Titanium, often referred to as the “wonder metal,” is renowned for its remarkable properties that make it indispensable in various industries. From aerospace engineering to medical applications, this metal’s unique combination of strength, low density, and corrosion resistance sets it apart from other materials. In this blog, we will delve into the fascinating world of titanium, exploring its properties, its versatile uses, and some interesting facts that reveal why it plays such a critical role in modern technology and innovation. Get ready to uncover the secrets behind one of the most extraordinary metals known to humanity!

What Are Some Fascinating Titanium Facts?

Historical Facts About Titanium

The discovery of titanium was made in 1791 by the priest and mineralogist, William Gregor, in Cornwall, England. He originally called it “manaccanite” due to where he found it – Manaccan parish. However, not until 1795 did the metal receive its current name from a German chemist Martin Heinrich Klaproth who named it after the Titans in Greek mythology. It was during the twentieth century that commercial production methods for titanium were refined using Kroll process invented in 1940 which led to its extensive use as an industrial material. This still is the most important technique of making titanium up to this day. Since Cold War times, first significant application of titanium occurred in military and aerospace sectors because of its strength-to-weight ratio and non-corrosive features.

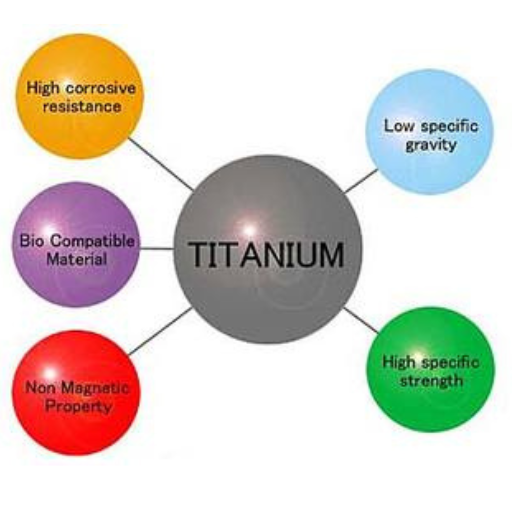

Fun Facts About Titanium’s Properties

- Biocompatibility: Titanium exhibits a high level of biocompatibility enabling successful utilization in medical implants without causing any adverse effects. Because of this property, titanium has become very popular for joint replacements such as knees and hips, dental implants and surgical instruments.

- Strength-to-Weight Ratio: Among metals, Ti possesses one of the highest strength-to-weight ratios. It is as strong as steel but weighs only about 45% of steel’s weight; thus, is highly valued in military and aerospace where reducing mass while maintaining strength is crucial.

- Corrosion Resistance: This metal has excellent corrosion resistance to even seawater and chlorine compounds. Resilience to rusting and corrosiveness makes it suitable for use under marine conditions as well as within chemical industries.

- Heat Resistance: Titanium can stand extremely high temperatures without losing its mechanical properties. As such it suits applications involving elevated temperatures such as aircraft engines or equipment used for space exploration.

- Non-Magnetic: The non-magnetism characterizes titanium which finds extensive use where magnetic influence should be minimized like MRI devices or electronic tools.

- Ductility and Malleability: Although it is hard, titanium exhibits very high levels of ductility and malleability that enable the shaping of thin wires or intricate shapes without fracturing. The material can be used in a wide range of industries including creativity.

Unique Titanium Uses

- Medical implants: As a result of its biocompatibility, titanium is commonly employed in medical implants, for example, hip and knee replacements, dental implants, and pacemaker cases. Technical parameters include the material’s high Young’s modulus and exceptional corrosion resistance, ensuring longevity and compatibility with human tissues.

- Aerospace components: The excellent strength-to-weight ratio of titanium enables it to produce aircraft parts such as jet engines, landing gear, and airframes. They have tensile strengths from 30 ksi to 200 ksi due to their capacity to operate at temperatures up to 900°C (1,672°F).

- Marine equipment: It is crucial that ornamental metals like steel are resistant to corrosions by seawater whenever they are used near marine environments. Examples include ship hulls along with propeller shafts in offshore drilling installations. It is resistance to crevice corrosion pitting provides robustness when exposed to saline.

- Sporting goods: For athletes’ bicycle frames or golf clubs made of this material will be both lightweight yet strong enough thus enhancing their performance while reducing fatigue experienced during practices. This makes it an ideal choice for performance-oriented sports equipment because its key attributes are density (4.51 g/cm³) and superior fatigue performance.

- Chemical Processing Plants: Thanks to its immunity against chemicals including both acids as well as bases which cause corrosion; therefore making heat exchangers tanks and piping systems in chemical plants. Its industrial resilience ensures that these systems function properly even under harsh chemical conditions.

- Consumer Electronics: In mobile phones, laptops or wearable gadgets, the non-magnetic nature of titanium is of importance in such gadgets and it helps avoid interference with the operation of a device. They have electrical resistivity (42 nΩ·m) as well as no reactive surface contributing to their use in this field.

- Art and Architecture: It can be moulded into intricate forms for both practical or aesthetic reasons due to its pliability and malleability. Such objects like sculptures, façade panels of buildings and jewelry are examples. A low coefficient of thermal expansion paired with high toughness make it an attractive option for innovative designs.

Why Is Titanium Used in Various Industries?

Titanium in Aerospace

Titanium is particularly deployed throughout the aerospace industry because of its incredible strength-to-weight ratio, corrosion resistance, and ability to withstand extremely high temperatures. These characteristics enable titanium as a metal with elevated energy density and low weight to be used in applications where its application can reduce the overall structural weight of an aircraft. Among other things, it stays structurally intact under the highly stressing conditions imposed on airframes and jet engines by temperature variations. Titanium is typically preferred when making landing gear, wing structures as well as fasteners due to its durability. This makes it a necessary content in building modern airplanes, space shuttles and helicopters.

Medical Implants from Titanium

Titanium is biocompatible, strong and resistant to corrosion; hence it is often used for medical implants. It does not have any poisonous elements that may affect human tissues thus reducing chances of allergic reactions. Its high tensile strength allows it to support considerable loads thus making it widely used in bone replacement systems such as joint replacements. By wearing out slowly this metal ensures that implantation continued working for long periods before becoming useless through wear and tear. Additionally, titanium’s osseointegration feature enables bone to grow into them thereby increasing their stability and performance rates which makes them appropriate for applications like dental implants. These are mostly used in dental surgeries, orthopedic procedures done using pins or plates, screws among others thus greatly helping patients during treatment process.

Construction With Titanium

In construction sector today people use titanium largely because of its excellent toughness and ability to resist extreme weather conditions. The light nature of titanium coupled with high tensile strength allows the construction of lighter yet stronger structures than those made from other metals. The longevity of this substance implies that it will endure harsh climatic conditions such as acid rain or sulphurous gases experienced by skyscrapers’ metallic frames when they are left ungalvanized over time unlike ordinary steel which only lasts up to 10-15 years. Moreover, its ability to keep the structural deformation that it had when subjected to temperatures changes makes it suitable for both cold and hot climates. It is thus a versatile material used in modern construction projects as it is dependable even in such conditions.

What Makes Titanium So Special?

Melting Point of Titanium

Titanium has an extremely high melting point that is about 1,668 degrees Celsius (3,034 degrees Fahrenheit). This attribute allows it to stay intact even when exposed to extreme temperatures making it suitable for use in aerospace and military sectors among other industrial applications. For instance, titanium is used in aircraft engines and space shuttles where good performance at high temperature is required. In addition to that, the high melting point makes it resistant to thermal expansion hence very durable as well as stable under conditions that can cause problems with most other materials. This unique characteristic makes titanium exceptional material in challenging environments.

Corrosion Resistance of Titanium

The thin oxide film formed on the surface of titanium due to exposure to oxygen forms the basis for its excellent corrosion resistance. As a result, this passive layer acts as a protective barrier thus inhibiting further oxidation or decay even in harsh surroundings. It is invaluable in marine, chemical processing and medical applications because it’s resistant to many kinds of corrosive substances such as seawater, chlorine and different acids. For instance, titanium implants and prosthetics are made from titanium because it is biocompatible and can be used within body fluids without breaking down. Due to its ability to resist corrosion; it becomes more economical since maintenance costs are lessened with extended life span of components made from titanium.

Titanium Is Stronger Than Aluminum

The strength-to-weight ratio of titanium is quite remarkable and especially so when compared with aluminum. Although both materials are known for their light weights; titanium has twice the strength of aluminum despite being only 60% heavier than it tis competitor. This increased strength is important where structural integrity and long-life are required such as aerospace manufacturing, automotive production, as well as military manufacturing among others. Additionally, unlike aluminium which may fail under harsh conditions; titanium maintains its mechanical properties at elevated temperatures providing better performance levels than aluminium does not have any impact on it. Therefore, titanium is highly efficient as a light weight material with sufficient mechanical strength to be used in high performance engineering solutions.

Where Can Titanium Be Found?

Titanium in the Earth’s Crust

By weight, titanium is the ninth most abundant element in the earth crust at about 0.63%. Predominantly, this is found in minerals such as ilmenite (FeTiO3) and rutile (TiO2), which are principal sources of titanium ore. These minerals are commonly located within igneous and metamorphic rocks and may be mined out. Ilmenite is more common and can be found in large amounts on beaches or river banks. The extracted titanium is then separated from these ores using various processes one of them being Kroll process where titanium tetrachloride reduced with magnesium to get metallic titanium. This makes it accessible but also highly valuable for different industrial applications due to its abundance and methods of extraction.

Titanium Ore and Its Extraction

Titanium extraction from its ore involves two main processes: Kroll process and Hunter process which is less used than the former. In a conventional Kroll process, Titanium dioxide (TiO2) is first extracted from either ilmenite or rutile. Using chlorine gas and carbon, the oxide transforms into TiCl4 that can be further reduced by magnesium forming porous titanium metal through a vacuum or inert atmosphere method. On the other hand, a hunter process utilizes sodium instead of magnesium within reduction step though it remains somewhat similar to kroll method as far as other steps are concerned. Both approaches illustrate complex ways for obtaining pure titanium metal from naturally occurring ores thereby suggesting its value as well as need for technical knowhow in manufacturing industry.

Abundance of Titanium as an Element

Being the ninth most widespread element on earth crust constitutes only about 0.63% of its composition making up Titanium’s abundance( Entry 1). The minerals ilmenite(FeTiO3)and rutile(TiO2) among others majorly contain it(Entry 2). Reasonable distribution of these minerals all over the world result to its accessibility. Despite titanium’s incidence extraction and refining processes like kroll method and hunters approach are relatively intricate and energy intensive thus affirming that it is of industrial significance or value due to technological advancement needed for its intended use. Of course, this abundance is associated with the desirable features of having high tensile strength, low density, and excellent corrosion resistance thereby making titanium an indispensable material in diverse industries ranging from aerospace to medical equipments.

How Is Titanium Used in Everyday Products?

The Role of Titanium Dioxide

Titanium dioxide (TiO2) has a lot to do with our daily lives, especially when it is used as the basic white pigment in such things as paints, coatings, plastics, papers, inks and foods, and most notably under this category – sunscreen. Due to its high refractive index titanium oxide scatters light noticeably well which gives it excellent opacity and brightness. This chemical makes another great use for sunscreens which are involved against harmful UV-rays. As well it is used in decorative cosmetics where it improves esthetics by covering up skin flaws and maintaining product stability. It is not only versatile but also non-toxic and inert thus can be applied in many ways.

Everyday Products Containing Titanium

It amazes me how titanium has been incorporated into everyday products so seamlessly. One of the materials that make up these types of things is titanium dioxide that I find in products like paint and coat giving them long life spans with bright white look. When I apply sunscreen on my body I put my trust into titanium dioxide because it is an excellent blocker of ultraviolet rays that can harm my skin after a long exposure to direct sunlight during summer days for example. In addition, there are dental items that contain titanium including implants, orthodontic tools among others due to its strongness and compatibility with biological tissues. In other words, I play sport using high-quality equipment made from this metal such as bikes or golf clubs that are both durable due to their lightweight structure than improves my performance while playing games. This implies that if one were to remove all the other elements apart from the metallic elements in normal day items then this would easily serve as an essential illustration of modern commodities.

Using Titanium in Alloys

In various industries, using titanium for alloys transformed material properties significantly. At the waytitanium is introduced into alloys; thus, its remarkable strength-to-density ratio makes it a crucial element of aerospace structures that are expected to be durable and lightweight. On the other hand, if titanium were added as an alloying element it would significantly enhance resistance to corrosion which is very important in marine environment and also medical implants that are expected to last for long time. I have come across titanium being used to make alloys for cars, thus contributing to the development of high power machines by raising engine efficiency and reducing overall weight. These features depict how much this metal matters in modern engineering and manufacturing specifically through its superior properties and wide range of uses with diverse adaptability.

Frequently Asked Questions (FAQs)

Q: What are some of the most interesting facts about titanium?

A: Some interesting things about titanium for example it has a high strength to weight ratio, is resistant to corrosion and is present in various industries like aerospace, medical and sporting goods. Besides, titanium is as strong as steel but 45% lighter.

Q: How and when was titanium discovered?

A: Titanium discovery dates back to 1791 when William Gregor, an amateur geologist found it. Subsequent in 1795, Martin Heinrich Klaproth a German chemist called the metal “titanium” after Greek mythology’s Titans.

Q: Why is titanium commonly used in medical applications?

A: The reason why titanium is widely used in medical applications is because it’s biocompatible i.e. non-harmful or toxic to living tissues. It is also used frequently as surgical instruments and implants including prosthetics due its strength.

Q: In which industries is titanium often used?

A: Such as those of aerospace engineering,titanium has been utilized by many other industries including automotive, medicinal sector and sports due to its extreme toughness, lightness of weight and resistance against rusting.

Q: Why does titanium not occur in its pure form naturally?

A: Titanium can not be found in its pure state since this element reacts vigorously with other elements. Normally it occurs together with minerals such as ilmenite and rutile that consist of compounds containing oxygen combined with titanium.

Q: What makes titanium a fantastic material for aerospace engineering?

A: Because this material offers excellent strength per unit mass ratio; can sustain high temperature environments without corroding at all thereby making it suitable for parts of airplanes or spacecrafts like the fuselage.