The requirement for accuracy and specialization has been the highest it ever was in the current world of manufacturing, which is continuously changing. Among many other things, these are among the significant reasons gravure laser machines have become pioneers in this wave of change; they offer businesses never-before-seen chances to improve their production capacity. This blog post will look at what gravure lasers can do and how useful they are. We will also consider where and when it can be applied to create customized objects for different industries. These units enable a person to have more flexibility in design as well as simplifying work processes. Besides, they open up unlimited previously hidden possibilities, thus paving the way for new ideas and products that meet specific market needs. Let’s dig into some features and uses of engraving lasers so that you can change your custom fabrication game through them.

What is a Gravure Laser and How Does it Work?

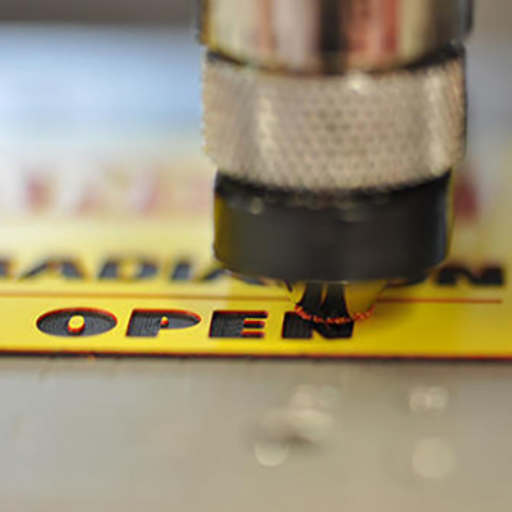

Image source: https://www.nouvelleecole.fr/

The engraving of images onto a cylindrical surface to produce high-quality prints is achieved using a modern technology known as gravure laser. This implies that delicate designs can be carved into the material precisely by altering its surface using light. This is done by directing different pulses of controlled lasers, which get rid of materials until they form an image, which can be used for printing. Consequently, it brings about a printout that is very detailed and uniform, thus making gravure lasers suitable for decorative packaging and labels, among other things. Manufacturers can reduce lead times and waste materials during production through design flexibility and efficiency enhancement made possible by lasers.

Introduction to Gravure Lasers

The combination of traditional gravure printing methods with the latest laser technology characterizes gravure lasers, which has dramatically improved the printing process’s potential. Employing high-precision laser engraving can enable companies to achieve unmatched precision and uniformity in their prints, making such technologies most useful for applications that need complex designs and lively colors. Gravure lasers speed up production time through quick design changes, allowing businesses to respond rapidly to market needs. Moreover, gravure laser technology’s ability to produce personalized, high-quality prints on different materials further enhances its versatility, thus establishing it as a game changer in the manufacturing and printing industries.

Understanding Laser Engraving Technology

Laser engraving is accomplished using narrow beams of light that are precisely focused to carve through a material, leaving behind a permanent design or image. This works because it directs its energy onto an object’s surface until it either evaporates or melts off. These devices can make very complicated patterns with tremendous accuracy, which would have been impossible otherwise due to their ability to create details at microscopic levels. This invention finds applications in many different fields like manufacturing and signage systems, among others, because it can work on metals, including gold and silver, as well as ceramics, such as porcelain and glass, while still delivering top-notch results every time without fail. Thus, laser etching is a contemporary solution for customizable items demanded by the current market where speed matters most.

Applications and Uses of Gravure Lasers

Gravure lasers are used in many different fields because they can create top-quality prints with wonderful details. One main use is flexible packaging, where gravure printing makes bags, pouches, and wrappers that must be eye-catching and robust. It is also applied to label printing to produce complex designs that catch customers’ eyes on shelves.

Another significant use is in publishing, where gravure lasers enable high-volume magazine or brochure printing while keeping quality and color fidelity consistent throughout each copy produced. Textile companies, too, have started adopting this technology by using it to print colourful fabrics with intricate patterns, thus making fashion and home decor items more visually appealing. In general, due to its ability to be able to deliver accurate results every time regardless of what kind of material is being worked upon, Gravure laser systems’ versatility makes them indispensable components across various industries where excellence matters most in the printed output.

How to Select the Right Laser Engraver?

To ensure that it suits your needs, there are several things to consider when choosing the correct laser engraving machine. First, you should look at what materials you want to work with because different engravers are optimized for different substrates like wood, metal, or acrylic. After that, think about how deep and accurate the engravings need to be; higher-wattage machines can do deeper cuts faster due to more power. Another thing to consider is the engraving area’s size: if you have larger projects, you may need one with more workspace. Also, consider software compatibility – ensure it works seamlessly with your design programs. Finally, check the manufacturer’s customer support/warranty options – sometimes, good service can save you lots of headaches with equipment problems down the line! Considering these factors, you can select a laser engraver that best meets your project requirements and operational goals.

Key Factors to Consider When Buying a Laser Machine

The laser machine selection process requires thoroughly evaluating several vital factors to deliver peak performance for your desired applications.

- Laser Type: Establish if you need a CO2 laser, fiber laser, or any other type. CO2 lasers are best for working on non-metal materials like wood and acrylic, while fiber lasers are perfect for cutting through metals with high precision.

- Power and Speed: The power output in watts directly determines how well the machine will engrave or cut. Higher wattages usually allow for faster cutting speeds and deeper engravings, so one must select the right power level depending on their project requirements.

- Size of Work Area: When dealing with large-scale projects, it becomes essential to consider the size of the engraving / cutting bed. Carefully evaluate its dimensions to avoid limiting yourself when accommodating various materials you may want to work with.

- Compatibility With Software: It is also crucial that any chosen laser machine be compatible with the design software(s) that you intend to use. This ensures seamless integration, which can significantly improve workflow efficiency and save time during the design stage through the production process until the final product is realized.

- Ease of Use: Some machines have features that make them easy to operate, such as user-friendly interfaces or pre-set engraving settings, especially if there are many operators who will use these machines at different times.

- Customer Support and Warranty: Many suppliers offer strong customer support services and extended warranties covering their products’ lifespan; this provides peace of mind should anything go wrong, thus making customer care an important factor worth considering before making a purchase decision.

By considering all these factors, one can always make an informed choice that considers both their creative vision and operational requirements.

The Importance of Material Compatibility

When one is choosing a laser engraving machine or cutter, material compatibility is essential because different materials react differently to laser processes. For instance, CO2 lasers work best with organic materials like wood, acrylic, and leather, while fiber lasers are more suitable for metals like steel and aluminum. Using an appropriate laser on your material ensures good-quality results and makes production safer and faster. Additionally, having knowledge about specific requirements for various materials like optimum power settings and speed may contribute towards achieving finer engravings with reduced waste, thus improving the general outcomes of projects. In conclusion, it is crucial to select a machine that can process the substances you intend to use; this will enable you to realize what you want creatively as well as achieve the highest level of fineness in your work.

Popular Laser CNC Brands and Models

Quality, reliability, and features are the most important factors when choosing a laser CNC machine.

- Epilog Laser: These machines are well-known among professionals for their precision and speed of engraving. They have several models, such as the Zing and Fusion Pro series, that come with an enhanced user interface for easy operation.

- Trotec: Trotec laser machines are loved worldwide because of their cutting speed, which no other competing brand can match. Rayjet and Speedy series have automated focus-setting abilities and can work on many materials.

-

Gravotech: Gravotech makes the LS series of engraving and marking lasers. Although these devices may be small, they are powerful enough to handle industrial engravings and personalized products because of their simplicity in design and ease of operation.

So when considering which brand or model might be most suitable for your project – whether based on cost-effectiveness, performance levels, etc.- always remember one thing: reliability matters!

What Materials Can You Engrave with a Gravure Laser?

Gravure lasers are versatile tools that can be used to engrave various materials and, therefore, have several applications. Examples of these include:

- Timber: For creating complex patterns or personalized things.

- Acrylic: It produces bright engravings, which is why it is commonly used for signs and displays.

- Plastic: Ideal for branding objects and making prototypes

- Leather: Fashion products, accessories, promotional items

- Metals: Small-sized lasers can mark metals like stainless steel or aluminum; this makes them perfect for custom engraving.

- Glass: Detailed engravings are possible on glass, often used for awards or gifts.

By adjusting the settings on the laser cutter, you can effectively engrave all these materials, allowing creativity and professionalism in design work or manufacturing processes.

Working with Wood, Bois, and Other Natural Materials

If you are working with wood or other natural materials and using a gravure laser, it is essential to know the characteristics of each. Wood can produce very detailed engravings with sharp contrast, especially when using softer kinds such as pine or birch. Lowering the speed and raising the power setting often helps achieve deeper depths and more excellent crispness.

Natural materials like cork and bamboo can also be engraved effectively; normally, cork gives off a distinct texture, while the latter boasts unique grain patterns that add beauty to any finished work. It is good practice for all natural materials to be well prepared, i.e., sanding down surfaces and cleaning them before engraving, leading to higher quality cuts with more accuracy. There are many reliable online sources where one can find more ideas about methods or parameters specific to different woods and other natural resources, ensuring an easy engraving process characterized by stunning outcomes.

Marking and Cutting Metal

Precision and settings are everything when it comes to marking and cutting metal with a laser engraver. What sort of metal is being utilized, and what are the specifications for your laser? These two things will determine whether or not the operation is effective. Fiber lasers work best on metals such as stainless steel or aluminum because they have shorter wavelengths, allowing more energy absorption near their surface.

People often use lower speed and higher power settings when marking stainless steel to get good-quality engravings. If you want clean edges without burn marks, slow speeds at high power levels should be used to cut through thick materials. Engraving or cutting may cause warping if there is not enough ventilation around it, so ensure there’s adequate air circulation during these processes. Look at manufacturer recommendations plus tips from industry experts; this way, you can get better results while working on various metal projects.

Engraving on Glass, Ceramic, and Other Fragile Surfaces

When etching fragile materials such as glass and ceramic, one should be cautious enough not to damage them but still achieve quality results. The recommended laser is usually CO2 to work on glass since its wavelength works well with non-metals. To avoid cracking the glass, one can lower the power of the laser and increase its speed to produce fine details. Sometimes, when engraving through something like this, some protective coatings may be used in order not to make it break much more accessible.

Similarly, delicate ceramics should use low-power settings so that lasers do not create chips or cracks. For better control over the depth of an engraving, you can try a raster engraving technique, which allows more flexibility in terms of controlling depths while engraving through certain areas. Before settling on a final design, you must experiment with different setups using scrap pieces because every material behaves differently.

In all cases where there’s risk involved due to fragility, cleanliness around your working area coupled with proper securing of materials being engraved cannot be overlooked if one is looking forward to achieving accurate, professional-looking finishes. More detailed tutorials on specific methods used for various materials could help improve skills and creativity during an engraver’s artistic journey; hence, websites with good reputations are worth exploring further.

How to Maintain and Handle a Laser Machine?

A laser machine must be adequately maintained for excellent performance and longer life. Firstly, remove any residues or dirt on the lenses or mirrors because they can significantly impact the quality of the engraving. In addition, one should ensure that the optics are aligned correctly so that the laser beam is focused correctly, enabling accurate cuts and engravings.

Moreover, belts, bearings, and motors need to be checked for signs of wear out; where necessary, lubrication should be done for them to operate smoothly. To keep air flowing well and prevent overheating, replace air filters regularly. Always follow the manufacturer’s instructions concerning the maintenance schedule and procedure; record everything done during servicing to monitor changes with time regarding machine condition. Lastly, it is essential to ensure that those who handle it are trained on safety precautions to reduce accidents while creating a safe working environment.

Routine Maintenance Tips for Your Gravure Laser

To guarantee that your engraving laser works effectively and has a long life, here are some maintenance tips:

- Cleaning: Clean lenses and mirrors regularly using appropriate cleaning solutions to avoid contaminants interfering with their performance. It is advisable to always wipe these parts gently using soft, lint-free cloths.

- Checking Alignment: Always verify the alignment of optics frequently because incorrect alignments cause uneven engravings and cuts; hence, adjustments should be made for accuracy purposes.

- Inspect Mechanical Parts: Belts, bearings, and motors must be checked often for signs of wear so that immediate replacements can be made where necessary. Also, ensure moving parts are adequately lubricated to prevent friction, which might lead to overheating.

- Updating Software: Ensure the laser software is regularly updated to benefit from new features and improvements that come with it. This will make operations more efficient, thereby resulting in sound output.

- Training Users: All operators involved should receive training on how best to handle different types of machines and maintenance procedures, which need to be followed strictly if errors are to be minimized while at work.

Adhering to these points will help maintain the performance of gravure lasers during engraving projects by ensuring quality results.

Proper Handling to Extend the Lifespan of Your Machine

Proper care and operation of the machine are necessary to make your gravure laser last longer. Here are a few of the things you should do:

- Follow Instructions from Manufacturer: Always stick with what the manufacturer says about how often it should be maintained or operated on. It will make sure that your usage is within its limitations.

- Don’t Overload: Do not exceed the machine’s capacity. Doing so may cause overheating and early part failure.

- Operating Environment Awareness: Ensure there is a stable environment around where this device operates. Temperature, humidity levels, dust particles, etcetera, can all affect its performance and durability.

- Make Routine Checks: You should have an inspection system for checking electrical connections and other mechanical components frequently. This is important because, through regular checks, potential problems can be identified and corrected before they become severe.

- Shutdown Right: Always shut it down correctly after using it by turning it off properly, then wait before switching off the power supply abruptly, as this might lead to damaging delicate parts.

By adopting these handling methods, you will dramatically improve the usefulness of your gravure laser printer.

Common Problems and Troubleshooting Tips

When using a gravure laser, users can face several common issues affecting its efficiency and performance. Here’s what to look out for:

- Inconsistent engraving quality: If the depth or clarity of the engraving varies, clean the focusing lens and check its alignment. You should also confirm material settings and adjust speed/power levels accordingly.

- Overheating: Frequent shutdowns or warning signals may indicate that the machine is overheating. Ensure adequate ventilation/cooling systems, remove obstacles blocking airflow around the device, and take periodic breaks during heavy use.

- Electrical problems: Engraving may be interrupted by sudden power cuts or failures. Secure all electrical connections tightly, inspect power supplies for faults, and consider using surge protectors against voltage spikes, which can also cause damage!

By proactively dealing with these typical issues, operators can keep their gravure lasers efficient over time while maximizing their helpful life spans.

Where to Find Digital Files and Designs for Laser Engraving?

The best results can only be achieved by finding the highest quality digital files and designs with laser engraving. There are several different online platforms that you can use to find a broader range of ready-to-use files, including:

- Design Marketplaces: Etsy, Creative Market, and Design Bundles are all such websites, all of which offer downloadable designs for purchase (or sometimes even free). They typically categorize these products under “laser cutting” or “engraving.”

- Stock Images and Vector Art Sites: Shutterstock, Freepik, and similar resources provide scalable vector graphics (SVG), among other formats better suited for laser engraving. Just be sure to read up on their licensing agreements for commercial use.

- Laser Engraving Communities: Sharing designs with other enthusiasts is always fun! You can join an online forum or social media group dedicated to laser engraving, such as Reddit or Facebook, where members often give away free files or sell them at low cost.

- CAD Software Libraries: If you’re handy with design software like AutoCAD or Adobe Illustrator, there are usually lots of templates available within those programs, but don’t forget about creating your own custom designs, too!

Using these resources, you should be able to find many different types of designs that will suit your specific needs for engraving projects.

How to Create Custom Designs for Your Engraving Projects

- Canva: Canva is a simple graphic design tool with an intuitive interface for creating your own designs. You can start from scratch or modify templates to fit your engraving needs. All you have to do is choose the dimensions of your design, add text, shapes, and images, and then export it in a laser-engraving-friendly format.

- Inkscape: Inkscape is a free, open-source vector graphics editor that’s great for creating scalable designs to be engraved. Like Adobe Illustrator, it has powerful features that allow users to create complex SVG files using various drawing tools, layers, and path operations. So, it’s perfect for projects that need lots of customization.

- Adobe Illustrator: If you can access premium software like Adobe Illustrator (an industry-standard tool for creating precise vector graphics), then lucky you! This software has more design capabilities than most people will ever need – but they’re there if you want them – so it’s perfect for highly detailed designs explicitly optimized for engraving. There are also tons (I mean TONS) of options when manipulating shapes/text, so every design can be unique AF and tailored to individual needs.

Use these platforms and make custom designs that enhance your engraving projects, giving each piece a personal touch.

Using Illustrate and Graphic Software for Precision

You have to use graphic software to make precise designs for laser engraving.

- Creative Bloq: Most notably recognized for its detailed reviews and step-by-step tutorials, it offers information on the top graphic design software available for laser engraving. They cover everything from picking the right tools to mastering advanced techniques – making this site perfect if you’re trying to improve your skills as a designer.

- Vecteezy: This platform offers a wide range of free vector graphics and design resources for engraving projects. With a huge library of customizable graphics, Vecteezy lets users find and edit designs so they can be engraved with utmost precision according to their needs.

- Tuts+: Tuts+ features extensive courses and tutorials on graphic design software such as Adobe Illustrator and Inkscape. Their guides are perfect for both beginners and experts because they provide the necessary tips to create accurate, intricate designs suited perfectly well for laser engraving.

Take advantage of these sources if you want better results with your engravings; they will help refine your design skills, which leads to accuracy when engraving and eventually produces refined outputs.

How Does Laser Engraving Compare to Other Methods?

Laser engraving differs from other engraving methods because of its accuracy and versatility. Rotary engraving or chemical etching are some of the conventional techniques, unlike laser engraving, which uses light beams to remove material with high precision, allowing for complex designs with beautiful details. Not only this, but laser engraving can also work on many different materials, including wood, acrylics, glass, and metals, thereby making it applicable across various projects.

This means that in most cases, physical contact is required when using these other methods, which often results in wearing out tools and giving uneven outcomes. Additionally, laser engraving is more efficient than any other method since it works faster; sometimes, there may be no need for setting up or cleaning after the process has been completed, unlike what happens in traditional ways where much time has to be spent before starting or finishing an operation. In general terms, among all other custom engraving methods available today, laser engraving is not beat because of accuracy coupled with speed, plus the fact that it can work on any material.

Advantages and Disadvantages of Laser Engraving

Laser engraving has several benefits, making it a good choice for many applications. They are as follows:

- Great Accuracy: It gives excellent accuracy; hence, one can make detailed designs and complex patterns, which would be difficult using traditional methods.

- Flexibility: This method can be used to work on different materials, including wood, glass, metal, and plastics, thus allowing for a wide range of products.

- Minimal Material Waste: Compared to other processes, laser engraving produces less waste by removing only the materials needed to create the design.

- Speed and Efficiency: Normally faster than traditional engraving methods, leading to shorter turnaround times for projects done through it.

On the other hand, some negative points need to be considered:

- High Initial Cost: Setting up this technology requires considerable investment, so small businesses may be unable to afford it.

- Material Limitations: Not all materials are suitable for laser engraving. Certain types of plastics can release harmful fumes when subjected to heat.

- Surface Limitations: The finish of an engraved surface may vary depending on the material used, thus sometimes failing to meet aesthetic expectations; some materials might require post-processing to achieve the desired look after being engraved.

- Skill Requirement: Users must have a certain level of technical know-how and design software skills to operate these machines, implying that additional training might be needed for them.

In conclusion, while laser engraving provides opportunities for higher precision and more comprehensive applicability, users should consider these strengths against their potential weaknesses.

Comparing CNC and Traditional Engraving Techniques

Several vital differences arise when comparing CNC engraving with traditional engraving methods. In this case, computer numerical control (CNC) is used to automate the carving process. This brings about precision and consistency, as well as the ability to duplicate complicated designs even without human involvement. On the other hand, conventional engraving relies heavily on manual skills. It can be done using hand tools or rotary machines, which gives it a more hands-on feel but varies in quality depending on the skill level involved.

CNC engraving is typically faster than traditional methods in terms of speed and allows for complex projects to be handled quickly. However, there are still some unique craft qualities that only come with doing things the old-fashioned way, where each piece is made by hand, thereby reflecting individuality through style. Another thing that sets these two processes apart is pricing; while starting up may require heavy investments into equipment for computerized numerical control systems (CNC), initial investment for analog machines could be lower, although they might need more labor hours to complete.

In summary, factors such as project requirements desired aesthetics, and budget constraints determine whether one chooses between CNC and traditional machining. All these methods have their own strengths, so proper consideration should be given to given task requirements before settling on any particular technique.

Why Choose Laser for Custom Projects?

Many professionals and hobbyists choose laser engraving for custom projects for several reasons. The first reason is its precision and detail, unmatched by any other engraving method. It can etch intricate designs into wood, glass, metal, or acrylic surfaces, among others. Such accuracy ensures that even the most complicated patterns are replicated consistently, making every piece unique but equal in quality.

Furthermore, compared to conventional techniques, laser engraving is generally faster, reducing production time significantly while maintaining high standards at all times. This speediness proves very useful for enterprises that need to complete orders quickly. What’s more, the flexibility shown by this technology allows it to work with different materials and formats, thus broadening the scope of application for customized works.

Lastly, when engraving with lasers, there is no contact between them and what they cut through; therefore, little or no harm is caused to the latter, resulting in fine finishes on good-looking items. In summary, laser engravers should be considered whenever one requires accuracy, swiftness, and variety during their personalization processes.

Frequently Asked Questions (FAQs)

Q: What is a gravure laser cutting machine?

A: A gravure laser cutting machine is a high-precision device that uses focused laser beams to cut or engrave intricate patterns, designs, and shapes on various materials such as metal, wood, and plastic. The de gravure laser sur technology allows for detailed customization, making it ideal for creating unique, custom items.

Q: How does a gravure laser cutting machine work?

A: The machine emits a laser beam that precisely cuts or engraves into the material based on a digital drawing or design. The laser cutting process involves the laser scrupulously following the pattern without physical contact, ensuring high accuracy and intricate details in the final item.

Q: What materials can be used with a gravure laser cutting machine?

A: Gravure laser cutting machines can be used on a variety of materials, including wood, acrylic, stone, leather, glass, metal, and fabric. Their versatility makes them popular in customization shops and manufacturing settings.

Q: What are the advantages of using a fiber laser machine over traditional cutting methods?

A: Fiber laser machines offer several advantages, including higher precision, faster cutting speeds, reduced material waste, and the ability to cut complex designs with ease. They also require less maintenance and a cleaner finish than traditional cutting methods.

Q: Can I use a gravure laser cutting machine for DIY projects?

A: Yes, gravure laser cutting machines are perfect for DIY enthusiasts. They allow users to create personalized items like jewelry, decorative plates, and customized gifts with intricate designs. You can unlock endless creative possibilities with the appropriate settings and safety measures.

Q: What is the difference between fiber and CO2 lasers?

A: The primary difference lies in the source of the laser beam. Fiber lasers use optical fibers doped with rare earth elements, providing a more concentrated and precise beam suitable for metal cutting. CO2 lasers, on the other hand, use a gas mixture and are typically used for cutting non-metal materials such as wood, acrylic, and fabric. Both types have their specific advantages depending on the application.

Q: How do I maintain my gravure laser cutting machine?

A: Regular maintenance of a gravure laser cutting machine includes cleaning the lenses and mirrors, checking the laser tube for any wear and tear, ensuring proper alignment of the components, and keeping the machine free of debris. Proper maintenance ensures optimal performance and longevity of the machine.

Q: What types of cuttings and engravings can I achieve with a gravure laser machine?

A: A gravure laser cutting machine can achieve various cuttings and engravings, such as high-contrast logos, intricate patterns, detailed drawings, and layered designs. These machines are versatile enough to handle simple and complex projects, making them suitable for various industries, including jewelry making, packaging, and more.

Q: Is there a difference in accuracy between different brands of gravure laser machines?

A: Yes, the accuracy of a gravure laser cutting machine can vary between different brands and models. Brands like Trotec and manufacturers from China often have different specifications and quality standards. It is essential to review the technical specifications and user reviews and possibly test the machine before determining the best fit for your needs.

Q: Can I find tutorials or videos on how to use a gravure laser cutting machine?

A: Absolutely. Many manufacturers and DIY enthusiasts share tutorials and instructional videos on platforms like YouTube to help users understand the setup process, operational tips, and creative ideas. These resources can benefit beginners and advanced users looking to improve their skills.