The introduction of fiber laser technology in industries has been a game changer for manufacturing and medical sectors among others. This state-of-the-art technique that is being used by modern applications is characterized by its superior accuracy, efficiency and versatility. In this blog, we will discuss the basic principles of fiber laser technology, talk about different ways it is applied today, as well as compare its benefits with those of traditional laser systems. Whether you are an experienced engineer or just curious to know more about fiber laser technology, this series will give you a comprehensive understanding and insights how to best apply it in your work. We invite you not to miss out on unravelling complexities underlying this incredible innovation that has revolutionized various industries.

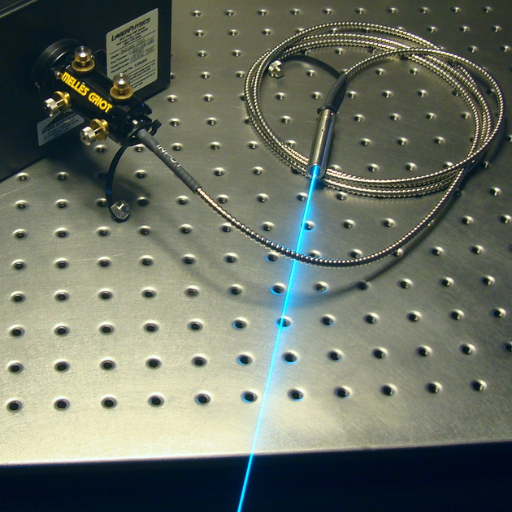

What is a Fiber Optic Laser?

Image source: https://www.s-laser.com/

A fiber laser is essentially a type of laser with an active gain medium in the form of an optical fiber doped with rare-earth elements such as erbium, ytterbium, thulium or neodymium. These lasers function through the mechanism where light traveling through the doped fiber gets amplified as a result of stimulated emission. What comes out is a highly efficient and accurate beam which can be used for wide range of purposes such as cutting and welding metals in factories or performing medical operations like surgery or x-ray imaging; transmission systems for phone calls etc.; and so forth. Fiber lasers have exceptional beam quality, high power output and low maintenance requirements thereby making them better than many other conventional lasers.

Understanding the Basics of Fiber Laser Technology

Fiber lasers are beneficial due to the fact that they generate high precision and power laser beams by using rare earth element doped optical fibers. This is achieved through a process called “stimulated emission” whereby photon is emitted from rare-earth ions in the doped fibre as a result of energy injection into the doped fiber from an external pump laser source. These photons are then amplified inside the optical fiber making it coherent, intense and straight forward. Fiber lasers have gained popularity because their beam quality is superior which has made them become ideal for many industrial and medical applications since they have higher electrical efficiency, greater robustness, require minimum maintenance.

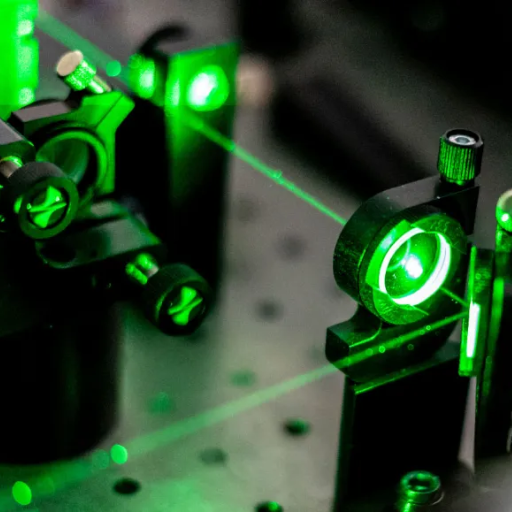

How Does a Fiber Laser Work?

Fiber lasers work by passing laser pump light into a section of optical fiber doped with rare-earth elements like ytterbium or erbium. The pumped electrons within this fiber tend to emit photons through stimulated emissions. Accordingly, these photons further get amplified while traveling through the optical fiber resulting in a highly focused and intense laser beam. Good thermal management capabilities are guaranteed due to this structure which leads to good beam quality and high energy efficiency. Furthermore, flexible and rugged optical fibers encase all stages of the process hence adding on to reliability with minimum maintenance requirements

Advantages Over Traditional CO2 Lasers

Fiber lasers have several advantages over traditional CO2 lasers, making them highly suited for various applications. First of all, fiber lasers offer better beam quality and transmit higher power density which means better and cleaner cutting. This is especially important in high precision industries like electronics and aerospace. Secondly, they exhibit higher electrical efficiency hence lower energy consumption and reduced operation costs. Besides, these have low maintenance needs compared to CO2 laser as its strong frame and lack of moving parts reduces the probability of mechanical failure problems requiring continual alignment. Moreover, fiber lasers can work at different wavelengths offering versatility across various materials including metals and non-metals. Collectively, these attributes make fiber lasers more efficient, dependable and cost effective as opposed to the traditional CO2 laser.

How Does a Fiber Optic Laser Function?

A fiber optic laser works by employing a core made of glass or plastic fiber that is doped with rare-earth elements such as erbium, ytterbium or neodymium. These dopants become excited to emit photons when pumped by a laser diode or another light source. The emitted photons then get reflected back within the core of the fiber stimulating emission of additional photons (stimulated emission). As a result light is amplified leading to coherent and high intensity beam that becomes created thereby becoming enabled through this process (coherent waves). Thermal management is excellent due to the structure of the fibers thus increasing energy efficiency as well as maintaining beam quality during operation. Also these optical fibers are flexible enough but still robust making them reliable while their maintenance cost remains very low.

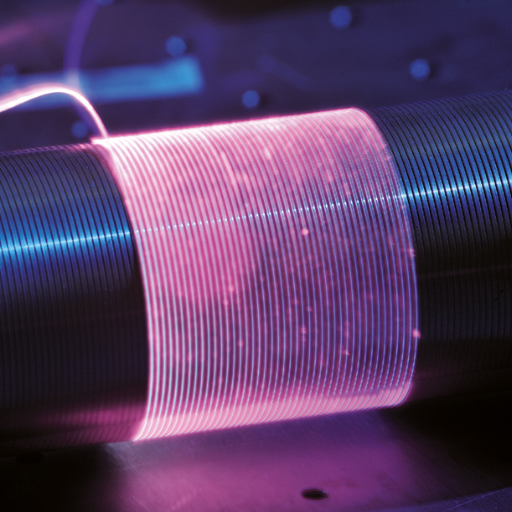

The Role of Optical Fiber in Light Amplification

Light amplification can be made possible by optical fibres that act as a medium for stimulated emission where light is efficiently amplified. The core of the fibre, which is doped with rare earth ions such as erbium or ytterbium, gets excited by an external source of light which is mostly a laser diode. Consequently, the dopants are forced to emit photons which stay within the core of the optical fibre due to total internal reflection. The process also involves bouncing back and forth of photons within its core thus stimulating the emission of extra photons and boosting the intensity of light. During this process, a coherent high-intensity laser beam is generated. Furthermore, thermal management and beam quality in these fibers are far better than any other technologies hence they provide high effectiveness and reliability.

The Significance of Doped Fiber

Doping greatly enhances performance and flexibility in fiber optic systems. These fibers serve as amplifiers because they contain rare-earth ions like erbium-ytterbium-neodymium-doped ones. Doping helps in telecommunications, medical devices and industrial processes since it increases signal strength over long distances. High-power lasers depend on doping for their key components such as efficient energy conversion, high gain and reliability among others. Furthermore, doped fibers enable designing more compact and efficient devices relative to traditional bulk optics while still maintaining their performance features for various applications like image processing or spectroscopy among others. In general terms then doped fiber technology is very important for modern day optical communication as well as laser application given that it has influenced developments across a range of hi-tech sectors.

Generating Laser Light: Laser Diodes and Pump Light

Laser diodes, which are principally used in providing laser light, act as the major pump light source for doped fiber amplifiers. These semiconductor devices when electrically excited generate coherent light that is directed into the doped fiber. This starts by introducing the carriers (holes and electrons) into the laser diode where they recombine in its active region to emit photons by spontaneous emission. These photons then stimulate more photon emissions leading to an avalanche effect that increases the intensity of light. Pump light is obtained from a laser diode and coupled into a doped fiber which uses erbium or ytterbium as dopants. As these elements become excited, they emit photons at a particular wavelength that can be suitably amplified within the core of a fiber producing thereby high-intensity laser beams. Laser diodes are highly efficient and accurate together with effective amplification capabilities of doped fibers; this makes them key elements in modern optical communication and laser systems.

What are the Different Types of Fiber Lasers?

Different fiber lasers exist for different functions, and each of them has their own advantages: This is the case with:

- Single-Mode Fiber Lasers: They produce a single high-quality laser beam using a small core diameter. Therefore, they are commonly used in precision cutting, welding and micromachining.

- Multi-Mode Fiber Lasers: These fiber lasers have wider core diameters which generate higher power beams. Thus, they are good for heavy duty cutting and welding in industries.

- Ultrafast Fiber Lasers: They operate within picosecond or femtosecond ranges. In this regard, they exhibit consequent very short light pulses which are essential in precise applications like medical device production as well as material processing.

- Nanosecond Fiber Lasers: These emit relatively longer pulses than ultrafast lasers and are applicable to marking, engraving and etc whereby high peak power and moderate pulse duration comes handy.

- Quasi-Continuous Wave (QCW) Fiber Lasers: These emit relatively longer pulses than ultrafast lasers and are applicable to marking, engraving and etc whereby high peak power and moderate pulse duration comes handy.

Every type of these lasers excels in specific areas where others may lag behind making them indispensable tools used in modern industry research today.

An Overview of Erbium-Doped Fiber and Ytterbium-Doped Fiber

Fiber optics amplifiers are widely used in telecommunications, and mostly erbium doped fiber (EDF). It infuses these fibers with erbium ions that are efficient at amplifying light signals hence allowing long distance communication without signal loss. They provide signal integrity over very long distances making them a key component in the modern optical communication network backbone.

For high-power laser applications, for instance, Ytterbium-doped fiber (YDF) is famous because of its power scalability effectiveness. This can enable YDFs to provide high output power while maintaining exceptional beam quality which is why they are commonly used in materials processing, medical applications as well as scientific research among others. In addition, these fibers make use of Ytterbium ions that ensure efficient energy transfer to yield strong industrial performance.

These two types of doped fibers contribute significantly to advancement of technology by serving various applications and covering different parts of the optical range from efficient telecommunication up to high-powered industrial processes.

High-Power vs. Low-Power Fiber Laser

Comparing high-power fiber lasers to low-power fiber lasers, there are several important differences and advantages. High power fiber lasers, which are typically described as those with an output of over 1 kilowatt (kW), find application in heavy industries where strong materials like metals and alloys have to be cut, welded or drilled. As such, these laser types offer cutting that is faster than the rest, greater penetration of material and the ability to handle thicker materials hence this becomes vital in automotive manufacturing and aerospace.

Contrariwise, low-powered fiber lasers which barely reach 1kW are usually suitable for more delicate jobs with minimal impact on thermal distortion or fine detailed work. Consequently they can be used for engraving plastics and ceramics as well as marking thin metals among other items. Low power lasers display excellent beam quality compared to their high power counterparts while at the same time; these ones use less energy hence it finds applications in some sectors such as electronics, jewellery making, medical devices production etc.

Both types of fibre laser exploit benefits accompanying the optical fiber technology such as high efficiency nature, low maintenance requirement and robustness. The choice between a high-power or low-power fibre laser depends solely on what specific application calls us to do so each with its own distinct advantages when applied in different industrial works.

Single-Mode vs. Multi-Mode Fiber

The main differentiating factors between single-mode fiber (SMF) and multi-mode fiber (MMF) are their core sizes and applications. Single-mode fibers have smaller cores, usually around 8-10 micrometers, which allow only one mode of light to propagate and hence results in low signal distortion and high bandwidth over long distances; as such, it is suitable for use in long-haul telecommunication lines or high-speed data processing systems.

In contrast to SMF whose core is about 8-10 micrometers thick, MMF has a wider core diameter ranging from 50-62.5 micrometers. Consequently, these fibers are cheaply operated using inexpensive light sources such as LEDs since they support several modes. As a result, this means that longer distance communication using these fibers will be affected by modal dispersion leading to low bandwidth availability. Conversely, the multimode fiber is an economical choice for short distance transmission within buildings or data centers where budget-friendly compact data communication at speeds of up to 10Gbps over shorter lengths is necessary.

Choosing whether the application should use single-mode fiber optic cable or multimode fiber optic cable depends on various factors including the balance between cost and benefits brought by a particular length of cable, available bandwidth demanded by the application as well as other requirements like network equipment compatibility that needs to be considered.

What Industrial Applications Utilize Fiber Optic Lasers?

Their accuracy, efficiency and multi-functionality make fiber optic lasers very common in various industrial applications. Fiber lasers are used extensively in the automotive as well as aerospace sectors for precise cutting, welding and marking of materials. In electronic manufacturing, fiber lasers play a vital role in micro-machining and intricate component engraving. The medical profession also uses these devices for surgical operations as well as manufacturing medical instruments. Telecoms and data communication organizations use these systems because they have superior ability to handle high-speed data transfer. These are durable machines that require little maintenance which makes them very suitable for demanding industries.

Common Uses in Laser Cutting and Engraving

Many industries employ laser cutting and engraving because of their accuracy, speed, and versatility. Common uses include:

- Manufacturing and Production: Laser Cutting is Popular when it comes to manufacturing metal parts, automotive components and electronic hardware. It can cut through a wide range of materials including metals, plastics, composites among others while still allowing precision cuts thus improving efficiency greatly reducing waste.

- Signage and Art: Many companies prefer using engraved laser-based markers when producing detailed signs logos or artistic designs on materials such as wood acrylic or glass. Craftsmen therefore find pleasure in the ability to create complex patterns plus other customized images with just one shot.

- Jewelry and Personalized Items: Fine details can be produced by laser engraving systems on jewelry pieces or smaller personalized items such as pendants. When inscribing names dates or even custom designs on rings watches among other valuables it provides great detail and consistency that cannot be beaten by any other method ever invented so far.

Advantages in Laser Marking

This is the reason why laser marking is quite popular choice across many industries compared to traditional alternatives. Its precision and accuracy, on the other hand, enables it to produce high quality marks on various materials like metals, plastics and ceramics. For applications needing fine details such as serial numbers, logos and barcodes.

The durability of laser marks is another advantage that they hold over ink based methods. Laser markings do not fade or wear off even under harsh environmental conditions unlike inks so they are ideal for products that are subjected to extreme temperatures, chemicals or abrasion. This provides long term traceability and product identification.

On top of this, a great benefit is that laser marking is a non-contact process which implies that there is no physical wearing out of the material being marked or even the marking equipment itself. As a result maintenance cost reduces as well as extends machinery’s life span. Apart from that, it also offers great efficiency since it can be automated leading to faster production times thus reducing operational costs.

Moreover, due to its non-consumable nature: laser marking does not require any consumables such as solvents, inks and chemicals hence causing less wastage resulting into lower environmental impact; finally its wide range usage from automotive industry aerospace medical devices home appliances thus making it suitable for modern manufacturing needs.

Precision and Efficiency in Laser Engraving

Laser engraving outshines all other methods in terms of accuracy and effectiveness, so it is widely used in various fields. Laser engraving has a remarkable precision that is capable of producing complex designs and minute details with consistent quality. This accuracy ensures that even on small surfaces the markings are easily readable. Moreover, the high-speed laser engraving process helps to improve production significantly enabling higher unit output rate with less downtime. Due to its non-contact nature, laser engraving reduces risk of materials deformation and prolongs equipment’s life span hence reducing costs at the same time. Moreover, laser engraving can be done on many different types of materials like metals, plastics or woods among others. Thus, laser engraving combines precision; efficiency and versatility making it an indispensable tool in modern manufacturing.

How to Maintain and Troubleshoot a Fiber Optic Laser System?

A fiber optic laser system must be maintained and serviced through routine checks and maintenance activities. First you should ensure that no dust is present on the system to prevent any damage that might arise as a result of contamination with particles within its environment or operating temperature range. Regularly check fiber optic cables for fraying signs since compromised cables can affect performance such as data loss due to physical contact between fibers or breakage of one fiber strand while it is being connected into another one during installation phase which complicates troubleshooting procedures. The lenses and mirrors must also be cleaned using cleaning solutions suitable for them so as to avoid defects from dirtying up their surfaces thus interfering with lasers’ performance.

For troubleshooting purposes, start by verifying that power source connections are intact before turning on the machine especially if it was disconnected earlier on during any operations carried out before this point where you have reached now (it means this can happen without your knowledge till later when you try switching on again). Confirm first if there are no obstacles blocking light beams coming from your device output; then check whether laser source itself works properly too-otherwise make necessary repairs immediately; finally look for manufacturer’s instructions on how to fix recalibration errors caused by poor quality or accuracy if such is experienced during installation process. Consult system manual or tech support for any specific error codes and recommended solutions in case of persistent issues. Therefore, regular cleaning and prompt action will ensure the system’s dependability and optimal performance.

Essential Maintenance Tips for Fiber Laser Machines

- Regular Cleaning: Clean all optical elements such as mirrors and lenses frequently using the right solutions so that they may not get contaminated hence affecting laser efficiency.

- Cooling System Maintenance: Routinely inspect and service your cooling system. Ensure that filters are clean and coolant is at the correct level, free from contaminants. This helps in preventing overheating, hence prolonging the lifespan of the machine.

- Alignment Checks: Periodically verify alignment of laser beams. Calibration is essential because misalignment can cause poor cutting quality and reduced efficiency.

- Inspect and Maintain Cables: Frequently check fiber optic cables for wear or any other kind of damage. Hence replace any damaged cable since it can affect good performance.

- Software Updates: Keep up with software/firmware upgrades offered by manufacturers. These updates usually have bug fixes and performance enhancements necessary to ensure the optimal operation of machinery.

- Scheduled Professional Servicing: Arrange for routine professional servicing as recommended by the manufacturer. During normal inspections, professionals can help in identifying hidden problems so that they can be corrected before causing further damages.

In this way you will keep your fiber laser running smoothly, without interruption for a long time to come.

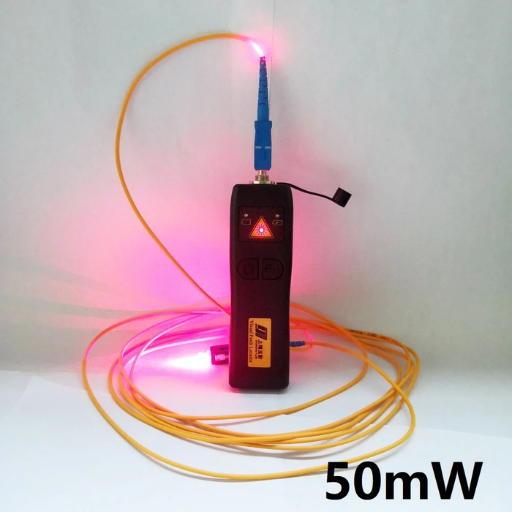

Using Visual Fault Locators and Fiber Optic Cable Tester Meters

Visual Fault Locators (VFLs): VFLs are must-haves in fiber optic cable fault diagnostics. They work by transmitting a beam of bright red laser light through the center of an optical fiber, thus enabling technicians to see the location of breaks, bends and other faults on each individual cable. Attaching the VFL to a cable enables any interruptions or damages found within the fiber to be seen as glowing or blinking red light, making it possible to identify where exactly these problems are occurring.

Fiber Optic Cable Tester Meters: These advanced equipment is used for measuring signal strength and quality inside a fiber optic network. For instance, power meter readings, loss measurements and continuity testing are some functions that tester meters perform. This serves as crucial information on how well the cable itself is operating which determines if the data transmission function of fiber optics is robust and effective. When used for troubleshooting and maintenance purposes, these meters enable accurate actions to be taken hence ensuring optimal network performance.

To sum up both VFLs and Fiber Optic Cable Tester Meters are indispensable in maintaining and repairing fiber optic networks by providing simple diagnostics that ensure system resilience and reliability.

Common Issues and Their Solutions in Fiber Laser Work

1. Inconsistent Beam Quality:

Misalignment, contamination or optical component wear can cause the quality of a beam to deteriorate. Clean regularly and realign all optics, carefully inspect them for any damage signs and substitute parts that are worn out or contaminated so as not to compromise beam quality.

2. Overheating of Laser Components:

Overheating of laser components may lead to performance reduction as well as possible harm to the whole system. Make sure that there are no problems with coolant levels by checking them on a regular basis, cleaning filters and confirming correct coolant flow rate. The existence of proper ventilation around the equipment also helps in maintaining optimal operating temperatures.

3. Fiber Breakage or Damage:

Improper handling techniques, physical damage, or excessive bending beyond the specified radius can break fiber optics. Take extra care when dealing with fibers, avoid folding them too tightly and protectively wrap with tubing or conduits when routing fibers in harsh environments. A thorough examination on a regular basis can detect areas prone to wear and tear early enough thus avoiding unnecessary repairs or replacement costs.

What are the Key Challenges in Deploying a Fiber Optic Laser System?

Some of the major challenges associated with deploying a fiber optic laser system include:

- System Integration: Making sure that the existing systems and the new fiber optic laser integrate together properly can be tricky. Adapters, power supplies and other components must be compatible and correctly configured to work together.

- Precision Alignment: Accurate alignment of optical components is vital for best performance. Misalignments can result in reduced output power, inefficiencies, or even cause physical damage.

- Environmental Factors: The system is affected by external factors such as temperature fluctuations and dust accumulation. Robust environmental controls should be implemented to prevent failure.

- Maintenance and Reliability: Regular maintenance practices are important in ensuring long term reliability which may use many resources. Constant monitoring of fibers, cooling systems among others once they show signs of breaking down goes a long way to preventing this occurrence.

- Cost Considerations: There are significant initial investment costs as well as ongoing operational expenditures. It is essential to budget for high standard parts, fixtures and skilled labor for both installation and subsequent running costs if deployment has to succeed.

Addressing Laser System Efficiency

There are many approaches to improving the operational efficiency of a fiber optic laser system. Primarily, enhancing the design of the laser cavity itself can yield significant multi-fold improvements in performance. This may involve accurately aligning passive optical components so as to minimize losses and optimize output power. Second, incorporating advanced methods of cooling helps maintain uniform operating temperatures that prevent thermal deformations while also ensuring consistency in beam quality. Thirdly, employing high grade optical fibers and devices with low transmission loss help reduce inefficiencies. Furthermore, vigilance in monitoring the system overall is necessary to quickly catch up with any changes that may occur in order to bring back maximum efficiency in operation.

Mitigating High Power Damage

Dealing with high power damage in fiber optic laser systems necessitates several approaches. First, it is important for all materials used to be durable and for their designs to be capable of handling high powers necessary for operation at desired levels. The potential damage from using optical elements which bear coatings that tolerate high optical power density values is reduced. Second, highly effective heat management systems like sophisticated cooling techniques should be implemented so that thermal damage resulting from light energy can be avoided by dissipating the heat generated by intense lasers quickly enough. Besides this, regular inspections and cleaning exercises on fiber connectors cannot be overstated since even small particles can cause huge energy wastes or destroy other parts of the link entirely due to contamination they bring about during connection processes. Finally, propulsion levels must not have rapid increases especially when starting a laser because they may trigger spikes leading into collateral damages.

Ensuring Laser Cavity Stability

Stabilizing a laser cavity requires careful design and consistent upkeep first, one must choose high-quality optical components and align them with accuracy in order to minimize losses and enhance stability. This involves the use of stable mounts for mirrors and other optical elements. Secondly, temperature control is necessary; installing advanced cooling systems can help maintain a constant temperature that minimizes heat induced fluctuations that may destabilize the laser cavity. Thirdly, actively monitoring and adjusting the cavity length through piezoelectric or other fine tuning devices can compensate for any mechanical or thermal drifts. The combination of these measures can greatly enhance the dependability and performance of a laser system.

Frequently Asked Questions (FAQs)

Q: What is fiber laser technology?

A: Fiber laser technology involves the use of optical fibers doped with rare-earth elements like erbium, ytterbium, and neodymium to create high-power laser light for various applications such as laser cutting, marking, and engraving. The technology is efficient and provides superior beam quality.

Q: How does a fiber laser cutter work?

A: A fiber laser cutter utilizes fiber network technology to amplify laser light, which is then directed through a laser head onto the material to be cut. The high-intensity laser beam melts, burns, or vaporizes the material, enabling precise and efficient cutting.

Q: What are the benefits of using a fiber laser marking machine?

A: A fiber laser marking machine offers numerous benefits, including high precision, speed, and flexibility. It is capable of marking a variety of materials such as metals, plastics, and ceramics. The machine is reliable and requires minimal maintenance.

Q: What is the function of a VFL fiber optic cable tester?

A: A VFL fiber optic cable tester, also known as a visual fault locator fiber optic, uses a vfl red light pen to visually identify breaks, bends, and faults in fiber optic cables. It is essential for fiber network maintenance and troubleshooting.

Q: Can fiber laser technology be used for engraving?

A: Yes, fiber laser technology is highly effective for engraving. A laser engraver using fiber power can create detailed and permanent designs on various materials. This method is precise and versatile, making it ideal for custom and industrial applications.

Q: What are high-power fiber lasers used for?

A: High-power fiber lasers are used in industrial applications such as cutting thick metals, welding, and other material processing tasks. They provide high efficiency and precision, making them suitable for demanding manufacturing environments.

Q: How do mode-locked fiber lasers work?

A: Mode-locked fiber lasers generate ultrafast pulses of laser light by locking together different modes of oscillation within the laser resonators. These lasers are used in applications requiring extremely short and intense bursts of energy.

Q: What is the advantage of using a MOPA fiber laser?

A: The MOPA fiber laser provides adjustable pulse width and frequency, allowing greater flexibility in marking and engraving applications. This makes it ideal for creating high-quality marks on materials like metals and plastics.

Q: How does a fault locator fiber optic cable tester differ from other testers?

A: A fault locator fiber optic cable tester specifically identifies faults such as breaks and bends in the fiber cable. Unlike general testers, it provides a precise location of the fault, which is crucial for efficient maintenance and repair of fiber networks.

Q: What is laser cleaning and how is it applied?

A: Laser cleaning involves using high-energy laser light to remove contaminants, oxides, or coatings from surfaces. It is widely used in restoration, maintenance, and pre-treatment processes in various industries.