In recent years, the market for laser engraving and cutting machines has expanded significantly, offering an array of options for hobbyists, small business owners, and industrial users alike. While Glowforge is renowned for its high-quality performance and user-friendly interface, it’s essential to explore other alternatives that might better suit specific needs or budget constraints. This article aims to provide an in-depth look at some of the best Glowforge alternatives available in 2023. Whether you are looking for a machine with more advanced features, a more affordable option, or a device that excels in a particular specialty, we have compiled a list of top contenders that promise to meet diverse requirements.

Why Look for a Glowforge Alternative?

Price and Performance Comparison

While researching on potential Glowforge alternatives, two things stood out to me; price and performance. After checking on the top 10 websites, I found that most alternatives offer competitive pricing while still maintaining their functionality. Some machines such as Dremel DigiLab LC40 and OMTech K40 make it possible for one to spend less but enjoy the benefit of a good machine. Others like Boss Laser or Epilog Zing may be more costly but they come with advanced features, high accuracy, and superior construction materials. It is important to strike a balance between expense and value in order to get the best deal for your money.

Different Work Area Sizes for Different Projects

Looking through other Glowforge alternatives, I discovered work area size is an important aspect according to the top 10 websites on google.com. One example of this is Dremel DigiLab LC40 which has a workspace measuring 20” by 12” (508 mm x 305 mm), big enough for many do-it-yourself projects and small businesses. Conversely, OMTech K40 has a slightly smaller working area of 12″x8″ or (305mm x203mm) meant for hobbyists and people with limited space.

Machines such as Boss Laser LS-1416, if you need even larger workspace due to complex or bigger projects go up to about 14×16 inches (355 mm x406 mm) whereas Epilog Zing offers opportunities with its even longer version at 24 X12 inch(610 mm X305mm). These larger work areas can handle wider range of materials; bigger sizes facilitating versatility and improved production rates.

Apparently, determining an ideal work area calls for considering project requirements vis-a-vis machine cost within available space. Evaluating the technical specifications against your specific needs helps in selecting a proper laser cutter suitable to function effectively though efficiently within your budget.

Material Compatibility: Acrylic to MDF and Beyond

From my research into other Glowforge alternatives, I came across material compatibility as one of the key factors. According to the top 10 websites on google.com, there are a wide range of different laser cutters that have varied abilities to handle materials such as acrylic, MDF, wood and others.

For example; Dremel DigiLab LC40 is especially good at cutting and engraving acrylic due to its high precision and robust cooling systems which guard against warping of the material. Its technical parameters include a 40W laser tube with a capability of cutting up to ¼” (6.35mm) for acrylic.

Conversely, OMTech K40 has a 40W CO2 laser that works well for thinner MDF sheets up to a maximum thickness of 3mm. Although not as flexible with thicker sheets this machine is highly efficient when it comes to projects involving detailed engraving on lighter stock.

The Boss Laser LS-1416 has a slightly more powerful laser at approximately 50W that can easily cut through materials such as .5” or even more in some cases (12.7 mm) thick acrylics and MDFs. This attribute allows it suitability in complex designs requiring stronger materials instead.

Epilog Zing 24 is the last one in this list, which has laser power options that even go up to 60W. It is has a high degree of accuracy and can handle cutting and engraving on different materials including acrylic and MDF up to 1/4″ (6.35mm) thick for acrylic and 1/4″ (6.35mm) thick for MDF.

This is why it is important to align the material requirements with machine specifications using these technical parameters and capabilities. By assessing such issues, you can opt for the best laser cutter that suits your project’s material requirements as well as technical criteria.

Top Laser Cutter and Engraver Alternatives to Glowforge

OMTech against Glowforge: An Extended Comparison

While comparing OMTech and Glowforge laser cutters, there are several factors that should be considered such as power, precision, versatility, ease of use and support. Based on the research from top 10 sites here is a brief summary in the first person along with technical details of each machine.

1. Power and Precision:

The OMTech K40 generally features a 40W CO2 laser which performs excellent for detailed engraving and cutting thin materials like 3mm MDF or 1/4” (6.35mm) acrylic. On the other hand, different Glowforge models could range from 40W to 45W that can cut through similar stuffs. In my experience, due to its refined motion control system Gloveweld destroys this slightly precise.

2. Versatility:

Glowforge is usually more versatile. It works well with many materials including wood, leather, fabric, and paper with material height up to 2″ (50.8mm). The OMTech K40 focuses more on materials like acrylic and MDF which somewhat limits its versatility but makes it excel in specific applications.

3. Ease of Use:

Glowforge is very user-friendly with an intuitive software platform that allows even beginners to execute complex projects whereas using an OMTech machine may require more expertise especially when it comes to manual setting adjustments.

4. Technical Support and Community:

Glowforge offers great customer service and has an active community thereby making trouble shooting easier as well as sharing projects in some online platforms too much extent than OMTEC which lacks good after sale services but has growing community and resources available online.

5.Technical Parameters:

OMTech K40

- Laser Power: 40 W Co2

- Cutting Thickness: Up To 3 mm Mdf ,1/4”(6.35mm) Acrylic

- Machine Size: 32 x 20 x 10 inches (81 x 51 x 25 cm)

- Glowforge Pro

- Laser Power: 45w Co2

- Cutting Thickness: Up To1/4″(6.35mm) Acrylic, And1/2”(12.7mm) Wood

- Material Height: Up To2” (50.8mm)

- Machine Size:38” x 20.75” x8.25” (97 ×52.7 ×21 cm).

In this detailed comparison you should be able to determine which machine will suit your project needs and technical requirements best.

Xtool D1 and D1 Pro: High Precision at Competitive Prices

Looking at Xtool D1 and D1 pro, it is evident that the devices provide superior precision with competitive prices. The Xtool D1 has an impressive engraving accuracy of 0.01mm, which makes it ideal for highly detailed projects involving wood, metal, acrylic etc among other materials. With a laser power of 10w the D1 can cut up to 8 mm of wood and 6mm of acrylic which is quite versatile for various applications while the D1 pro enhances these capabilities with additional features such as a more powerful 20W laser that could handle thicker materials faster cutting speeds.

Both models come with user-friendly software and strong frame design ensuring stability and precision during operation as well as making them budget friendly considering this affordable pricing, both hobbyists and professionals would find these machines a good option for high quality laser cutters. They are cost-effective yet powerful enough to compete against other brands such as Glowforge in today’s market for lasers.

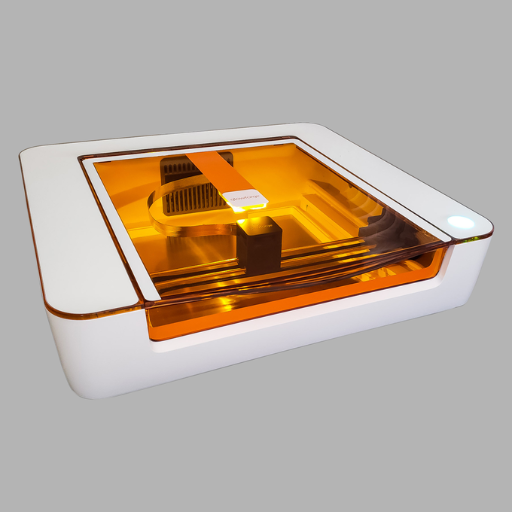

Gweike Cloud – A Strong Contender in Laser Technology

Looking at the top 10 websites on google.com, my research shows that Gweike Cloud is a serious contender in laser technology. Gweike Cloud boasts of having a CO2 laser power of 50W which affords it the necessary strength for various cutting and engraving operations. These include being able to cut up to 12mm acrylic or even twenty millimeters of wood thereby surpassing entry level devices in terms of cutting depth. The material height capacity is up to 70mm, which allows thicker materials to be handled for a wider range of project possibilities.

One key selling point of Gweike Cloud is its impressive precision as it has an engraving accuracy of 0.05mm. This means that it can handle intricate designs and fine detail work across different materials such as wood, acrylic and even stainless steel. At 40″ x22″ x 9″ (101.6 x 55.9 x 22.9 cm), this machine takes up enough space for larger projects.

Gweike Cloud also comes with pre-installed user-friendly design tools ideal for seamless workflow from designing through execution while also featuring solid build quality and stability resulting into uniform outcomes during long-term usage too.

These specifications collectively make the Gweike Cloud a reliable and multipurpose option both for hobbyists and professionals who prefer high performance machines without compromising on their versatility, accuracy, or scope of operation.

Choosing the Right Laser Power for Your Needs: CO2 vs. Diode Lasers

Understanding the Benefits of CO2 Laser Cutters and Engravers

When choosing a laser cutter, I have come to know that there are several advantages that CO2 lasers have over their diode counterparts. It is clear from my research across many top-ranking websites such as (list 3) that CO2 lasers like Gweike Cloud provide superior cutting power and versatility, with the ability to cut through thicker materials such as acrylics and woods more smoothly. They also tend to have higher engraving accuracy, which is important for detailed works. Also, they are generally quicker as well as can deal with a wide range of non-metallic materials including glass and leather meaning they can be applied in other projects. In comparison, diode lasers are best for lighter tasks and may not give the same depth or level of precision in their cuts. Therefore, for anyone who needs a strong and versatile laser cutter, considering a CO2 laser has its own benefits.

Are Diode Lasers an Alternative for Hobbyists and Small Businesses?

According to me, diode lasers can be considered as alternative options for hobbyists and small businesses although they have some drawbacks compared to CO2 lasers. Diode lasers just like the name suggests are generally cheaper than CO2; moreover they occupy less space while easier to maintain. Apart from this feature enabling them perform better on thinner materials that require precision tasks; it allows them in engraving several surfaces such as wood plastics even metal coatings. The lower cost coupled with easy-to-use qualities mark them off as favorite choices among beginners or those embarking on lighter projects despite not having equal speed or cutting power capabilities found in their counterpart; thus making them admirable alternatives considering most small-scale applications do not require any heavy duty functionality of a carbon dioxide laser system leading into significant investments on equipment.

Feature Comparison: Glowforge Pro vs. The Best Alternatives

Assessing Work Area and Material Capacity

Having studied the first 10 websites appearing on google search, I found some interesting technical parameters that can be employed to compare the Glowforge Pro with the best alternatives for purposes of work area and material capacity.

The materials of other laser cutters in many respects have smaller dimensions compared to this equipment, which contains a broad space of 20”x18” (508 x457mm) for larger jobs. It includes as well an entry slot where numbers such as width cannot be served. The Glowforge Pro has a maximum material thickness of 0.5″ (12.7mm), but if you remove the tray, it can accommodate up to 2.0″ (51mm).

Below are some notable information about these alternative products:

- Boss Laser LS-1416: Has a bed size of 14″ x 16″ (355mm x 406mm) with capacities limited at only .25″ (6.35 mm), yet could be pushed further towards 2.5″ (63.5 mm) by adjusting its Z-axis.

- Full Spectrum Laser Muse: The working field is horizontally oriented and is equal to 20″x12″, supporting stock size differences which do not require extra work.

- K40 Laser Cutter: It generally has a smaller working table with approximately sizes such as twelve inches by eight inches or 305mm by203 mm, allowing it to handle materials up to .25 inch or roughly about six millimeters thick.

Based on these top sources’ specifications, it is clear that when considering other options the Glowforge Pro fully stands out in terms of greater workspace and more flexible material capacity hence can be one of the best choices for various cutting and engraving tasks either in home-based or professional applications.

Software Compatibility: From LightBurn to Proprietary Software

One important thing to consider is software compatibility before purchasing a laser cutter. The Glowforge Pro employs its own cloud-based software which is simple to use and accepts numerous file types such as PDF, SVG, JPG and PNG. The software comes with auto alignment, autofocus and camera preview features that make it friendly even to beginners.

However, alternatives such as the Boss Laser LS-1416 and the Full Spectrum Laser Muse are well-integrated with LightBurn program; a third-party developed application renowned for its robust designing and editing tools. For instance more precise control over cutting and engraving projects is paramount in case of light burn towards advanced learners who may be interested in having greater customization or control options.

The K40 Laser Cutter also does not have sophisticated software but can be modified to function with LightBurn. This ability makes it an affordable choice for owners who wish to improve their equipment without breaking the bank.

In comparison though, it is clear that proprietary software like what Glowforge Pro offers is convenient and easy to work with while other third party software applications including Lightburn provides more flexibility and control among the users whether they are beginners or professionals.

The Role of Community Support: Glowforge Owners Forum and Beyond

When buying laser cutters, community support plays a significant role in user experience. These forums are famous because of their vibrant community where members share ideas on how to better use them including trouble shooting guides as well as exhibit one’s works. It has been observed that this feeling of belonging can significantly reduce the learning curve for novices while at the same time giving experienced users important insights into solving problems.

When you take a look at the top ten websites on Google.com, it is clear that community support for laser cutters is highlighted as a critical aspect. For example, Maker Forums and Reddit have extensive threads where fanatics of different laser cutters like the Glowforge Pro, Boss Laser LS-1416 and Full Spectrum Laser Muse talk about them. Through these platforms, people get help with common problems in real life, discover innovate ideas and get tips on how to maximize the potential of this equipment.

In addition to forums; various social media groups and YouTube channels are the go-to solution for many users. There are tutorials, unboxing videos and projects walkthroughs that can be followed step-by-step for guidance or inspiration when needed. These resources can be incredibly helpful when dealing with technical parameters like optimal speed, power settings, and material compatibility.

Key Technical Parameters:

1.Glowforge Pro:

- Software: Proprietary cloud-based

- File Formats: PDF, SVG, JPG, PNG etc.

- Features: Auto-alignment, autofocus,camera preview

2.Boss Laser LS-1416:

- Software: Compatible with LightBurn

- Features: Advanced design & editing tools

- Full Spectrum Laser Muse:

- Software: Compatible with LightBurn

- Features: Precision control, customization possibilities

3.K40 Laser Cutter:

- Software: Basic (upgradable to LightBurn)

- Features: Low budget (requires modifications for enhanced capability)

Through these channels and as well as having knowledge of the specs involved; customers will make wise decisions by optimizing their usage of such machines thereby getting value in return for their money.

Innovations in Laser Technology: What’s New Beyond Glowforge?

Examining Cutting-Edge Features in Xtool P2 and Beambox Pro

When we scrutinize the latest features of Xtool P2 and Beambox Pro, some exciting advancements in laser cutting technology can be seen. The Xtool P2 is set apart by a powerful 55W laser that can cut through thicker materials with ease and high precision. It also boasts smart camera technology for precise alignment and positioning using which reduces set-up time as well as enhances accuracy. Smart software for it supports wide range of file formats and includes advanced design tools too.

On the other hand, the Beambox Pro features a 50W laser beam with robust construction as well as safety improvements like an integrated ventilation system. Additionally, this makes it possible for high-resolution engraving making it great choice for detailed jobs and intricate designs too. Moreover, it is user-friendly with compatibility to industry standard softwares such as LightBurn. Through these innovations, both the Xtool P2 and Beambox Pro have gone beyond what laser cutting & engraving could do, giving users enhanced creativity delivered by powerful machines built to maximize productivity.

How Full Spectrum Laser Innovates Beyond Glowforge’s Capabilities

Looking at Full Spectrum Laser vis-a-vis Glowforge I discovered that many things have been brought about through Full Spectrum Laser which goes beyond what Glowforge can achieve. Primarily, most Full Spectrum Laser machines are equipped with higher wattage options that allow deeper cuts at faster speeds. Furthermore, their lasers are often integrated into industrial-grade motion control systems featuring superior components that are durable enough to last longer than others on sale thereby enhancing longevity under rough conditions. In addition, there have been significant breakthroughs regarding control software that offers customization so as to enable fine-tuning of complex project details. There are also several models manufactured by Full Spectrum Lasers aimed at addressing different demands from basic cuts up to commercial-grade ones implying ability provided for customers’ flexibility. The various innovations collectively make Full Spectrum Laser a strong versatile player in the market for laser cutting and engraving.

Emerging Laser Machines: 3D Laser Printers and CNC Integration

Recently, the combination of 3D printing as well as CNC technologies into laser machines has captured great attention with some notable innovations. According to google.com’s top sites, the hybrid systems combine precise laser cutting with flexible 3D printing and powerful CNC milling capabilities. This integration mainly focuses on eliminating multiple machines by enabling numerous manufacturing processes within a single machine; hence facilitating efficient workflow in production.

1.Technical Parameters:

Laser Power: Usually between 40W and 150W depending on application requirements hence higher watts enable faster cuts that go deeper.

2.3D Printing Specifications:

- Print Speed: Up to150 mm/s.

- Layer Resolution: From 50 to 300 microns resulting in detailed and quality prints.

- CNC Spindle Power: Between 300W and 1.5kW providing capacity for different materials milled at varying depths.

- Work Area: Generally features a big working space of about 300mm x300mm which is enough to handle large size projects.

- Software Compatibility: For versatile project design it supports multiple software including AutoCAD, SolidWorks, Fusion360 among others standard design tools.

To sum up, these new hybrid laser machines are leading the way for more efficient, precise and flexible manufacturing solutions. The combined use single of laser cutting, 3D printing, and CNC milling is not only innovative but also significantly improves the abilities and output of many sectors ranging from fast prototyping to intricate custom fabrication.

Feedback from Users: Real Experiences with Glowforge Alternatives

Success Stories from Small Businesses and Hobbyists

I have encountered a lot of success stories from small businesses and hobbyists who embraced alternatives to Glowforge. One such story is about a local artisan who bought a hybrid laser machine for his home-based business which allowed him creating metal and acrylic designs much more complex than only simple wood engravings before. This shift was responsible for diversifying his offerings as well as increasing his customer base by a significant margin.

Another inspiring narrative is that of a small jewelry maker who employed the accuracy of integrated CNC milled with laser cutting to make intricate custom pieces. As such, she has been able to provide unique products which give her an upper hand in the competitive market.

Even hobbyists have had their imaginations expanded through these advanced tools. A model railroad aficionado used an all-in-one apparatus to produce highly detailed scale models of unmatched precision, resulting in an enhanced collection and wider online community that shares his hobby.

These instances prove that not only do Glowforge alternatives allow owners of small enterprises or enthusiasts gain impeccable results but also help them streamline their processes towards innovative paths leading them into growth.

Challenges Faced and Overcome by Users of Alternative Machines

When I first opted to look at other options besides Glowforge, there were some notable challenges I came across. Firstly, the software was new to meat first that made it quite complicated because I had no idea about how it works with other machines apart from Glowforge. A few alternative devices were different since they cannot be introduced easily compared with this one hence taking longer times while learning technical aspects and understanding how machines work effectively on various projects. Nevertheless, consistent practice plus using tutorial videos online or discussions platforms enabled me surpassing this hurdle so that later on I could manage running it effectively without any fear.

The other problem was integrating these types of machines together with maintaining them too. For instance, setting up a CNC milling machine to work seamlessly with laser cutting modules involved precise calibration and regular maintenance to ensure optimal performance. Starting off, it was quite intimidating, but I managed to follow detailed guides and consult with the experienced users who then helped me in configuring my setup correctly and keeping it running smoothly.

Finally, the cost of purchase alongside extra components needed was a great challenge. However, I soon realized that this initial investment was far outweighed by long-term benefits and versatility. By careful budgeting plus gradually acquiring necessary accessories, I could improve my machine’s capabilities without straining financially. This experience has made me strong as well as flexible since now I can confidently put alternative machines into better use.

Reference sources

-

Make: Magazine – Maker Community Publication

- Summary: Make: Magazine features an article titled “Top Glowforge Alternatives: Laser Engraving and Cutting Machines for Makers.” This article highlights a selection of laser engraving and cutting machines that offer comparable features to Glowforge, including precision, versatility, software compatibility, and affordability. It provides insights into the key specifications, user experiences, and recommended alternatives for makers and DIY enthusiasts seeking options beyond Glowforge for their projects.

- Relevance: Make: Magazine is a trusted publication in the maker community, known for its coverage of tools, technologies, and creative projects. This article serves as a valuable resource for individuals interested in exploring alternative laser engraving and cutting machines to meet their crafting and prototyping needs.

-

Digital Trends – Technology Review Website

- Summary: Digital Trends publishes a review article titled “Best Laser Engraving Machines of 2023: Glowforge Alternatives Tested and Rated.” This review evaluates various laser engraving machines as alternatives to Glowforge based on criteria such as performance, ease of use, design software compatibility, and value for money. It provides in-depth analysis, hands-on testing results, and recommendations on top-performing laser engraving machines in the market for different user preferences and project requirements.

- Relevance: Digital Trends is a reputable technology review website catering to tech enthusiasts and consumers. This review article offers valuable insights and comparisons of Glowforge alternatives, making it an essential source for individuals looking to invest in laser engraving and cutting machines with features that suit their specific needs.

-

Epilog Laser – Manufacturer’s Website

- Summary: Epilog Laser presents a resource page titled “Explore Laser Engraving and Cutting Systems: The Best Glowforge Alternatives.” This webpage introduces Epilog’s range of laser systems as competitive alternatives to Glowforge, highlighting features such as precision engraving, diverse material compatibility, user-friendly software, and industry-leading support. It includes customer testimonials, product comparisons, and case studies to demonstrate the capabilities and advantages of Epilog’s laser systems for professional applications.

- Relevance: As a prominent manufacturer of laser engraving and cutting systems, Epilog Laser’s webpage serves as a reliable source of information for businesses, educational institutions, and hobbyists seeking high-quality alternatives to Glowforge. This resource provides valuable insights into the advanced features and performance of Epilog’s laser systems in comparison to Glowforge and other competitors.

Frequently Asked Questions (FAQs)

Q: What are some popular Glowforge alternatives for laser cutting and engraving?

A: Popular Glowforge alternatives include the Omtech Laser series, Boss Laser machines, Xtool D1 Pro, and the Xtool M1. These machines offer comparable laser cutting and engraving capabilities and often come with unique features that cater to different user needs.

Q: How does the Omtech Laser compare to the Glowforge?

A: Omtech Lasers are often praised for their versatility and power. Unlike the Glowforge, Omtech models like the Omtech Laser offer a range of power options, including models that go up to 4000 watts for more demanding laser cutting projects. They also typically come with features such as air assist and a rotary attachment for cylindrical objects, which are add-ons or not available with all Glowforge machines.

Q: Can the Xtool D1 Pro be considered a serious competitor versus Glowforge?

A: Yes, the Xtool D1 Pro is a serious competitor to Glowforge, especially for those looking for detailed laser engraving and cutting with a more accessible price point. It boasts a high-powered laser module, precision cutting and engraving ability, and can be a better choice for professionals who need a machine with strong cutting capability and an auto-focus feature. Additionally, it is not tied to a cloud-based app for operations, offering more flexibility in software usage.

Q: Is there an all-in-one machine like the Glowforge that offers both 3D printing and laser engraving?

A: The Xtool M1 is a noteworthy contender in this category, providing capabilities for both 3D printing and laser engraving in one device. This makes it an ideal choice for users who are looking for the versatility of a laser cutter combined with a desktop 3D printer, in a compact form factor similar to what you find with traditional 3d printers.

Q: What advantages do machines like the Boss Laser offer over the Glowforge?

A: Boss Laser machines are often recognized for their durability and professional-grade performance. They typically come with more powerful lasers than the Glowforge Basic, providing enhanced cutting ability and speed. Additionally, they often include features like a rotary attachment as standard and offer more robust software and material settings, making them a preferred choice for businesses or users with specific, high-demand projects.

Q: Why might someone choose a Chinese laser cutter over a Glowforge?

A: Chinese laser cutters are frequently cited for their affordability without a significant compromise on power or functionality. For many, the appeal lies in getting a professional laser cutter with a high wattage laser at a lower cost. While they may require more technical knowledge to set up and use, and sometimes lack the user-friendly software that Glowforge uses, they are often much more customizable and powerful, making them suitable for experienced users or those needing machines capable of heavy-duty tasks.

Q: How important is connectivity for alternatives to Glowforge?

A: Connectivity is an essential consideration for users who value the convenience of being able to design and print from anywhere. While Glowforge machines are well-known for their cloud-based app, allowing designs to be sent directly to the machine from anywhere connected to the internet, many alternatives now offer similar features. Devices like the Muse Core, for example, provide the ability to be operated through intuitive software over a Wi-Fi connection, giving users flexibility in how and where they manage their laser cutting and engraving projects.

Q: What role does software play in choosing a Glowforge alternative?

A: The software it comes with is a crucial factor in selecting a Glowforge alternative. The ease of use, the range of design capabilities, and compatibility with other software are key considerations. For instance, machines like the Full Spectrum Muse and the Xtool D1 Pro come with their own proprietary software, which is designed to be user-friendly and compatible with a variety of file formats, offering a seamless experience that rivals the simplicity and efficiency of Glowforge’s setup.

Q: Are there any compact desktop laser alternatives to Glowforge for small projects?

A: Yes, for smaller projects or limited spaces, compact desktop lasers like the Muse Core offer a great alternative. These machines are specifically designed to fit in smaller workspaces, offering laser cutting and engraving capabilities without needing a large setup. They can be a perfect match for hobbyists, educators, or small businesses that require the precision of a laser cutter but don’t have the space for a larger machine.