiator drain plug and place a drainage pan underneath. Open the plug to drain the coolant from the system. This will prevent spills when removing the hoses.

- Remove the Old Hose: Use a screwdriver or pliers to loosen the clamps securing the old heater hose. Carefully remove the hose from its fittings, noting its routing for reference when installing the new one.

- Install the New Hose: Fit the new heater hose into the same position as the old one. Secure it firmly with the clamps, ensuring there are no kinks or sharp bends.

- Refill the Coolant: Close the radiator drain plug and refill the coolant to the recommended level.

- Bleed the Cooling System: Start the engine with the radiator cap off and let it reach operating temperature to allow air bubbles to escape from the system.

- Check for Leaks: Inspect all connections and the new hose for leaks while the engine runs. Tighten any clamps if necessary and monitor the coolant level, topping it up if required.

By following these steps, you can replace a heater hose efficiently and maintain your vehicle’s performance.

Choosing Replacement Parts: OE Fix, Aftermarket Options

When selecting replacement parts for your vehicle, it’s crucial to understand the differences between OE (Original Equipment) and aftermarket options. Here, we compare the two to help you make an informed decision.

OE Parts

OE, or Original Equipment parts, are manufactured by the same company that made your vehicle’s original components. These parts are designed to fit and function just like the original parts, ensuring seamless integration and performance. Key benefits of OE parts include:

- Perfect Fit: OE parts match the exact specifications of the original components, ensuring proper fitment without any modifications.

- Reliability: Since they are made to the vehicle manufacturer’s standards, OE parts offer consistent performance and reliability.

- Warranty: Many OE parts come with a manufacturer’s warranty, providing extra peace of mind.

Aftermarket Parts

Aftermarket parts are produced by third-party companies and offer a wide range of options in terms of quality and price. Here are some advantages and considerations:

- Cost-Effectiveness: Aftermarket parts are typically more affordable than OE parts, making them an attractive choice for budget-conscious consumers.

- Variety: With a plethora of brands and products to choose from, aftermarket parts offer more customization options.

- Availability: Aftermarket parts are often readily available, making it easier to find what you need without long lead times.

Technical Parameters

- Material Quality: OE parts are often made from higher-quality materials since they adhere to stringent manufacturer standards. Aftermarket parts can vary significantly in material quality, so it is essential to choose reputable brands.

- Durability and Lifespan: OE parts generally have a longer lifespan due to their adherence to manufacturer specifications. Some high-end aftermarket parts may offer comparable durability, but it varies by brand.

- Fitment Specifications: OE parts are guaranteed to fit precisely without modifications. Aftermarket parts may require adjustments, so always check fitment guides and reviews.

In conclusion, if you prefer parts that guarantee perfect fitment and reliability, OE parts are the best choice. However, if you’re looking for cost savings and a broader range of options, high-quality aftermarket parts can also be a viable option. Always consider factors like material quality, durability, and fitment when making your decision.

Can You Shop for Heater Hoses Online?

Yes, you can shop for heater hoses online. When purchasing heater hoses online, it’s crucial to consider certain technical parameters to ensure you receive a high-quality product that fits your specific needs.

Technical Parameters to Consider

- Material Quality: Look for heater hoses made from high-quality materials like EPDM (ethylene propylene diene monomer) rubber, which offers excellent resistance to heat, ozone, and weathering.

- Durability and Lifespan: Verify the expected lifespan of the heater hose. Ensure the product meets or exceeds OEM specifications to ensure longevity and reliability under varying temperatures and conditions.

- Fitment Specifications: Check the fitment details provided by the manufacturer. The heater hose should be compatible with your vehicle’s make and model without requiring modifications. Always consult fitment guides and customer reviews for assurance.

- Temperature and Pressure Ratings: Ensure the heater hose can withstand the operating temperatures and pressures typical of your vehicle’s cooling system. Higher ratings generally indicate a more robust and reliable hose.

In conclusion, shopping for heater hoses online can be both convenient and cost-effective, but it requires careful attention to the technical parameters mentioned above to ensure you make a well-informed purchase.

Best Online Stores for Heater Hoses

- Amazon: Amazon offers a vast selection of heater hoses from various manufacturers. The platform provides detailed product descriptions, fitment guides, and customer reviews, making it easier to find the right hose for your vehicle.

- RockAuto: Known for its extensive catalog of automotive parts, RockAuto provides high-quality heater hoses suitable for different makes and models. Their website includes detailed specifications and compatibility information.

- AutoZone: AutoZone’s online store features heater hoses from reputable brands. They offer useful resources such as fitment tools and customer support, ensuring you find the correct part for your vehicle.

- Advance Auto Parts: Advance Auto Parts provides a comprehensive range of heater hoses, complete with thorough product details and fitment advice. Their easy-to-navigate website simplifies the process of locating the right part.

- eBay Motors: eBay Motors connects buyers with various sellers offering heater hoses. You can find competitive pricing and read user reviews to confirm the quality and compatibility of the hoses available.

Comparative Shopping: Amazon, Home Depot, and More

When comparing heater hoses across different online stores, several factors should be considered to ensure you are making an informed decision. Below is a concise comparison highlighting key parameters:

- Amazon:

- Selection: Offers a broad range of products from various manufacturers.

- Customer Reviews: Provides extensive user feedback to help gauge product reliability and performance.

- Technical Specifications: Detailed descriptions including material type, length, diameter, and temperature rating.

- Price Range: Competitive pricing with frequent discounts and deals.

- Home Depot:

- Selection: Features a selection of heater hoses suitable for basic to intermediate needs.

- Customer Reviews: Moderately comprehensive reviews, primarily focused on mainstream products.

- Technical Specifications: Adequate product details including material composition and thermal performance.

- Price Range: Generally reasonable with occasional promotional offers.

- RockAuto:

- Selection: Extensive catalog tailored to a wide variety of makes and models.

- Customer Reviews: In-depth reviews and quality ratings specific to automotive needs.

- Technical Specifications: High level of detail including compatibility, material, pressure rating, and temperature range.

- Price Range: Variable, often offering competitive prices.

- AutoZone:

- Selection: Good mix of reputable brands and heater hose options.

- Customer Reviews: Sufficient reviews with a focus on fitment and durability.

- Technical Specifications: Comprehensive information including length, diameter, burst strength, and temperature capacity.

- Price Range: Fair pricing with loyalty rewards and occasional discounts.

- eBay Motors:

- Selection: Wide variety due to multiple sellers offering new and used parts.

- Customer Reviews: Variable quality of reviews; important to scrutinize seller ratings and feedback.

- Technical Specifications: Inconsistently detailed, requiring careful review of individual listings for specific parameters.

- Price Range: Broad range with potential for finding lower prices.

When choosing the best heater hose for your vehicle, focus on parameters such as material type (e.g., rubber, silicone), internal/external diameter, length, burst strength, and temperature rating. Ensuring these parameters align with your vehicle’s requirements will lead to a more reliable and satisfactory purchase.

Checking Online Reviews and Ratings

When evaluating online reviews and ratings for heater hoses, it is crucial to prioritize those that offer detailed insights into fitment, durability, and performance. Look for comprehensive feedback from verified purchasers and cross-reference reviews across multiple platforms when possible. Pay special attention to consistent praise or issues highlighted in various reviews, as these can indicate the most reliable products or common pitfalls to avoid. Also, scrutinize seller ratings and feedback, particularly when purchasing from marketplaces like eBay Motors where the quality and accuracy of listings can vary significantly. This diligent approach will help you make an informed purchase that meets your vehicle’s specifications and your quality expectations.

Reference sources

-

-

Everything You Need to Know About Water Supply Lines: This article offers an in-depth look at water supply lines, their components, and their importance in home plumbing systems.

-

What You Need To Know About Your Water Supply Lines: This source provides detailed information about water supply lines, including their role in supplying hot and cold water throughout a property.

-

Your Water Supply Line Explained: Useful Information For Homeowners: This guide explains the essentials of water supply lines and helps homeowners understand how these crucial piping systems operate within their homes.

-

Frequently Asked Questions (FAQs)

Q: What is a heater pipe and how does it function in a vehicle?

A: A heater pipe is a component that transports heated coolant from the engine to the heater core, where the air and coolant systems exchange heat to warm the vehicle’s interior. It’s crucial for maintaining comfortable cabin temperatures during cold weather.

Q: What types of heater pipes are available?

A: There are various types of heater pipes, including the engine heater hose assembly compatible with several vehicle models, safety stripe standard straight heater pipes, and heater hose coolant radiator straight pipes. The specifics will vary depending on the vehicle’s make and model.

Q: How can I determine if my heater pipe needs replacement?

A: Signs that a heater pipe may need replacement include visible wear and tear, leaking coolant, overheating engine, and poor heating performance inside the vehicle. It’s advisable to conduct regular inspections and follow any loading recommendations provided by your vehicle’s manufacturer.

Q: Are there heater pipe kits available for easy installation?

A: Yes, there are heater pipe kits that include all necessary components for installation. These kits can be particularly useful for DIY enthusiasts or when performing maintenance without professional assistance.

Q: Can I buy heater pipes online?

A: Yes, you can purchase heater pipes and related components online. Websites like amazon.com offer a range of options. Additionally, many automotive parts stores offer ‘buy online pick up in store’ services for added convenience.

Q: What does ‘engine heater hose assembly compatible with select chrysler’ mean?

A: ‘Engine heater hose assembly compatible with select chrysler’ refers to a heater hose assembly that fits specific Chrysler vehicle models. These assemblies are designed to meet the dimensions and requirements of Chrysler’s coolant systems.

Q: What should I look for when choosing a heater pipe?

A: When selecting a heater pipe, consider factors such as compatibility with your vehicle (e.g., hose assembly compatible with select chrysler), durability (e.g., safety stripe standard straight heater pipes), and pressure ratings (e.g., heater hose coolant radiator straight 100psi).

Q: How can I ensure the longevity of my heater pipes?

A: To ensure the longevity of your heater pipes, follow the manufacturer’s maintenance schedule, use the correct coolant (e.g., motorcraft coolant), and avoid using incompatible products. Regularly inspect pipes for signs of wear and replace them as necessary.

Q: Do heater pipes affect the engine’s cooling system?

A: Yes, heater pipes are part of the engine’s cooling system. They transport coolant between the engine and the heater core, playing a crucial role in maintaining optimal engine temperature and providing cabin heat.

Q: Are there any safety considerations when replacing heater pipes?

A: Safety considerations when replacing heater pipes include ensuring the engine is cool before starting work, using appropriate tools, and following the manufacturer’s instructions closely. Additionally, ensure all connections are secure to prevent coolant leaks.